7

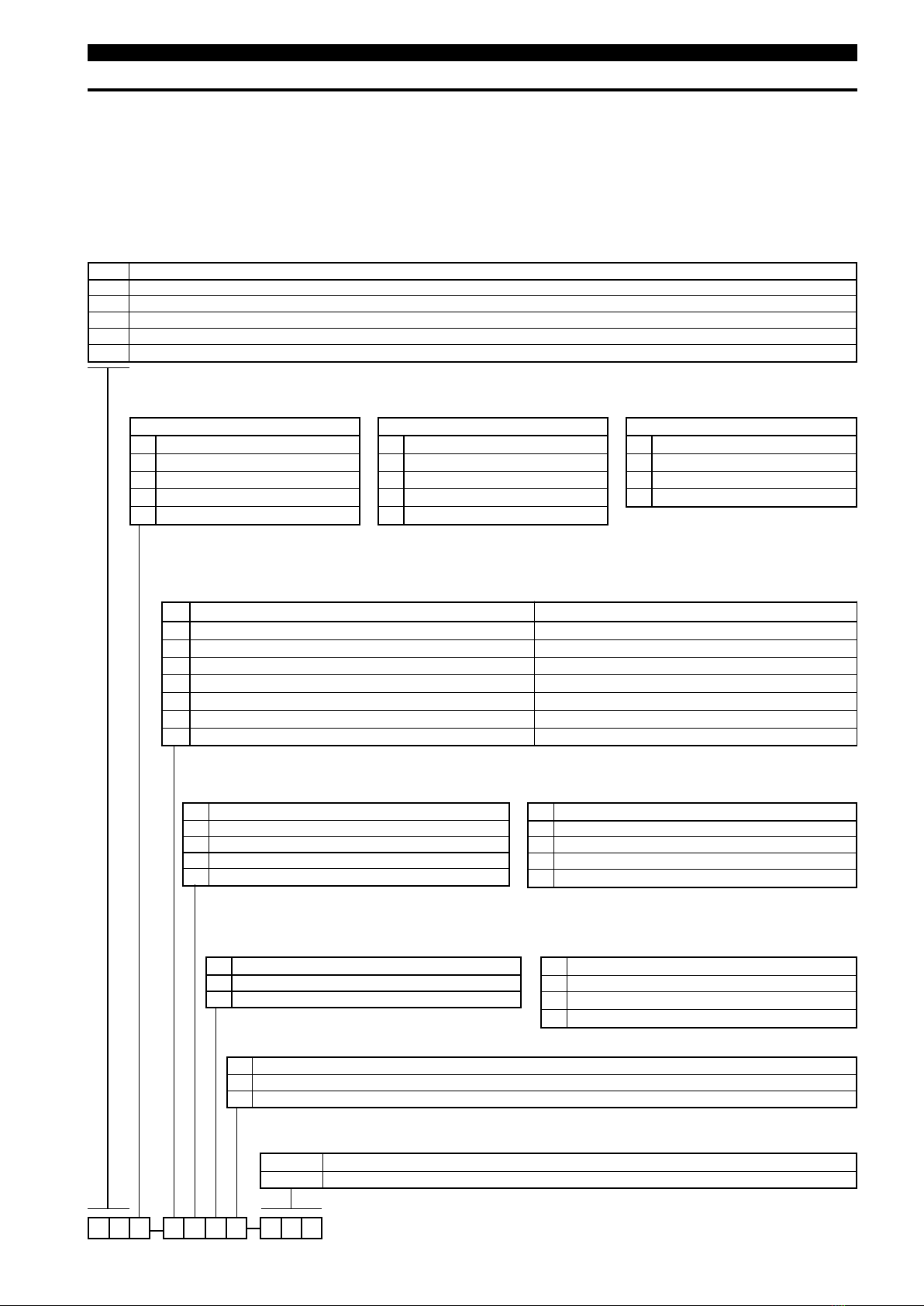

MODEL IDENTIFICATION

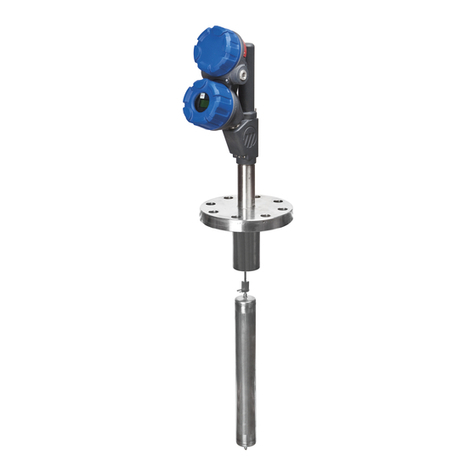

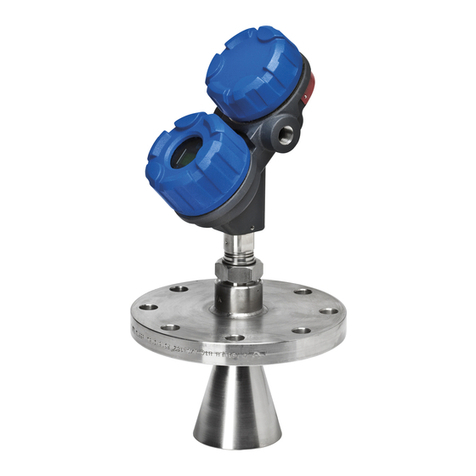

Acomplete measuring system consists of:

1 Code for Vizual®MLI cage (for modified models or adders, put an “X” in front of the closest matching order code and

specify the modifications separately. E.g. XGSD-H23F-120 X = with material certification EN 10204-3.1

2. Always specify operating temperature/ pressure/ S.G. and viscosity if > 80 cP

3. Code for options:

-Reed chain transmitter / Micro-switches / Bi-stable (reed type) switches: consult factory

- Scale: standard 304 stainless steel

Code: 032-3930-xxx: scale in cm. Consult factory for tailor made scales

3-last digits represent the measuring range in cm increments (e.g. 120 = 120 cm)

Gcomplete code for Vizual®Magnetic Level Indicator

PROCESS CONNECTION: SIZE

0 1/2"

13/4"

21"

31 1/2"

4 2" ➀

PROCESS CONNECTION: STYLE

NNPT-F coupling (size: max 1")

SSocket weld coupling (size: max 1")

FFlanged (all sizes)

Z DN 15

A DN 20

B DN 25

CDN 40

D DN 50 ➀

3 150 lbs - RF flange

4 300 lbs - RF flange

5 600 lbs - RF flange

APN 16 EN 1092-1 B1 flange

BPN 25/40 EN 1092-1 B1 flange

DPN 63 EN 1092-1 B2 flange

E PN 100 EN 1092-1 B2 flange

BASIC MODEL NUMBER - ANSI CLASS CAGES IN 316/316L (1.4401/1.4404) - FLANGES AND CAGE

MATERIALS OF CONSTRUCTION

CAGE & FLANGES: 316/316L (1.4401/1.4404) – FLOAT: 316 Ti (1.4571) except code A: Titanium

SPECIFIC GRAVITY RANGE AND FLOAT HYDROTEST PRESSURE➀

ALWAYS SPECIFY EXACT OPERATING S.G, max temp & pressure when ordering Vizual

PRESSURE RATING - FLANGE TYPE (if applicable)

