Models No.

Description

PRODUCT

TECHNICAL INFORMATION

CONCEPT AND MAIN APPLICATIONS

Specification

P 1 / 20

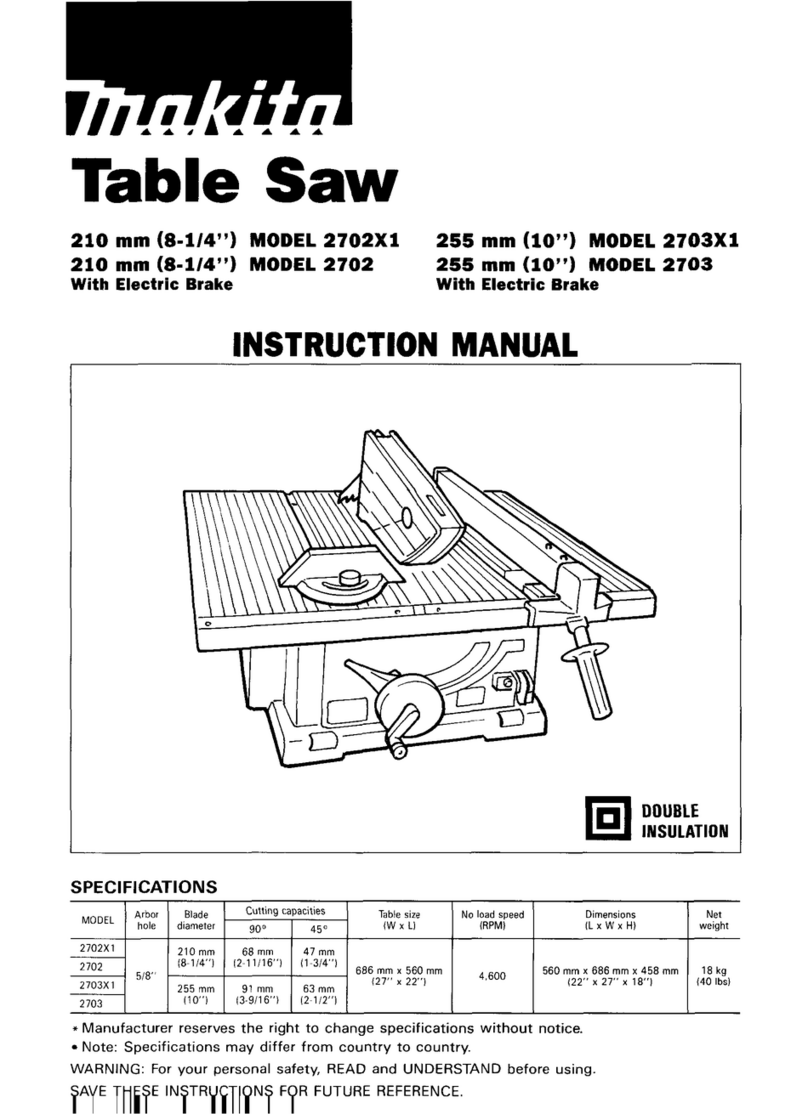

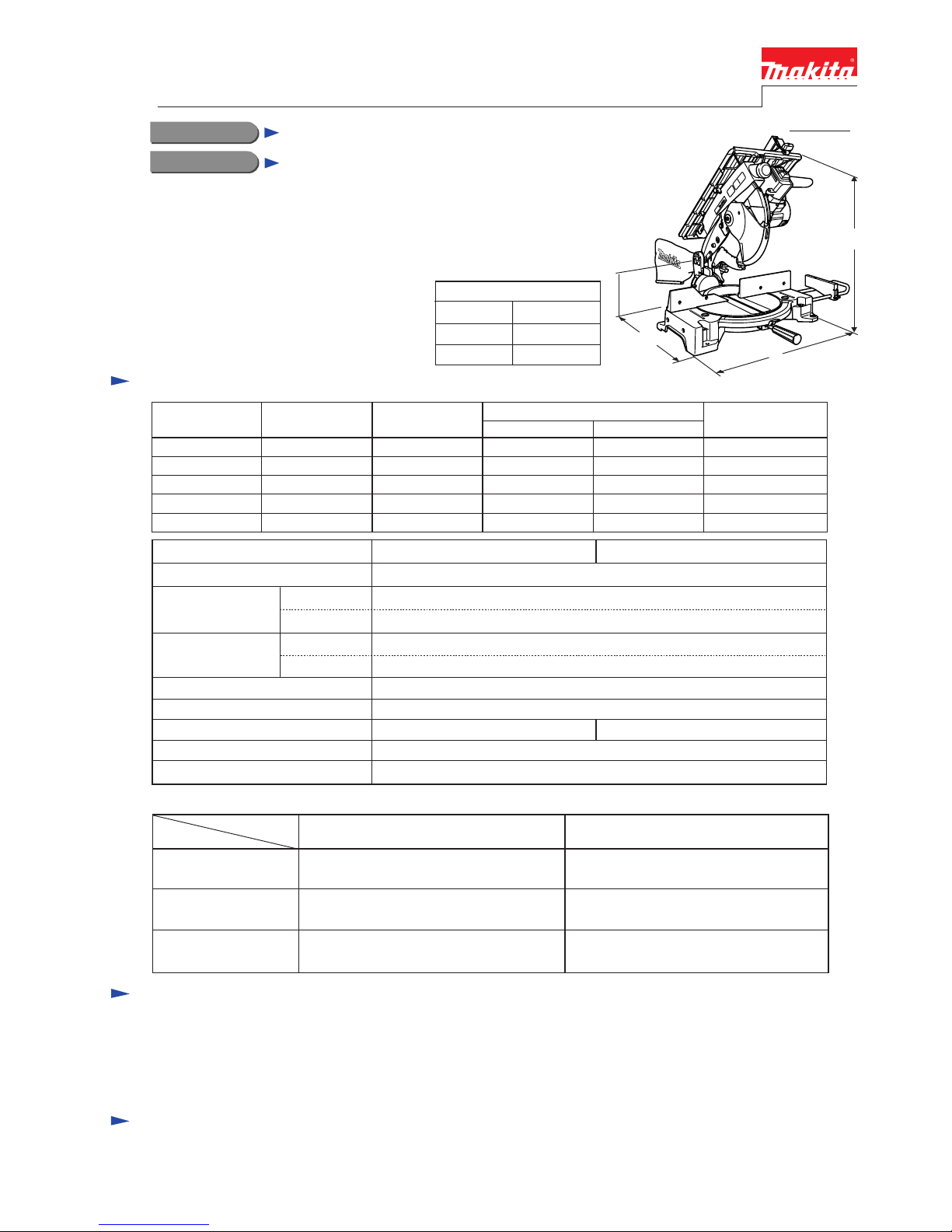

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

476 (18-3/4)

530 (20-7/8)

535 (21)

LH1040, LH1040F

Table Top Miter Saw 260mm (10-1/4")

Models LH1040 and LH1040F have been

developed as multi-purpose miter saws.

Installation of a table on Model LS1040

has enabled miter saw and table saw to be

packed in one tool for great versatility.

LH1040F features LED built-in job light

for accurate tracing of ink line in dark places.

Continuous Rating (W)

Voltage (V) Cycle (Hz) Input Output Max. Output(W)

120

110 15 1,650

1,650

2,30050 / 60

7.9 1,650 1,000 2,30050 / 60

7.5 1,650 1,000

1,000

1,000

2,30050 / 60

7.2 1,650 1,000 2,30050 / 60

15 2,30050 / 60

220

230

240

Current (A)

Model No.

No load speed: min-1 = rpm.

Cutting capacity as Miter Saw

LH1040

Double insulation

LH1040F

Diameter

Hole diameter

Protection against electric shock

Cord length: m (ft)

Net weight: kg (lbs)

LED job light

Miter angle

Bevel angle

Electric brake

Saw blade: mm (")

No Yes

Yes

4,800

255 - 260 (10 - 10-1/4 )

15.88 (5/8) 30.0 ( for European countries)

Table saw

Miter saw

Capacity: mm (")

(with 260 mm saw)

40 (1-9/16 )

See the table below.

