Model No.

Description

CONCEPT AND MAIN APPLICATIONS

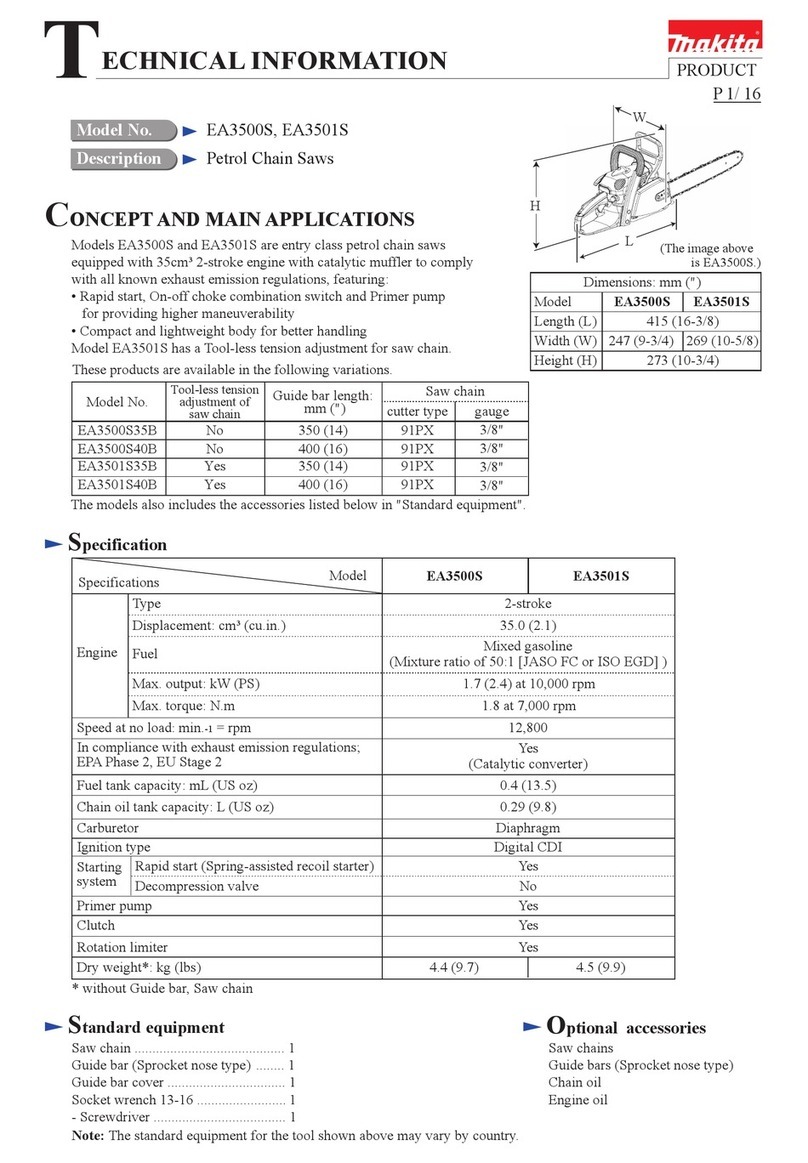

Dimensions*1: mm (")

Width (W)

Height (H)

Length (L) 468 (18-1/2)

197 (7-3/4)

233 (9-1/8)

*1With Battery BL1830, BL1840

or BL1850

OFFICIAL USE

for ASC & Sales Shop

DPB181

Cordless Portable Band Saw

Model DPB181 is lightweight and compact cordless portable band saw.

The design is specialized in excellent maneuverability in horizontal and

overhead applications.

The following features are the same as BPB180/ DPB180.

• Adjustable stopper plate

• Easy blade replacement

• powered by 18V Makita Li-ion battery

Battery protection circuit is equipped with DPB181. The function works when

the battery with a star mark is set on DPB181.

Note: BL1815 is not compatible.

Battery*4

Charger*4

Battery cover*5

Band saw blade 13-835 (18 teeth per inch)

Hex wrench 4

Wheel cover set (for some countries)

Tool bag (for some countries)

Fast charger DC18RC

Charger DC18SD

Charger DC24SC

Automotive charger DC18SE

Battery BL1815N

Battery BL1820

Battery BL1830

Battery BL1840

Battery BL1850

Battery

Variable speed control dial

Blade speed: m/s (ft/min.)

