INDEX

A DECLARATIONOF CONFORMITY

B GENERALWARNINGS

C SAFETYINSTRUCTIONS

C.1 SAFETYWARNINGS

C.2 FIRSTAID RULES

C.3 GENERAL SAFETYRULES

C.4 PACKAGING

C.5

PACKAGE CONTENTS/PRE-INSPECTION

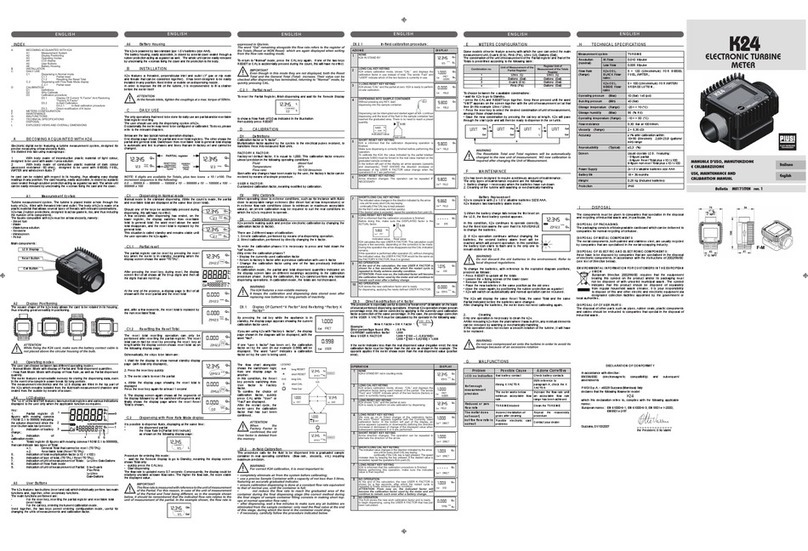

D BECOMING ACQUAINTEDWITH K24

D.1 COMPATIBLE LIQUIDS

D.2 DISPLAYLCD

D.3 DISPLAYPOSITIONING (METERVERSION ONLY)

D2 USERSBUTTONS

E OPERATING MODES

F INSTALLATION

G DAILYUSE

G.1 DISPENSING INNORMAL MODE

G.1.1 PARTIALRESET (NORMALMODE)

G.1.2 RESETTINGTHE RESETTOTAL

G.2 DISPENSINGWITH FLOWRATEMODE DISPLAY

G.2.1 PARTIALRESET (FLOW RATEMODE)

H CALIBRATION

H1 DEFINITIONS

H2 CALIBRATIONMODE

H.2.1 DISPLAYOF CURRENT CALIBRATIONFACTOR AND

RESTORINGFACTORYFACTOR.

H.2.2 IN FIELD CALIBRATION

H.2.2.1 IN-FIELDCALIBRATIONPROCEDURE

H.2.3 DIRECTMODIFICATION OFK FACTOR

I METERCONFIGURATION

L MAINTENANCE

M MALFUNCTIONS

N DISPOSAL

O DATITECNICI /TECHNICALDATA

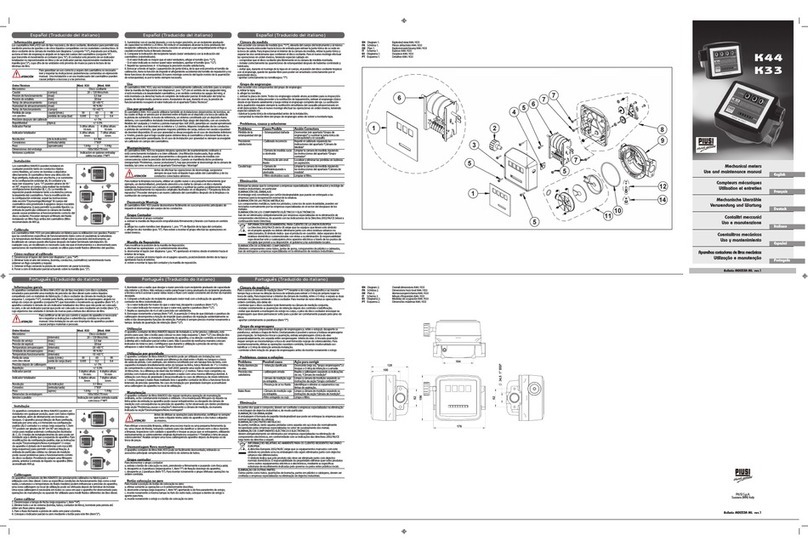

P EXPLODEDVIEWS AND OVERALLDIMENSIONS

A DECLARATION OF CONFORMITY

Theundersigned:

PIUSIS.p.AViaPacinotti 16/A z.i.Rangavino

46029Suzzara- Mantova- Italy

HEREBY STATES

underits own responsibility,that theequipment describedbelow:

