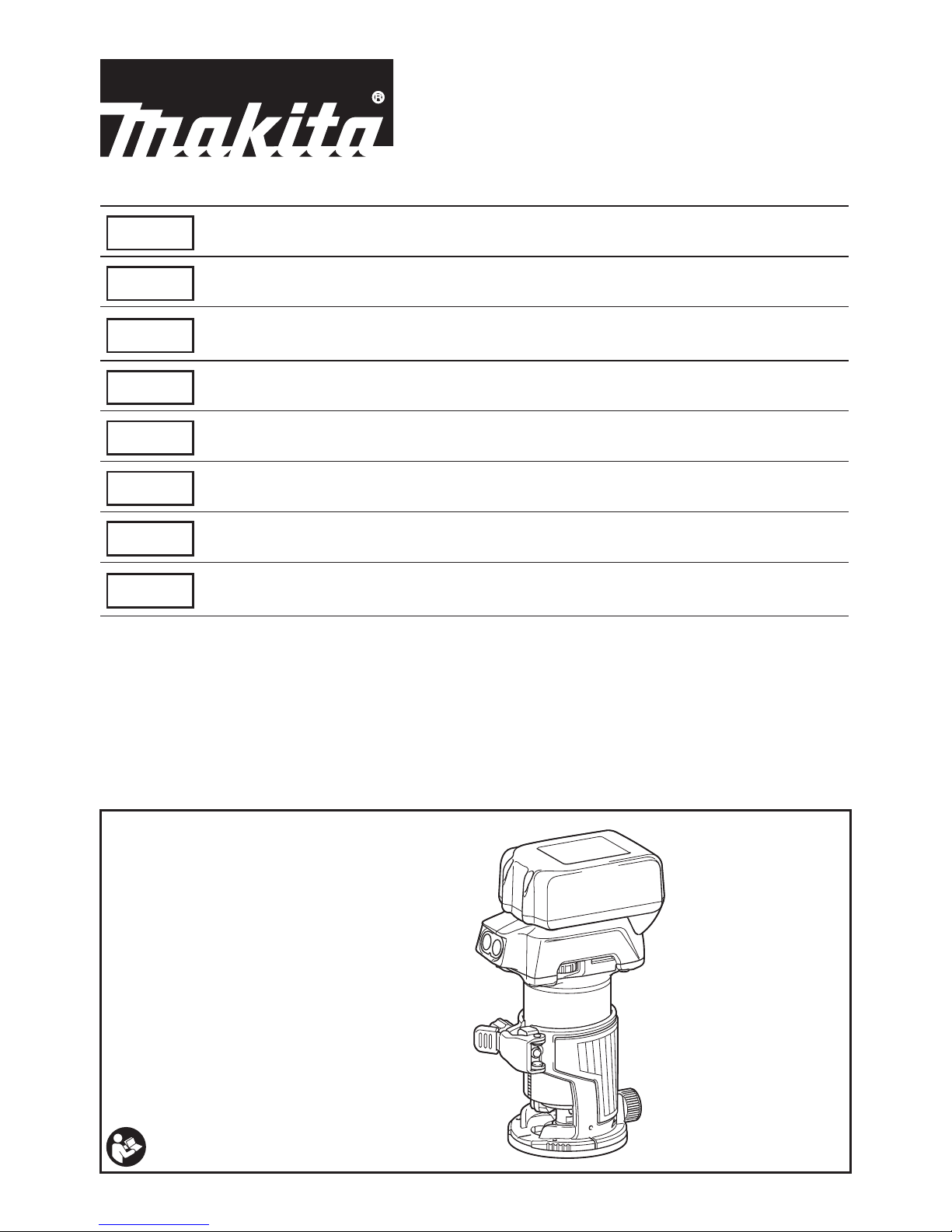

Makita DRT50 User manual

Other Makita Trimmer manuals

Makita

Makita DUR36UZ User manual

Makita

Makita DUR365UPM2 User manual

Makita

Makita UR002G User manual

Makita

Makita UH013G User manual

Makita

Makita XRU15PT User manual

Makita

Makita DUR141 User manual