030 minimum 30 cm (12")

5 7 0 maximum 570 cm (224")

GA Side/bottom process connection with sealed top cap

G B Side/bottom process connection with flanged top

G S Side/Side process connection with sealed top cap

G R Side/Side process connection with flanged top

GT Top/bottom process connection with sealed top cap

G U Top/bottom process connection with flanged top

Hydrotest 36 bar @ +40 °C

A0,56 to 0,60

B0,61 to 0,70

C0,71 to 0,80

D0,81 to 0,90

E0,91 to 1,50

Hydrotest 52 bar @ +40 °C

F0,58 to 0,61

G0,62 to 0,70

H0,71 to 0,80

J0,81 to 0,90

K0,91 to 1,50

Hydrotest 85 bar @ +40 °C

M0,62 to 0,70

N0,71 to 0,80

O0,81 to 0,90

P0,91 to 1,50

Indication rail without scale ➀Temperature range

HAluminium rail / SST flappers / Polycarbonate window -20 °C upto +160 °C (-5 °F upto +320 °F)

JAluminium rail / SST flappers / Polycarbonate window -50 °C upto +125 °C (-60 °F upto +260 °F)

KAluminium rail / SST flappers / Polycarbonate window -20 °C upto +200 °C (-5 °F upto +390 °F)

LAluminium rail / SST flappers / Polycarbonate window -20 °C upto +250 °C (-5 °F upto +480 °F)

MAluminium rail / SST flappers / Glass window -20 °C upto +300 °C (-5 °F upto +570 °F)

NAluminium rail / SST flappers / Glass window -20 °C upto +350 °C (-5 °F upto +660 °F)

PAluminium rail / SST flappers / Glass window -20 °C upto +400 °C (-5 °F upto +750 °F)

ANSI EN/DIN

➀See options for scales

➀Consult factory for low S.G, interface applications or high pressure floats

➀2"/DN 50 process flanges are machined to 1" size

Note: segmented cage for lengths > 570 cm (224"), consult factory

MEASURING RANGE (as per drawings at left page) – per 1 cm (0.39") increments