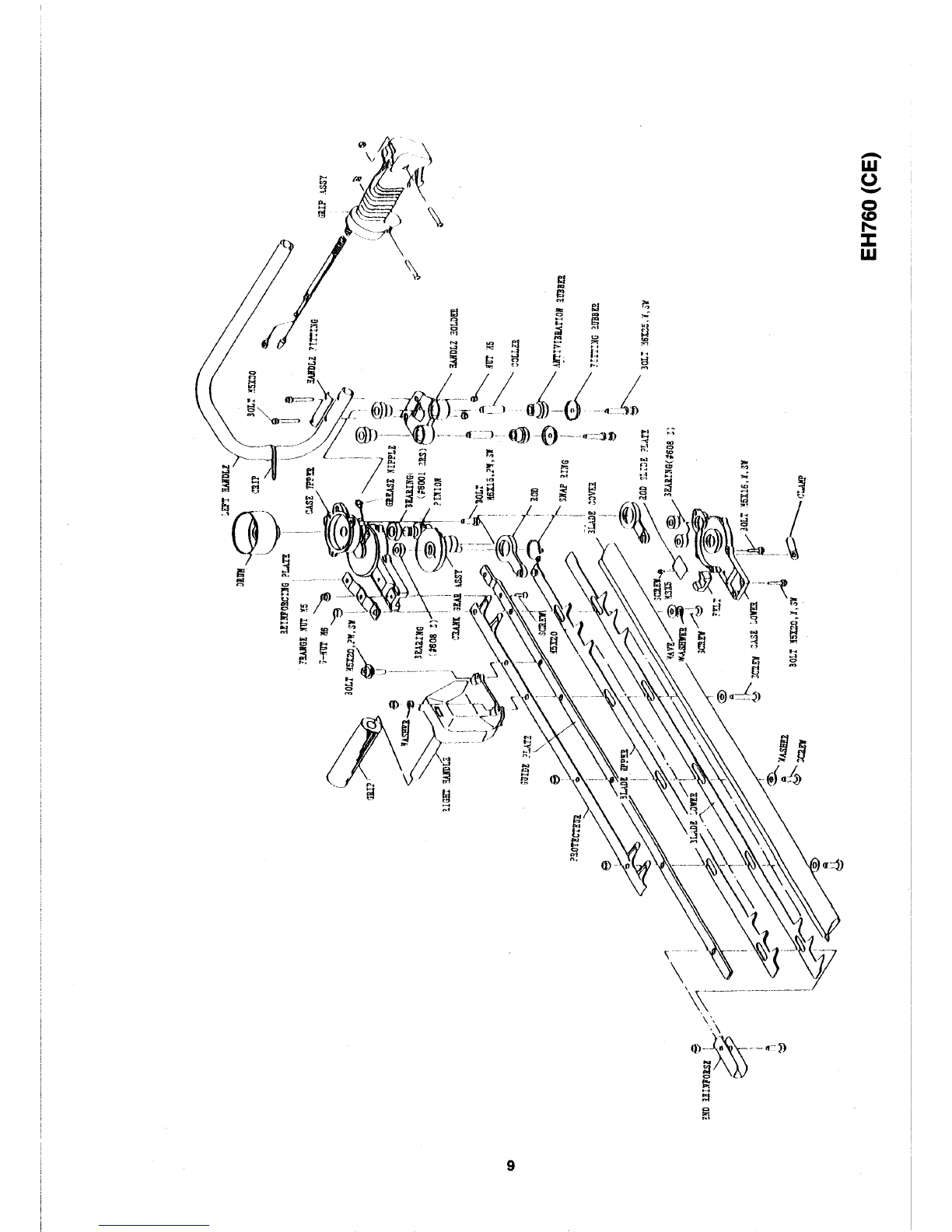

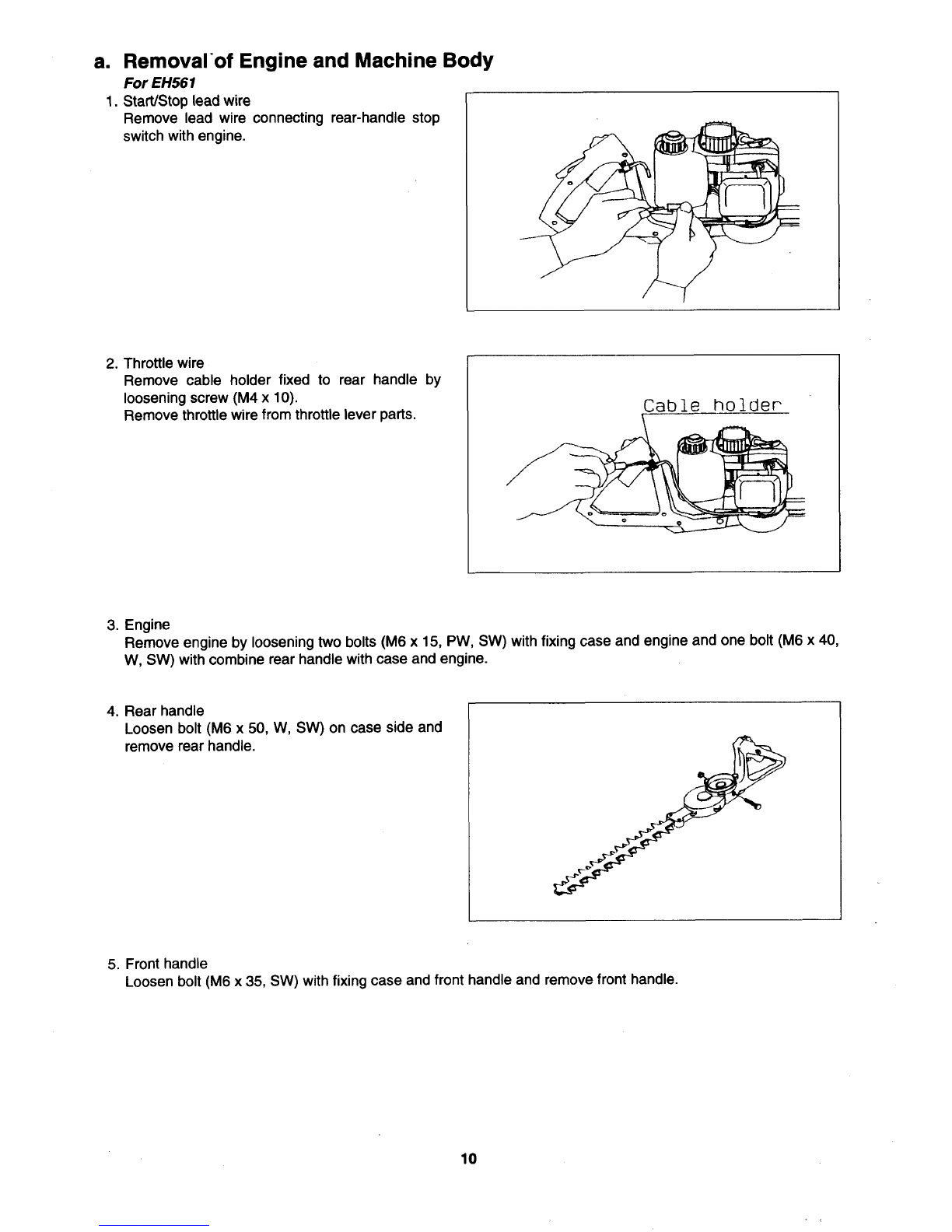

Makita EH561 User manual

Other Makita Trimmer manuals

Makita

Makita BUH550 User manual

Makita

Makita EY2650H User guide

Makita

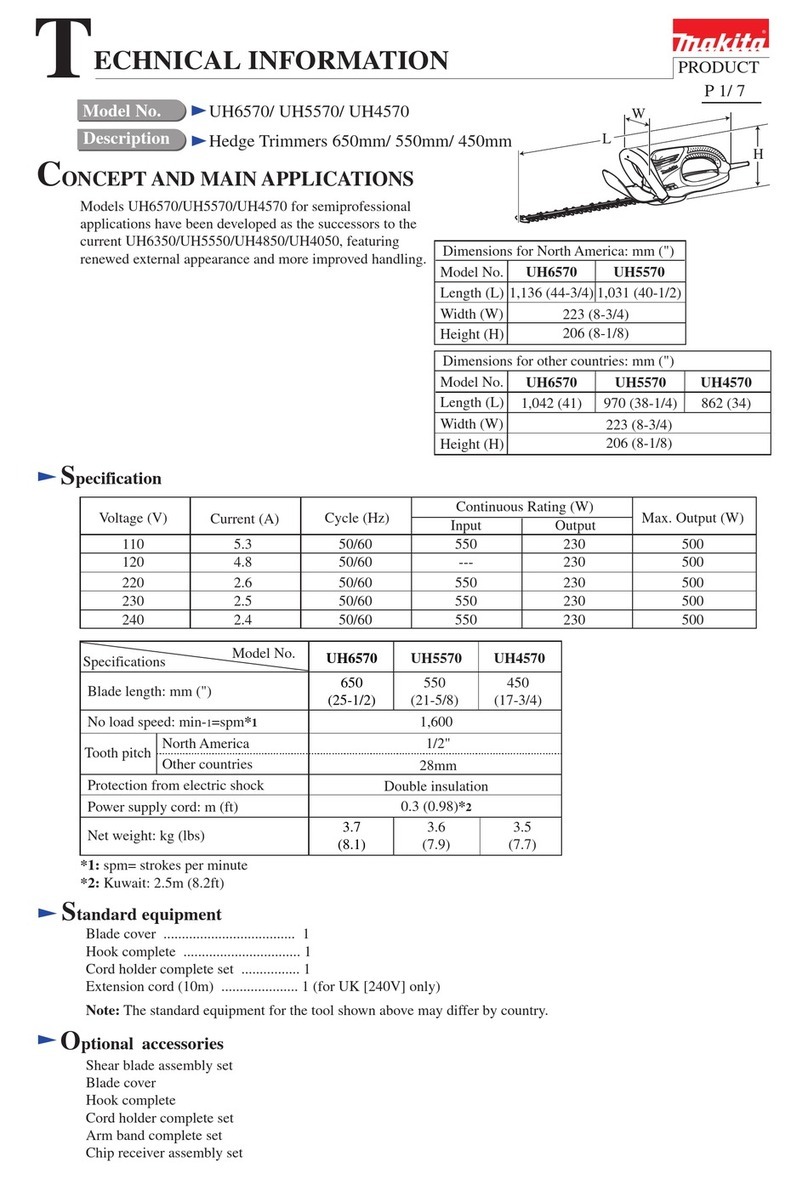