Descriprion: METER

Model: K24

!"#$%&'()*+"#,'#"-"#'./'0/.'1)*+"#'23/4('/('56'7&%."'%-89":'./'7#/:);.<"%#'/-'

*%()-%;.)#",'#"-"#'./'.3"'="%#'/-'7#/:);.$/('23/4('/('.3"'56'7&%."'%-89":'./'.3"'

7#/:);.$2'$(';/(-/#*$.='4$.3'.3"'&">%&'7#/?$2$/(2'$(:$;%.":'$('.3"':$#";.$?"2','

@'6&";.#/*%>(".$;'5/*7%.$+$&$.='A$#";.$?"'BCCDEFCGE65''

H3"':/;)*"(.%.$/('$2'%.'.3"':$27/2%&'/-'.3"';/*7"."(.'%).3/#$.='-/&&/4$(>'*/.$?%.":'

#"I)"2.'%.'J$)2$'!K7KLK'/#'-/&&/4$(>'#"I)"2.'2"(.'./'.3"'"*%$&'%::#"22,':/;M.";N

7$)2$K;/*H3"'7"#2/('%).3/#$2":'./';/*7$&"'.3"'.";3($;%&'8&"'%(:':#%4')7'.3"':";&%-

#%.$/('$2'O../'P%#$($'%2'&">%&'#"7#"2"(.%.$?"K

' !)QQ%#%R'CFECFEBCFB' ' ' OttoVarini

' ' ' ' ' &">%&'#"7#"2"(.%.$?"K

B GENERAL WARNINGS

Important

precautions

Toensureoperatorsafetyand to protect thepump frompo-

tential damage,workersmust be fully acquainted with this

instruction manual beforeperforming anyoperation.

Symbolsused

in themanual

Thefollowing symbols will be usedthroughoutthe manual

to highlight safety informationand precautions of particular

importance:

ATTENTION

Thissymbolindicatessafe working practices foropera-

torsand/orpotentiallyexposedpersons.

WARNING

Thissymbolindicatesthat thereis riskof damageto the

equipmentand/orits components.

NOTE

Thissymbolindicatesuseful information.

Manualpres-

ervation

hismanualshouldbe complete andlegible throughout. It

should remainavailableto end users andspecialistinstallation

andmaintenance techniciansfor consultation atany time.

Reproduction

rights

All reproduction rights arereservedby PiusiS.p.A. The text

cannot be reprinted withoutthe written permission of Piusi

S.p.A.

THISMANUALIS THE PROPERTYOF Piusi S.p.A.

ANYREPRODUCTION, EVEN PARTIAL, ISFORBIDDEN.

C SAFETY INSTRUCTIONS

C.1 SAFETY WARNINGS

Mains- prelim-

inarychecks

before instal-

lation

ATTENTION

Youmust avoidany contactbetweenthe electrical pow-

er supplyand the uidthat needs to beFILTERED.

Maintenance

control

Before anychecksor maintenancework are carriedout, dis-

connect thepower source.

C.2 FIRST AID RULES

Contactwith

theproduct

In theevent of problems developing following EYE/SKIN

CONTACT,INHALATION or INGESTION of thetreatedproduct,

please refer to theSAFETY DATA SHEET of theuid handled.

NOTE Please refer tothe safetydata sheetfor the product

SMOKING

PROHIBITED

Whenoperating thedispensing system andin particular dur-

ing refuelling,do not smoke and donot use opename.

C.3 GENERAL SAFETY RULES

Essentialpro-

tectiveequip-

mentcharac-

teristics

Wear protective equipmentthat is:

suited to theoperationsthat need tobe performed;

resistantto cleaning products.

Personalpro-

tectiveequip-

mentthat

mustbe worn

Wear the following personal protective equipmentduring

handlingand installation:

safety shoes;

close-tting clothing;

protective gloves;

safety goggles;

Protective

equipment

instruction manual

C.4 PACKAGING

FOREWORD K24 COMES PACKED INA CARDBOARD BOXWITH A LABEL

INDICATINGTHE FOLLOWING DATA:

1 - contentsof the pack-

age

2 - weight of thecontents

3 - description of the

product

C.5

PACKAGE CONTENTS/PRE-INSPECTION

FOREWORD Toopen the packaging, usea pair of scissorsor a cutter,being careful

not todamage thedispensing systemor its components.

NOTE In theeventthat oneor more ofthe componentsde-

scribed below aremissingfrominside thepackage,

please contactPiusiinc technicalsupport.

WARNING Checkthatthe data onthe platecorrespondto the

desiredspecications. Inthe eventof anyanomaly,

contactthe supplier immediately, indicatingthe nature

of thedefects. Do notuse equipmentwhichyou suspect

might notbe safe.

