PRODUCT

CONCEPT AND MAIN APPLICATIONS

P 1/ 13

Specification

Standard equipment

Optional accessories

Note: The standard equipment for the tool shown above may vary by country.

Model No.

Description

UH520D

UH422D/ UH482D/ UH522D

BUH481/ BUH521

BUH483/ BUH523

Cordless Hedge Trimmer 520mm (20-1/2")

Cordless Hedge Trimmers 420mm/ 480mm/ 520mm

(16-1/2"/ 18-7/8"/ 20-1/2")

Cordless Hedge Trimmers 480mm/ 520mm (18-7/8"/ 20-1/2")

Cordless Hedge Trimmers 480mm/ 520mm (18-7/8"/ 20-1/2")

Dimensions: mm (")

Width (W)

Height (H)

*2with 3.0Ah Li-ion battery *3with 1.3Ah Li-ion battery

Length (L)

888 (35)/ 938 (37)*1

873 (34-3/8)/ 923 (36-1/4)*3

923 (36-1/4)

829 (32-5/8)/ 879 (34-1/2)/ 929 (36-1/2)

BUH483/ 523

881 (34-3/4)/ 931 (36-3/4)*2

869 (34-1/4)/ 919 (36-1/4)*3

BUH481/ 521

UH520D

UH422D/ 482D/

522D

195 (7-5/8)

193 (7-5/8)

Battery

Charging time (approx.): min.

Weight according to

EPTA-Procedure 01/2003*5: kg (lbs)

Capacity: Ah

Cell

Voltage: V 14.414.4 18

No load speed: minˉ¹=spm*3

420 (16-1/2)/ 480 (18-7/8)/ 520 (20-1/2)

--- / --- / UH520D --- / BUH481/ 521 --- / BUH483/ 523

Blade length: mm (")

--- / --- / 3.0

(--- / --- / 6.7)

--- / 3.0/ 3.0 (--- / 6.5/ 6.7),

--- / 3.1/ 3.2 (--- / 6.9/ 7.1)

3.0/ 3.0/ 3.1

(6.6/ 6.7/ 6.8)

--- / 3.0/ 3.1 (--- / 6.7/ 6.8),

--- / 3.2/ 3.3 (--- / 7.1/ 7.3)

1.3, 3.01.1 1.3, 3.0

Energy capacity: Wh 19, 4416 24, 54

Li-ion

190190 210210

15, 22 with DC18RC60 with DC18WA

18

UH422D/ 482D/ 522D

1.1

20

60 with DC18WA 15, 22 with DC18RC

1,350

Max output (W)

Blade cover ............................................. 1

Battery cover ........................................... 1 (same quantity as that of spare battery)

Battery BL1815 (for BUH483/ 523)

Battery BL1830 (for BUH483/ 523)

Charger DC18WA (for UH422D/ 482D/ 520D/ 522D)

Fast charger DC18RC (for BUH481/ 483/ 521/ 523)

Charger DC18SD (for BUH481/ 483/ 521/ 523)

Charger DC24SC (for BUH481/ 483/ 521/ 523)

Automotive charger DC18SE (for BUH481/ 483/ 521/ 523)

The subject models are 14.4V/18V cordless hedge trimmers.

Their main features are:

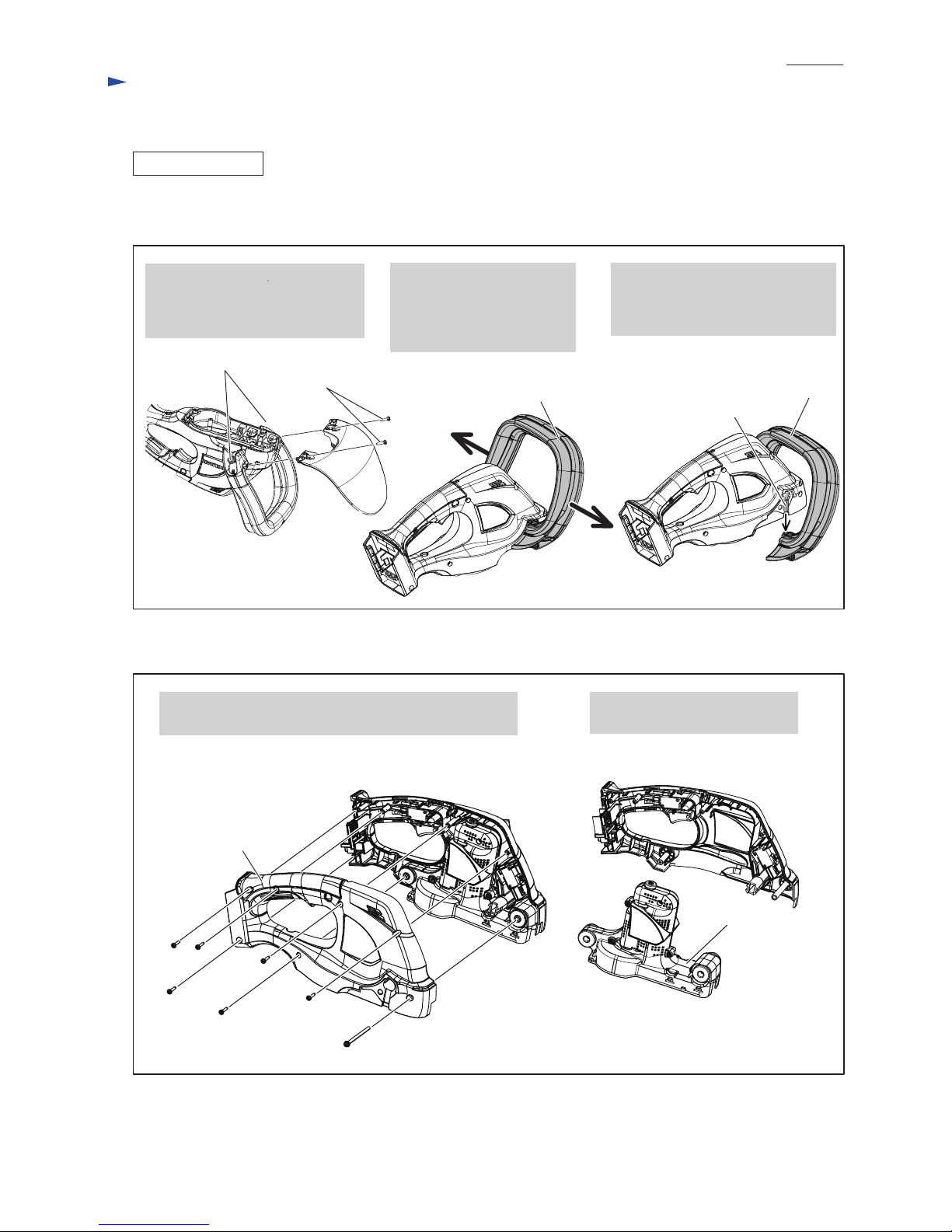

• Anti-vibration structure

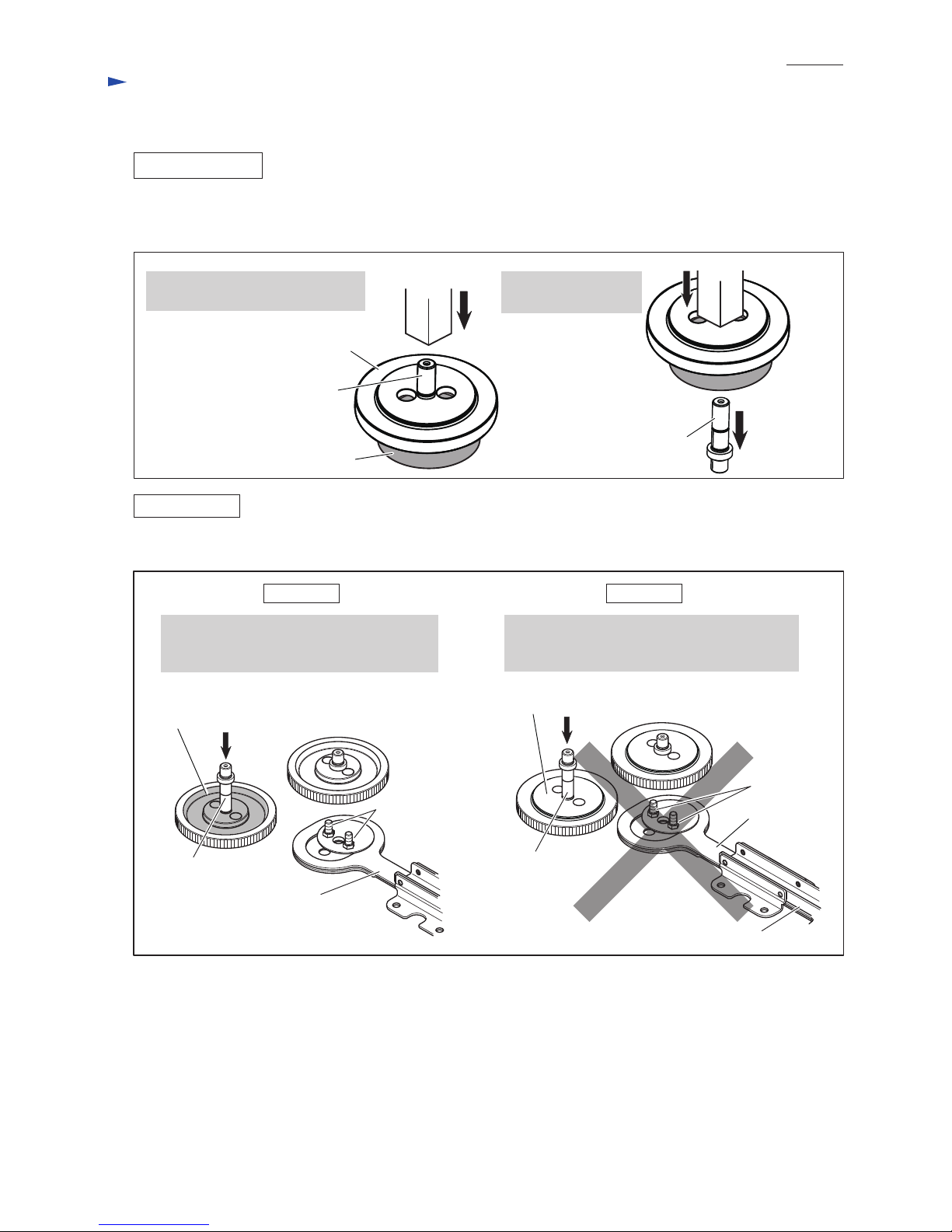

• User-replaceable blade

These products are compatible with the batteries

and the chargers in the list below.