Makita UH4570 User manual

Makita

Makita DRT50ZX06 User manual

Makita

Makita UH6570 Manual

Makita

Makita EN402MP User manual

Makita

Makita EN422MP User manual

Makita

Makita 3707 User manual

Makita

Makita RT0702C User manual

Makita

Makita RT0700C User manual

Makita

Makita UR008GD201 User manual

Makita

Makita EM2650UH User guide

Makita

Makita M3700 User manual

Makita

Makita DUR369N User manual

Makita

Makita ER2650LH Manual

Makita

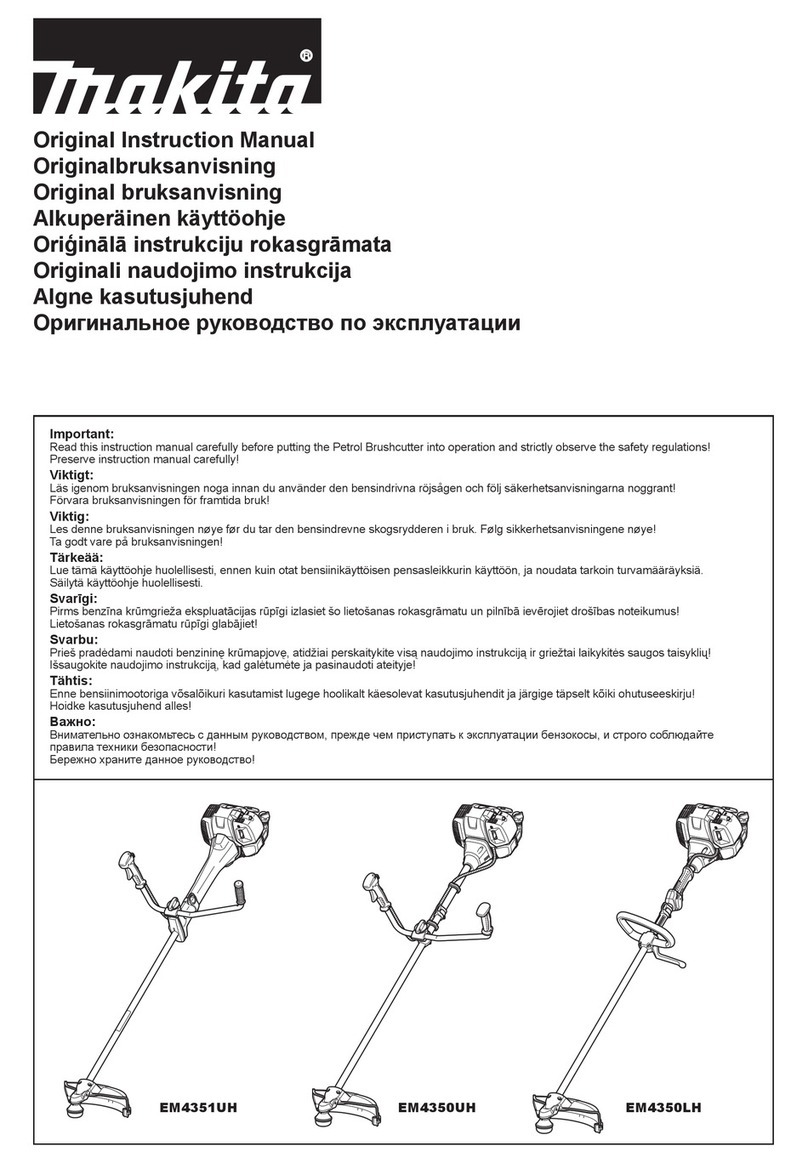

Makita EM4351UH User guide

Makita

Makita RBC221 User manual

Makita

Makita M3702 User manual

Makita

Makita DUR187U User manual

Makita

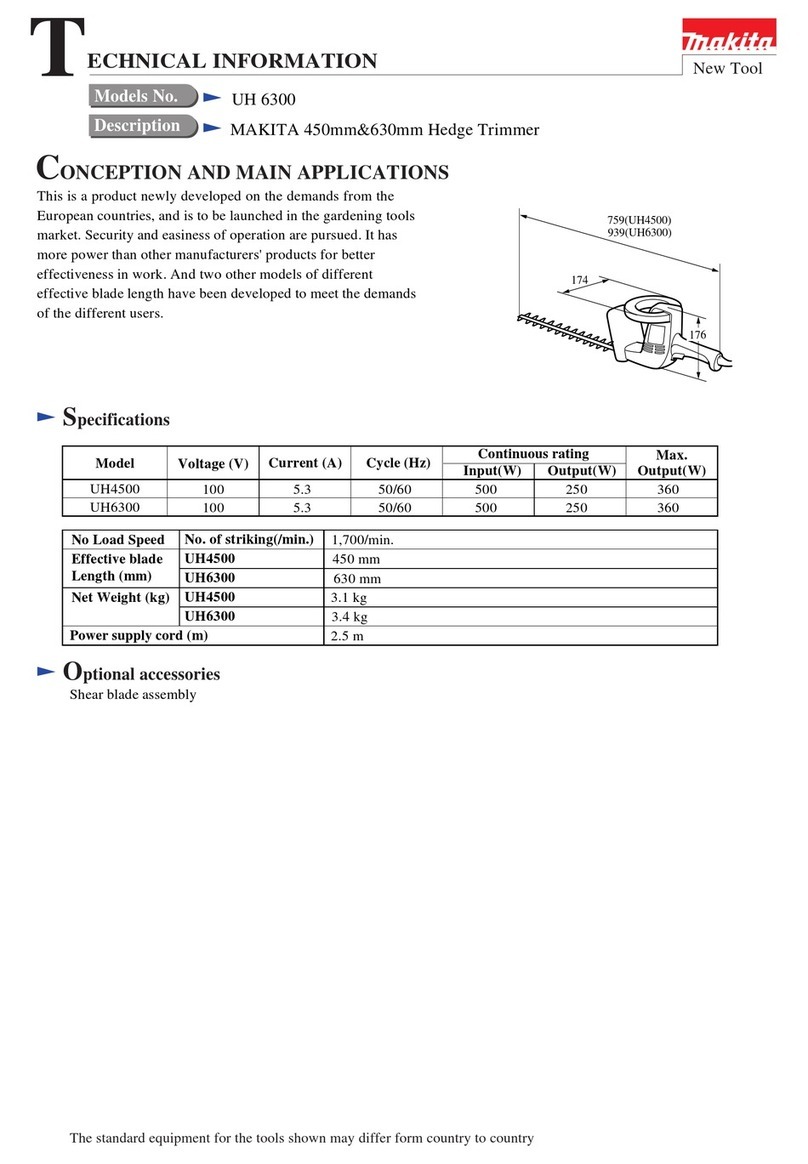

Makita UH6300 Manual