1) To ope ate the machine safely and co ectly, follow the indications contained in this manual ca efully and

sc upulously.

2) The machine will have to be ope ated only by pe sonnel who is both qualified and ove 18. People esponsi-

ble fo safety should make su e that the machine ope ato has ead and fully unde stood all the info mation

contained in this manual.

3) Maintenance inte ventions must be ca ied out only by pe sonnel who is both qualified and ove 18.

4) Pe sonnel esponsible fo outine and ext ao dina y se vicing must have a good knowledge of mechanics

and elect onics.

5) Keep away f om any moving pa t in the machine.

Neve touch the spindles and /o the d ills when the machine is ope ational.

6) Neve supe impose wood pieces to be wo ked. Always bo e one piece at a time, afte having adjusted the

machine co ectly.

3. OPERATIVE NOTES

4. DESCRIPTION OF THE MACHINE

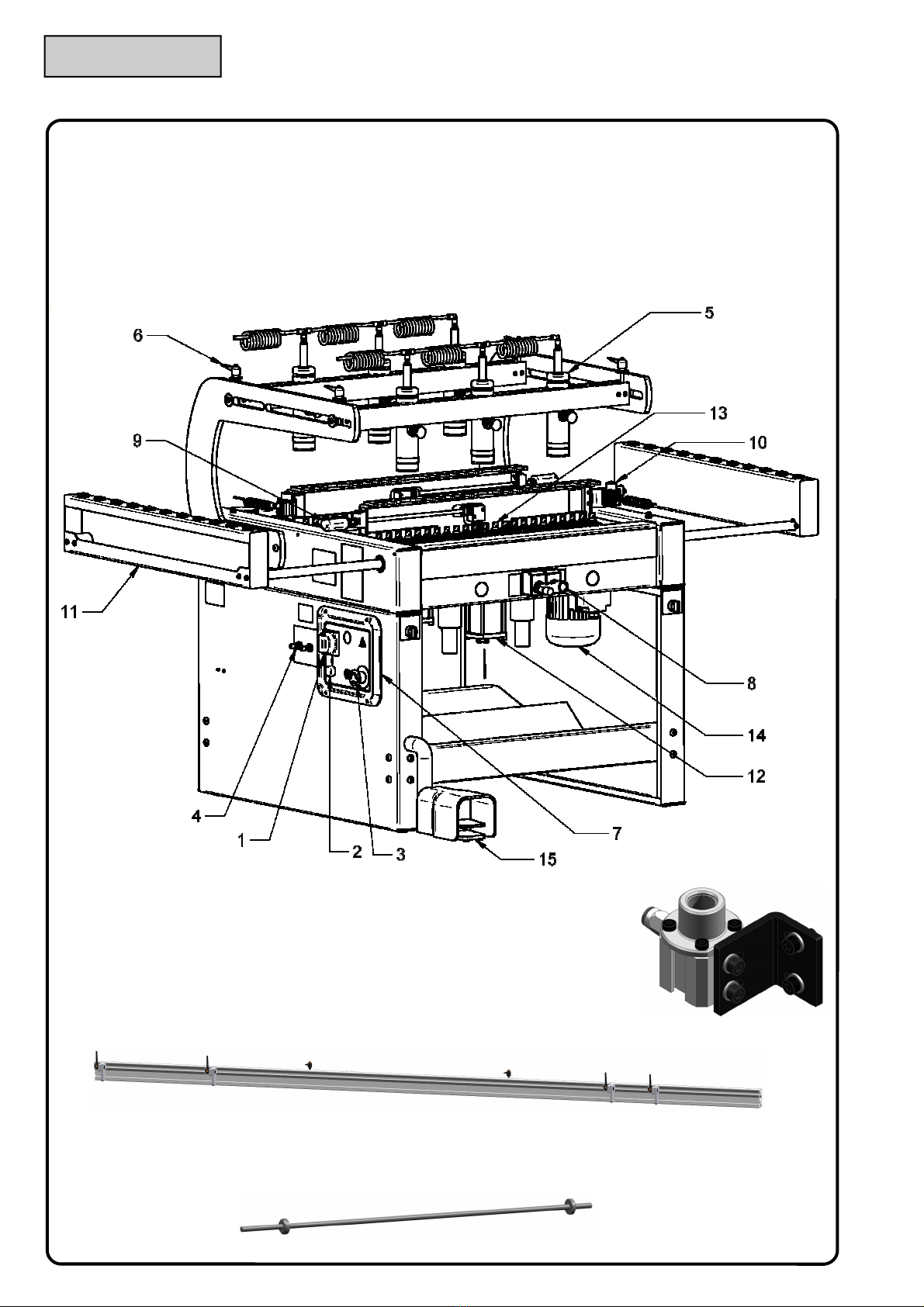

Ou Bo ing Machines have been manufactu ed to make a se ies of holes at a fixed 32-mm distance between

cent es on wooden pieces (with maximum p ecision).

The pieces to be bo ed a e fed by the ope ato , who places them on the machine table. The ope ato will fi st

ca y out the equi ed adjustments by p essing the cont ol pedal. He will then lock the pieces into place with the

elevant hold down clamps and will sta t bo ing ope ations.

The following pa ts make up the machine:

A steel f ame

Spindlehead unit with t ansmission ( apid-attachment).

Hold down clamps unit to clamp the piece to be cut in a ve tical position.

Pneumatic system fo head positioning and head feed.

C ank mechanism to adjust spindles distance equipped with mechanical counte and device to adjust hole

depth f om 0 mm to 100 mm.

Rapid head-positioning device and head depth-adjustment device

Elect ic Powe plant complying with standa ds.

4.1 APPLICABLE TOOLS

D ills fo quick change spindles, 10 mm O. D. and 20 mm length shank ( Fig. A )

D ills up to 35 mm O. D. can be used ( Fig. B )

85 mm max useful length (connection excluded)

WOODWOORKING MACHINES CAN BE DANGEROUS

Fig. A Fig. B

ANY ADULTERATION OR REMOVAL OF SAFETY PROTECTION DEVICES CAN CAUSE SE-

VERE DAMAGE. ANY REMOVAL, EXCLUSION OR MODIFICATION OF THESE DEVICES IS

STRICTLY FORBIDDEN. YOU MUST VERIFY AND GUARANTEE THE PERFECT RUNNING OF

SAFETY DEVICES BY MEANS OF PERIODIC CHECKS. ANY DEFECT OR PROBABLE DRAW-

BACK MUST BE IMMEDIATELY RESOLVED.

Page

5