TCT saw blade ..... 1

Rear table set

(exclusively Europe,

Turkey, South Africa..1

Stand set .................................... 1

Left table set .............................. 1

Rear table set.............................. 1

Joint for connecting a hose.........1

Sliding guide set ........................ 1

Ring 15.8 (257060-5) for use of

25.4mm (1") inner diameter blade........ 1

Ring 16 (257262-3) for use of

30mm inner diameter blade ..................1

Ring 16 (257022-3) for use of 25mm

inner diameter blade .............................1

Model No.

Description

CONCEPT AND MAIN APPLICATIONS

Specification

Standard equipment

Note: The standard equipment and the optional equipment for the tool shown above may differ from country to country.

Ring 15.8 (257060-5) or Ring 16 (257262-3) is factory-assembled for some countries.

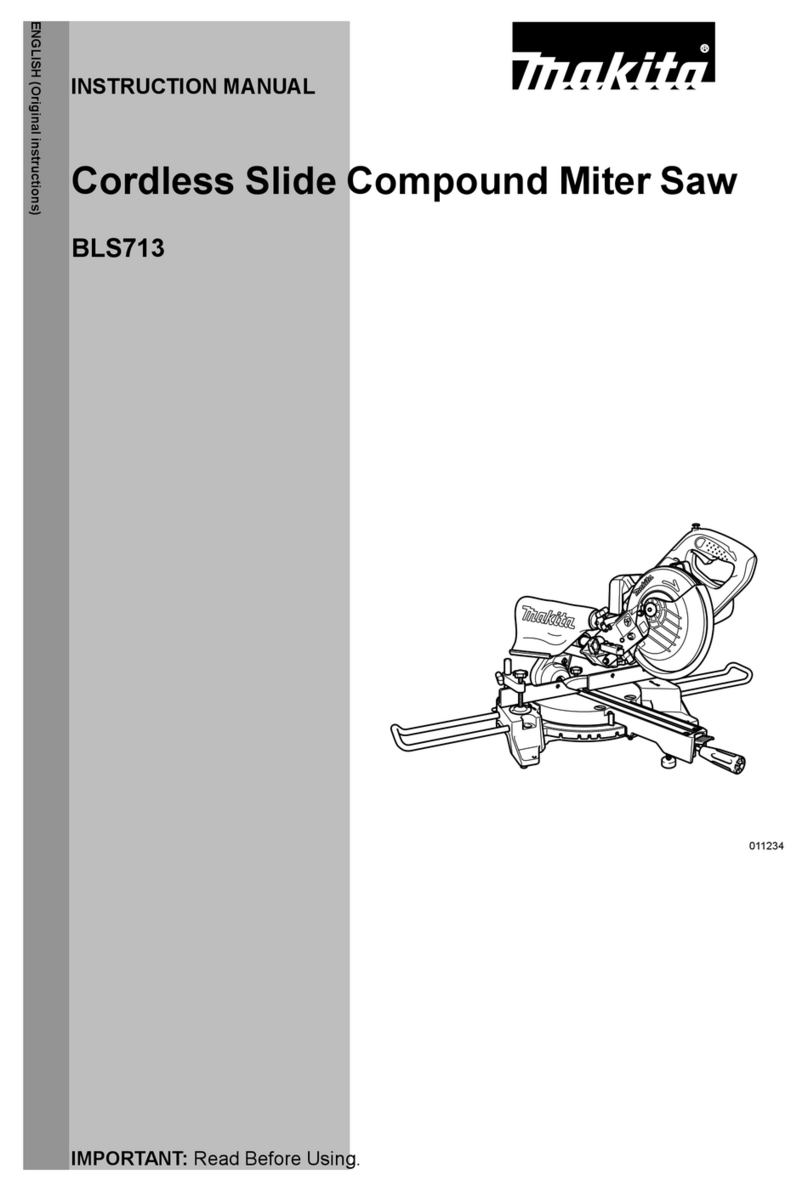

Dimensions: mm (")

Height (H)

Length (L)

