7

SPECIFICATIONS

Description Specifications

Power at terminals 24 V DC (± 20 %)

Power consumption 5 W max.

Flow range Standard sensors: 0,003 to 1,5 m/s (0.01 to 5.0 FPS) – water

0,03 to 150 m/s (0.1 to 500 FPS) – air

HTHP, Hastelloy C / Monel: 0,003 to 0,3 m/s (0.01 to 1.0 FPS) – water

(1 mm wall sensors) 0,03 to 150 m/s (0.1 to 500 FPS) – air

1/4" Low flow body: 0,02 to 5,7 l/h – water and 0,006 Nm3/h min – air/gases

1/2" Low flow body: 0,04 to 11,5 l/h – water and 0,015 Nm3/h min – air/gases

Signal output Alarm 2 Amp SPDT relay

Continuous mA output ( non linear, non scaleable)

Error 22 mA in "HIGH" Fail-safe mode / 3,6 mA in "LOW" Fail-safe mode (as per NAMUR NE 43)

User interface Set point Adjustable via potentiometer located on DIN Rail housing

Range selection

Selectable in probe electronics

LED indication Power LED’s for Power/Alarm status

Error Red LED blinks in case of error

Alarm 4 x green LED's – for safe/ (normal) condition

1 x yellow LED – indicates when flow or level is approaching the alarm set point

1 x red LED – indicates an alarm condition (TG1)

all LED's OFF – indicates an alarm condition (TG2)

Approvals ATEX II 1 G EEx ia II B T5

SIL (Safety Integrity Level) Functional safety to SIL1/SIL2 in accordance to IEC 61508 – SFF of 79,4 % – full FMEDA

reports and declaration sheets available

Housing materials DIN Rail: IP 20, polycarbonate / Sensor housing: IP 65, Aluminium or Stainless Steel

Net and gross weight 2 kg. (4.6 lbs.) with 50 mm (2") sensor

Description Specification

Response time 1-10 s typical (dependant on sensor type, application and set point)

Repeatability < 1 % @ constant °C

Ambient temperature -40 to +70 °C (-40 to +158 °F) – operational

-50 to +76 °C (-58 to +170 °F) – storage

Humidity 0-99 % non condensing

Electromagnetic compatibility Meets CE requirements (EN 61326) and Namur NE 21

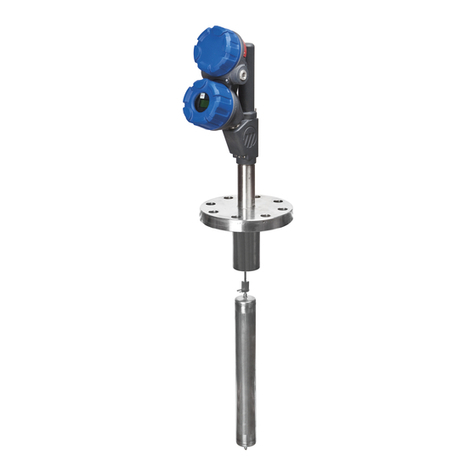

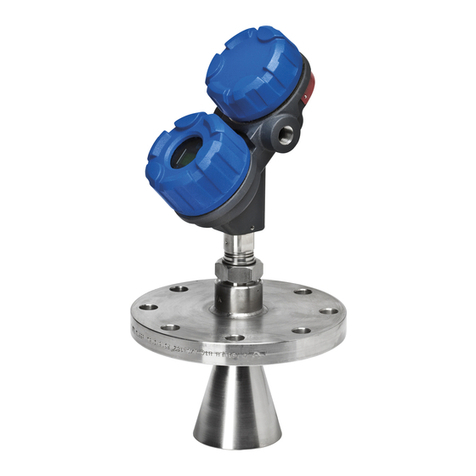

Description Twin tip - spherical sensors

TMM - TMA/TMB - TMC/TMD

HTHP sensor

TMH

Low flow body

TML

Materials 316/316L (1.4401/1.4404)

Hastelloy C (2.4819) –

TMC/TMD

Monel (2.4360) –

TMC/TMD

316/316L (1.4401/1.4404)

Hastelloy C (2.4819)

316/316L (1.4401/1.4404)

Sanitary finish 0.82 µm (RA 32) – consult factory for electropolishing – only for TMA/TMB

Sensor / pipe diameter 22 mm (0.87") – except TMM

16 mm (0.63") – TMM

22 mm (0.87") 1/4" or 1/2"

Process connection Threaded: 1/2" NPT (TMM), 3/4" NPT, 1" NPT, G1 (1" BSP)

Flanged: ANSI, EN/DIN or sanitary

F- 1/4" or 1/2" NPT or BSP

Probe length 5 - 330 cm (2" - 130")

2,5 - 150 cm (1" - 60") – TMM

5 to 90 cm (2-36") Not appicable

Max process temperature ➀TMA/TMC/TMM:

-70 to +120 °C (-100 to 250 °F)

TMB/TMD:

-70 to +200 °C (-100 to 400 °F)

-70 °C to +450 °C

(-100 °F to +850 °F)

-70 °C to +120 °C

(-100 °F to +250 °F)

Max process pressure TMA/TMB: 41 bar (600 psi)

TMC/TMD: 207 bar (3000 psi)

TMM: 207 bar (3000 psi)

413 bar (6000 psi) 400 bar (5800 psi)

Recommended for TMA: best sensitivity for liquid flows / suitable for gas flow – resists heavy coating

TMB: same as TMA but can be used with integral electronics up to +200 °C (+400 °F)

TMC: best sensitivity for air/gas flows – resists light coating

TMD: same as TMC but can be used with integral electronics up to 200 °C (+400 °F)

TMM: for direct mounting in “T” pieces on small pipe sizes – light coating

TMH: high temperature and pressure conditions – light coating

TML: for the detection, control of extreme low flows, resists light coating

➀Use remote electronics (TD2) for temperatures > +120 °C (+250 °F) up to max +200 °C (+400 °F) or sensors with heat extension

(TMB/TMD) when using integral electronics.

Performance

Sensor specifications