Makerfarm Pegasus 12 User manual

Updated 6/19/17

2

Maker Farm Inc. Limited Warranty

1. Limited Warranty. Maker Farm Inc. (“MFI”) warrants to the original purchaser (the “Customer”) that the products purchased by Customer

from MFI (the “Products”) are free from defects in material and workmanship for a period of thirty (30) days from the date of shipment to

Customer for Products, unless otherwise specified by MFI. MFI will accept returns of any non-clearance, unopened, unused and unassembled

item ordered directly from www.Makerfarm.com, after the warranty your purchase is final and no returns will be accepted. MFI charges a

restocking fee of 20% of the purchase price (price of product, excluding tax and shipping), and in addition the buyer must pay all shipping

charges (shipping charges on the initial purchase is not refundable). Once a kit has left our shop there is no way for us to know how it was

handled. Therefore, only unopened, unbuilt, kits that have no evidence of an attempted build or use will be refunded less the 20% restock fee.

Things like opened/unsealed plastic bags, any marks on the components, etc. Will result in no refund given on the kit. Should you purchase a

kit and begin to assemble it, you will not be able to return that kit for a refund.

2. MFI’s Obligation. The sole obligation of MFI, at its option and without charge, is to repair, replace, or refund the original purchase price paid

by Customer for, any Product or part, which MFI manufactures and which MFI agrees is defective. Repair parts or replacement Products may be

new, remanufactured, or refurbished, at the sole discretion of MFI. All returned parts or Products that are replaced become the property of MFI.

3. Transfer of Other Warranties. In the case of equipment and accessories not manufactured by MFI, if a warranty is extended by the

manufacturers thereof and transferable to Customer, MFI shall transfer such warranty to Customer.

4. Exclusions. MFI’s limited warranty provided herein does not cover: (i) normal wear and tear; (ii) transport damage; (iii) failure to follow

operation or maintenance instructions; (iv) Customer’s negligent modification (including painting or staining wood pieces), disassembly or

attempted repairs of the Product; (v) abuse, misuse or negligent acts; (vi) accidental or intentional damage; or (vii) cosmetic shortcomings which

do not influence Product function.

5. Disclaimers. unless expressly set forth in this limited warranty, MFI makes no warranty of any kind whatsoever, express or implied, with

respect to any products furnished hereunder. MFI expressly disclaims, where legally permitted to make such disclaimer, any warranties implied

by law, including but not limited to any warranty of merchantability or fitness for a particular purpose.

6. Limitation of Damages. IN NO EVENT SHALL MFI BE LIABLE TO CUSTOMER FOR ANY INDIRECT, CONSEQUENTIAL,

PUNITIVE, EXEMPLARY, INCIDENTAL OR SPECIAL DAMAGES, OR ANY DAMAGES WHATSOEVER RESULTING FROM LOSS

OF USE, PROFITS, OR DOWN-TIME (HOWEVER CAUSED AND UNDER ANY THEORY OF LIABILITY, WHETHER THE BASIS OF

LIABILITY IS BREACH OF CONTRACT, TORT (INCLUDING NEGLIGENCE AND STRICT LIABILITY), STATUTE OR ANY OTHER

LEGAL THEORY), EVEN IF MFI HAS BEEN ADVISED OF THE POSSIBLITY OF SUCH DAMAGES. MFI’S TOTAL LIABLITY TO

CUSTOMER, FROM ALL CAUSES OF ACTION AND UNDER ALL THEORIES OF LIABILITY, WILL BE LIMITED TO THE

AMOUNTS PAID TO MFI BY CUSTOMER. THESE LIMITATIONS SHALL APPLY NOTWITHSTANDING ANY FAILURE OF

ESSENTIAL PURPOSE OF ANY LIMITED REMEDY. THE REMEDIES UNDER THIS LIMITED WARRANTY ARE CUSTOMER’S

SOLE AND EXCLUSIVE REMEDIES.

7. Return Merchandise Authorization (RMA) Process for Defective Products.

7.1 A Return Merchandize Authorization (“RMA”) number must be obtained from MFI before Customer can return any Product to

MFI for warranty service. An MFI representative will gather the appropriate account and Product information and verify warranty status. MFI

must receive notification of the need for warranty service before the end of the applicable limited warranty period. The RMA number must be

included on the outside packaging of the returned Product. To obtain an RMA number, please contact MFI by email as follows:

7.2 Any approved RMA should be considered provisional, based on verification of in-warranty status when the Product is received at

MFI. If MFI determines that the Product is out-of-warranty, Customer will be notified. At the Customer’s discretion, MFI will either scrap the

out-of-warranty Product or return it to Customer.

