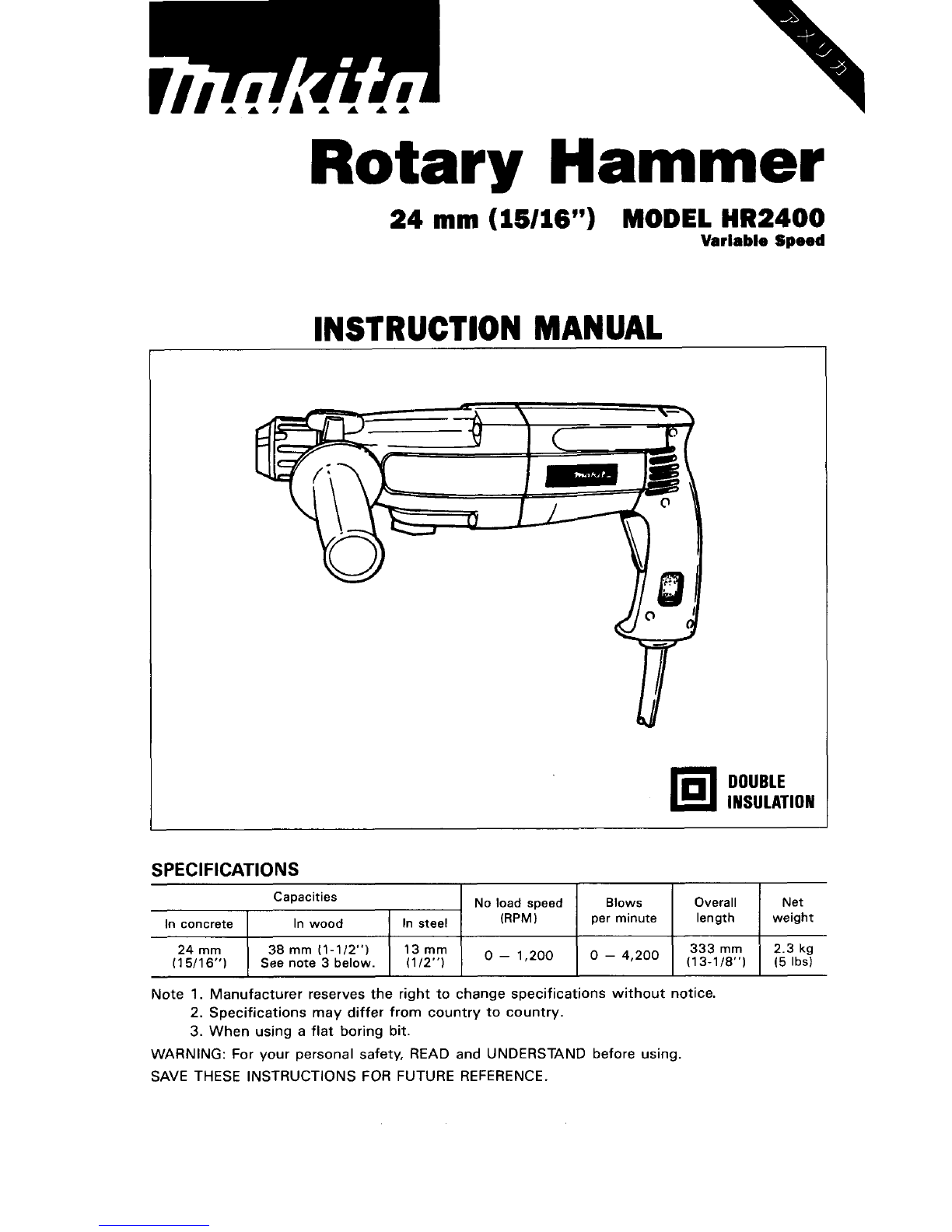

Makita HR2400 User manual

Other Makita Rotary Hammer manuals

Makita

Makita HR1830 User manual

Makita

Makita HR2432 User manual

Makita

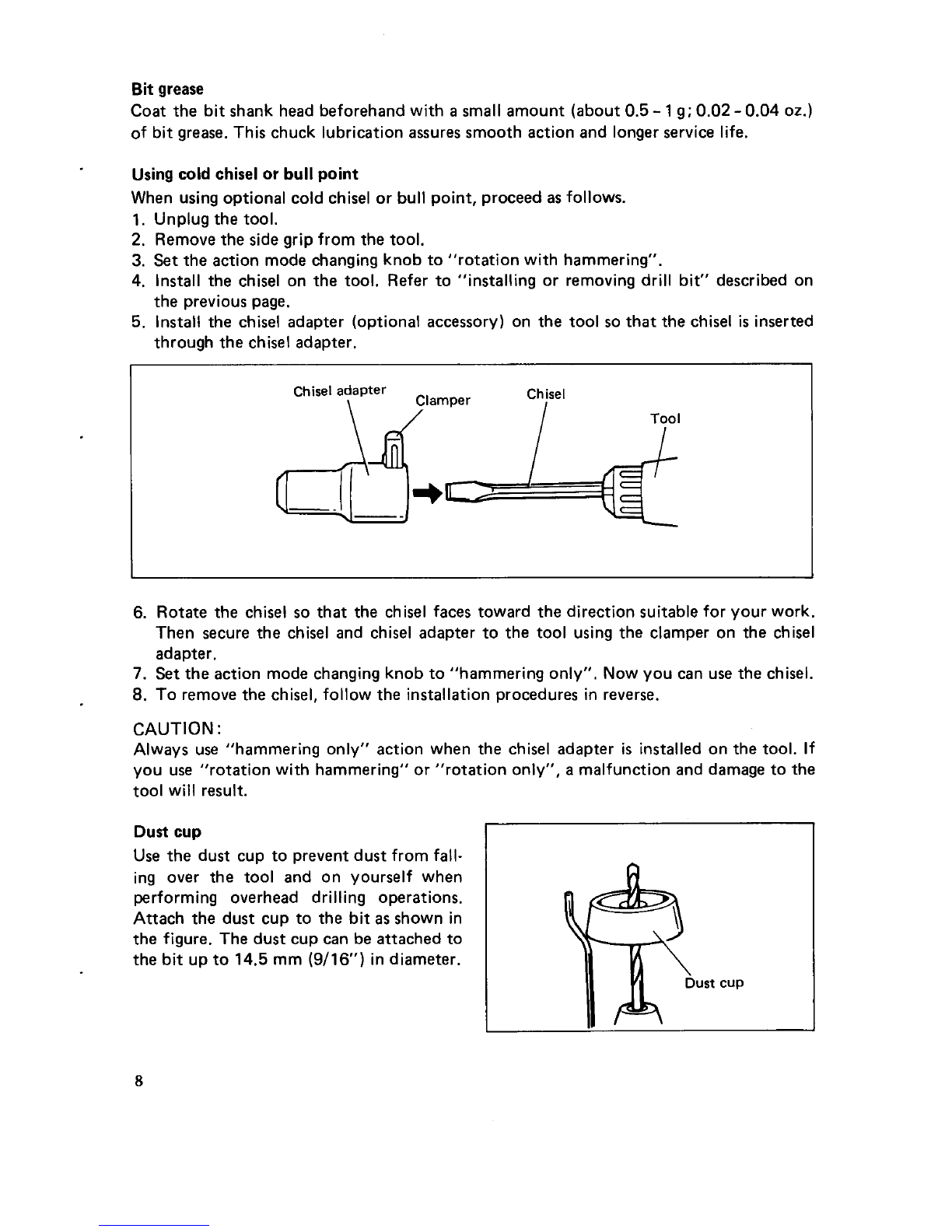

Makita HR160D User manual

