Models No.

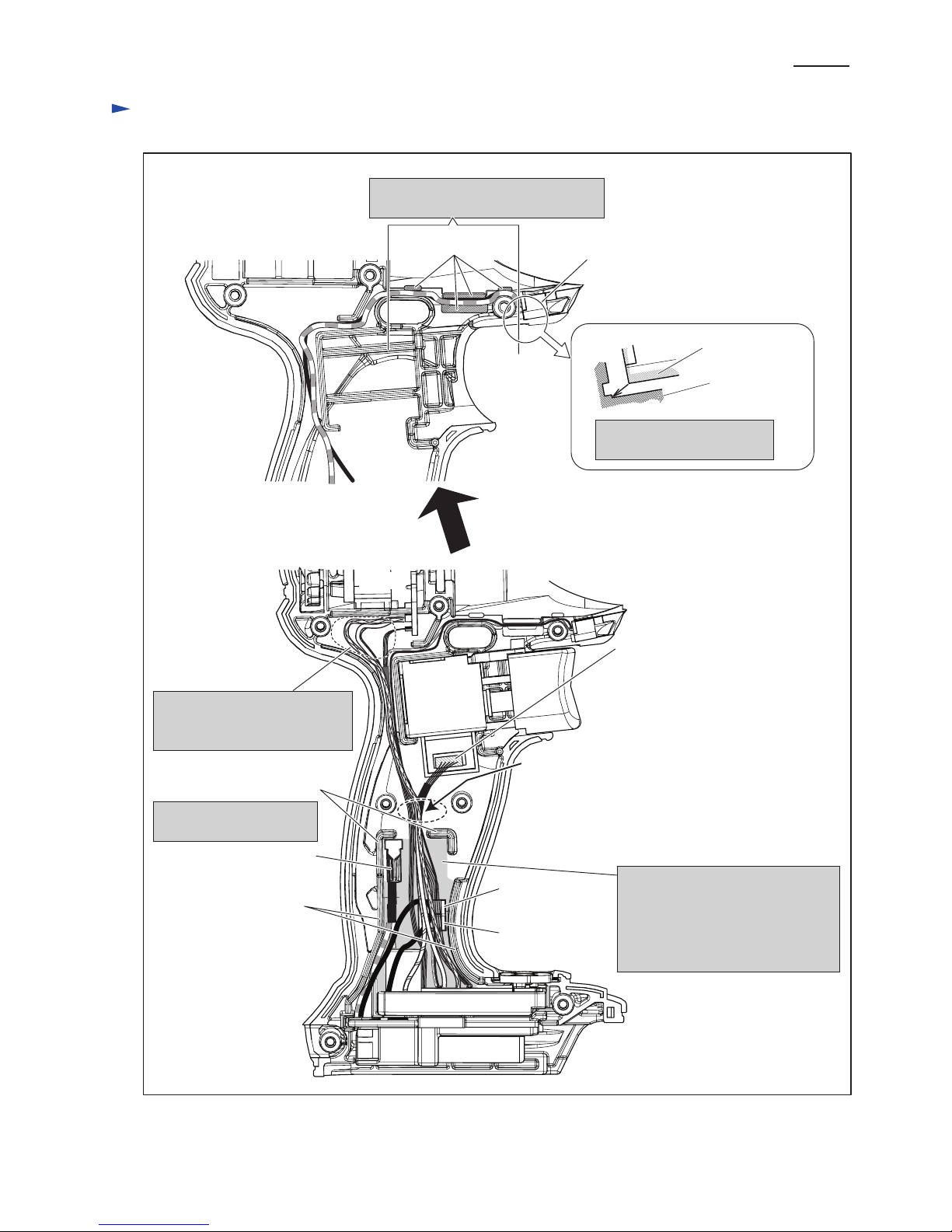

Description

PRODUCT

CONCEPT AND MAIN APPLICATIONS

P 1/ 10

BTD133

Cordless Impact Driver

Specification

Standard equipment

Optional accessories

See the model variation list above.

Note: The standard equipment for the tool shown above may differ by country.

Model BTD133 Cordless Impact Driver is an advanced version of

Model BTD132, featuring the same BLDC motor (BrushLess DC

motor) and electronic 3-stage impact power settings with variable

power control in each range as BTD132, plus redesigned belt clip

for more convenience and improved switch and electronic controller

for higher durability.