Makita

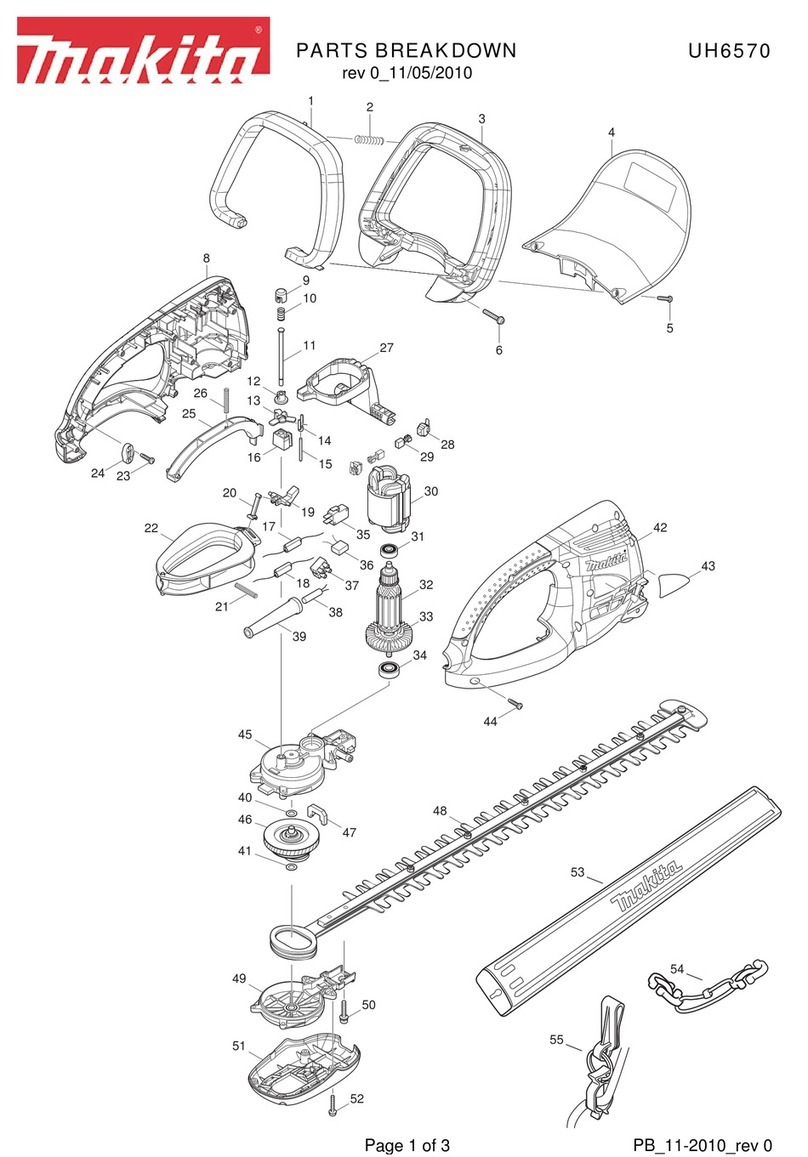

Makita DUH481 User manual

Makita

Makita DUR181SY User manual

Makita

Makita 3703 User manual

Makita

Makita DUR190U User manual

Makita

Makita 3709 User manual

Makita

Makita DUR361U User manual

Makita

Makita DUR361U User manual

Makita