2.5 ( 8.2 )

13.7 (30.2 )

90

°

45

° Left

69mm x 130mm (2-3/4" x 5-1/8")

93mm x 95mm (3-5/8" x 3-3/4")

35mm x 130mm (1-3/8" x 5-1/8")

53mm x 95mm (2-1/16" x 3-3/4")

35mm x 65mm (1-3/8" x 2-9/16")

49mm x 42mm (1-15/16" x 1-5/8")

35mm x 91mm (1-3/8" x 3-5/8")

49mm x 67mm (1-15/16" x 2-5/8")

69mm x 85mm (2-3/4" x 3-3/8")

93mm x 67mm (3-5/8" x 2-5/8")

69mm x 85mm (2-3/4" x 3-3/8")

93mm x 67mm (3-5/8" x 2-5/8")

45

° Left bevel

90

°

45

° Right

W

L

H

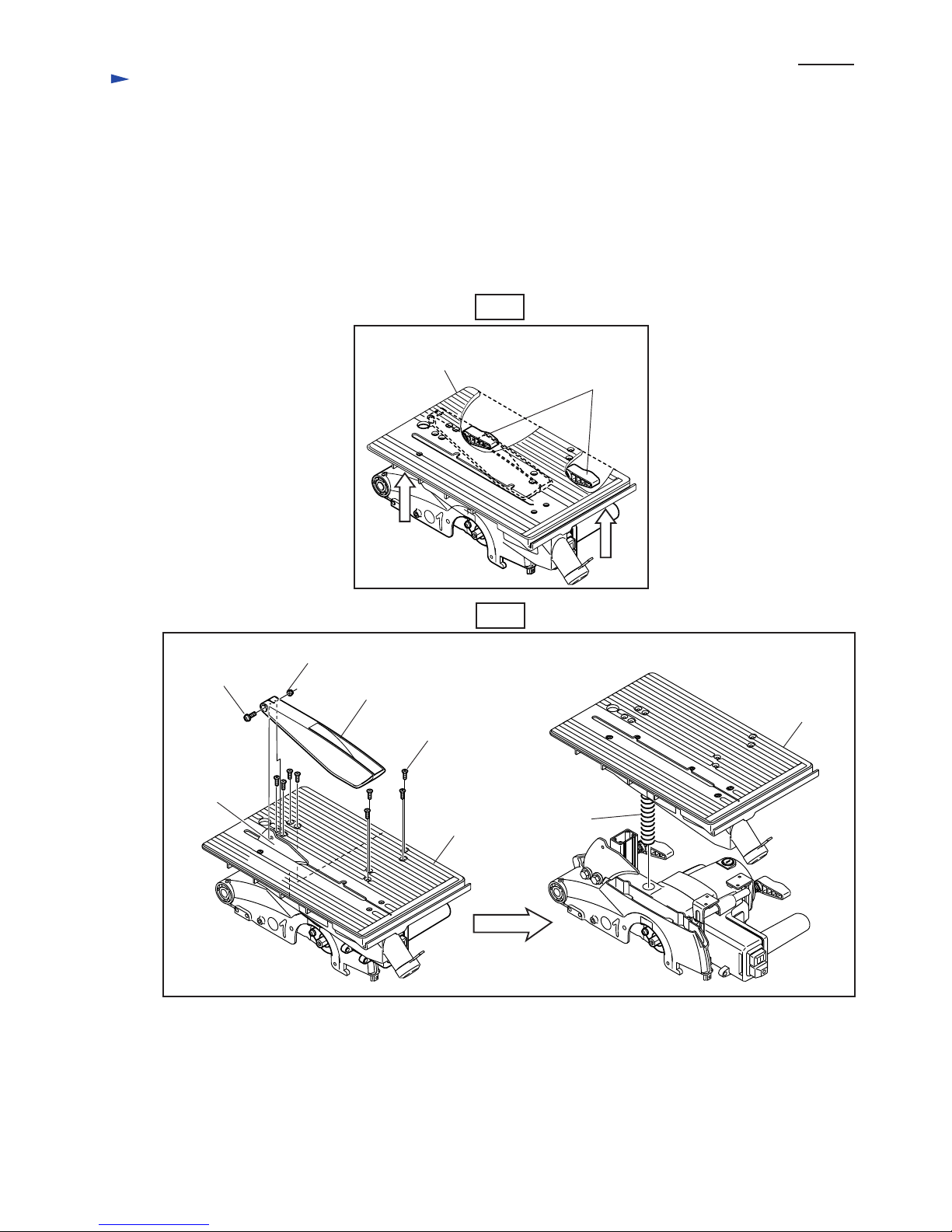

Standard equipment

Optional accessories

Note: The standard equipment listed above may differ from country to country.