Makita

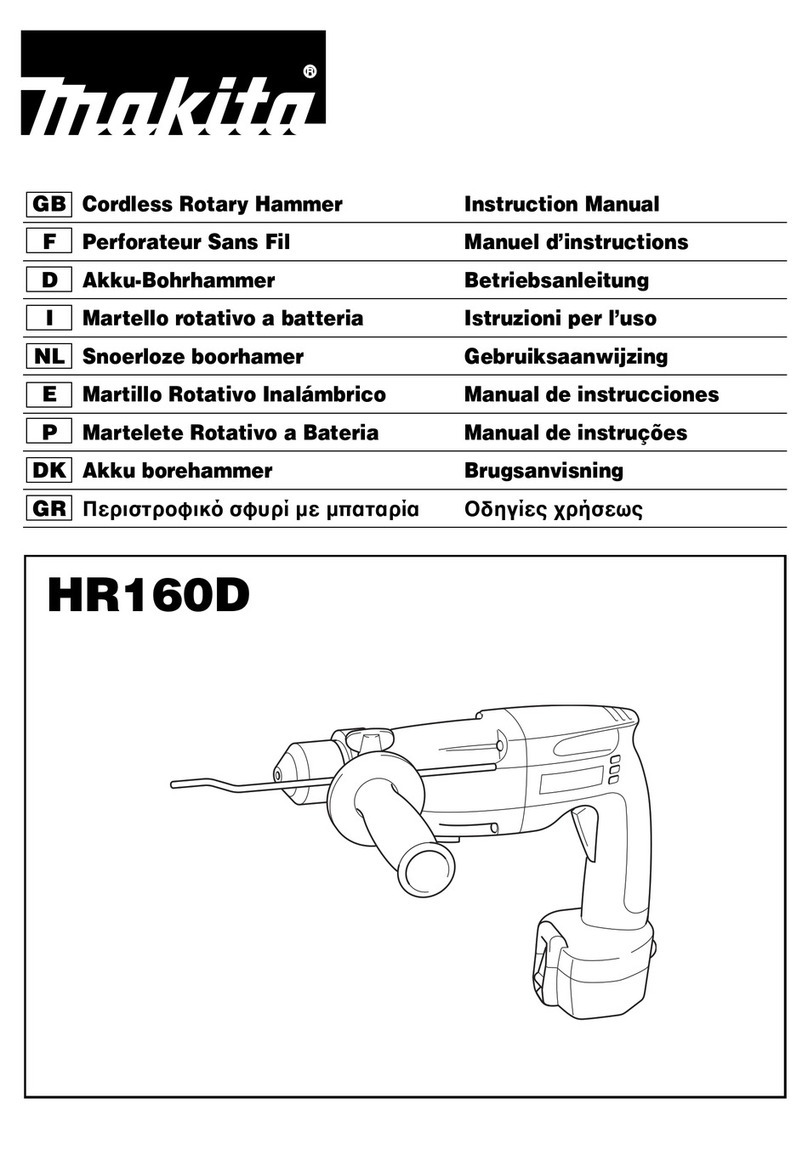

Makita HR3200C User manual

Makita

Makita HR2420 Quick start guide

Makita

Makita HR2440 User manual

Makita

Makita M8701 User manual

Makita

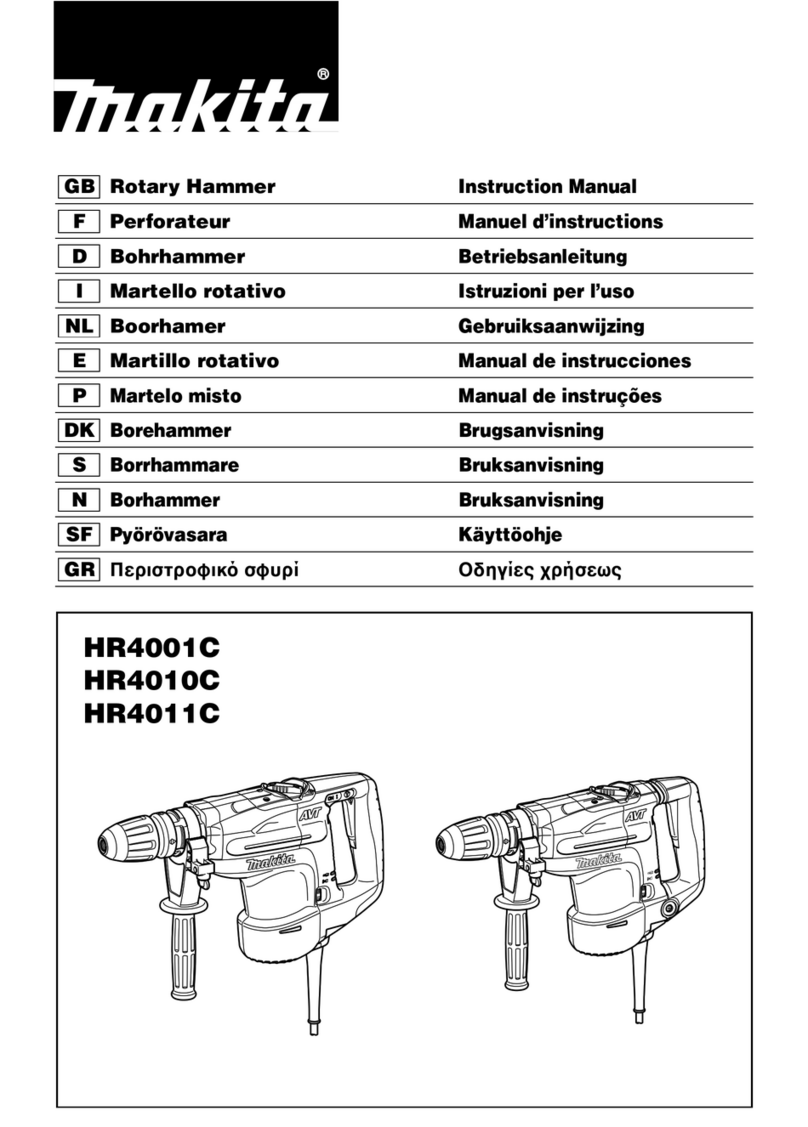

