BA492401-en

Pos: 5 /Papierkorb/Format/Inhaltsverzeichnis - 3 Ebenen @ 5\mod_116886744 1046_75.do cx @ 729 20 @ @1

Safety ....................................................................................................................5

1.1 Introduction..............................................................................................................5

1.2 Symbols and Signal Words ......................................................................................5

1.2.1 Personal Injury..........................................................................................................5

1.2.2 Property Damage.....................................................................................................5

1.2.3 Information...............................................................................................................5

1.3 Intended Use ...........................................................................................................6

1.4 Inappropriate Use.....................................................................................................6

1.5 Requirements on Operating and Service Personnel ..................................................6

1.6 Safety Instructions for Commissioning......................................................................6

1.7 Safety Instructions for Operation...............................................................................7

1.8 Safety Instructions for Servicing................................................................................7

1.9 What to Do in the Event of Defects or Malfunctions ..................................................8

1.10 What to Do in the Event of an Accident ....................................................................8

1.11 Safety Features ........................................................................................................9

1.11.1 Locking Device.........................................................................................................9

1.11.2 Braking Motor ..........................................................................................................9

1.11.3 Phase Sequence Relay ............................................................................................9

1.11.4 Thermal Overload Protection ....................................................................................9

1.11.5 Safety Shutdown after Motor Overload.....................................................................9

1.11.6 Warning and Information Labels ...............................................................................9

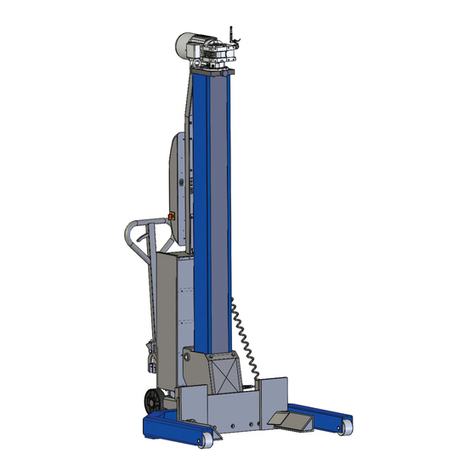

Description ..........................................................................................................10

2.1 Design and Operating Principle ..............................................................................10

2.2 Specifications.........................................................................................................11

2.3 Sample Nameplate.................................................................................................12

Operation.............................................................................................................13

3.1 Handling / Moving the Columns..............................................................................13

3.2 Controls and Indicators ..........................................................................................14

3.3 Main Switch ...........................................................................................................16

3.4 Initial Operation ......................................................................................................16

3.5 Positioning, Logging in and Interconnecting the Columns .......................................17

3.6 Switching over to Group Mode...............................................................................18

3.7 Switching over to Single Mode ...............................................................................18

3.8 Raising and Lowering.............................................................................................19

3.9 Shutdown ..............................................................................................................19