7.3 Customer is responsible for all shipping charges for RMAs to MFI, and MFI is responsible for all shipping charges to return the

Product or its replacement to the Customer. Standard Shipping is used to return products to Customers.

7.4 MFI will typically not decide whether to repair, replace, or refund the purchase price for, any returned Product until the returned

Product is received at MFI and the warranty status is confirmed.

7.5 Under special circumstances, if the Customer would like to expedite the RMA process, MFI may agree from time to time to cross-

ship a replacement Product after the issuance of an RMA number but before receipt of the returned Product, but MFI shall not be obligated to do

so. Cross-ship orders require a valid credit card number or credit account to secure the MFI Product. The Customer’s credit card or credit

account will be credited if MFI receives the returned Product within fifteen (15) days of the date on which MFI ships the replacement Product,

and provided further that the returned Product was in-warranty.

8. Discontinuance of Products. Notwithstanding any language in this limited warranty to the contrary, MFI shall have the right to discontinue

the availability of any Product or components or replacement parts therefor, or to make design changes or improvements in the Products at any

time and such discontinuance or change shall not constitute a breach of warranty, or result in liability for MFI under any legal theory

whatsoever. MFI shall have no obligation to retrofit, change or improve Products purchased by Customer prior to the discontinuance or change.

9. Other Rights. This limited warranty gives you specific legal rights, and you may also have other rights which vary from State to State, and

from Country to Country.

9.1 EXCEPT TO THE EXTENT LAWFULLY PERMITTED, THIS LIMITED WARRANTY DOES NOT EXCLUDE, RESTICT OR

MODIFY STATUTORY RIGHTS APPLICABLE TO WHERE THE PRODUCT IS SOLD, BUT RATHER IS IN ADDITION TO THESE

RIGHTS.

3

Pg 2: Warranty information

Pg 4: Information on Power Supply, Glass and Filament

Pgs 5-6: Identification

Pg 7: Frame

Pgs 8-14 : Y,Z Motor & Y Extrusion

Pgs 15-23: Y Bed

Pgs 24-27: Metal X Motor Assembly

Pgs 28-30: Metal X Idler Assembly

Pgs 31-33 : X Carriage

Pgs 34-40 : X Axis

Pgs 41-43 : Belts

Pgs 44-46: Heat Bed

Pgs 47-48: Endstops

Pgs 49-52: LCD Installation

Pg 53: E3D Hot End Assembly

Pgs 54: Extruder Assembly

Pgs 55-57: Z Rods

Pgs 58-65: RAMPS Install / Wiring Diagram

Pgs 66-72: Wiring your Power supply

Pgs 73-76: Software/Firmware/First Prints

Pg 77: Wire Management

Pgs 78-80: Pronterface

Troubleshooting Guide: Download

4

Pegasus 12”

This Guide has Hyper links so is not recommended to print the guide. To use the guide click

File then Download and open the PDF in your PDF Viewer, if you view the Guide online the

Hyper links will not function

Thank you for purchasing the Pegasus 12” Kit. To complete your build you will need a

couple other items, Piece of Glass, Power Supply, Insulation and Hairspray:

Piece of Glass: 12”x12” then break the corners off to avoid hitting the bolt heads (3/16” or

5mm Thick Minimum if your heat bed relay is built into the Heat bed or 3.5mm thick if you

have a separate heat bed relay). Most hardware stores will cut it to the size you need, Inside

the USA Lowes or Home Depot

For the Power Supply, Insulation and Hairspray see the links at the bottom of the 12”

Pegasus Page here: http://www.makerfarm.com/index.php/3d-printer-kits/12-pegasus-

kit.html

You may also want some filament to print with after you have built your printer.

Makerfarm.com does sell filament and we would recommend using our filament or another

high quality manufacturer. If you want to purchase your filament somewhere else make sure

you get high quality filament, poor quality filament (Amazon and eBay) will jam and cause

problems.