Makita HR4001C User manual

Makita

Makita HR5210C User manual

Makita

Makita BHR162 User manual

Makita

Makita HR4040C User manual

Makita

Makita HK1820 User manual

Makita

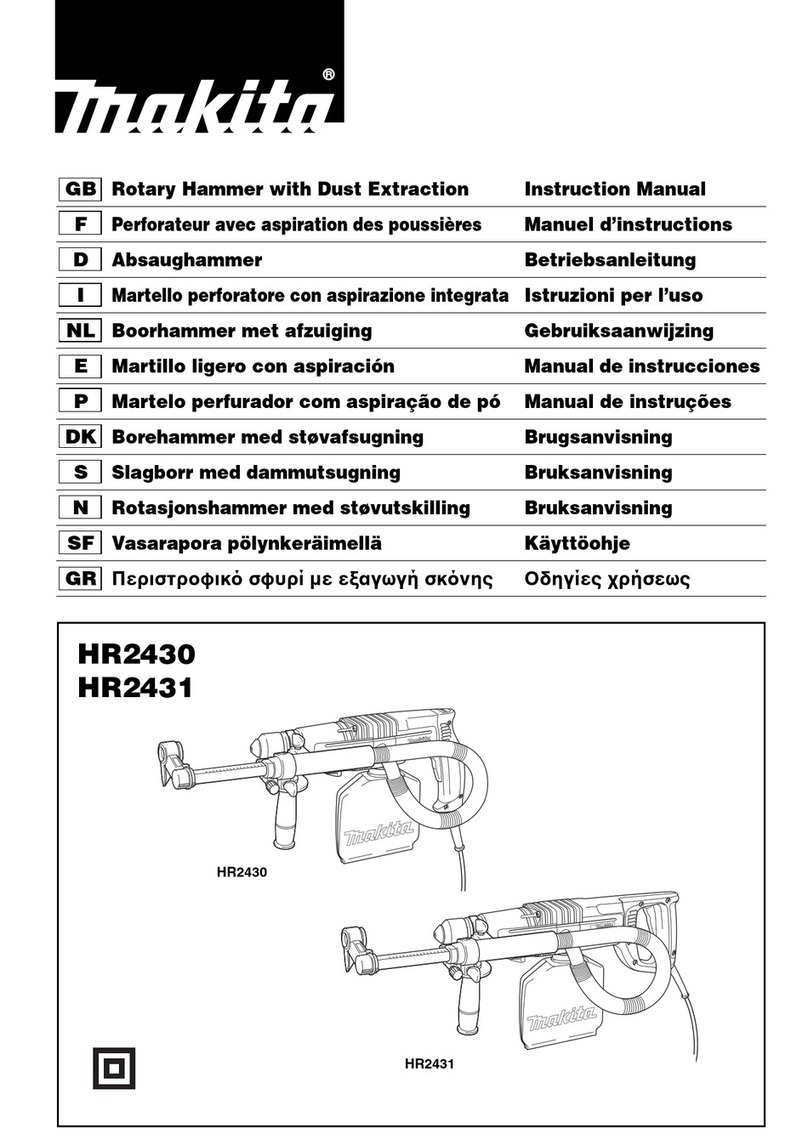

Makita HR2430 User manual

