9

parts. This ill ensure that the safety of the po er tool

is maintained.

2. Follow instruction for lubricating and changing

accessories.

CIRCULAR SAW SAFETY

WARNINGS GEB144-3

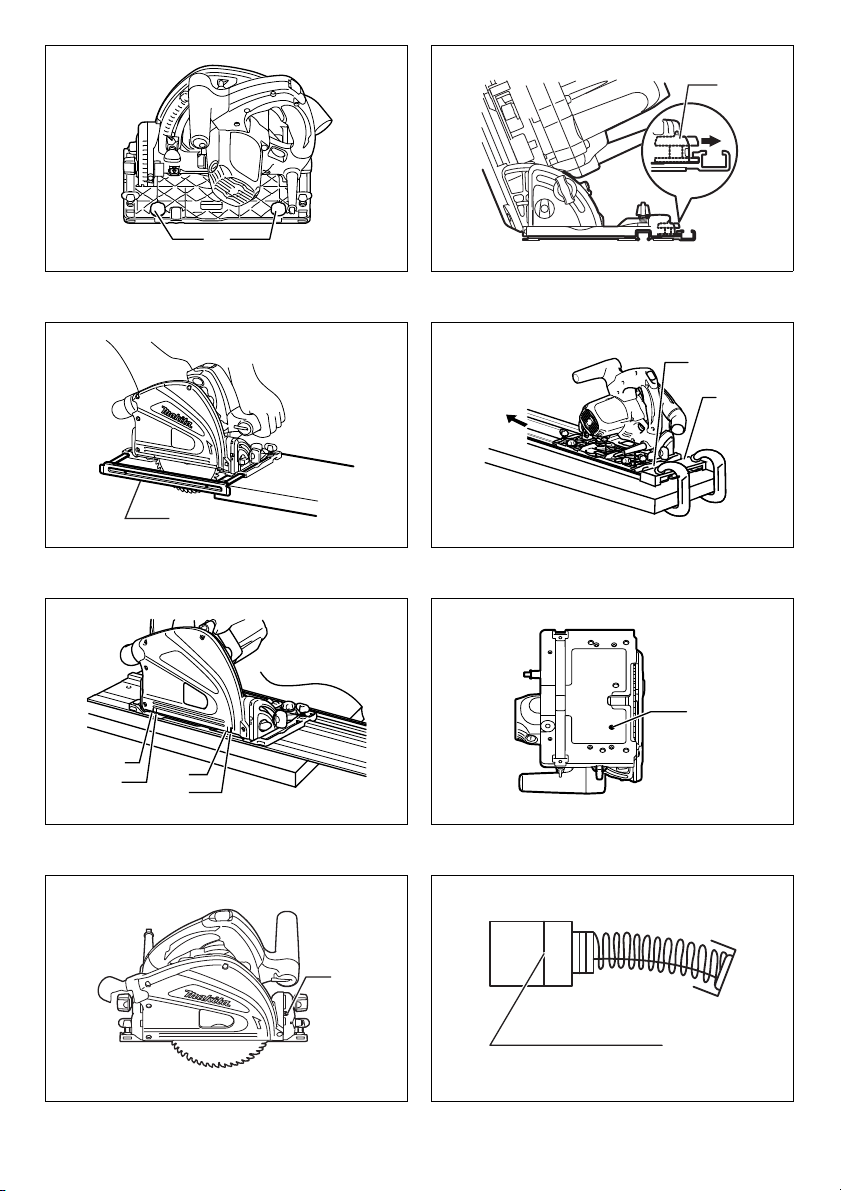

Cutting procedures

1. DANGER: Keep hands away from cutting area

and the blade. Keep your second hand on

auxiliary handle, or motor housing. If both hands

are holding the sa , they cannot be cut by the blade.

2. Do not reach underneath the workpiece. The guard

cannot protect you from the blade belo the

orkpiece.

3. Adjust the cutting depth to the thickness of the

workpiece. Less than a full tooth of the blade teeth

should be visible belo the orkpiece.