TCT saw blade 260mm .......... 1 pc

Dust bag ................................. 1 pc

Holder set ............................... 1 pc

Sub plate ass'y ........................ 1 pc

Socket wrench 13 ....................... 1 pc

Ring 16 (adaptor for saw blades

with 25mm hole diameter) ......... 1 pc

Triangular rule ............................ 1 pc

Set plate ................................... 1 pc

Blade cover .............................. 1 pc

Push stick ................................. 1 pc

Guide rule rule ........................ 1 pc

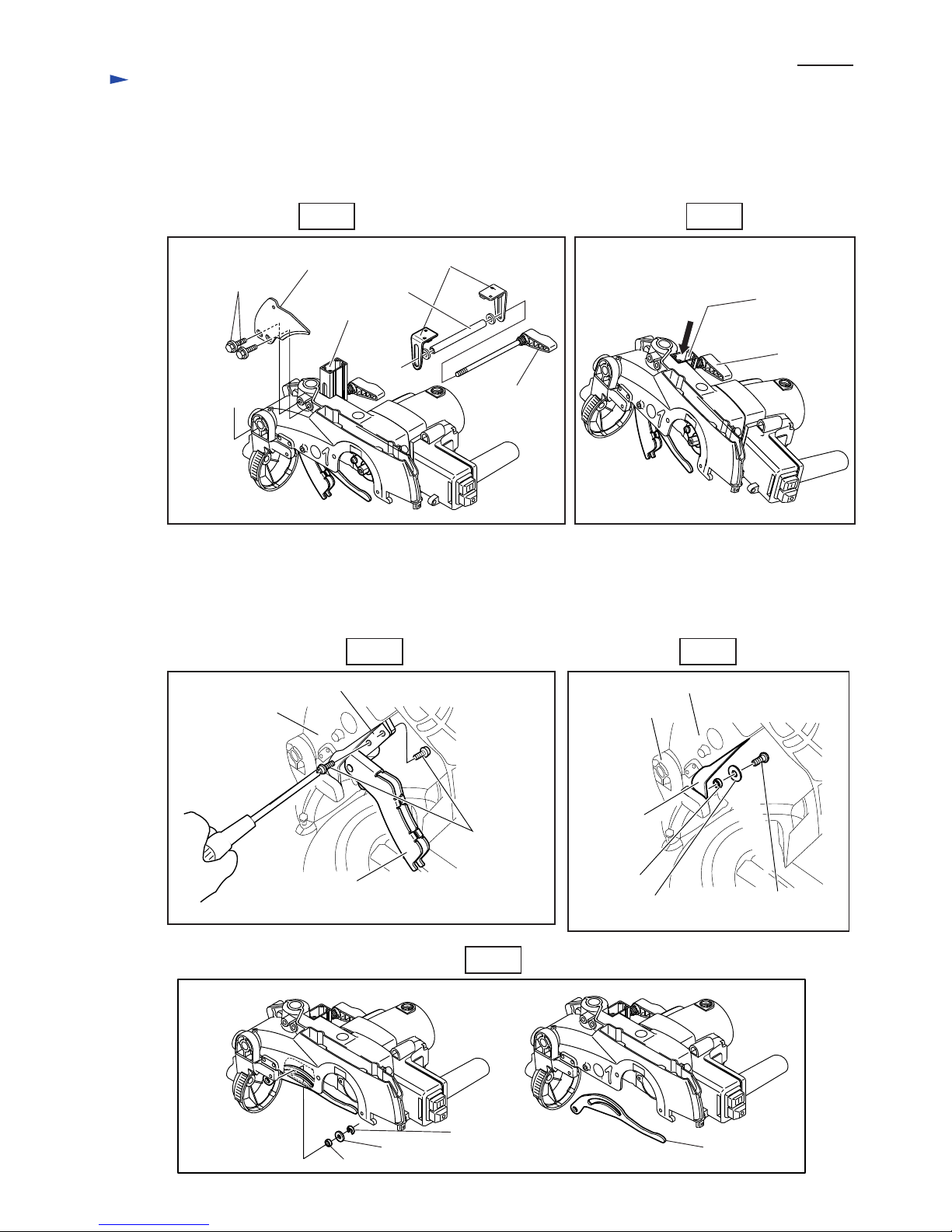

Vertical vise

Horizontal vise

Holder set

Assorted TCT saw blades