2704

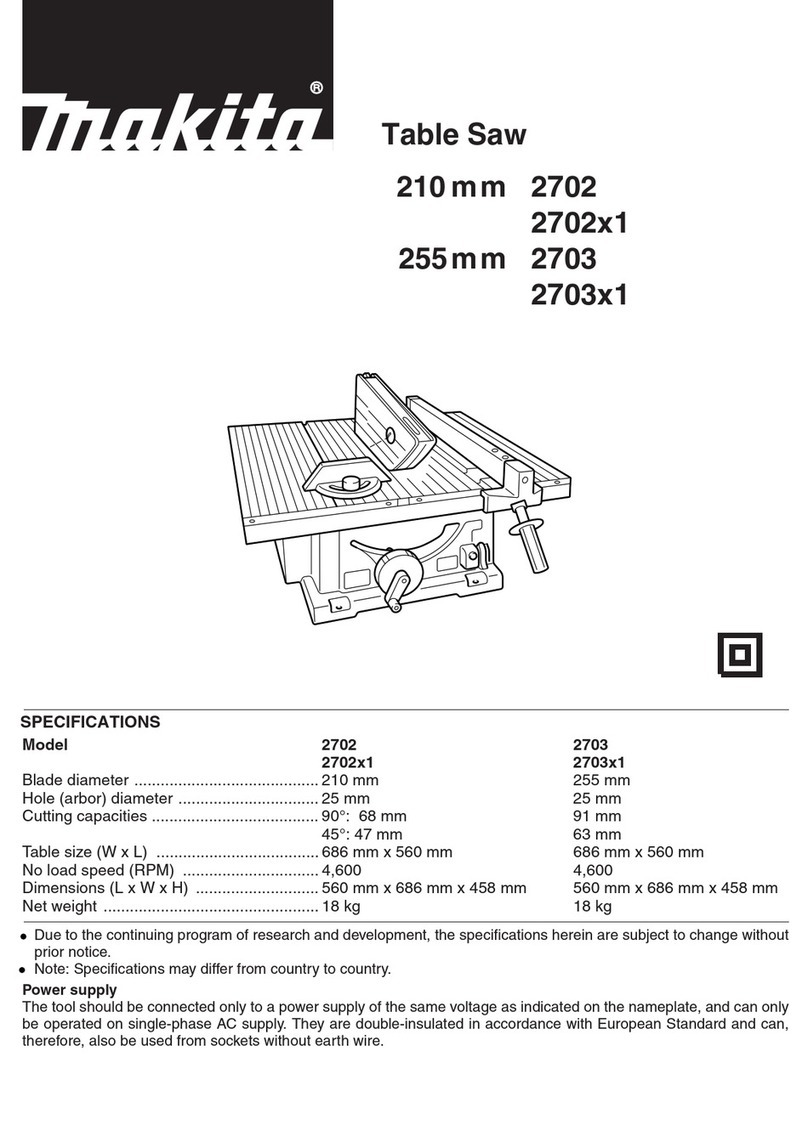

This is a sister model ranked higher than our current table saw model 2703.

The right sub table extends to rip cutting capacity of 4'x8' material.

The other main different features are below.

* Large machined aluminum table top for accurate cutting work

* Precision rip fence provides accuracy

* Powerful 1650W motor

Table Saw 255mm (10")/ 260mm (10-1/4") L

W

H

760 (30) 665 (26-1/4)

Europe, Turkey,

South Africa The others

766 (30-1/4)

344 (13-1/2)

Width (W)

Continuous rating input: W

Rated amperage for North America: A

Bevel cutting capacity: degrees

15.88 (5/8)

1,650

4,800

15

Diameter

Hole diameter

Saw Blade: mm (")

No load speed: min.-1=rpm

Cutting capacity

: mm

(") at 90

degrees

at 45

degrees

Electric brake

Double insulation

Power supply cord: m (ft)

Yes

Yes

2.5 (8.2) / Australia and New Zealand: 2.0 (6.6)2.5 (8.2)

No

UK 110V and all 220V-240V countries:Yes

All 110V-127V countries except UK: No

Electronic

feature

Constant speed control

Soft start

Net weight: kg (lbs) 33 (72) 28 (61)

From minus 0.5 to plus 45.5

91 (3-5/8)

63 (2-1/2)

93 (3-5/8)

64 (2-1/2)

Table size (WxL)

: mm

(") Main table

Sub table

625x567 (24-5/8x22-1/4)

128x570 (5x22-1/2)

255 (10)

30 (1-3/16)

260 (10-1/4)

The othersEurope, Turkey, South Africa

Max. width of dado: mm (") 21 (13/16)

Canada, USA, Mexico, Panama

Europe: 260mm Other countries: 255mm (10")

25.4 (1)

PRODUCT

TECHNICAL INFORMATION

P 1 / 15

Rip fence............... 1

Miter gauge .... ...... 1

Right table set ....... 1

Wrench 19 ............ 1

Socket wrench 13-22 ..1

Ring 15.8 (257060-5) for use of 25.4mm

inner diameter blade exclusively

Canada, USA, Mexico and Panama..... 1

Ring 16 (257022-3) for use of 25mm

inner diameter blade ....1 (It does not comes

with the products for Canada, USA, Mexico,

Panama, Europe, Turkey and South Africa)

Optional accessories

The components of Dado head set

and the relevant parts

(Exclusively Canada, USA, Mexico

and Panama: See instruction manual)........ 1

Hex wrench 5................... 1

Push stick ........................ 1

Joint for connecting a hose

(exclusively Europe,

Turkey, South Africa) ...... 1