While your printer is on you should always be by your printer, do not leave it unattended

At any time if you have any questions feel free to e-mail or chat via google chat:

elderfarrer@gmail.com

Thanks,

Colin Farrer—Sales@MakerFarm.com

5

6

There are two different hardware kits for the Frame. Follow the guide

for your version by clicking on the

link below, after you finish that

guide come back to this build

guide to finish your build.

Frame Kit Version 1 has 10 Cast

Corner Brackets with Nubs, 4 Cast

Corner Brackets without Nubs and

32 Hidden Corner Brackets.

FRAME KIT VERSION 1 Build

Guide

Frame Kit Version 2 has

one kit with 35 Cast Corner

Brackets with Nubs, 4 Cast

Corner Brackets without

Nubs and 7 Hidden Corner

Brackets.

FRAME KIT VERSION

2 Build Guide

8

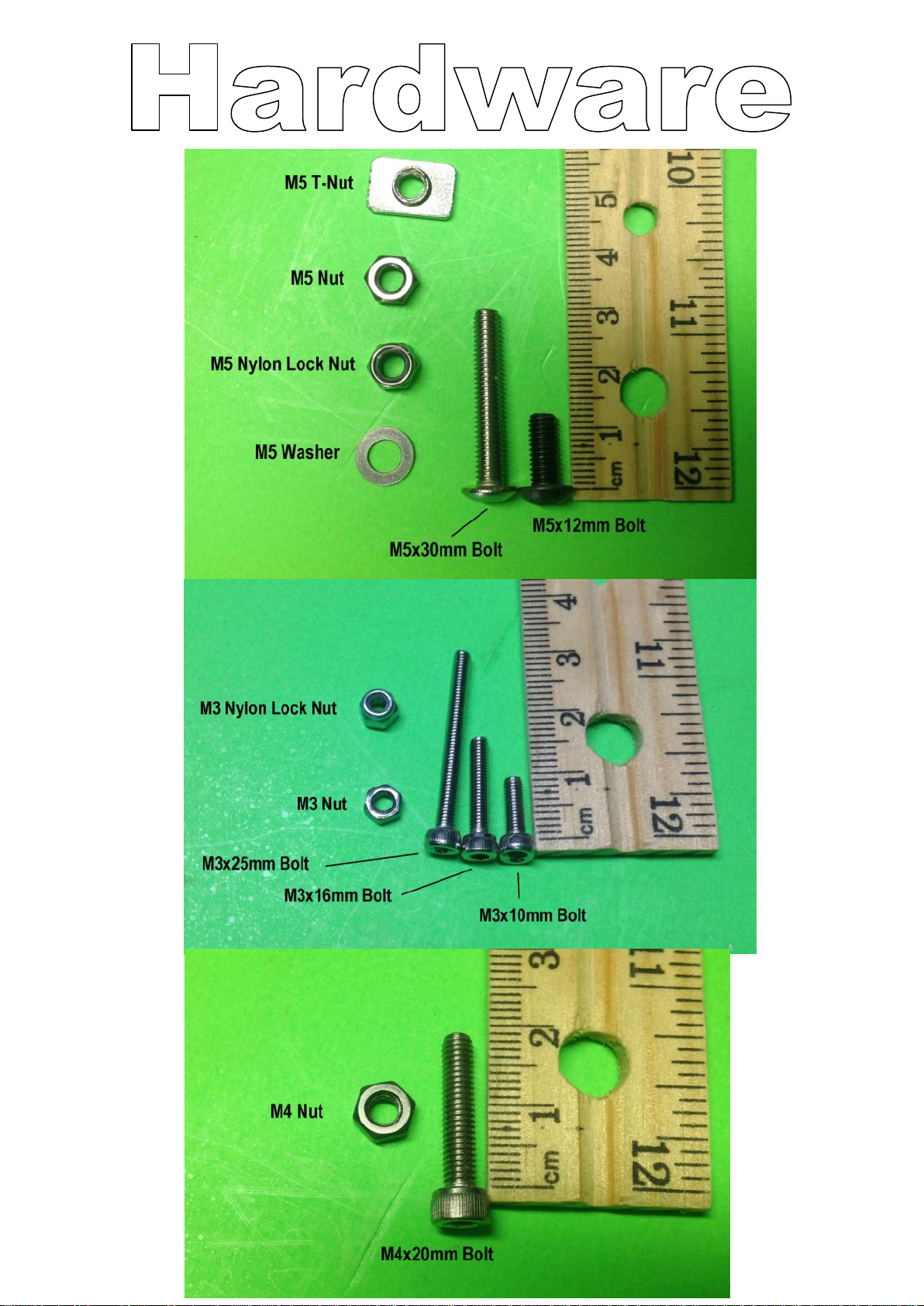

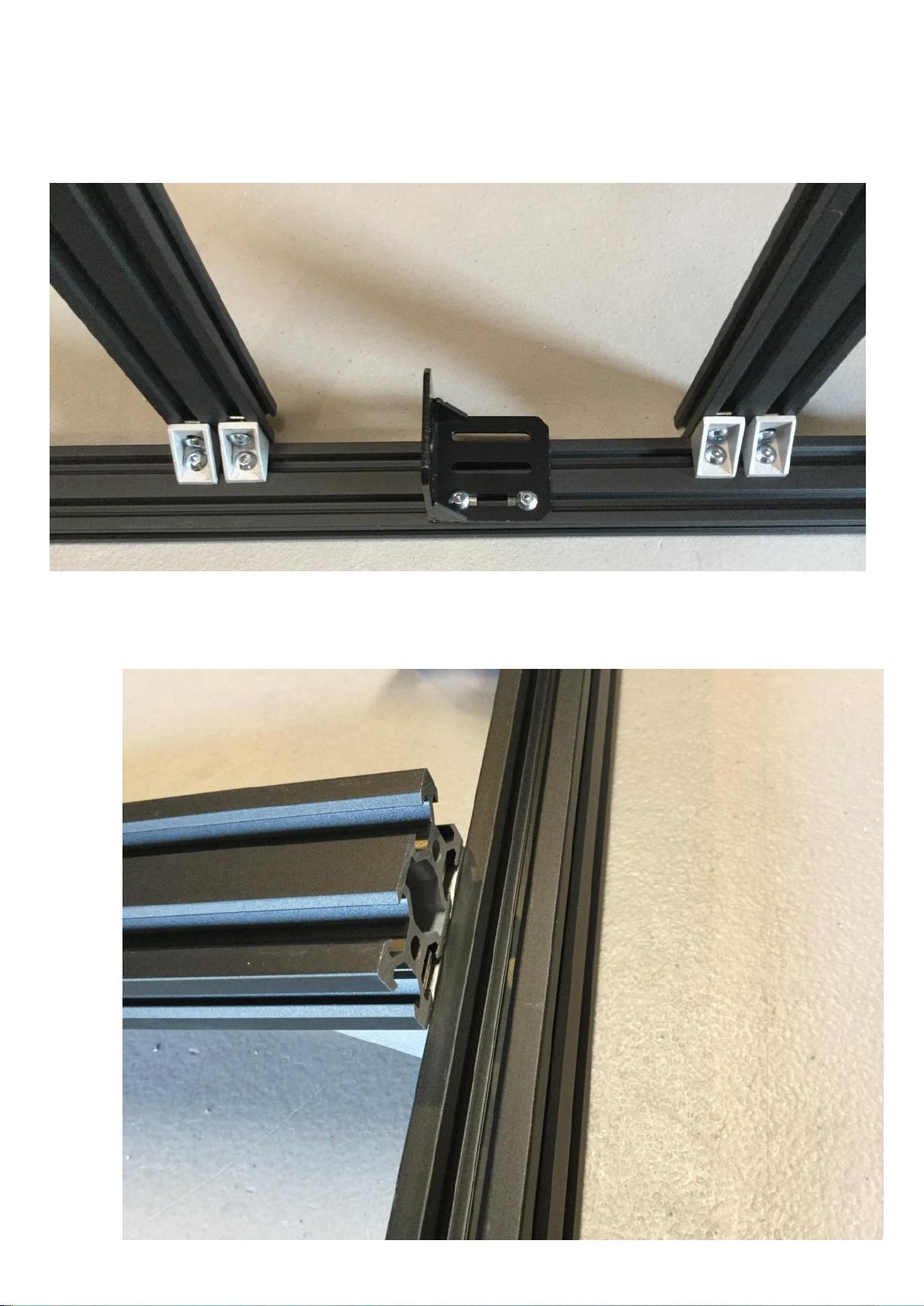

Gather the following parts if your kit came with 14 of

the 20x40 extrusions then follow pages 9, 10, 11

2 20x20mmAluminum Extrusions

2 x Cast Corner Brackets with Nubs if you have

any left (Shown by the red circle in the photo below,

if none of your brackets have nubs then use 2 without

nubs)

