P 2/ 35

Cutting capacities [Height x Width in mm (")]

Cutting capacities [Height x Width in mm (")]

Miter angle Bevel angle

0 degree

45 degrees left

92 x 382 (3-5/8 x 15)

107 x 363 (4-1/4 x 14-1/4)

61 x 382 (2-3/8 x 15)

71 x 363 (2-13/16 x 14-1/4)

78 x 325 (3-1/16 x 12-3/4)

80 x 292 (3-1/8 x 11-1/2)

115 x 325 (4-1/2 x 12-3/4)

120 x 292 (4-3/4 x 11-1/2)

115 x 227 (4-1/2 x 8-15/16)

120 x 212 (4-3/4 x 8-3/8)

115 x 197 (4-1/2 x 7-3/4)

120 x 180 (4-3/4 x 7-1/8)

115 x 155 (4-1/2 x 6-1/8)

120 x 140 (4-3/4 x 5-1/2)

61 x 325 (2-3/8 x 12-3/4)with 20 x 38 (13/16 x 1-1/2)

auxiliary wood fence

with 15 x 25 (9/16 x 1)

auxiliary wood fence

with 15 x 25 (9/16 x 1)

auxiliary wood fence

with 15 x 25 (9/16 x 1)

auxiliary wood fence

44 x 382 (1-3/4 x 15)

54 x 363 (2-1/8 x 14-1/4)

45 degrees

left & right

92 x 268 (3-5/8 x 10-1/2)

107 x 255 (4-1/4 x 10)

61 x 268 (2-3/8 x 10-1/2)

71 x 255 (2-13/16 x 10)

44 x 268 (1-3/4 x 10-1/2)

54 x 255 (2-1/8 x 10)

92 x 233 (3-5/8 x 9-1/8)

107 x 220 (4-1/4 x 8-5/8)

45 degrees right0 degree

52 degrees

left & right

92 x 185 (3-5/8 x 7-1/4)

107 x 178 (4-1/4 x 7)

60 degrees right

Capacities of cutting Crown molding and Baseboard (Skirt board)

Crown molding,

45 degree type

203 (8)*2Diagonal cut*1

Workpiece Capacity: mm (")

How to cut

320 (12-5/8)Horizontal cut

165 (6-1/2)Vertical cut

416 (16-3/8)*3Horizontal cut

Baseboard

(Skirt board)

European countries

All countries

*1 Diagonal cut is to cut a crown molding that is

held tilted against the guide fence using

Crown molding stopper.

*2 The capacity of crown molding diagonal cut

is the length L shown in the drawing on right.

*3 No need for setting auxiliary wood facing

on the turn base

L

All countries except European countries

Standard equipment

Optional accessories

Note: The standard equipment for the tool shown may vary by country.

Vertical vise ................. 1

TCT saw blade ............ 1

Dust bag assembly ....... 1

Socket wrench 13 ....... 1

Triangular rule ........... 1

Lock-off button ........... 1

TCT saw blades, Holder set, Stand, Horizontal vise, Crown molding stopper set, Dust box set

Holder set ............. 2 (all countries except North America)

Hex wrench .......... 1 (LS1216L only)

Miter angle Bevel angle

0 degree

45 degrees left

87 x 382 (3-7/16 x 15)

102 x 363 (4 x 14-1/4)

59 x 382 (2-5/16 x 15)

69 x 363 (2-3/4 x 14-1/4)

78 x 290 (3-1/16 x 11-3/8) 115 x 300 (4-1/2 x 11-3/4)

120 x 250 (4-3/4 x 9-7/8)

115 x 202 (4-1/2 x 8)

120 x 172 (4-3/4 x 6-3/4)

115 x 178 (4-1/2 x 7)

120 x 155 (4-3/4 x 6-1/8)

115 x 140 (4-1/2 x 5-1/2)

120 x 122 (4-3/4 x 4-13/16)

