ORI-652 Jupiter®Model JM4 Magnetostrictive Transmitter – SIL Safety Manual 3

1.0 Introduction

1.1 Product Description

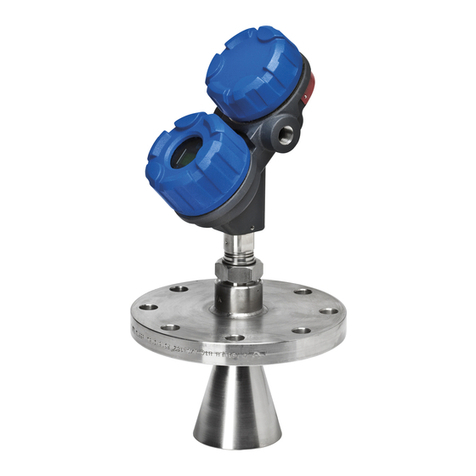

e JUPITER Model JM4 magnetostrictive level transmitter is a

loop-powered 24 VDC level transmitter based on magnetostric-

tive technology.

NOTE: For Safety Instrumented Systems usage, it is assumed that

the 4-20 mA output is used as the primary safety variable.

e analog output for the Model JM4 meets the NAMUR

NE 43 standard (3.8 mA to 20.5 mA usable). e transmitter

contains self-diagnostics and is programmed to drive the output

to a user-selected failure state, either low or high, upon internal

detection of a diagnostic indicator. e device can be equipped

with or without a graphic liquid crystal display (LCD).

Table 1 indicates the version of the JUPITER Mode JM4

transmitter suitable for SIL 2 applications based on the hardware

assessment.

1.2 Theory of Operation

Magnetostrictive level sensors are based on “time-of-ight”

technology.

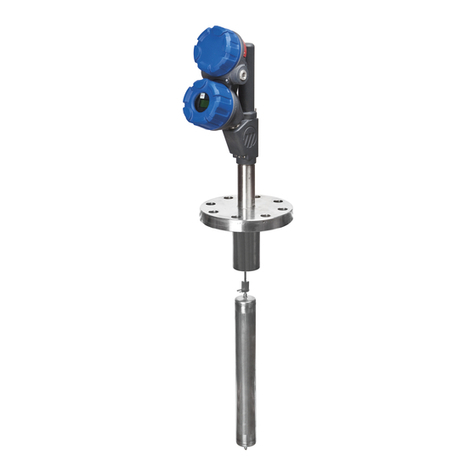

Permanent magnets contained within a oat device track the

process liquid as it changes level. e JUPITER probe is xed

within close proximity to this magnetic eld. A short current

pulse is then applied to a specially designed wire alloy contained

within the probe. e interaction of the current pulse and

magnetic eld causes distortion in a small section of the wire

alloy. is in turn creates a vibratory disturbance which begins

to travel through the wire at a very constant rate of speed. e

disturbance is later detected via a sensing device at the top of

the probe and sent to the electronics unit where it is ltered and

amplied.

Extremely accurate level measurement can thus be obtained

precisely measuring the elapsed time between the current pulse

(start), and the returned pulse (stop). e JUPITER electronics

module processes these signals, and then performs various math-

ematical operations in order to provide the user with an analog

and/or digital representation of the liquid level.

1.3 Determining Safety Integrity Level (SIL)

e JUPITER Model JM4 is classied as a Type B device

according to IEC61508.

Tables 2 & 3 dene the criteria for the achievable SIL against the

target mode of operation in Demand Mode Operation.

• Table 2 shows the relationship between the Safety Integrity

Level (SIL) and the Probability of Failure on Demand Average

(PFDavg).

Table 1

JUPITER JM4 Model Number

Table 2

SIL vs. PFDavg

Safety

Integrity Level

(SIL)

Target Average

probability of failure on

demand (PFDavg)

4≥ 10-5 to < 10-4

3≥ 10-4 to < 10-3

2≥ 10-3 to < 10-2

1≥ 10-2 to < 10-1

Table 3

Minimum hardware fault tolerance

Type B sensors, nal elements and non-PE logic solvers

SFF

Hardware Fault

Tolerance (HFT)

0 1 2

None: < 60% Not

Allowed SIL 1 SIL 2

Low: 60% to < 90% SIL1 SIL 2 SIL 3

Medium: 90% to <99% SIL 2 SIL3

High: ≥99% SIL 3

Model:JM4-511X-XXX (HART Transmitter)

2YX-XXXX-XXX-XX-XXX (Probe)