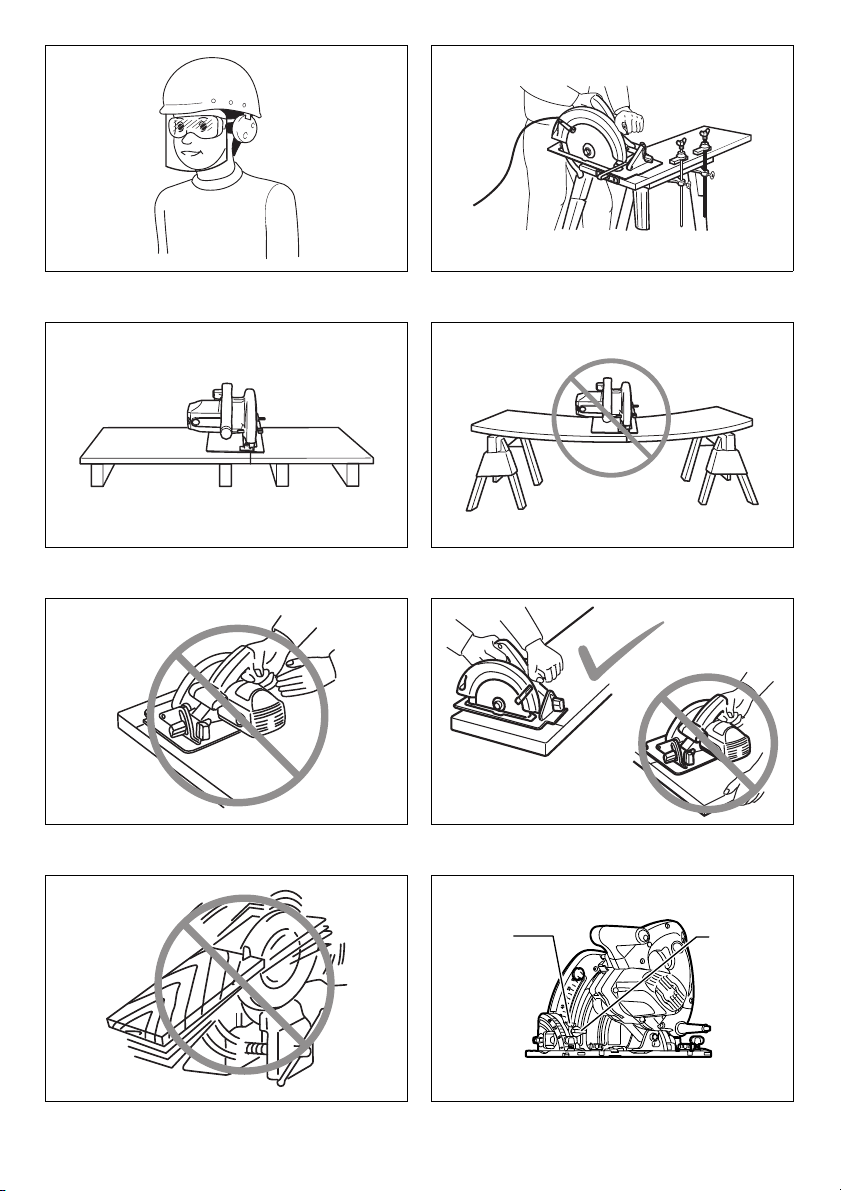

4. Ne er hold the workpiece in your hands or across

your leg while cutting. Secure the workpiece to a

stable platform. It is important to support the ork

properly to minimise body exposure, blade binding, or

loss of control. (Fig. 2)

5. Hold the power tool by insulated gripping

surfaces, when performing an operation where the

cutting tool may contact hidden wiring or its own

cord. Contact ith a “live” ire ill also make exposed

metal parts of the po er tool “live” and could give the

operator an electric shock.

6. When ripping, always use a rip fence or straight

edge guide. This improves the accuracy of cut and

reduces the chance of blade binding.

