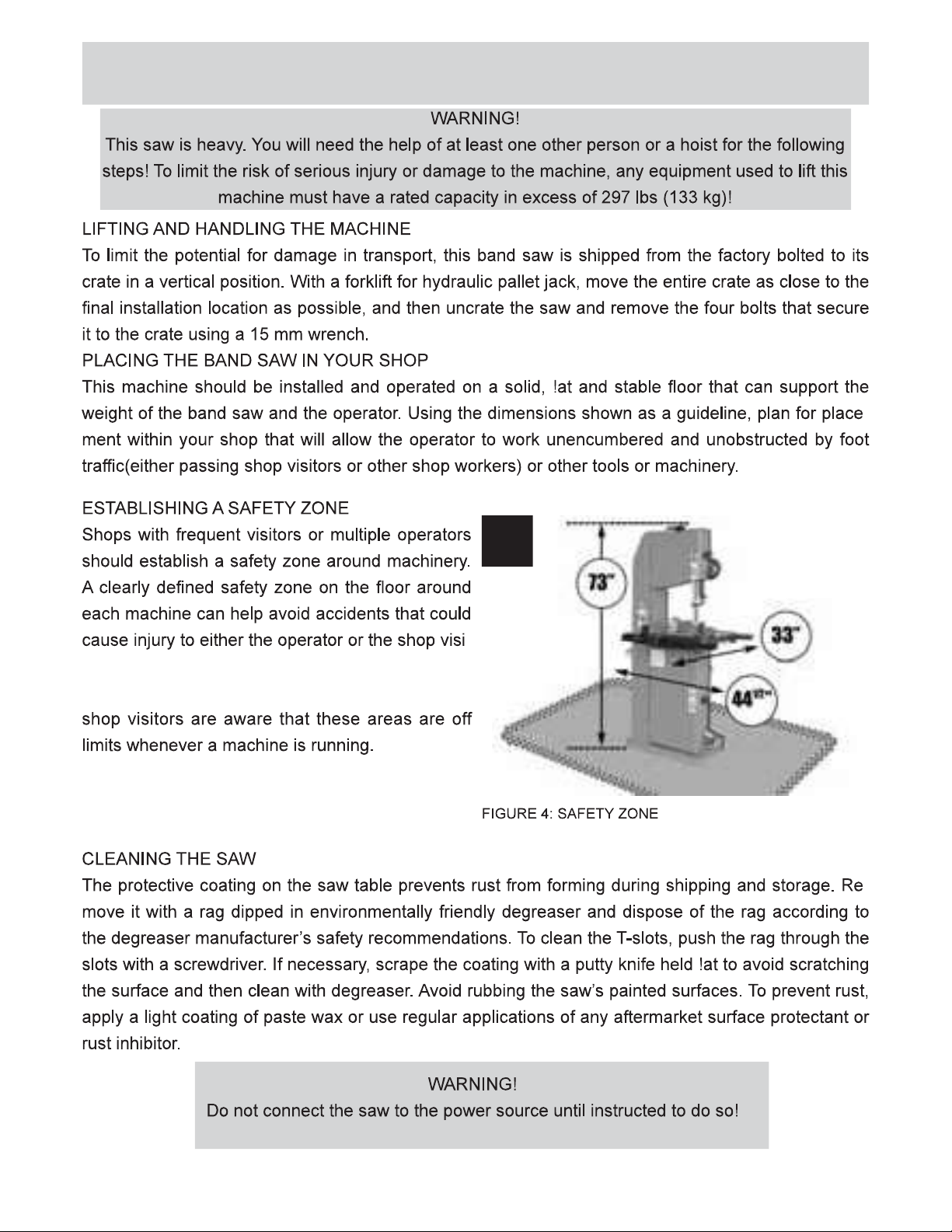

ASSEMBLY INSTRUCTIONS

MAGNUM INDUSTRIAL MI-91520 DELUXE 14” BAND SAW

INSTALLING THE FENCE ASSEMBLY

The MI-91520 is equipped with a deluxe T-fence

and guide rail system. Follow all assembly and

adjustment instructions

INSTALLATION OF THE FRONT AND REAR

MOUNTING BRACKETS TO THE BANDSAW’S

TABLE on page 18~23

INSTALLING THE FENCE ASSEMBLY

This band saw is equipped with a foot brake locat-

ed at the bottom of the machine. The foot brake

allows for immediate immobilization of the blade

1. Open the lower wheel cover door.

2. Attach the foot brake to the FOOT BRAKE

MOUNTING BAR (Q) using the two supplied CAP

SCREWS AND LOCK WASHERS (R), in the as-

sembly order shown in Figure 20.

3. Firmly tighten with the supplied 8 mm Allen key.

The foot brake is not designed to function as the

primary stop mechanism of this saw. The foot

brake should be used for emergency situations or

any time it is necessary to immobilize the blade

quicker than normal. Under normal working condi-

tions the red stop button should be used as the

primary stop mechanism. Continuously using the

foot brake as the primary stop mechanism can

lead to premature wear of the brake and may

cause damage to the motor.

WARNING!

This tool is for indoor use only. Do not

expose to rain or use in wet or damp

locations.

EMERGENCY FOOT PEDAL STOP

MAY NEED TO BE ADJUSTED MACHINE

WILL NOT START IF THE LIMIT SWITCH

IS ACTIVATED

WARNING!

Do not operate the unit with a damaged

power cord or plug.

18

19

20

FIGURE 18: FENCE INSTALLATION

FIGURE 19: FOOT BRAKE LOCATION

FIGURE 20: FOOT BRAKE INSTALLATION