D BECOMING ACQUAINTEDWITH K24

FOREWORD Electronicdigitalmeter featuring a turbinemeasurement system,de-

signed forprecisemeasuring of lowviscosity uids.

K24is availablein 2 versions:

1METER – withLCD displayand calibrationbuttons

2

PULSER – single-channel impulse, cannectable with a remote display.

Twobig groups aresuitablefor its use:

AWithbody madeof inconductive plastic materialof lightcolour,

divided into highow rateversionsand low owrate versions, with

stainlesssteel F/Fbushing

BWithbody madeof conductiveplastic material of darkcolourwith

galvanized steel bushing

owrate values Highow rate 120l/min

Lowow rate60 l/min

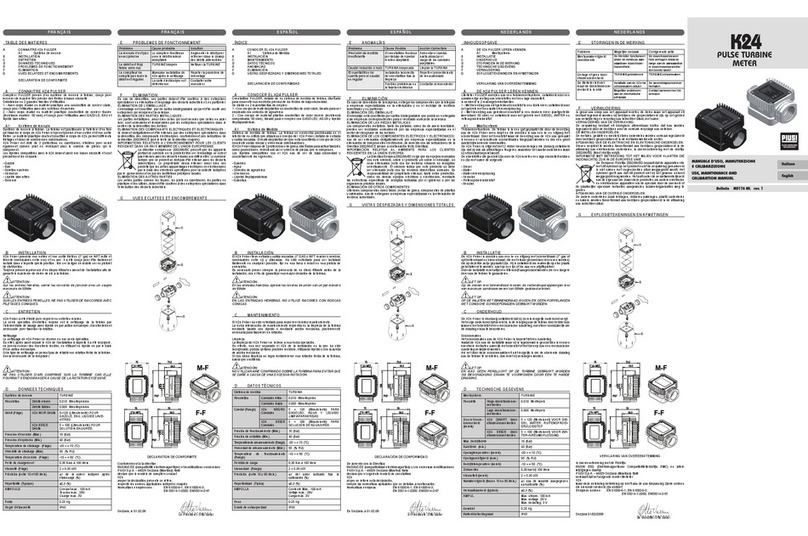

D.1 COMPATILE LIQUIDS

Turbine

measurement

system

Theturbine isplaced inside a hole throughthe body of k24, tted

withM-M threaded inlet andoutlet.The suppliedF-F bushingenables

several combinations of threads. K24 HAS2 RUBBERPROTECTIONS,

DESIGNEDTO ACT ASGASKETSTOO.

Theliquids compatiblewith k24 areat low viscosity, namely:

bodymade of incon-

ductiveplasticmaterial

of light colour

Water

Aus32 (D.E.F., Ad-Blue)

Milknot suitable forhuman consumption

bodymade of conduc-

tiveplastic materialof

darkcolour

Diesel fuel

Windscreen

Maincomponents:K24 Meter Main components:K24 Pulser

1 LCDdisplay 1 Plate with technicaldata

2 RESETkey 2 F-Fbushing

3 CAL key

4 F-F bushing

1

234

12

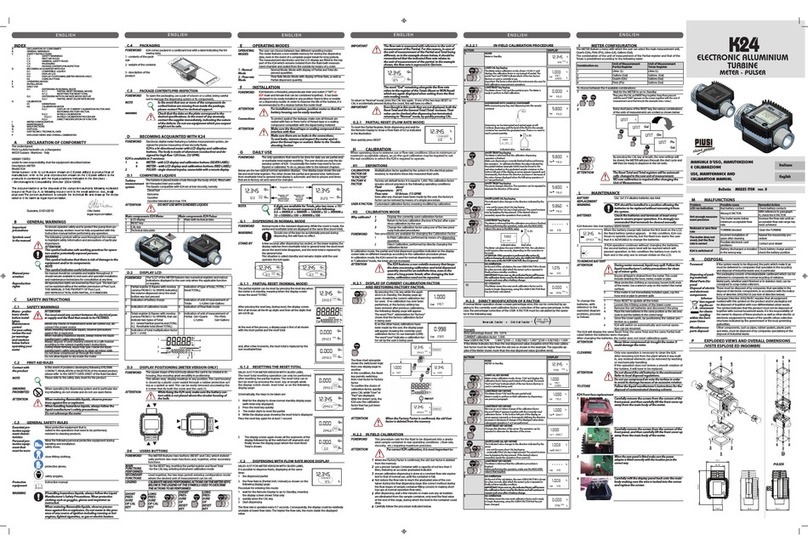

D.2 DISPLAY LCD

FOREWORD The“LCD”of theMETER featurestwo numericalregisters andvarious

indications displayed tothe user onlywhen theapplicable function

so requires.