Type

Voltage: V

Capacity: Ah

Li-ion

18

1.5, 2.0, 3.0, 4.0, 5.0

No

Weight according to

EPTA-Procedure 01/2003*2: kg (lbs)

3.2 (7.1)*3

3.5 (7.7)*1

Overload protector No

LED job light Yes

3.2 (630)

Max output (W) 350

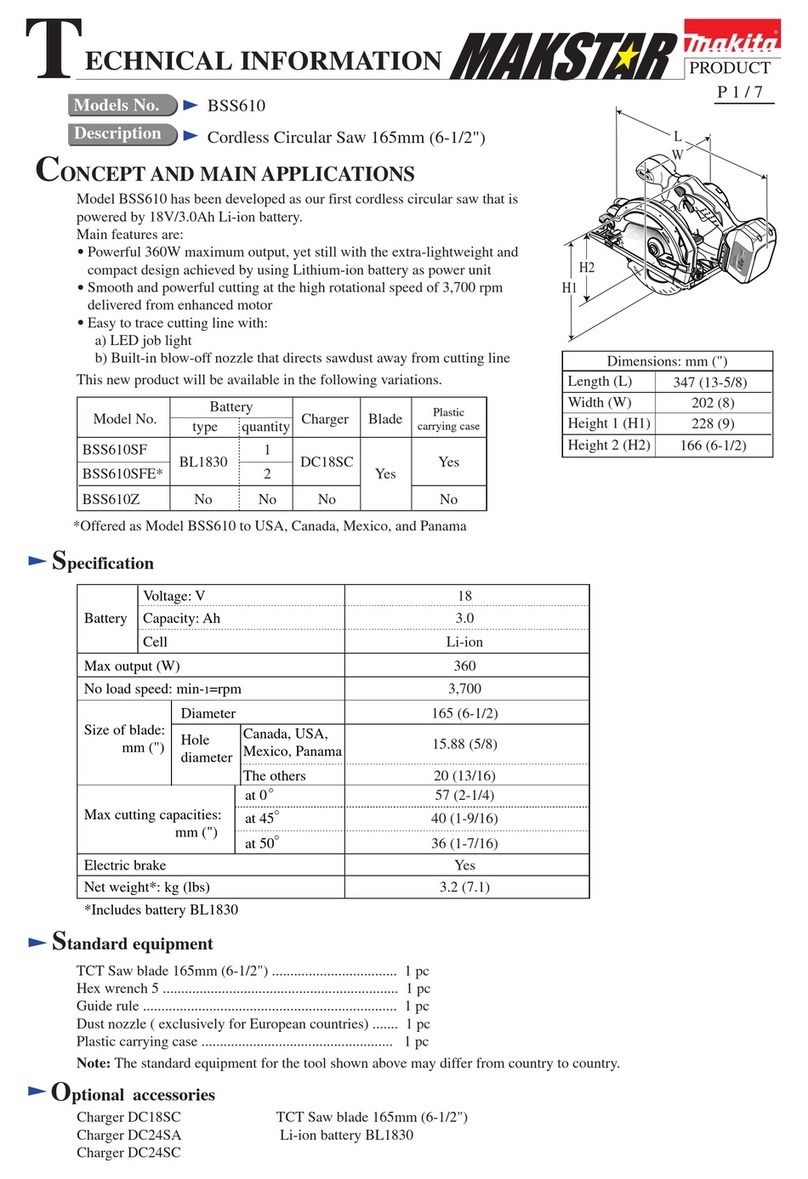

Square pipe [width x height]

Length

Width

Height

Cutting capacity:

mm (")

Blade size:

mm (")

Round pipe [diameter]

64 x 64 (2-1/2 x 2-1/2)

13 (1/2)

0.5 (0.02)

835 (32-7/8)

64 (2-1/2)

Note: The standard equipment may vary by country or model variation.

PRODUCT

P 1/ 18

*2With Band saw blade 13-835 and Battery *3With Battery BL1815N or BL1820

*4 Battery and Charger are not supplied with “Z” model.

*5 Supplied with the same quantity of extra Battery

Specification

Standard equipment

Optional accessories

Band saw blade 13-835

(14, 18, 24 teeth per inch)

Wheel cover set

Hook set

Cutting wax

TECHNICAL INFORMATION

Energy capacity: Wh 27, 36, 54, 72, 90

Charging time (approx.): min. 15, 24, 22, 36, 45 with DC18RC

L

W

H