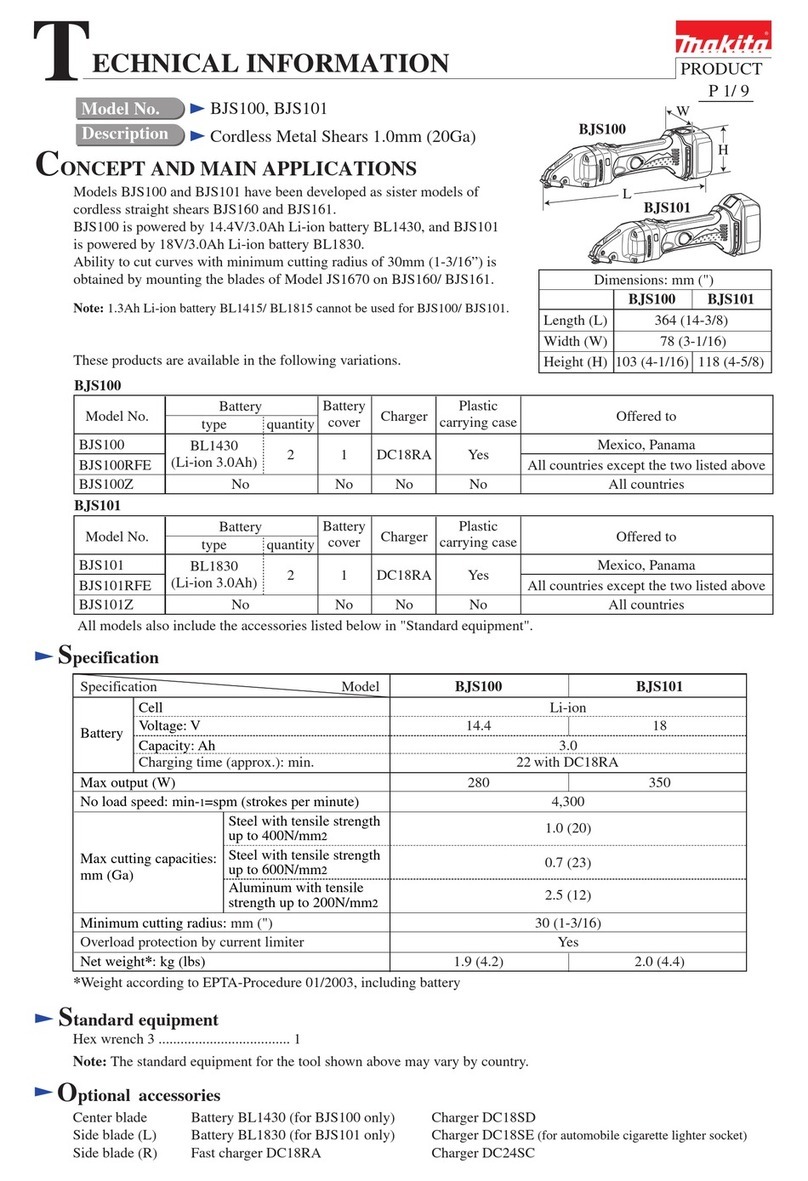

Model No.

Description

Standard equipment

Optional accessories

Note: The standard equipment for the tool shown above may vary by country.

JN3201

Nibbler 3.2mm (10Ga)

Punch

Die

Punch .................................................. 1

Die ....................................................... 1

Wrench 50 .......................................... 1

Hex wrench ........................................ 1

Washer ............................................... 2

Plastic carrying case .......................... 1 (for some country only)

PRODUCT

Outer edge: 128 (5-1/16),

Inner edge : 120 (4-3/4)

TECHNICAL INFORMATION

CONCEPT AND MAIN APPLICATIONS

P 1/ 9

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

225 (8-7/8)

90 (3-1/2)

254 (10)

Model JN3201 Nibbler is the aesthetic change model of current model JN3200

by using Motor housing of Angle grinder GA5010 series and Rubberized soft grip.

Its Blade section is the same as Nibbler JN3200.

Addition to the above, it has the following advantages.

• 710W continuous rating input

• Low noise level at 81 dB(A)

L

W

H

Specification

Continuous Rating (W)

Voltage (V) Cycle (Hz) Input Output Max. Output (W)

110

120

220

230

240

6.8

6.2

3.4

3.3

3.1

50/60

50/60

50/60

50/60

50/60

710

---

710

710

710

400

400

400

400

400

600

600

700

700

700

Current (A)

Max cutting capacities:

mm (Ga)

Steel with tensile strength

up to 600N/mm²

Weight according to EPTA-Procedure 01/2003*: kg (lbs) 3.4 (7.4)

2.5 (13)

Steel with tensile strength

up to 800N/mm² 1.0 (20)

Aluminum with tensile

strength up to 200N/mm² 3.5 (10)

Steel with tensile strength

up to 400N/mm² 3.2 (10)

No load speed: min.ˉ¹=spm (strokes per minute) 1,300

Minimum cutting radius: mm (")

Power supply cord: m (ft)

European countries: 4.0 (13.1),

Australia, New Zealand: 2.0 (6.6)

Other countries: 2.5 (8.2)

*with Punch and Die