1 Partial register (5 gureswith moving

commaFROM 0.1to 99999)indicating

the volumedispensed since the reset

button waslast pressed

6 Indication of type of total,( TOTAL /

ResetTOTAL);

2 Indication of battery charge 7 Indication of unit of measurementof

Totals: L=Litres Gal=Gallons

3 Indication of calibrationmode 8 Indication of Flow Rate mode

4 Totalsregister (6 gureswith moving

commaFROM 0.1to 999999), thatcan

indicatetwo types ofTotal:

4.1.

GeneralTotalthatcannotbe reset(TOTAL)

4.2. Resettable total (Reset TOTAL)

9 Indication of unit of measurementof

Partial: Qts=Quarts Pts=Pints

L=Litres Gal=Gallons

5 Indication of total multiplication factor

(x10 / x100)

456

9

7

1

2

3

8

D.3 DISPLAY POSITIONING (METER VERSION ONLY)

FOREWORD The squareshape of thek24 body allowsthe card tobe rotatedin its

housing, thus ensuringgreat versatilityin positioning

This allows easy display readings in any position. The card housing

is closed by a plastic cover sealed through a rubber protection act-

ing as a gasket as well. This can be easily removed unscrewing the

4 screws that x both the cover and the card (1).

ATTENTION While xingthe K24card,make surethe battery con-

tactcableis not placed above thecircularhousing of

thebulb.

D2 USERS BUTTONS

FOREWORD The METER features two buttons (RESET and CAL) which individ-

ually perform two main functions and, together, other secondary

functions

.

MAIN

FUNCTIONS

PERFORMED

- forthe RESET key, resetting thepartial register and Reset Total

- forthe CAL key, enteringinstrument calibrationmode

SECONDARY

FUNCTIONS

Used together, the two keys permit entering conguration mode

where the desired unit of measurement can be set.

LEGEND CALIBRATEMEANSPERFORMINGACTIONS ON THEMETER KEYS.

BELOW IS THELEGEND OFTHESYMBOLS USEDTODESCRIBE

THEACTIONSTO BEPERFORMED

SHORT

PRES

SURE

OF CAL

KEY

CAL

LONG

PRES

SURE

OF CAL

KEY

CALCAL

CAL

SHORT

PRES

SURE

OF

RESET

KEY

RESET

LONG

PRES

SURE

OF

RESET

KEY

RESET

RESET

RESET

E OPERATING MODES

OPERATING

MODES

Theuser can choose between two dierent operatingmodes:

Themeter featuresa non-volatile memoryfor storing the dispensing

data,even in theevent ofa completepowerbreak forlong periods.

Themeasurement electronics and the LCD display are tted in the top

part ofthe K24 which remains isolated fromthe uid-bathmeasure-

mentchamberand sealedfrom the outside by means of a cover.

1 - Normal

Mode

Normal Mode:Mode withdisplayof Partialand Total dis-

pensed quantities

2 - Flowrate

Mode

FlowRate Mode:Mode withdisplayof Flow Rate, aswell as

Partial dispensed quantity.

F INSTALLATION

FOREWORD K24 features a threaded, perpendicularinlet andoutlet (1”BSP male

and femalethat can becombinedtogether). It hasbeen designedto

be easily installed in any position:xed in-line or mobileon a dispens-

ing nozzle. In order to improvethe lifeof the turbine,it is recommend-

ed tot a strainerbeforethe meteritself

ATTENTION An F/Fcoupling, complete with itsgasket, is supplied

forinstallations on male couplings.Alwaysscrew the

sidewith gasket on K24.

It isup to the installer touse anothergasket on the

other sideof the coupling.

Thegasketused hasthe followingcharacteristics: at

sealid=24,od=35.5, thick=2 Material:NBR 70SH

Forinstallations onsystem,position K24so that the

battery housingcan be easily reached.

G DAILY USE

FOREWORD

Theonly operationsthat needto be donefor daily use are partial and/

or resettabletotalregister resetting. The user should useonly thedis-

pensingsystemof k24. Occasionally themetermay needto be con-

gured or calibrated.Todo so, pleasereferto the relevant chapters.

Beloware the twotypicalnormal operation displays. One display pageshows thepar-

tialand resettotal registers. The other shows the partialand general total. Switchover

fromresettable total to general totaldisplayis automatic and tiedto phasesand times

thatare in factory setand cannotbe changed.

NOTA 6 digits areavailable for Totals, plus two icons x 10 /

x100. Theincrement sequenceis the following:

0.0-> 99999.9-> 999999 -> 100000x 10 -> 999999x

10 ->100000x 100 ->999999 x 100

G.1 DISPENSING IN NORMAL MODE

FOREWORD

Normal mode is the standarddispensing.While thecountis made,the

partial and resettable totalare displayed at thesame time (resettotal).

WARNING Shouldone of the keys be accidentally pressed during

dispensing, this willhave no eect.

STAND BY A few seconds after dispensing hasended, onthe lowerregister,the

display switches fromresettable total to general total: theword reset

above the word total disappears, and thereset total is replacedby

the general total.

