10 ENGLISH

źІżLISHăĚЇrТРТЧКХăТЧstruМtТШЧsě

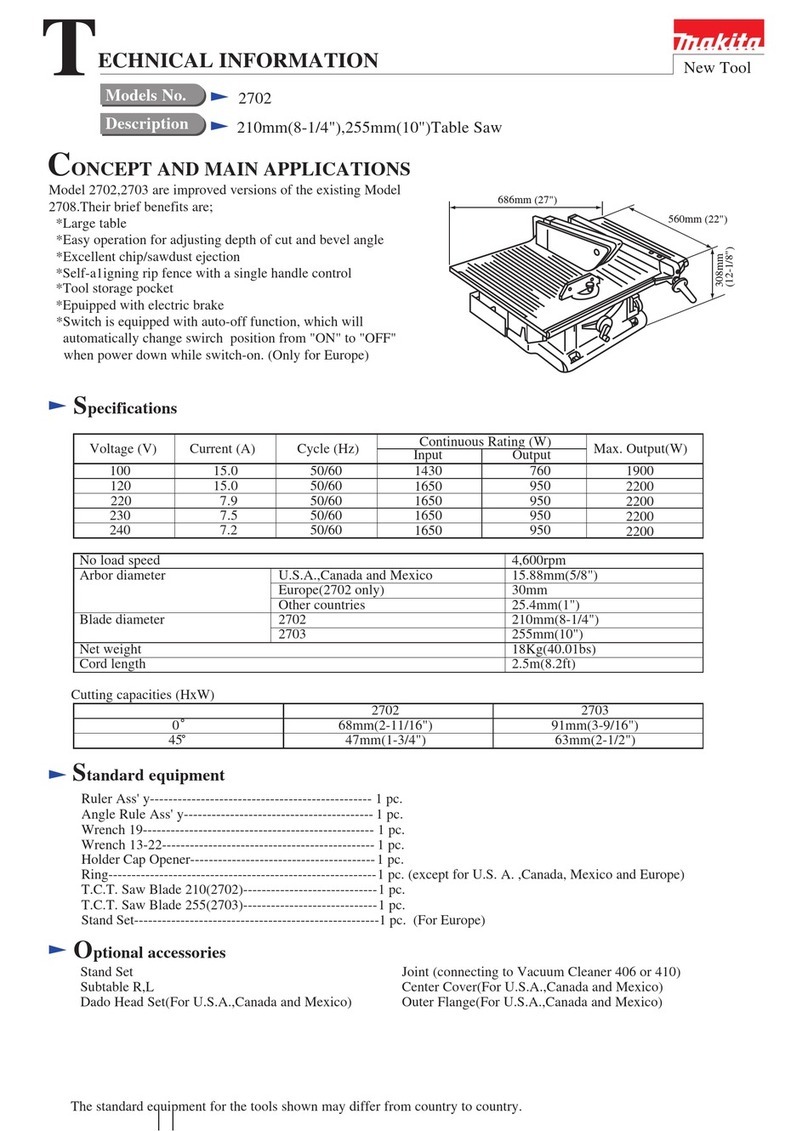

SPECIFICATIONS

Model: DLS714

Blade diameter 190 mm

Blade body thickness 1.3 mm - 2.0 mm

20 mm or 15.88 mm

Max. miter angle Left 47°, Right 57°

Max. bevel angle Left 45°, Right 5°

No load speed 5,700 min-1

Dimensions (L x W x H) 655 mm x 430 mm x 445 mm

Rated voltage D.C.36 V

Battery cartridge BL1815N, BL1820, BL1820B BL1830, BL1840, BL1840B, BL1850,

BL1850B

Net weight 13.0 kg 13.5 kg

Cutting capacities (H x W) with blade 190 mm in diameter

Miter angle Bevel angle

Őő°ăĚХОПtě 0° ő°ăĚrТРСtě

0° 40 mm x 300 mm 52 mm x 300 mm 40 mm x 300 mm

45 mm x 265 mm (NOTE 1) 60 mm x 265 mm (NOTE 1) –

45° (left and right) 40 mm x 212 mm 52 mm x 212 mm –

45 mm x 185 mm (NOTE 2) 60 mm x 185 mm (NOTE 2) –

57° (right) –52 mm x 163 mm –

–60 mm x 145 mm (NOTE 3) –

1. Max. Cutting capacity when using a wood facing 20 mm thickness

2. Max. Cutting capacity when using a wood facing 15 mm thickness

3. Max. Cutting capacity when using a wood facing 10 mm thickness

without notice.

• Weight, with battery cartridge, according to EPTA-Procedure 01/2003

Symbols

The following show the symbols used for the equip-

ment. Be sure that you understand their meaning before

use.

Read instruction manual.

holding the saw head down, after making

cuts, until the blade has come to a com-

plete stop.

-

riage fully and press down handle, then

push carriage toward the guide fence.

blade.

Always set SUB-FENCE to left position

when performing left bevel cuts. Failure to

Only for EU countries

Do not dispose of electric equipment or battery

pack together with household waste material!

In observance of the European Directives,

on Waste Electric and Electronic

Equipment and Batteries and Accumulators

and Waste Batteries and Accumulators

and their implementation in accordance

with national laws, electric equipment and

batteries and battery pack(s) that have

reached the end of their life must be col-

lected separately and returned to an envi-

ronmentally compatible recycling facility.

Intended use

The tool is intended for accurate straight and miter

cutting in wood.

Noise

The typical A-weighted noise level determined accord-

ing to EN61029:

Sound pressure level (LpA) : 88 dB(A)

Sound power level (LWA) : 97 dB (A)

Uncertainty (K) : 3 dB(A)