For differentiation from BTD132, equipped with transparent hammer

case cover and three stripes printed next to the "BL motor" logo.

Shoulder belt

Drill chucks

Stopper set (w/o Bit)

Stopper set (w/ Bits)

Battery protector

Hook set (Belt clip)

Bit piece

Phillips bits

Socket bits

Connecting bit 6.35-48

Tool holder

Li-ion battery 1430

Li-ion battery 1430A

Fast charger DC18RA

Charger DC18SD

Charger DC24SC

Automotive charger DC18SE

Automatic refreshing adapter ADP03

Battery

No load speed: min.-1=rpm

Impacts per min.: min.-1=ipm

Max. fastening torque*4: N.m (kgf.cm/ in.lbs)

Charging time (approx.): min.

Capacities

Electric brake

Reverse switch

Weight according to

EPTA-Procedure 01/2003 *5: kg (lbs)

Variable speed control by trigger

Capacity: Ah

Cell

Voltage: V 14.4V

0 - 2,400/ 1,800/ 1,100

0 - 3,200/ 2,600/ 1,100

160 (1,630/ 1,420)

Standard bolt

High tensile bolt

Machine screw

Driving shank

M5 - M14 (3/16 - 9/16")

M5 - M12 (3/16 - 1/2")

Coarse thread screw 22 - 125mm (7/8 - 4-7/8")

M4 - M8 (5/32 - 5/16")

Yes

Speed selection (Impact power selection) Electronic 3 stage

Yes

Yes

LED job light Yes

1.4 (3.1)

3.0

Li-ion

210

22 with DC18RA

60 with DC18SD, DC18SE

6.35mm (1/4") Hex

Max output (W)

*4 Catalog value (torque at 3 seconds after seating, when fastening M14 high tensile bolt)

*5 with Battery BL1430

This product is available in the following variations.

BTD133RFE

BTD133Z

---

BL1430

(Li-ion 3.0Ah)