Makita

Makita HR3520B User manual

Makita

Makita DHR171 User manual

Makita

Makita HR4001C User manual

Makita

Makita BHR200 User manual

Makita

Makita DHR183 User manual

Makita

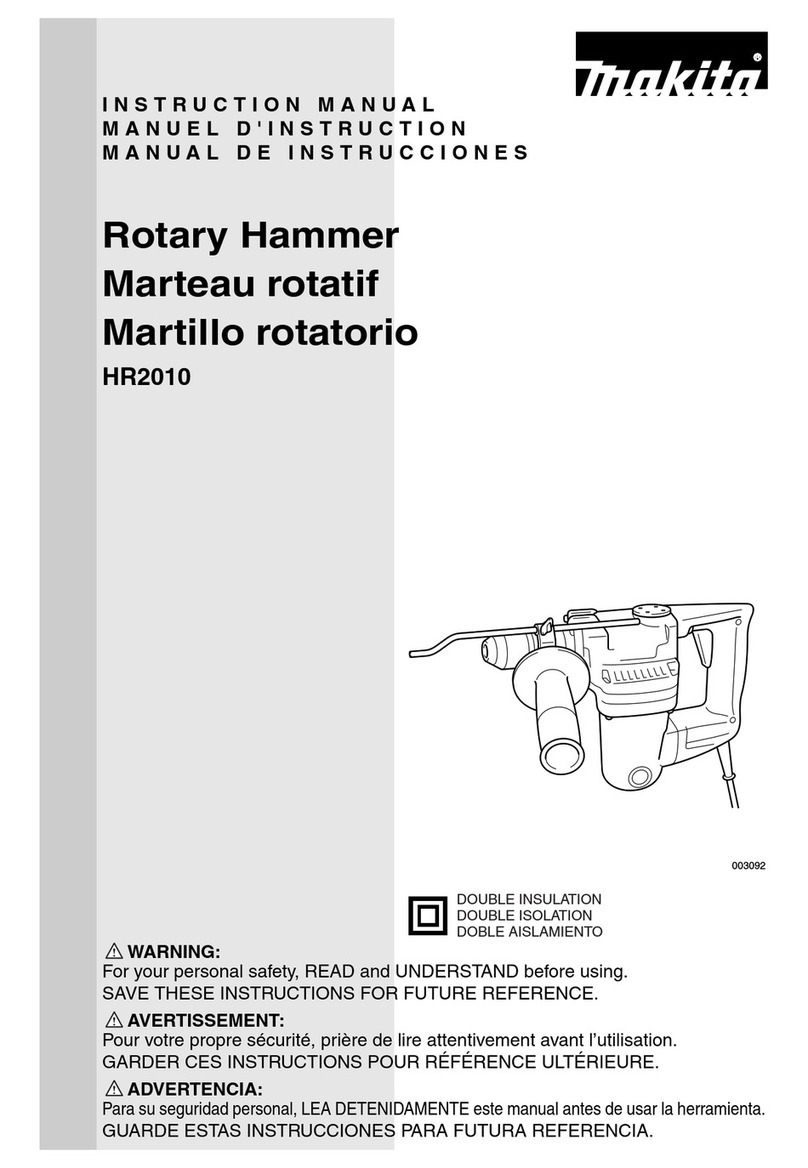

