PRODUCT

P 1/ 7

Specification

Standard equipment

FS4300, FS4200, FS4200A, FS4200TP, FS4000

Drywall Screwdriver

The five models in the subject are drywall screwdrivers

well balanced for easy handling and maneuverability,

featuring the following main benefits;

Best possible tool body for screwdriving

One-touch locator

More durable belt clip

LED job light (except for FS4000)

See the table of “Specification” for the specification

differences between the five models.

FS4300, FS4200, FS4000 are also available with

plastic carrying case as

Model FS4300K, FS4200K, FS4000K.

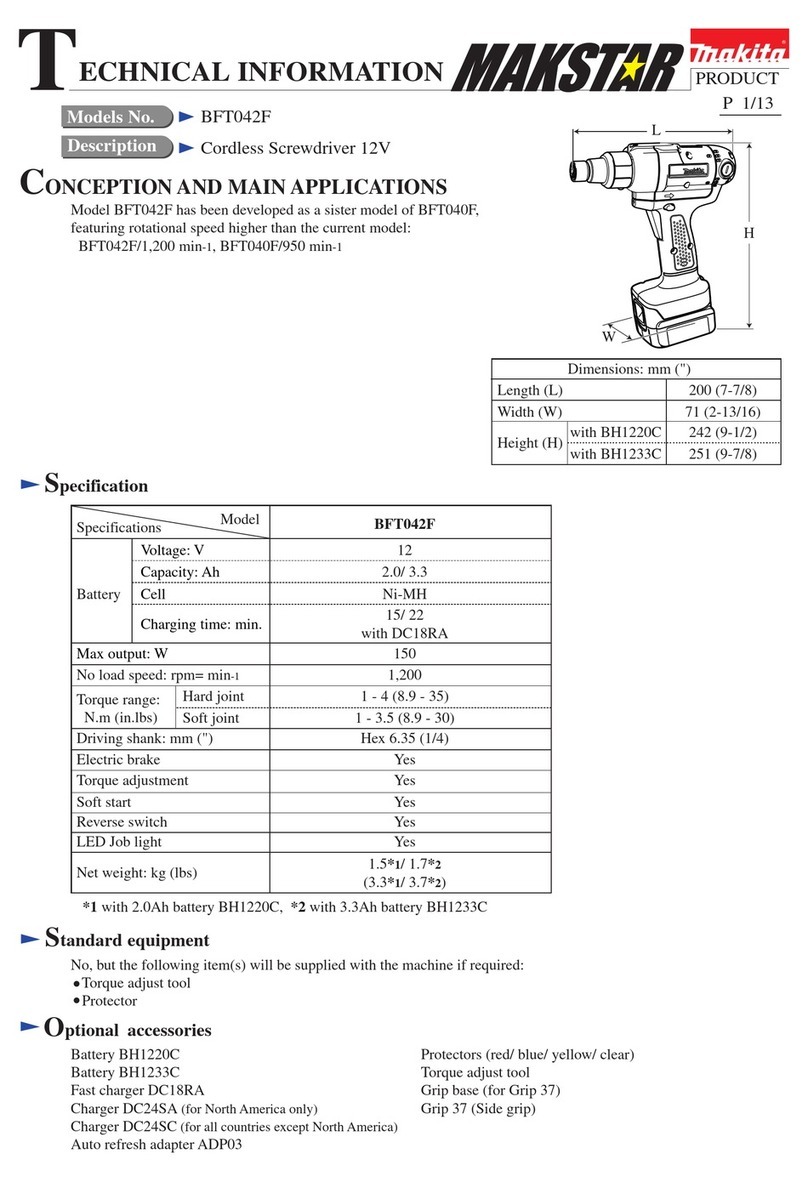

Dimensions: mm (")

Width (W)

Height (H)

*for countries where noise suppressing device is required

to conform to regulations

with connect bit 76

with connect bit 60

Length (L) 293 (11-1/2) 284 (11-1/8)

279 (11) 269 (10-5/8)

FS4300

FS4200

FS4200A

FS4200TP

FS4000

65 (2-9/16)

207 (8-1/8)*

192 (7-9/16)

Optional accessories

TECHNICAL INFORMATION

Specification

Net weight*: kg (lbs) 1.4 (3.1)

Model FS4200A FS4200TPFS4200 FS4000

Power supply cord

Europe: 4.0 (13.1) ,

Australia/ Chile/

Brazil: 2.0 (6.6),

Other countries: 2.5 (8.2)

Europe: 4.0 (13.1),

Australia/

Brazil: 2.0 (6.6),

Other countries: 2.5 (8.2)

Europe: 4.0 (13.1),

Australia/

Brazil: 2.0 (6.6),

Other countries: 2.5 (8.2)

15 (50) 15 (50)

Twist lock plug type

FS4300

Phillips insert bit 2-25 .............................................................. 2

Magnetic connect bit 6.35-60 or 6.35-76 ............................... 1

Plastic carrying case (FS4300K, FS4200K, FS4000K only) ......... 1

Continuous Rating (W)

Voltage (V) Cycle (Hz) Input Output Max. Output (W)

110

120

220

230

240

5.5

6.0

2.7

2.6

2.5

50/60

50/60

50/60

50/60

50/60

570

---

570

570

570

260

360

260

260

260

500

500

500

500

500

Current (A)

Note: The standard equipment for the tool shown above may vary by country.

Phillips insert bits 1-25, 2-25, 3-25

Magnetic connect bit 6.35-60

Magnetic connect bit 6.35-76

5 (3/16)

6 (1/4)

Drywall screw

Self drilling screw

0 - 4,000No load speed: min.-1 = rpm

Driving shank: mm (")

Capacity: mm (")

Reverse switch

Protection against electric shock

6.35 (1/4) Hex

Yes

Variable speed control by trigger Yes

Silent clutch No NoNo NoYes

LED job light Yes Yes NoYes Yes

Double insulation by Grounding

Double insulation

*Weight according to EPTA-Procedure 01/2003

North America: 1.4 (3.0)

Other countries: 1.4 (3.1)

North America: 1.3 (2.8)

Other countries: 1.3 (2.9)

Model No.

Description

CONCEPT AND MAIN APPLICATIONS

L

H

W

FS4300 FS4200

FS4000

Type Normal type Normal type Normal typeLong type

Length: m (ft)