No

DC18RA

No

Model No. type quantity Charger

Yes

Belt

clip

1

No

Battery

cover

Yes

No

Plastic

carrying case

2

No

Battery

Makita-blue

Housing

color

USA, Canada, Mexico, Panama

All countries except

the four described below

--- USA, Canada, Mexico, Panama

All countries except

the four described below

Offered to

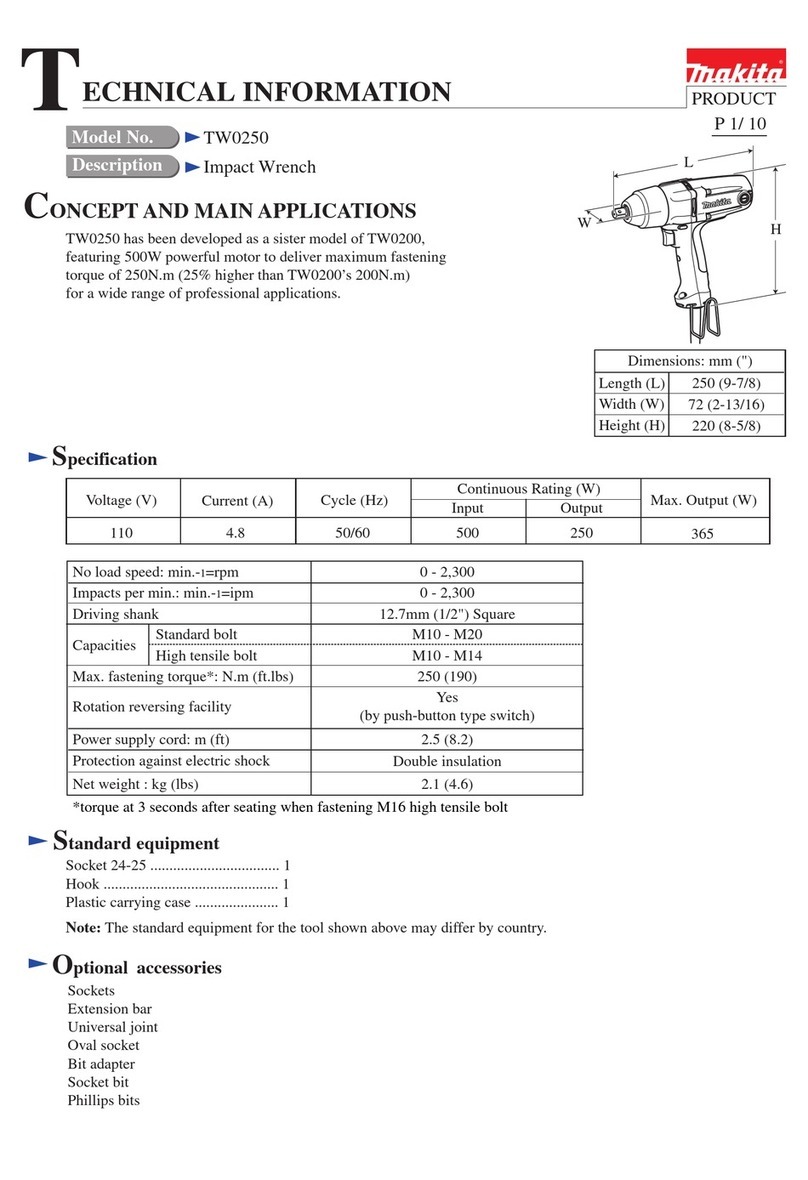

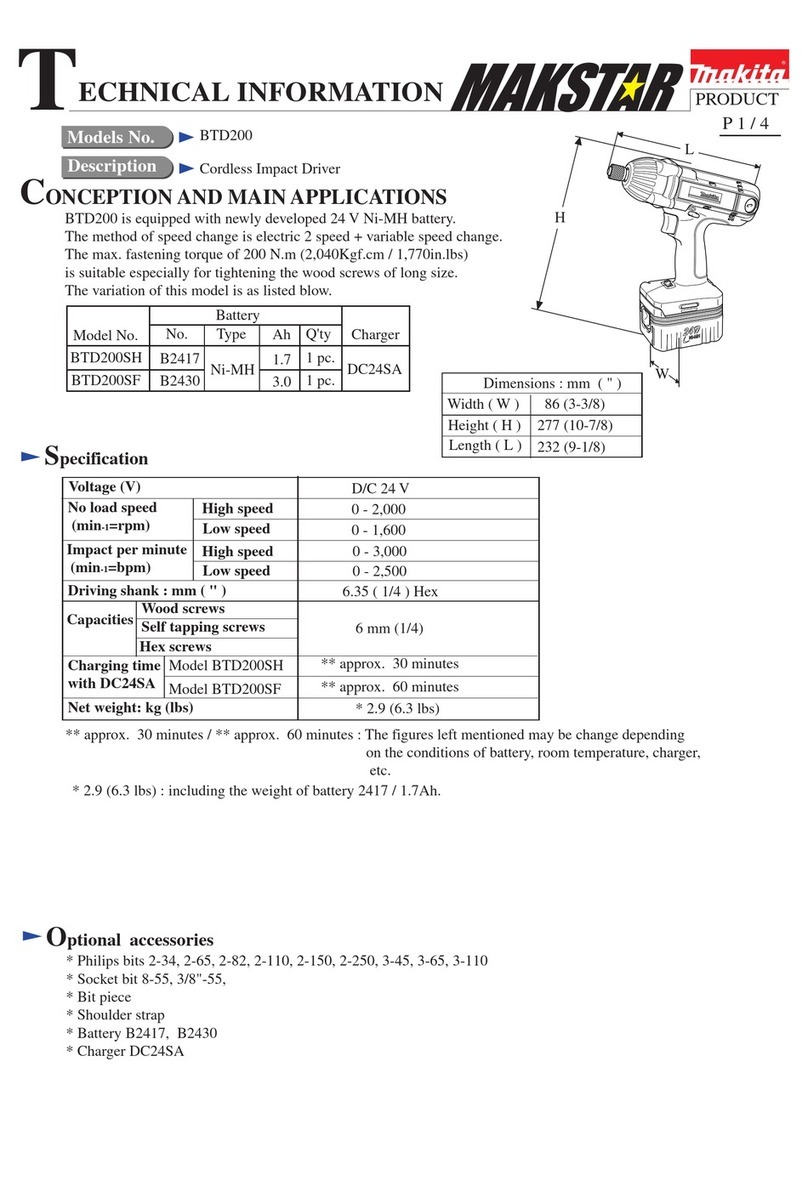