Thissituation is called standby and remainsstable until theuser

operates the k24again.

G.1.1 PARTIAL RESET (NORMAL MODE)

Thepartial register can bereset by pressing the resetkey when

the meter is in standby, meaning when the displayscreen

shows the word“TOTAL”.

Afterpressing the resetkey, during reset, thedisplayscreen

rstof all showsall the lit-updigits andthen all thedigitsthat

arenot lit up.

At theend of the process, a displaypage is rstof all shown

withthe resetpartial andthe resettotal

and,after a fewmoments, the reset total is replaced bythe

non resettableTotal.

G.1.2 RESETTING THE RESET TOTAL

The reset total resetting operation can only be performed

after resetting the partial register. The reset total can in

fact be reset by pressing the reset key at length while

the display screen shows reset total as on the following

display page:

Schematically, the stepsto be takenare:

1 Waitfor the display to shownormal standbydisplaypage

(withtotal only displayed)

2 Pressthe resetkey quickly

3 Themeter startsto resetthe partial

4 Whilethe display pageshowingthe resettotal is displayed

Press the resetkey again for at least 1 second

5 The display screenagain shows allthe segments of the

display followed byall the switched-o segmentsand

nally shows thedisplaypage wherethe resetReset

Totalis shown.

C.2 DISPENSING WITH FLOW RATE MODE DISPLAY

It is possibleto dispense uids, displaying at the same

time::

1 the dispensed partial

2 the Flow Ratein [Partial Unit/ minute]as shown onthe

following display page:

Procedure forenteringthis mode:

1 wait for the Remote Display to go toStandby, meaning

the display screen shows Total only

2 quicklypress theCAL key.

3 Start dispensing

Theow rate isupdatedevery 0.7 seconds. Consequently, the display could be relatively

unstable at lowerow rates. The higher theow rate,the morestable thedisplayed

value.

IMPORTANT Theow rateis measured withreferenceto the unitof

measurement of the Partial. Forthis reason, incase of

theunit of measurementof the Partial andTotal being

dierent, as inthe example shown below, it should be

remembered thatthe indicated owrate relatesto

theunit of measurementof the partial.In the example

shown, theow rateis expressedin Qts/min.

Theword “Gal” remaining alongsidethe owrate

refers tothe register of the Totals (Reset orNON Reset)

which areagain displayed whenexitingfromthe ow

ratereading mode.

Toreturnto “Normal”mode, pressthe CAL keyagain. Ifone of the twokeys RESETor

CAL isaccidentallypressedduring thecount,this will have noeect.

IMPORTANT

Even though in thismodethey arenot displayed,boththe

ResetTotalandthe General Total(Total) increase. Their

valuecan be checked afterdispensing hasterminated,

returningto “Normal” mode,by quickly pressingCAL.

G.2.1 PARTIAL RESET (FLOW RATE MODE)

Toreset thePartialRegister, nishdispensing andwait for

the RemoteDisplayto show a Flow Rateof 0.0 as indicated

in theillustration

thenquickly press RESET

H CALIBRATION

Whenoperating close to extremeuse or ow rate conditions (closeto minimum or

maximum acceptablevalues),an on-the-spotcalibration may be required to suit

the real conditions inwhich theK24 is required to operate.

H1 DEFINITIONS

CALIBRATION

FACTOR OR

“K FACTOR”

Multiplicationfactor applied by thesystem tothe electrical pulses

received, to transform these intomeasured uid units.

FACTORYK

FACTOR

Factory-set defaultfactor. It is equal to 1,000. Thiscalibration factor

ensures utmostprecisionin the following operating conditions:

Fluid water/ureasolutionor liquidfood products

Temperature: 20°C

Flowrate: 10- 30 ltr/min

Evenafter anychangeshave beenmade by theuser,the factoryk

factor canbe restored by means of a simple procedure.

USERK FACTOR: Customized calibrationfactor,meaningmodiedby calibration.

H2 CALIBRATION MODE

Whycalibrate? 1 Display the currently used calibration factor:

2Return to factory calibration(FactoryK Factor) after a pre-

viouscalibration by the user

3Change the calibration factorusing oneof the two previ-

ouslyindicated procedures

FOREWORD

Two procedures are available for changing the Calibration Factor:

1 In-Field Calibration,performedby meansof a dispensing

operation

2 DirectCalibration, performed by directly changingthe

calibration factor

In calibration mode, the partial and total dispensed quantities indicated on thedisplay

screen takeon dierent meanings according to thecalibration procedurephase.

In calibration mode, the K24 cannot beused for normal dispensingoperations.

In“Calibration”mode, the totalsare not increased

ATTENTION TheK24 features a non-volatile memory thatkeeps

thedata concerning calibrationand total dispensed

quantitystoredfor an indenite time,evenin the

caseof a longpower break;after changing the bat-

teries,calibration neednot be repeated.