4 x Cast Corner Brackets without Nubs

4 x M5x8mm Bolts

3 x Motor Mounts

1 x M5x12mm Bolt

1 x T-Slot Nut

If you have 16 20x40 extrusions instead of 14 the

following then follow pages 12, 13 and 14

2 20x40mmAluminum Extrusions

8 x Cast Corner Brackets without Nubs

2 x Cast Corner Brackets with Nubs

(Shown by the red circle in the photo below, if none

of your brackets have nubs then use 2 without nubs)

8 x M5x8mm Bolts

3 x Motor Mounts

1 x M5x12mm Bolt

9

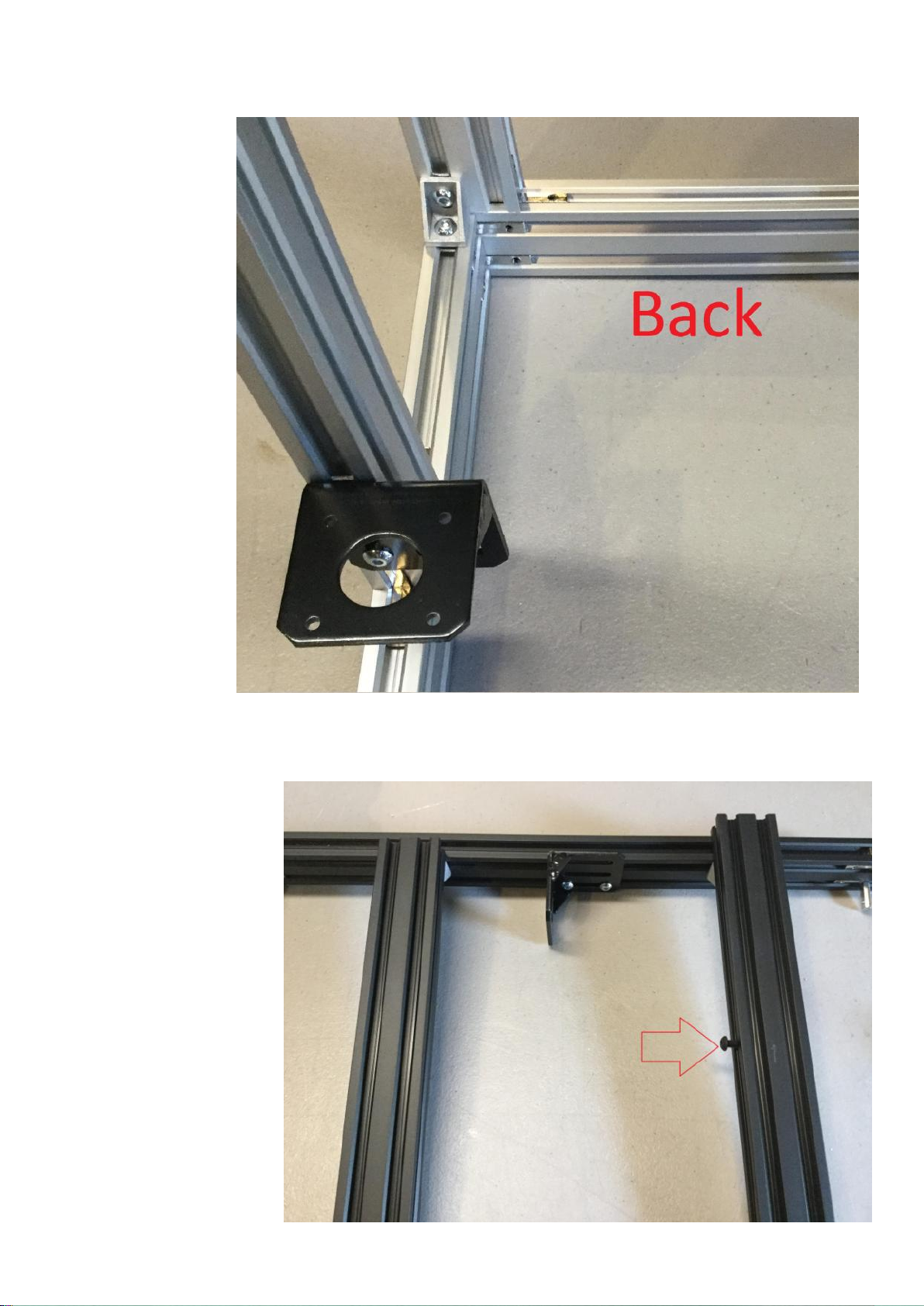

Install 4 Cast Corner Brackets on the bottom front of the machine using the M5x8mm

bolts installed previously (Use the ones with Nubs if you havent already installed them

them in the position with a Red Circle). You will adjust the actually placement later.

Now install 2 Cast Corner Brackets without Nubs and one Motor Mount on the bottom

back of the frame using the previously installed M5x8mm Bolts. You will adjust the

actually placement later.

Now Install a Motor Mount of the right side of the printer, make sure you use the slot

on the far left of the motor bracket.

10

Now Install a Motor Mount of the left side of the printer, make sure you use the slot on

the far left of the motor bracket.

Next using the Extrusion and M5 bolts install the extrusion into the cast corner

brackets. Also install the M5x12mm bolt and T-Slot nut onto the right extrusion.

11

Connect the extrusion to the Cast Corner Brackets in the front of the machine also.

Make sure the bottom of the Extrusion is aligned with the bottom of the cast corner

bracket on all 4 brackets otherwise yourY axis will not be flat.

12

Install 6 Cast Corner Brackets on the bottom front of the machine using the M5x8mm

bolts installed previously. You will adjust the actually placement later.

Now install 4 Cast Corner Brackets and one Motor Mount on the bottom back of the

frame using the previously installed M5x8mm Bolts. You will adjust the actually

placement later.

Now Install a Motor Mount of the right side of the printer, make sure you use the slot

on the far left of the motor bracket.

13

Now Install a Motor Mount of the left side of the printer, make sure you use the slot on

the far left of the

motor bracket.

Next using the

Extrusion, M5 bolts

and T-Slot nuts install

the extrusion into the

cast corner brackets.

Also install the

M5x12mm bolt and T-

Slot nut onto the right

extrusion (Shown by

red arrow).

14

Connect the extrusion to the Cast Corner Brackets in the front of the machine also.

This picture will show how the underside of the extrusion will look.

Make sure the bottom of the Extrusion is aligned with the top of the front and back

extrusion pieces otherwise yourY axis will not be flat.