Makita HR2010 User manual

Makita

Makita HR2445 User manual

Popular Rotary Hammer manuals by other brands

BorMann

BorMann BPH7000 Translation of the original instructions

Metabo HPT

Metabo HPT DH 3628DD Safety instructions and instruction manual

Black & Decker

Black & Decker KD650 manual

Bosch

Bosch GBH Professional 2-20 DRE Original instructions

Bosch

Bosch 2-26 E operating instructions

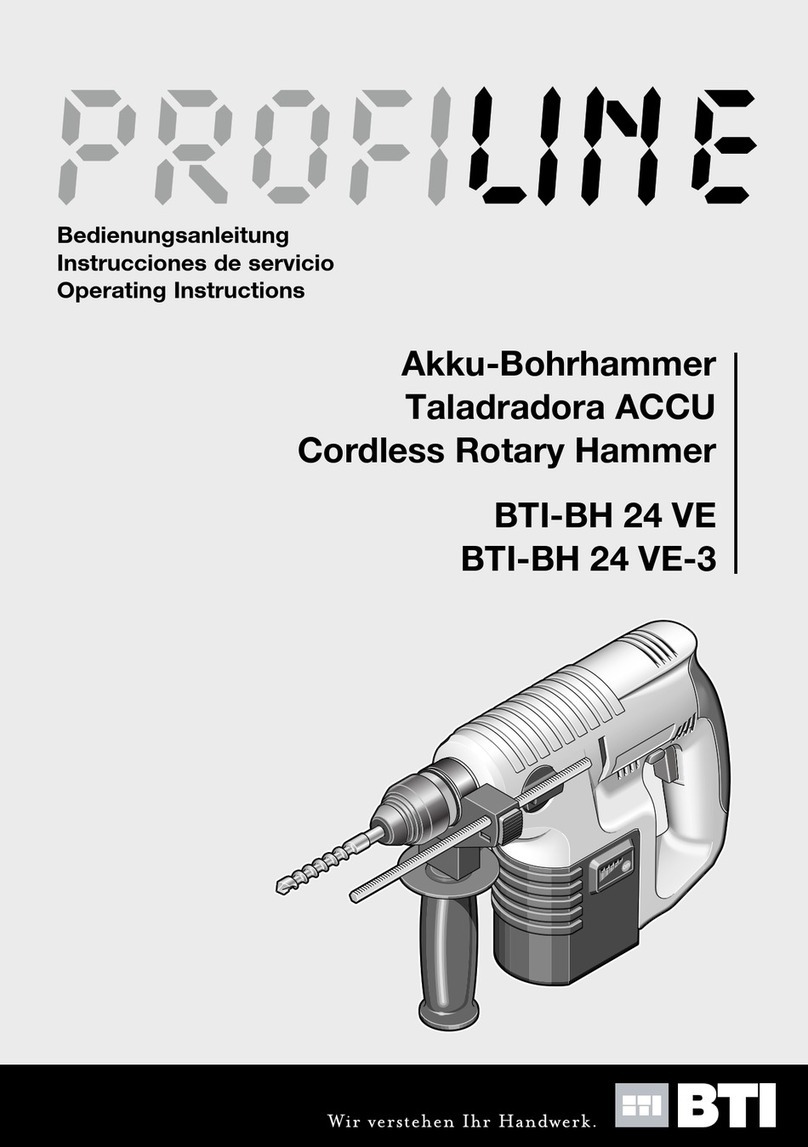

BTI

BTI Profiline BTI-BH 24 VE operating instructions