Makita HR2440F Manual

Other Makita Rotary Hammer manuals

Makita

Makita HR2460F User manual

Makita

Makita HR2300 Manual

Makita

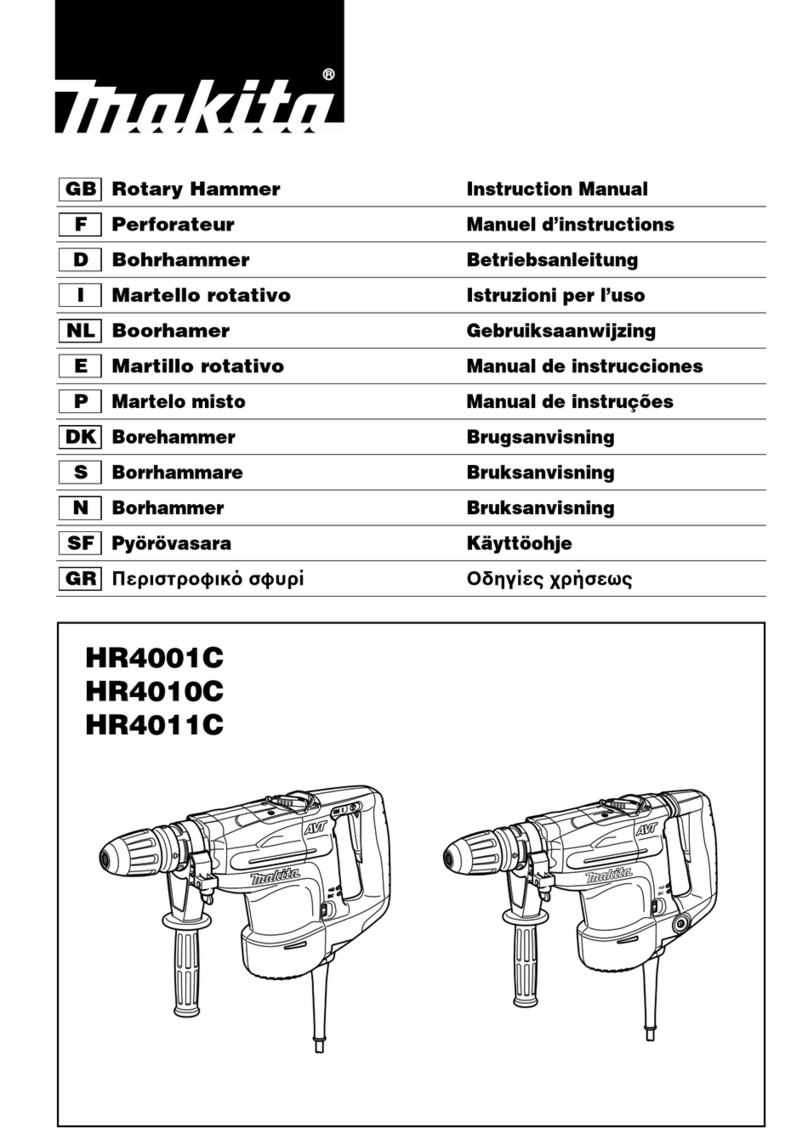

Makita HR4001C User manual

Makita

Makita HR2230X2 User manual

Makita

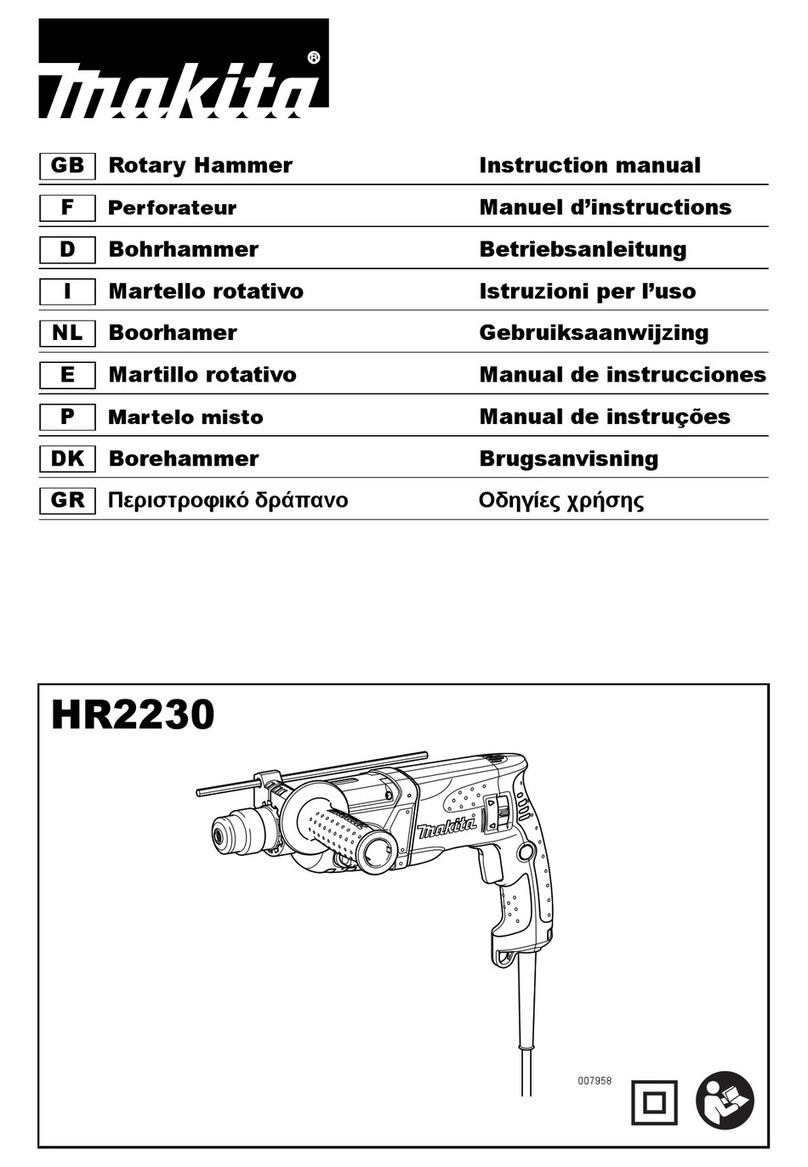

Makita HR2230 User manual

Makita