61 x 290 (2-3/8 x 11-3/8)with 35 x 60 (1-3/8 x 2-3/8)

auxiliary wood fence

with 30 x 45 (1-3/16 x 1-3/4)

auxiliary wood fence

with 25 x 35 (1 x 1-3/8)

auxiliary wood fence

with 25 x 35 (1 x 1-3/8)

auxiliary wood fence

44 x 382 (1-3/4 x 15)

54 x 363 (2-1/8 x 14-1/4)

45 degrees

left & right

87 x 268 (3-7/16 x 10-1/2)

102 x 255 (4 x 10)

59 x 268 (2-5/16 x 10-1/2)

69 x 255 (2-3/4 x 10)

44 x 268 (1-3/4 x 10-1/2)

54 x 255 (2-1/8 x 10)

87 x 233 (3-7/16 x 9-1/8)

102 x 220 (4 x 8-5/8)

45 degrees right0 degree

52 degrees

left & right

87 x 185 (3-7/16 x 7-1/4)

102 x 178 (4 x 7)

60 degrees right

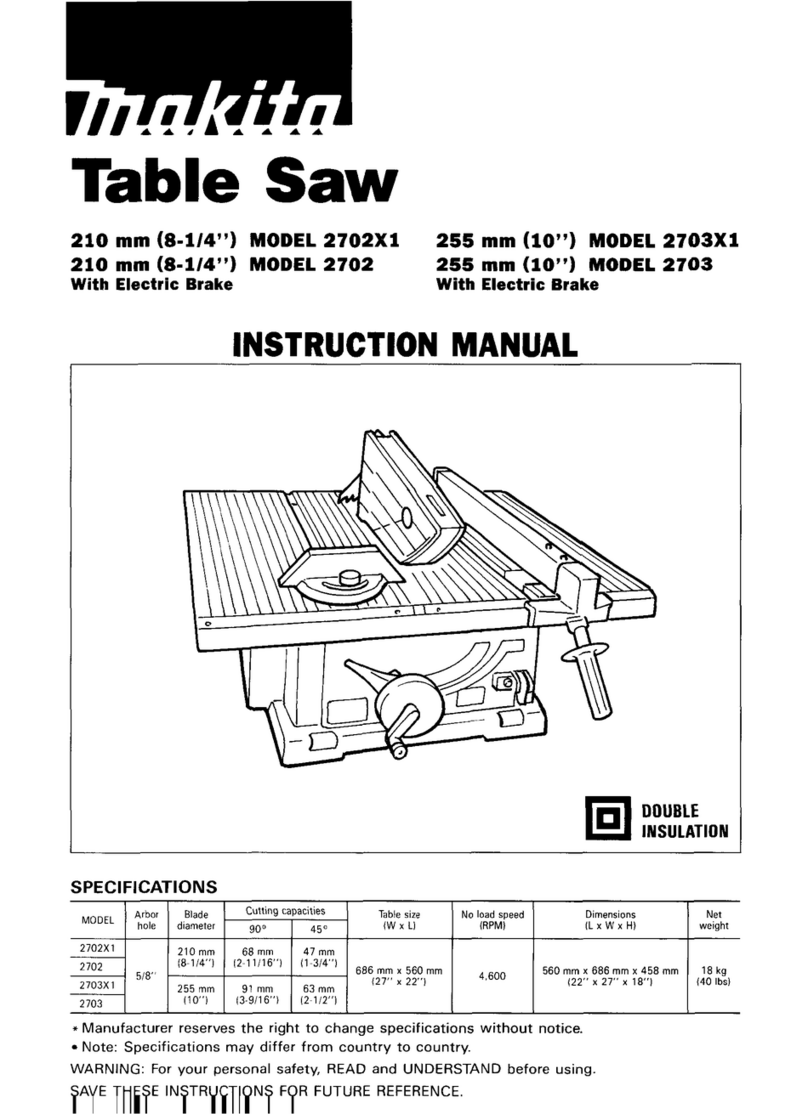

Specification (cont.)