|10 |ATJ-1000H

Maintenance and Inspection

8. Maintenance and Inspection

WARNING - The jack must be inspected accordingto

the requirements of this section. Failure to properly

inspect the jack could lead to severe injury or death.

The jack must be removed from service and inspected

immediately if it is subjected to an abnormal load or a

shock load. If any irregularities or problems are

detected during an inspection, the jack must be

removed from service immediately and repaired.

Contact the manufacturer at the numbers and address

printed on the back cover of this manual.

8.1 Inspection – before each use

The jack owner (or a knowledgeable person appointed by

the owner) must give the jack a more thorough inspection

weekly (if it is used on a daily basis) or monthly (if used

less frequently). In addition to a visual inspection (as

described above), the inspector should also operate and

move the jack to assist in identifying any problems that

might exist. The jack must be removed from service and

repaired if the jack appears damaged, if it is badly worn,

or if it operates abnormally.

Visual inspection of the jack must be made before each

use of the jack. The jack should be immediately removed

fromservice ifanyofthe followingconditions are detected

or observed:

Visually inspect the jack for signs of cracking,

chipping, or excessive wear, including all welds.

Visually inspect all four casters for cracking, chipping

or excessive wear.

Visually inspect the power unit for oil leaks.

Any abnormal condition or sign of damage that

suggests the jack will not work properly.

If any irregularities or problems are detected during an

inspection or during operation, the unit must be

removed from service immediately and repaired.

Contact the manufacturer using the contact

information on the back cover of this manual.

8.2 Maintenance instructions

WARNING - All inspection and maintenance procedures

must be performed after the jack has been removed from

service. Failure to do this may result in personal injury

and/or property damage.

Lower unit completely and exhaust all air from the air

cylinder before servicing the air cylinder. Failure to

exhaust all air from the air cylinder can cause rapid

separation of the piston rod from the air cylinder.

Failure to heed this warning may result in serious

personal injury and / or property damage.

Apply light machine oil at all portions of movement to

the jack monthly.

All warning and capacitylabels should be readable and

complete. Wash external surfaces of jack, labels, and

decals with a mild soap solution.

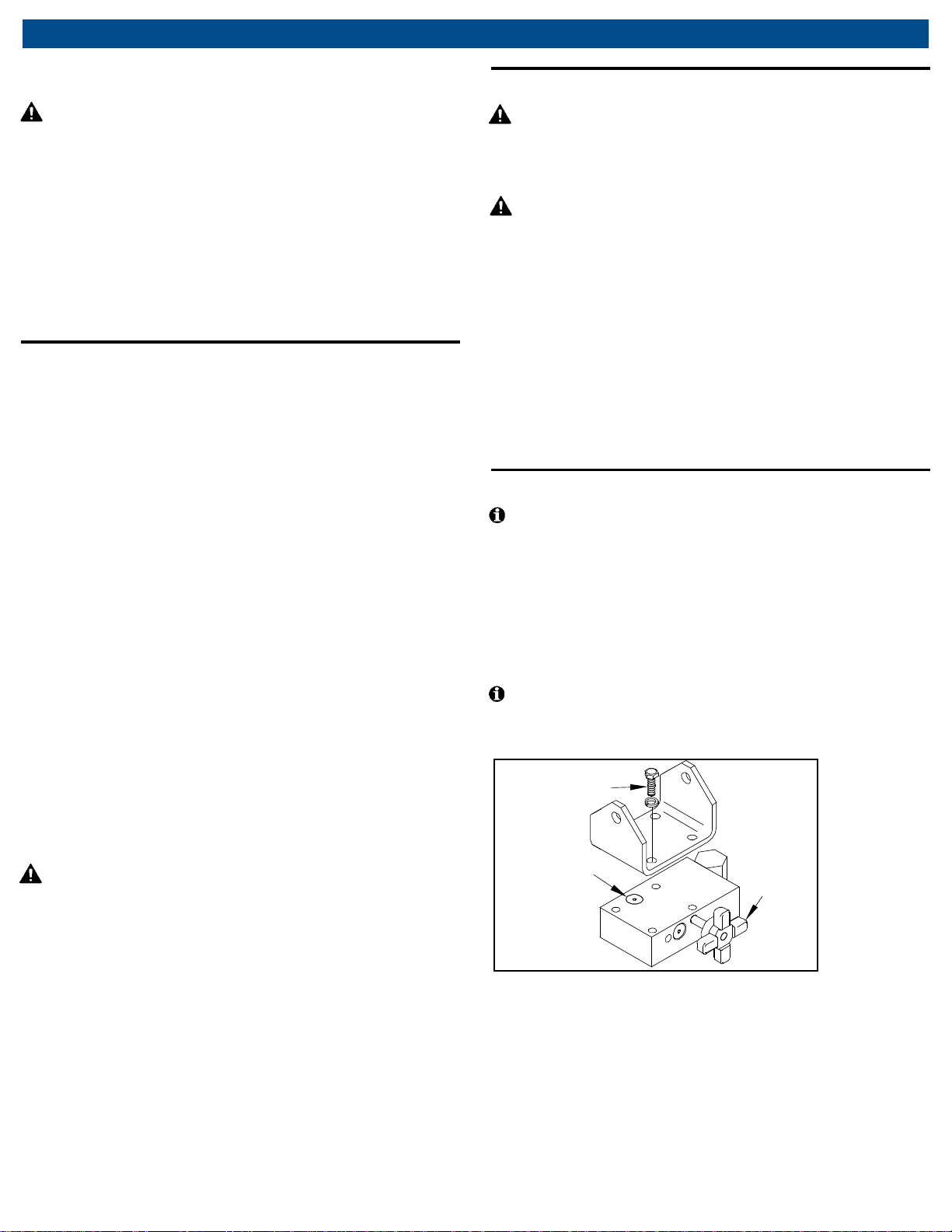

8.3 Replenish oil supply

With all four casters of the jack resting on the floor,

lower the hydraulic stage fully and remove the head

assembly by extracting the four head mounting bolts.

See Fig. 6. Carefullyclean the top of the jackto remove

all dirt, especially in the vicinity of the fill plug. Remove

the release knob by turningcounterclockwise. Remove

the fill plug and using a squirt-oil can, slowly add Tellus

T22 oil (or equivalent) until reservoir overflows.

Note: The release knobopeningserves asreservoirvent

during filling. Be sure to reinstall release knob and fill

plug, and then remount the head assembly.

Fig. 6: Replenish oil

Fill Plug Release

Knob

Head Mounting

Bolts