H.2.1 DISPLAY OF CURRENT CALIBRATION FACTOR

AND RESTORING FACTORY FACTOR.

CALCAL

CAL By pressing the CAL key while the appli-

anceis in Standby, the display page ap-

pearsshowing thecurrent calibration fac-

tor used. If no calibration has ever been

performed, orthe factory setting has

been restored afterprevious calibrations,

the following display page will appear:

The word “Fact” abbreviation for“factory”

showsthat the factory calibration factor

is beingused

If,on the otherhand, calibrationshave

beenmade by theuser,the display page

willappear showingthe currently used

calibration factor ( in our example 0,998) .

Theword“user”indicatesa calibration fac-

torset by the useris beingused..

CAL

Theow chart alongside

shows the switchoverlogic

fromone display page to

another

In thiscondition, theReset

key permitsswitching

fromUser factor to Factory

factor.

Toconrmthe choiceof

calibration factor, quickly

press CAL while“User”or

“Fact”are displayed.

Afterthe restart cycle, the

K24 uses the calibration

factor thathas just been

conrmed

CAL

CALCAL

CAL

RESET

RESET

TIMEOUT

ATTENTION When the Factory Factor is conrmed, the oldUser

factor isdeletedfrom thememory

H.2.2 IN FIELD CALIBRATION

FOREWORD This procedure calls for the uid to be dispensed into a gradu-

ated sample container in real operating conditions ( ow rate,

viscosity, etc.) requiring maximum precision.

ATTENTION For correct K24 calibration,it is mostimportantto:

1Whenthe Factory Factoris conrmed, theold User factoris deleted

fromthe memory

2use a preciseSampleContainer witha capacityof not lessthan 5

litres,featuring an accurate graduated indicator.

3ensure calibration dispensing isdone at a constant ow rate equiva-

lentto that of normal use, until thecontainer is full;

4Not reducethe ow rate to reach thegraduated area of thecon-

tainer during thenal dispensingstage (the correct method during

the nal stages of sample container lling consists in making short

top-ups atnormal operation owrate) ;

5afterdispensing,wait a fewminutesto make sureany air bubbles

areeliminated from the samplecontainer; onlyread theReal value

at theend of thisstage, during which the levelin the containercould

drop.

6Carefullyfollowthe procedureindicated below.

H.2.2.1 IN-FIELD CALIBRATION PROCEDURE

ACTION DISPLAY

1NONE

Meter in Standby

2

CALCAL

CAL

LONG CALkey keying

TheMeterenterscalibration mode,shows<<CAL>>and

displaysthe calibrationfactorin use insteadof partial.The

words “Fact”and“USER”indicatewhichof the twofactors

(factory or user)is currently in use.

Important: This factor is that which theinstrumentalso usesfor

eldcalibration measurementoperations

3

RESET

RESET

RESET

LONG RESETkeykeying

TheMetershows“CAL” andthe partial at zero.The Meter is

ready toperformin-eldcalibration.

4DISPENSINGINTOSAMPLE CONTAINER

Without pressingany key,start dispensing into thesample

container

Dispensing can be interrupted and started again atwill.

Continuedispensinguntilthe levelof theuid in thesample

container hasreachedthe graduated area. Thereis no needto

reach a presetquantity.

Indicated value Realvalue

5

RESET

SHORT RESETkeykeying

TheMeteris informed thatthe calibrationdispensing

operation is nished.

Makesure dispensing is correctlynishedbeforeperforming

thisoperation. Tocalibrate the Meter, the valueindicatedby

thepartialtotaliser(example9.800)must beforcedto the

realvaluemarkedon the graduated samplecontainer.In the

bottom leftpart ofthe display an arrowappears(upwardsand

downwards),that shows the direction(increase or decrease)of

thevalue changedisplayedwhen thefollowing operations 6

or 7 areperformed.

6

RESET

SHORT RESETkeykeying

Thearrowchangesdirection.The operation canbe repeated to

alternate thedirection of the arrow.

7

CALCAL

CAL

CAL

SHORT/LONGCAL keykeying

Theindicatedvalue changesin the directionindicated by the

arrow

- oneunitfor everyshort CALkey keying

- continuallyif theCAL key is kept pressed.Thespeed increase

risesby keepingthe key pressed. Ifthe desired valueis

exceeded, repeat the operations frompoint(6).

8

RESET

RESET

RESET

LONG RESETkeykeying

TheMeteris informed that thecalibration procedure is nished.

Beforeperforming this operation, makesurethe INDICATED

value is thesame asthe REALvalue.

.