Makita DUR190U User manual

Makita

Makita 3707F User manual

Makita

Makita EM404MP User guide

Makita

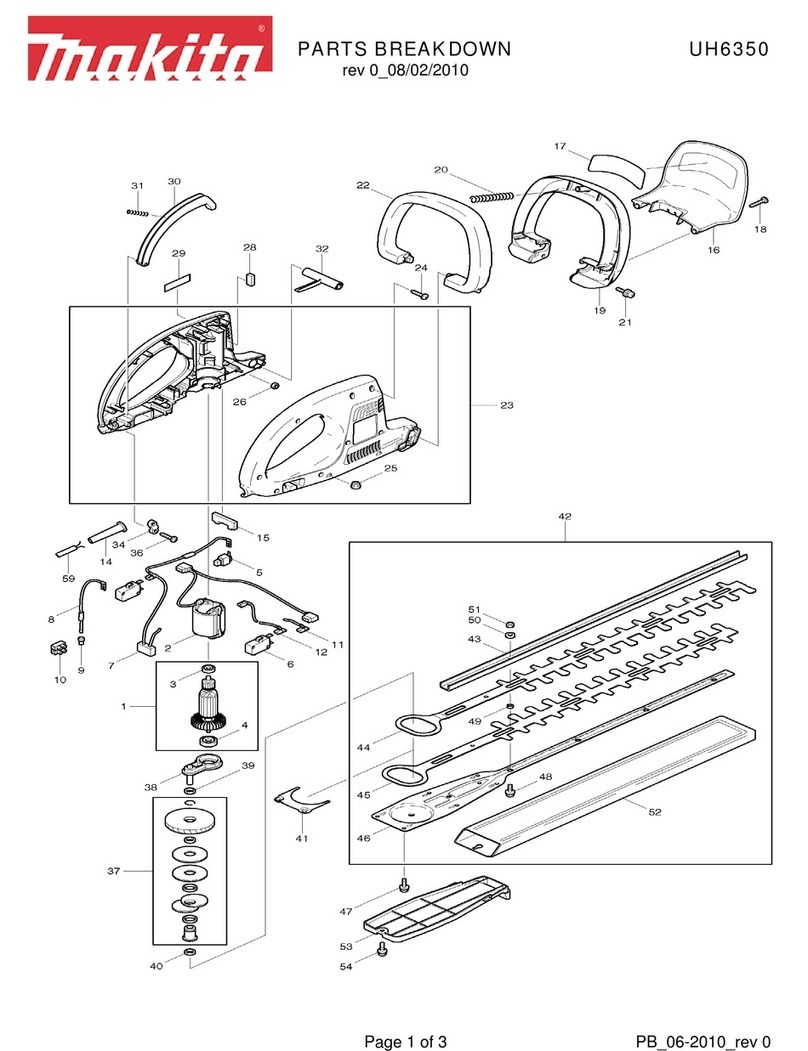

Makita UH200D User manual

Makita

Makita UR017GZ User manual

Makita

Makita DRT50 User manual

Makita

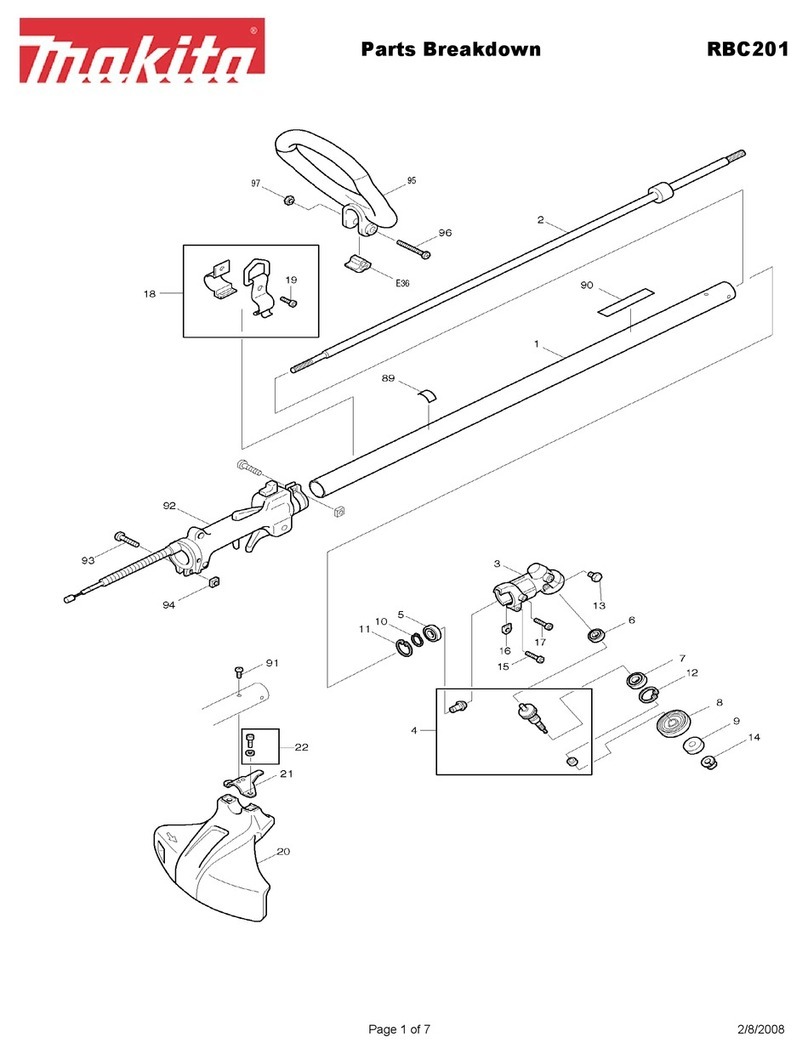

Makita DBC340 User manual