BUH483/ 523

UH422D/ 482D/ 522D BL1811G

UH520D BL1411G DC18WA

BUH481/ 521 BL1415

BL1430 DC18RC,

DC18SD,

DC24SC,

DC18SE

Model No. Compatible

charger

BL1815

BL1830

Compatible

battery

Model

Specification

*3: spm= strokes per minute

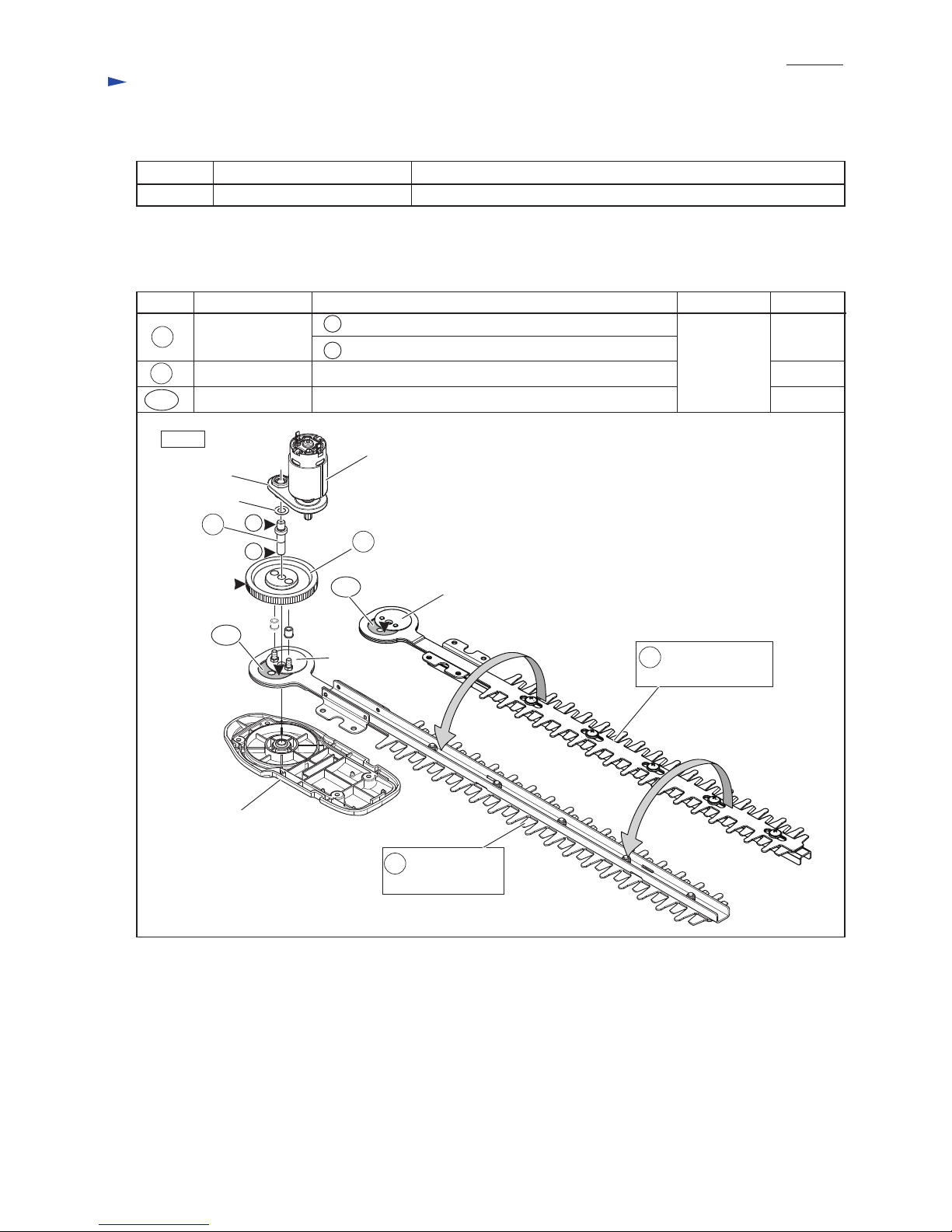

*4: Indicates maximum diameter of the branch that can be received

between adjacent two blade teeth. (See the figure on right.)

*5: with battery, shear blade assembly

Shear blade complete set

Blade cover

Chip receiver assembly set

Battery BL1411G (for UH520D)

Battery BL1811G (for UH422D/ 482D/ 522D)

Battery BL1415 (for BUH481/ 521)

Battery BL1430 (for BUH481/ 521)

Max. cutting diameter*4: mm (") ø15 (9/16)

TECHNICAL INFORMATION

L

H

W