Indicated value Realvalue

TheMetercalculatesthe new USERK FACTOR ; this calculation

could requirea few seconds,dependingon the correction to

be made

ATTENTION: Ifthisoperationis performed after action (5),

withoutchangingtheindicatedvalue,the USERK FACTORwould

bethesameas theFACTORYK FACTOR,thusitis ignored.

9

NOOPERATION

Atthe end ofthe calculation, thenew USERK FACTOR is shown

fora few seconds,afterwhich therestartcycleis repeated to

nally achieve standby condition.

IMPORTANT:Fromnowon, theindicated factorwillbecome

thecalibration factor used bythe Meterandwill continue to

remain such evenaftera batterychange

10

NO OPERATION

TheMeterstoresthe new workcalibration factorand is

ready tobegin dispensing,usingthe USERK FACTOR that

hasjust beencalculated.

.

H.2.3 DIRECT MODIFICATION OF K FACTOR

If normal Meter operation shows a meanpercentage error, thiscan be corrected by ap-

plying to the currentlyused calibration factor a correction of the samepercentage. In this

case, the percentagecorrection of the USER K FACTOR must be calculated bythe opera-

torin the followingway

1"4';%&K'S%;./#''''T''''O&:'5%&'S%;./#''U ( )

FCC'@'6V

FCC

Example:

Errorpercentagefound: E% - 0.9%

CURRENT calibrationfactor: 1.000

New USER K FACTOR: 1.000* [(100 – ( - 0.9))/100] = 1.000 * [(100 + 0.9)/100] = 1.009

If theMeter indicates lessthan the real dispensed value(negative error) thenew calibra-

tionfactor mustbe higherthan theold one as shown in the example. The oppositeap-

pliesif the Meter shows morethan the real dispensed value(positive error).

ACTION DISPLAY

1

NONE

METER in Standby.

2

CALCAL

CAL

LONG CALKEY KEYING

Meter enters calibrationmode,shows “CAL” anddisplays the

calibrationfactorbeing usedinstead of the partial.The words

“Fact”and“User”indicate whichof thetwo factors (factory or

user) is currently being used.

3

RESET

RESET

RESET

LONG RESETKEYKEYING

TheMetershows“CAL” andthe zeropartialtotal.

Meter is ready toperformin-eldcalibration bydispensing–

seeprevious paragraph.

4

RESET

RESET

RESET

LONG RESETKEYKEYING

Wenow go onto Directchangeof the calibrationfactor:

theword“Direct”appears togetherwith theCurrently Used

calibrationfactor. Inthe bottom left part ofthe display, an

arrow appears(upwards or downwards)dening thedirection

(increase or decrease) ofchangeof the displayed value when

subsequent operations 5 or 6 are performed.

5

RESET

SHORT RESETKEYKEYING

Changesthe direction of thearrow.Theoperation can be

repeatedto alternate thedirection ofthe arrow.

6

CALCAL

CAL

CAL

SHORT/LONGCAL KEYKEYING

Theindicatedvalue changesin the directionindicated by the

arrow

- oneunitfor everyshort CALkey keying

- continuallyif theCAL key is kept pressed.Thespeed increase

risesby keepingthe key pressed. Ifthe desired valueis

exceeded, repeat the operations frompoint(5).

7

RESET

RESET

RESET

LONG RESETKEYKEYING

TheMeteris informed thatthe calibrationprocedure is

nished.

Beforeperforming this operation, makesurethe INDICATED

value is that required.

8

NOOPERATION

Atthe end ofthe calculation, thenew USERK FACTOR is shown

fora few seconds,afterwhich therestartcycleis repeated to

nally achieve standby condition.

IMPORTANT:Fromnowon, theindicated factorwillbecome

thecalibration factor used bythe Meterandwill continue to

remain such evenaftera batterychange

9

NOOPERATION

TheMeterstoresthe new workcalibration factorand is ready

tobegin dispensing,usingthe USERK FACTOR thathas just

beenchanged.

I METER CONFIGURATION

TheMETER feature a menu withwhich theuser can select themain measurement unit,

Quarts(Qts),Pints (Pts), Litres (Lit), Gallons (Gal);

The combination of the unit of measurement of the Partial register and that of the

Totals is predened according to the following table:

Combinationno. Unitof Measurement

Partial Register Unitof Measurement

Totals Register

1 Litres (L) Litres (L)

2 Gallons (Gal) Gallons (Gal)

3 Quarts(Qts) Gallons (Gal)

4 Pints (Pts) Gallons (Gal)

Tochoosebetween the4 available combinations:

1Wait forthe METER togo to Standby

2

CAL

RESET

+

Thenpressthe CALand RESETkeys together. Keep these pressed

until theword“UNIT”appears on the screen together withthe unitof

measurementset at thattime(in thisexampleLitres/ Litres)

3 Everyshort press of theRESET key, the variouscombina-

tionsof the units of measurementsare scrolled as shown

below:

Gal

Qts

Pts

Gal

RESET

RESET

RESET

4

CALCAL

CAL By pressing the CALkey at length, thenew settings will

be stored, the METER willpass through thestart cycleand

willthen be ready to dispensein the setunits.