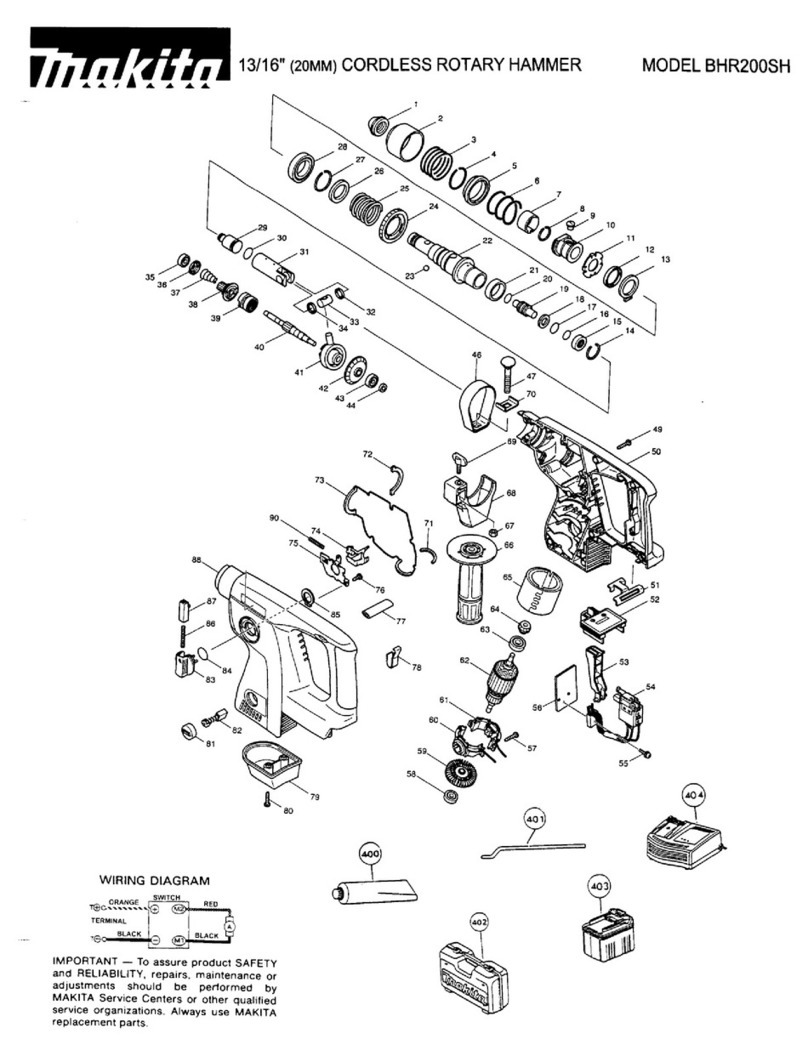

Makita BHR200SH Quick start guide

Makita

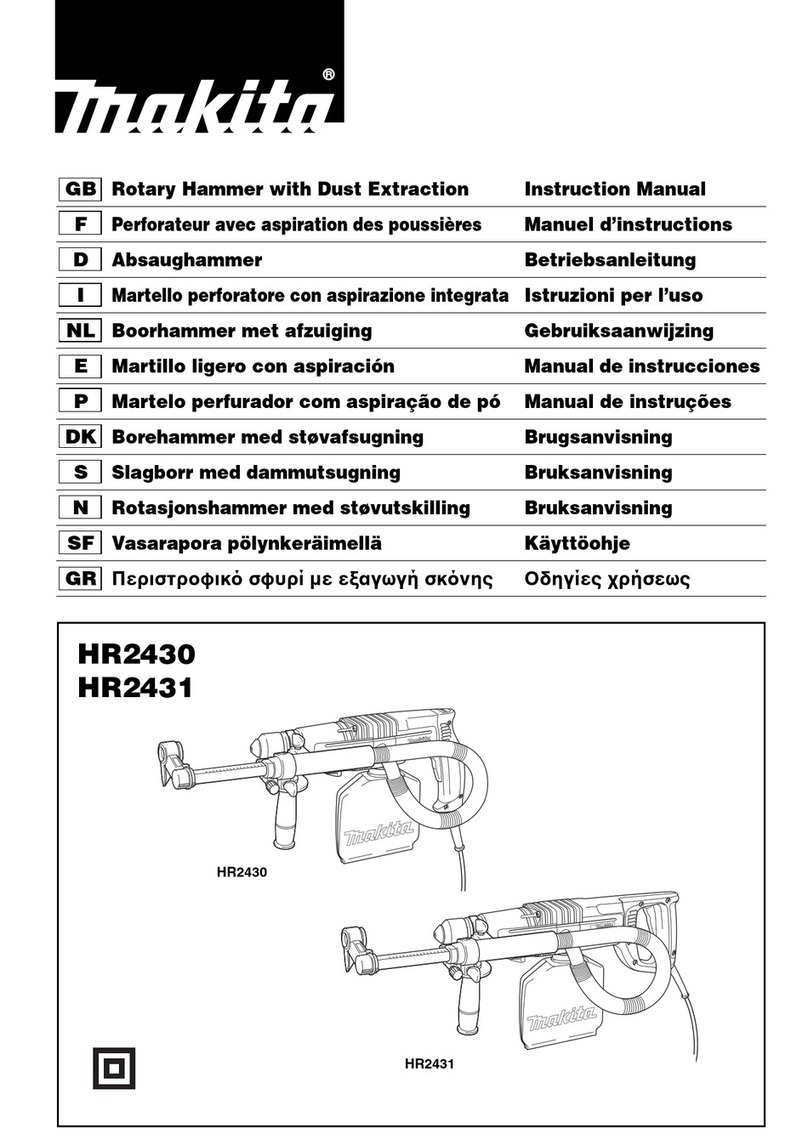

Makita HR2430 User manual

Makita

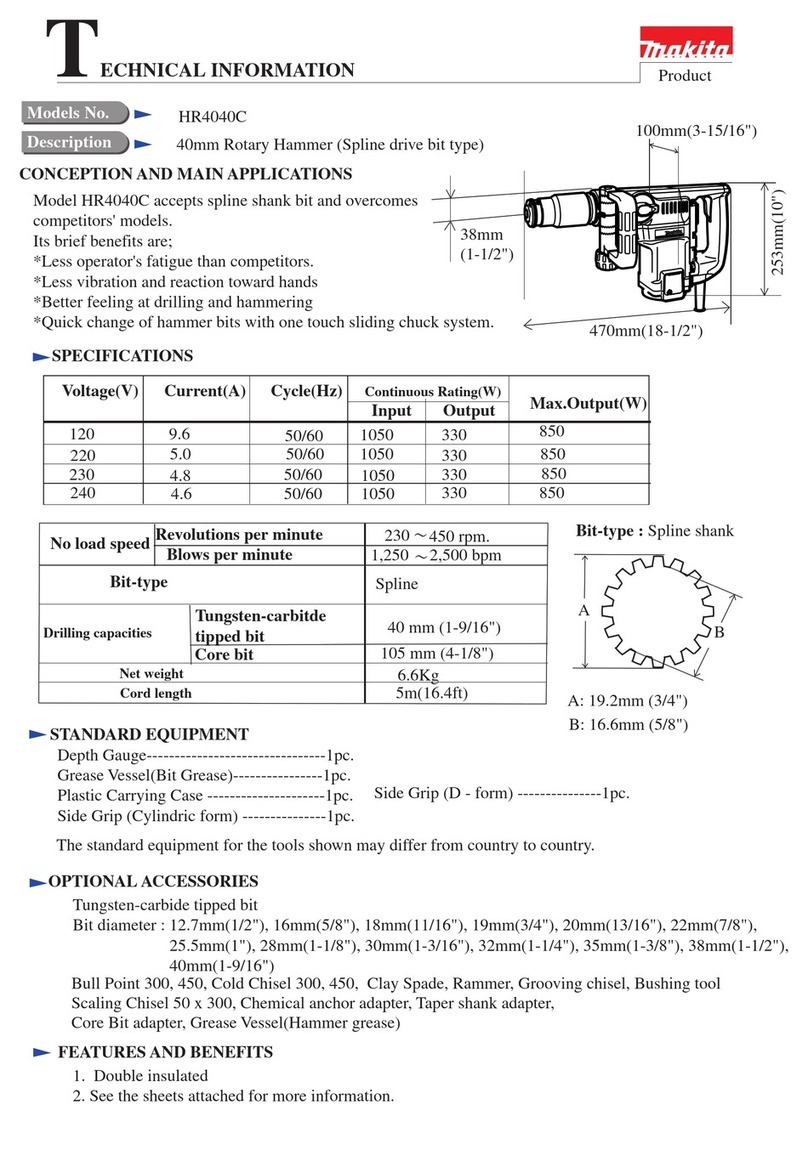

Makita HR4040C Manual

Makita

Makita DHR400 User manual

Makita

Makita HR4511C User manual

Makita

Makita HR4003C User manual

Makita

Makita HR1830 User manual

Makita

Makita BHR162 User manual

Makita

Makita BHR162 User manual

Makita

Makita HR4500C User manual

Makita

Makita HR2440 User manual

Makita

Makita HR2010 User manual

Makita

Makita HR2400 User manual

Makita

Makita HR5001C Quick start guide

Makita

Makita HK1800 User manual

Popular Rotary Hammer manuals by other brands

BorMann

BorMann BPH7000 Translation of the original instructions

Metabo HPT

Metabo HPT DH 3628DD Safety instructions and instruction manual

Black & Decker

Black & Decker KD650 manual

Bosch

Bosch GBH Professional 2-20 DRE Original instructions

Bosch

Bosch 2-26 E operating instructions

BTI

BTI Profiline BTI-BH 24 VE operating instructions