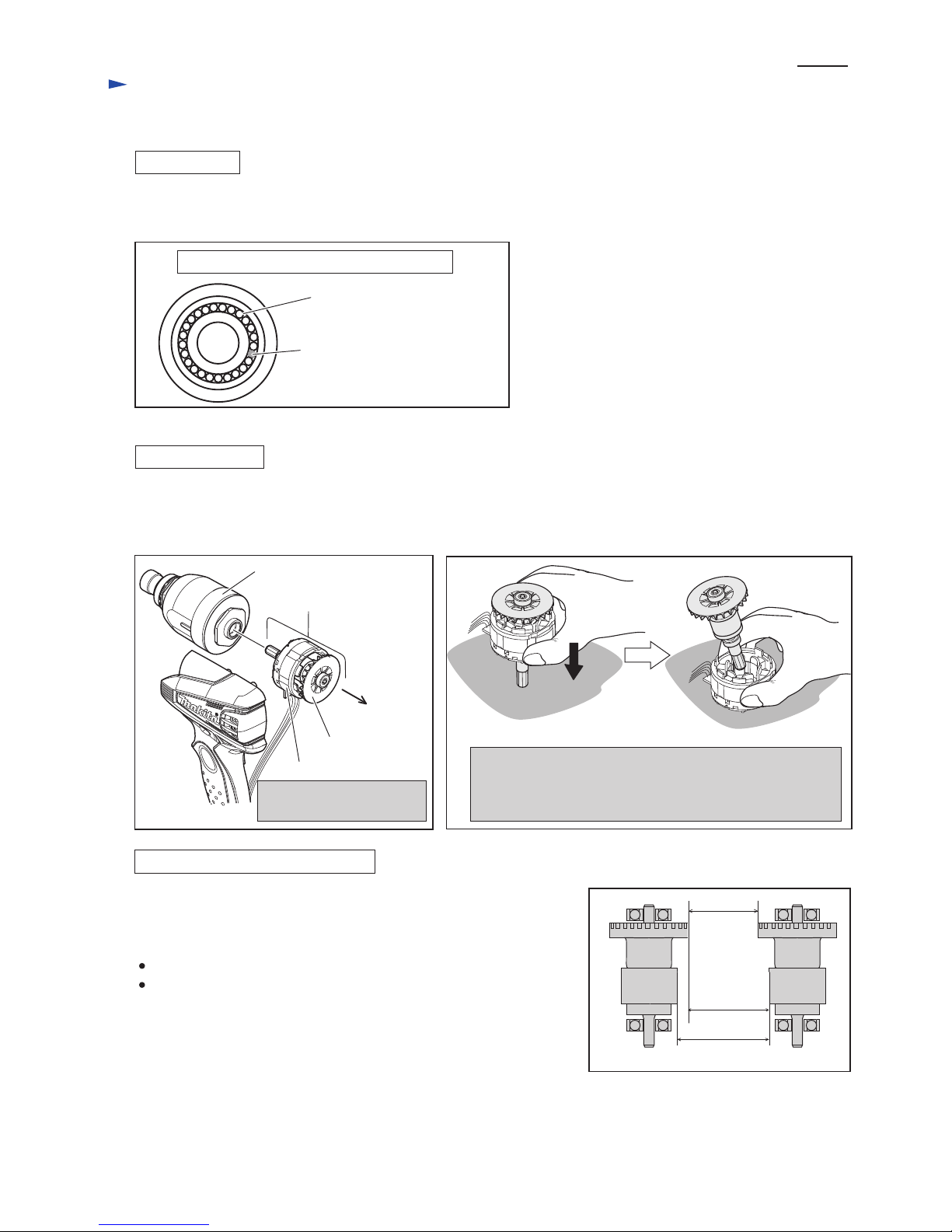

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 139 (5-1/2)*2

140 (5-1/2)*3

79 (3-1/8)

236 (9-1/4)

*2: with One-touch bit holder

*3: with Standard bit holder

L

H

W

TECHNICAL INFORMATION

This product is powered by 14.4V/ 3.0Ah Li-ion batteries BL1430/

BL1430A*.

*Not compatible with 14.4V/1.3Ah Li-ion battery BL1415

OFFICIAL USE

for ASC & Sales Shop