ATTENTION The Reset Total and Total registers will be auto-

matically changed to the new unit of measure-

ment.

NO newcalibration is required afterchanging the

Unitof Measurement.

L MAINTENANCE

BATTERY

REPLACEMENT

Use 2x1.5V alkalinebatteries sizeAAA

WARNING K24shouldbe installed in a position allowingthe

batteriesto be replaced without removing it from

thesystem.

K24 features two low-battery alarm levels:

1When the battery charge falls below the rst level on the LCD,

the xed battery symbol appears. In this condition, K24 con-

tinues to operate correctly, but the xed icon warns the user

that it is ADVISABLE to change the batteries.

2If K24 operation continues without changing the batteries,

the second battery alarm level will be reached which will

prevent operation. In this condition the battery icon starts to

ash and is the only one to remain visible on the LCD.

o change the

batteries, with

reference to the

exploded diagram

positions, proceed

as follows

1 Press RESET to update all the totals

2 Loosen the 4 xing screws of the lower cover

3 Remove the old batteries

4 Place the new batteries in the same position as the

old ones

5 close the cover again, by positioning the rubber pro-

tection as a gasket

6 K24 will switch on automatically and normal opera-

tion can be resumed

The K24 will display the same Reset Total, the same Total and the same Partial indi-

cated before the batteries were changed.

After changing the batteries, the meter does not need calibrating again.

CLEANING Only one operation is necessary to clean the k24.

After removing k24 from the plant where it was built

in, any residual elements can be removed by washing

or mechanically-handling.

If this operation does not restore a smooth rotation of

the turbine, it will have to be replaced.

ATTENTION Do notdiscardthe oldbatteries in the environment.

Refer tolocal disposalregulations.

Do not use compressed air onto the turbine in

order to avoid its damage because of an exces-

sive rotation

K24Front face replacement

1Carefullyremove thescrewsfrom thecornersof the

front panel, and thencarefully liftthe frontcoverup

awayfromthe main bodyof the meter.

2Carefullyremove thescrewsfrom thecornersof the

front panel, and thencarefully liftthe frontcoverup

awayfromthe main bodyof the meter.

3

Whenthenew panelis tted make sure thepower

adapter is tted correctlywith thelocation pin in the

correctway

4Carefullyretthe display panelbackonto the main

bodymakingsure thewire is tucked into thecorner

andreplacethe screws

M MALFUNCTIONS

Problem Possible cause Remedial Action

LCD: no indication Bad battery contact Check batterycontacts

Notenough measure-

mentprecision

Wrong K FACTOR Withreferenceto paragraph H,

checkthe K FACTOR

Themeter worksbelow

minimum acceptable ow rate.

Increasethe ow rateuntil an

acceptable owrate rangehas

beenachieved

Reduced or zeroow

rate TURBINEblocked Clean the TURBINE

Themeter doesnot

count, butthe ow

rateis correct

Incorrect installation of

gears after cleaning

Repeat the reassembly pro-

cedure

Possible electronic card

problems Contact your dealer

ELECTRONIC TURBINE

METER - PULSER

N DISPOSAL

Foreword If thesystem needs tobe disposed, the parts which makeit up

mustbe delivered to companiesthat specialize in the recycling

and disposal of industrial waste and, in particular:

Disposing of pack-

ingmaterials

Thepackagingconsistsof biodegradable cardboard which canbe

delivered to companies fornormal recycling of cellulose.

Metal PartsDis-

posal

Metalparts, whetherpaint-nished or in stainless steel, can be

consigned to scrap metal collectors.

Disposal of electric

andelectronic

components

These mustbe disposed of by companies that specialize in the

disposal of electroniccomponents, in accordance withthe indica-

tionsof directive2002/96/CE (see text ofdirective below).

Informa-

tionregard-

ingthe en-

vironment

forclients

residing

within theEuro-

peanUnion

EuropeanDirective 2002/96/EC requiresthat allequipment

marked withthis symbol on the product and/or packagingnot

be disposed of together with non-dierentiated urbanwaste.

Thesymbol indicates thatthis product must not bedisposedof

together with normal household waste. It isthe responsibilityof

the owner todisposeof these productsas well asother electric or

electronic equipment by means of thespecicrefuse collection

structures indicated by thegovernment orthe local governing

authorities.

Miscellaneous

partsdisposal

Othercomponents, such aspipes, rubber gaskets, plastic parts

and wires, must bedisposedof by companiesspecialisingin the

disposal of industrial waste.

P EXPLODED VIEWS AND OVERALL DIMENSIONS

/VISTE ESPLOSE ED INGOMBRI