16. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories.

17. DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits,

cutters, and the like.

18. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in off

position before plugging in.

19. USE RECONNENDED ACCESSORIES. Consult the owner’s manual for recommended

accessories. The use of improper accessories may cause risk of injury or persons.

20. NEVER STAND ON TOOL Serious injury could occur if the tool is tipped or if the cutting tool

is unintentionally contacted.

21. CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and perform its

intended function-check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its operation. Aguard or other part that is

damaged should be properly repaired or replaced.

22. DIRECTION OF FEED. Feed work into a blade or cutter against the direction of rotation of the

blade or cutter only.

23. NEVER LEAVE TOOLRUNNING UNATTENDED. TURN POWER OFF. Don’t leave tool

until it comes to a complete stop.

24. MAME SURE TOOL IS DISCONNECTED from power supply while motor is being mounted,

connected or reconnected. SAVE THESE INSTRUCTIONS

ADDITIONAL SAFETY RULES FOR BAND SAWS

1. If you are not thoroughly familiar with the operation of band saws, obtain advice

from your supervisor, instructor or other qualified person.

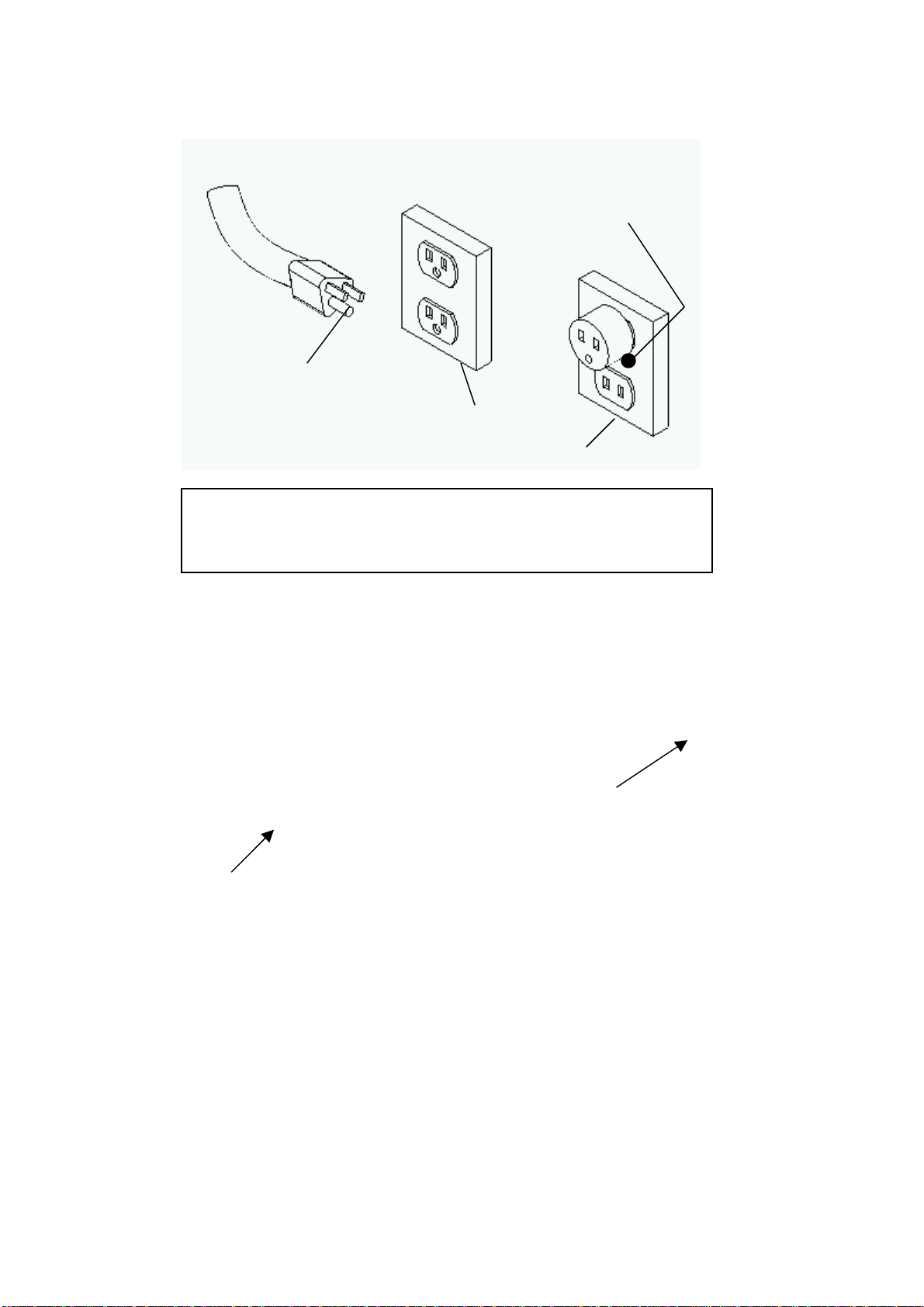

2. Follow all wiring codes and recommended electrical connections. Make certain that

the tool is properly grounded.

3. Make all adjustments with the power “OFF”

4. Always maintain proper adjustment of blade tension, blade guides, and blade

support bearings.

5. Avoid awkward hand positions. A sudden slip could allow the hand to contact the

blade.

6. Do not attempt to saw stock that does not have a flat surface, unless a suitable

support is used.

7. Make sure blade is not contacting the workpiece before turning on the power switch.

8. Always keep hands and fingers away fromthe blade when the machine is running.

9. Hold workpiece firmly against table and feed into blade at a moderate speed.

2