15

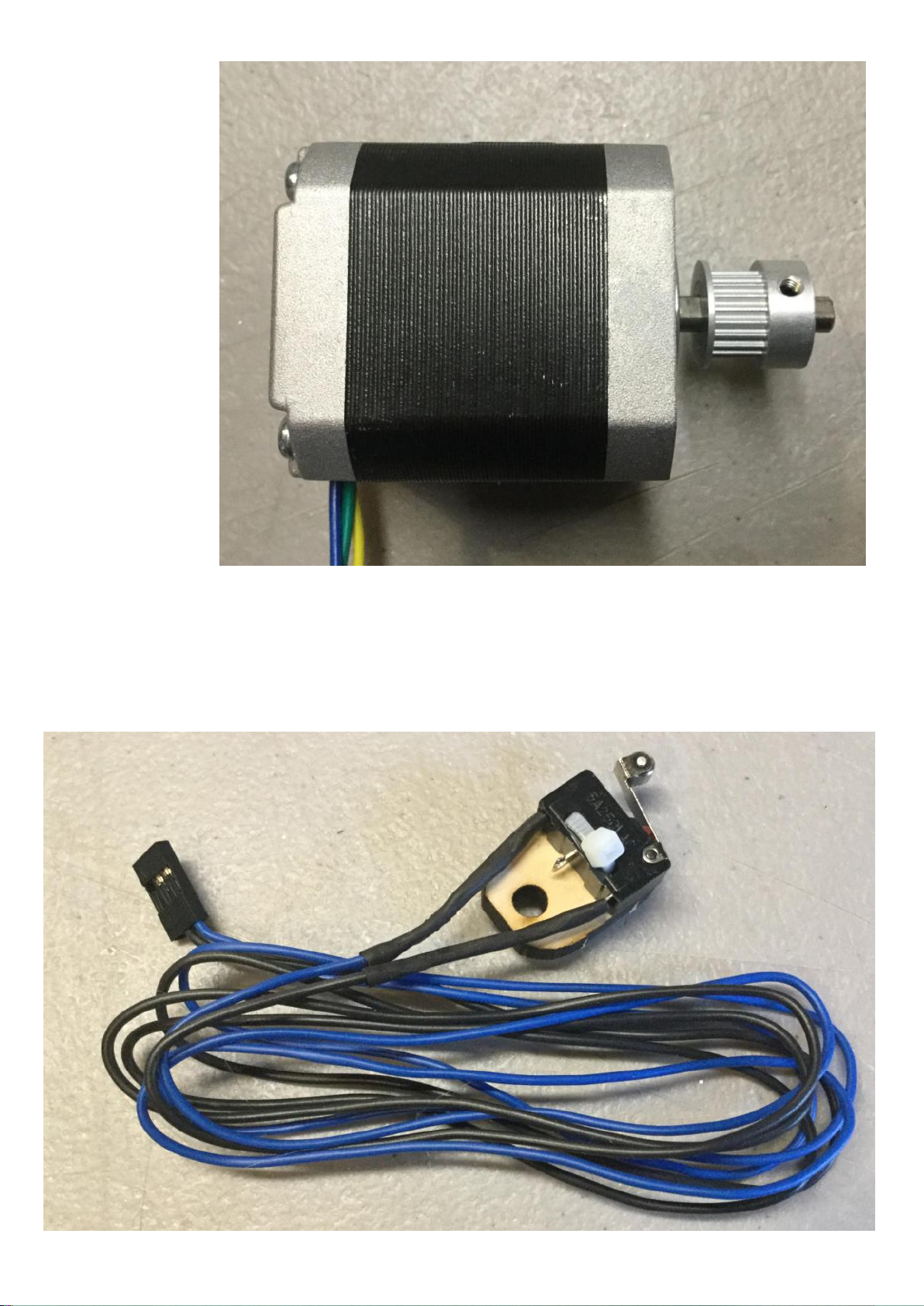

Gather the following parts

1 x Aluminum Heat Bed Mount

3 x Motors

1 x GT2 Gear and Set Screws

1 set of wood Y belt Mount

2 x Aluminum Spacers

2 x Eccentric Spacers

4 x M5x30mm Bolts

4 x M5 Nylon Lock Nut

4 x Delrin Idlers

1 x M3x25mm bolt

1 x M3x16mm bolt

3 x M3 Nylon Lock Nut

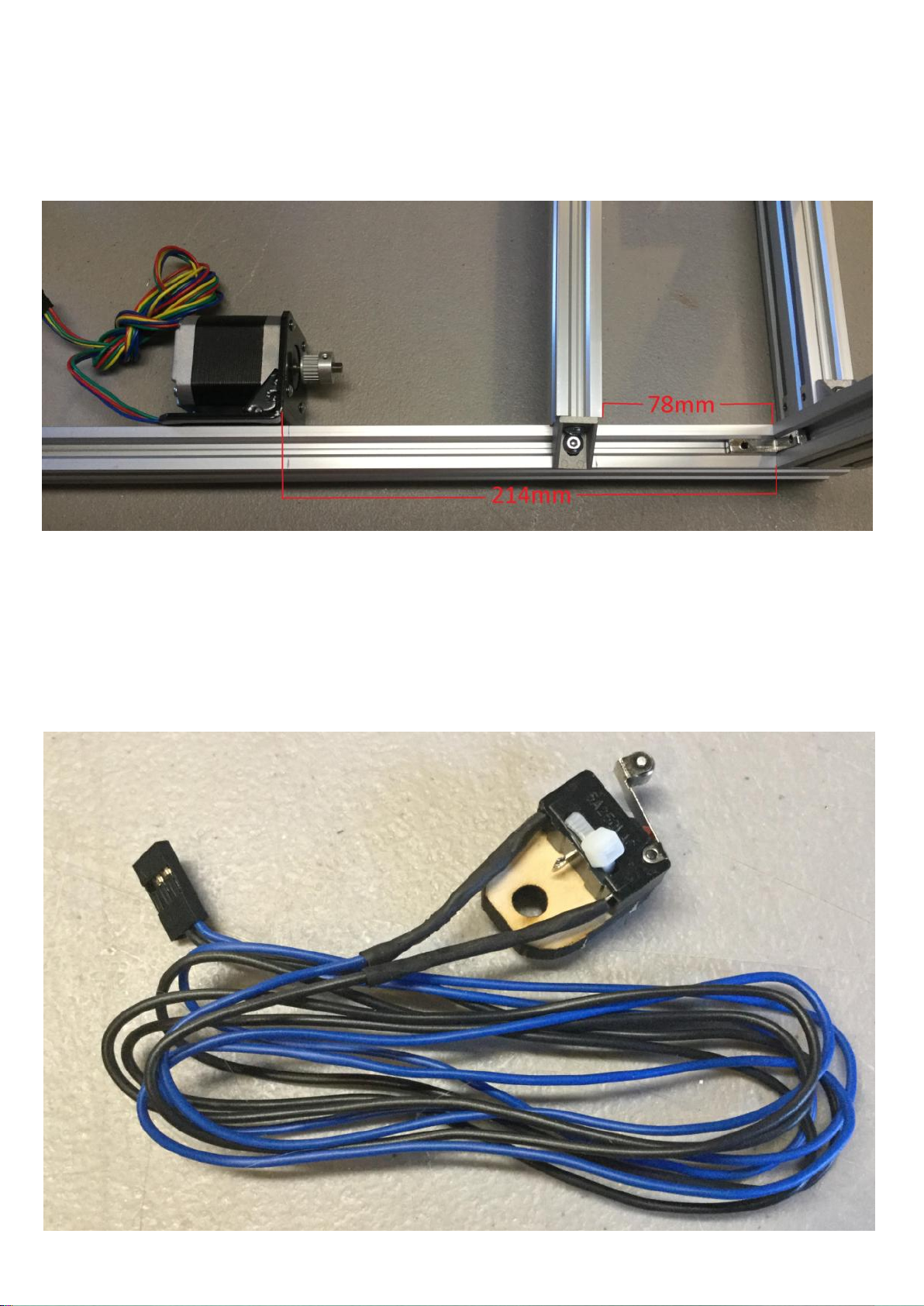

1 x Endstop

1 x Zip Tie

1 x Wood Endstop Mount

12 x M3x6mm Bolts

16

To start install a

GT2 gear onto a

motor as shown

below, make

sure to align one

of the set screws

with the flat spot

on the Motor.

Using the Wood Endstop mount and a zip tie install the endstop as shown below.

17

Next adjust the Y motor mount so the front of the mount is 214mm away from the

inside of the extrusion as shown below, then move the extrusion in between the motor

and side of the frame so its 78mm from the inside of the extrusion as shown below.

Next install the Motor with the GT2 gear using 4 of the M3x6mm bolts.

18

Install the endstop on the extrusion as shown below.

Adjust the two Z motor mounts so the surface the Z motor contacts is 55mm above the

extrusion as

shown.

Tighten the Z

motor mount

in place,

make sure the

mount is not

tilted. This

should let you

just barely

squeeze the

motor into

the mount.

19

Installl the two Z motors into the Z mounts using 4 M3x6mm bolts on each motor.

20

Get yourAluminum Heat bed mount, position the mount so the bolt hole shown by the

Blue arrow is in the top left corner. Install the M3x16mm bolt with an M3 Nylon lock

nut, then install a 2nd M3 Nylon lock nut onto the end of the bolt. (If you have

upgraded your Y Extrusions to 20x40 you will want to install the M3x16mm Bolt and

nut shown by the blue arrow in a hole 20mm to the right to allow for the thicker

extrusion, you may need to drill a new hole if your kit didn’t ship with the wider Y

extrusion)

Install the 4 M5x30mm bolts in the 4 larger holes as shown by the Red and Green

Arrows, then install an Aluminum Spacer on the bolts with the Red arrows and an

eccentric spacer on the ones with the Green Arrows. Turn the Eccentric spacers so the

Fat part of the spacer is closer to the center of the heat bed mount.

Table of contents

Other Makerfarm 3D Printer manuals