7. Always use blades with correct size and shape

(diamond ersus round) of arbour holes. Blades

that do not match the mounting hard are of the sa

ill run off-centre, causing loss of control.

8. Ne er use damaged or incorrect blade washers or

bolt. The blade ashers and bolt ere specially

designed for your sa , for optimum performance and

safety of operation.

Kickback causes and related warnings

- kickback is a sudden reaction to a pinched, jammed or

misaligned sa blade, causing an uncontrolled sa to

lift up and out of the orkpiece to ard the operator;

- hen the blade is pinched or jammed tightly by the kerf

closing do n, the blade stalls and the motor reaction

drives the unit rapidly back to ard the operator;

- if the blade becomes t isted or misaligned in the cut,

the teeth at the back edge of the blade can dig into the

top surface of the ood causing the blade to climb out

of the kerf and jump back to ard the operator.

Kickback is the result of sa misuse and/or incorrect

operating procedures or conditions and can be avoided by

taking proper precautions as given belo .

1. Maintain a firm grip with both hands on the saw

and position your arms to resist kickback forces.

Position your body to either side of the blade, but

not in line with the blade. Kickback could cause the

sa to jump back ards, but kickback forces can be

controlled by the operator, if proper precautions are

taken.

2. When blade is binding, or when interrupting a cut

for any reason, release the trigger and hold the

saw motionless in the material until the blade

comes to a complete stop. Ne er attempt to

remo e the saw from the work or pull the saw

backward while the blade is in motion or kickback

may occur. Investigate and take corrective actions to

eliminate the cause of blade binding.

3. When restarting a saw in the workpiece, centre the

saw blade in the kerf so that the saw teeth are not

engaged into the material. If a sa blade binds, it

may alk up or kickback from the orkpiece as the

sa is restarted.

4. Support large panels to minimise the risk of blade

pinching and kickback. Large panels tend to sag

under their o n eight. Supports must be placed

under the panel on both sides, near the line of cut and

near the edge of the panel. (Fig. 3 & 4)

5. Do not use dull or damaged blades.

Unsharpened or improperly set blades produce

narro kerf causing excessive friction, blade binding

and kickback.

6. Blade depth and be el adjusting locking le ers

must be tight and secure before making the cut. If

blade adjustment shifts hile cutting, it may cause

binding and kickback.

7. Use extra caution when sawing into existing walls

or other blind areas. The protruding blade may cut

objects that can cause kickback.

8. ALWAYS hold the tool firmly with both hands.

NEVER place your hand, leg or any part of your

body under the tool base or behind the saw,

especially when making cross-cuts. If kickback

occurs, the sa could easily jump back ards over

your hand, leading to serious personal injury. (Fig. 5)

9. Ne er force the saw. Push the saw forward at a

speed so that the blade cuts without slowing.

Forcing the sa can cause uneven cuts, loss of

accuracy, and possible kickback.

Guard function

1. Check the guard for proper closing before each

use. Do not operate the saw if the guard does not

mo e freely and enclose the blade instantly. Ne er

clamp or tie the guard so that the blade is

exposed. If the sa is accidentally dropped, the guard

may be bent. Check to make sure that guard moves

freely and does not touch the blade or any other part,

in all angles and depths of cut.

2. Check the operation and condition of the guard

return spring. If the guard and the spring are not

operating properly, they must be ser iced before

use. The guard may operate sluggishly due to

damaged parts, gummy deposits, or a build-up of

debris.

3. Assure that the base plate of the saw will not shift

while performing a “plunge cut”. Blade shifting

side ays ill cause binding and likely kick back.

4. Always obser e that the guard is co ering the

blade before placing the saw down on bench or

floor. An unprotected, coasting blade ill cause the

sa to alk back ards, cutting hatever is in its path.

Be a are of the time it takes for the blade to stop after

s itch is released.

Additional safety warnings

1. Use extra caution when cutting damp wood,

pressure treated lumber, or wood containing