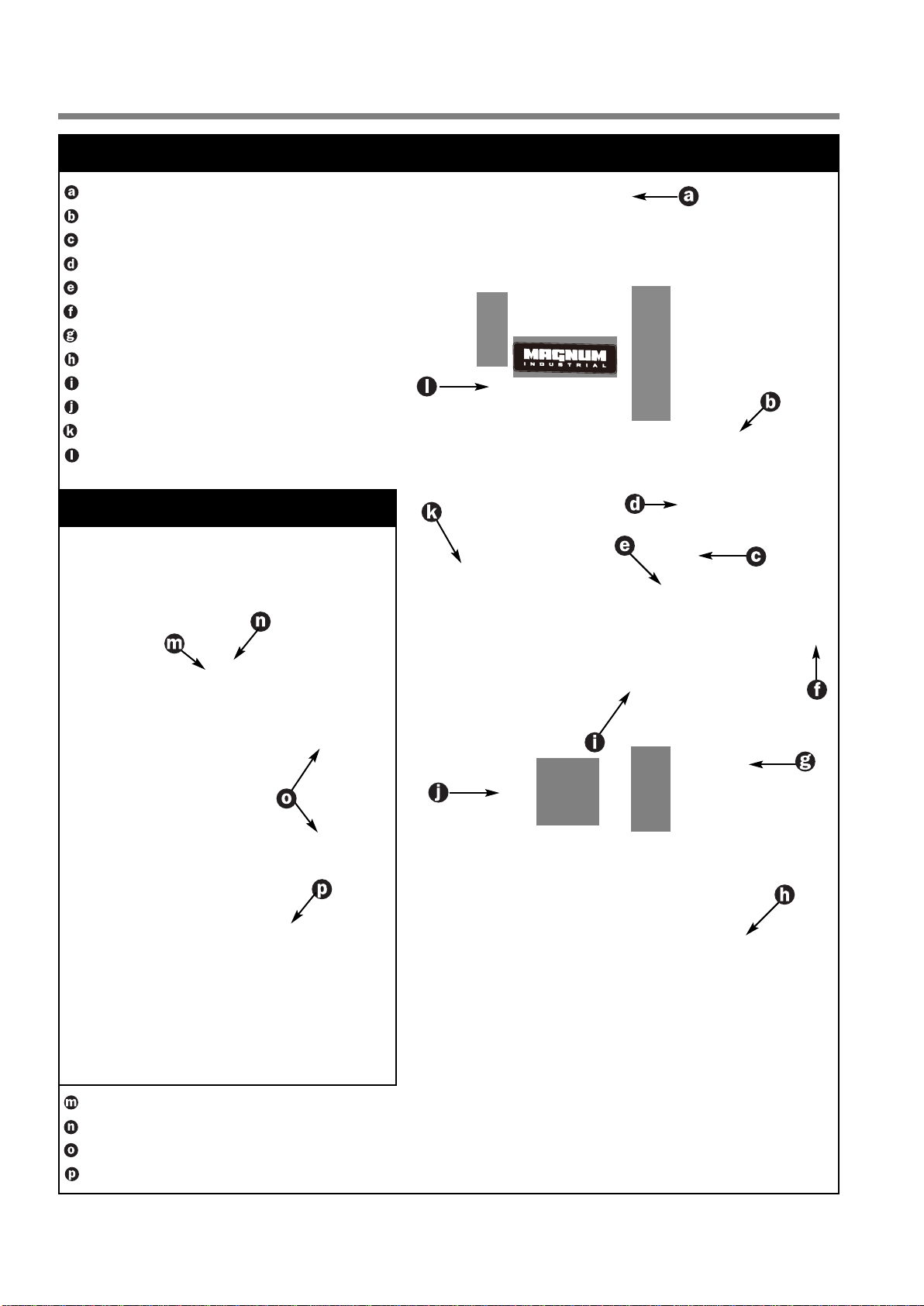

ADJUSTING THE BLADE GUARD FOR DEPTH OF CUT

The blade guard can be moved up or down to accommodate

the height of the work to be cut. To prevent the

blade (which is exible and which would not otherwise

be supported) from slipping out of position during cutting,

and to reduce risks of injuries, a minimum amount

of blade should be exposed.

The blade guard should be set 1/8” - 1/4” above

the workpiece A to prevent the blade from exing

out of position or o-line during cutting.

Adjust the height of the blade guard B to suit the thickness

of the workpiece as follows:

1. Make sure the bandsaw is turned off and the power cord is

disconnected from the power source.

2. Loosen the smaller lock knob C.

3. Move the blade guide assembly up or down D, then re-tighten

the lock knob C.

Note: The depth gauge E on the front of the blade

guard can be used as a reference but it is not

intended for high precision measurements.

ADJUSTING THE UPPER GUIDES BLOCKS AND THRUST BEARING

Note: Before adjusting the upper and lower blade guides and thrust bearings, make sure the

blade is tensioned and tracking properly. Adjust the upper and lower blade guides and thrust

bearings after each blade tension and tracking adjustment. Whenever the upper blade guide

and thrust bearing are adjusted, the lower blade guide and thrust bearing should also be

adjusted.

The blade guides blocks keep the blade from moving from side to side during cutting and must be snug but not touching the

blade in order to ensure accurate cuts. The space between each block and the blade must not exceed 0.02" (the thickness

of a sheet of paper). If less space is left, the blade will get stuck or jammed between both blocks. Too much friction will

cause blade to overheat and break. Also, the guide blocks must remain at least 1/32” behind the blade teeth to prevent

damage to the blade.

The thrust bearing keeps the blade from moving back and out of position when the work is being fed into the blade and

must be very close to the back of the blade to prevent damage to the blade during cutting.

Adjust the positioning of the upper blade guides blocks:

To avoid injury, make sure that the switch is in

the “OFF” position and that the power cord is

unplugged before performing any adjustments

on the bandsaw.

1. Loosen the two set screwsAusing the supplied 3 mm

Allen key.

2. Push the guide blocks B towards the blade.