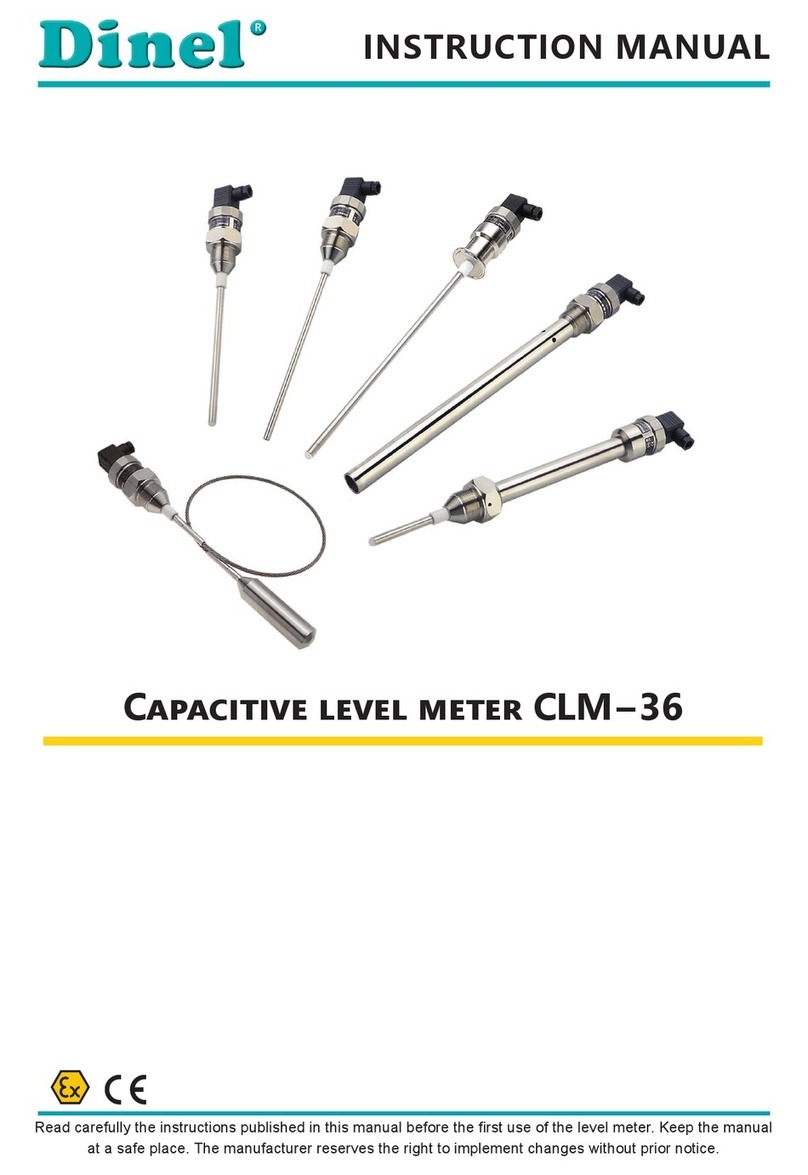

Dinel CLM-36 User manual

Other manuals for CLM-36

2

Table of contents

Other Dinel Measuring Instrument manuals

Dinel

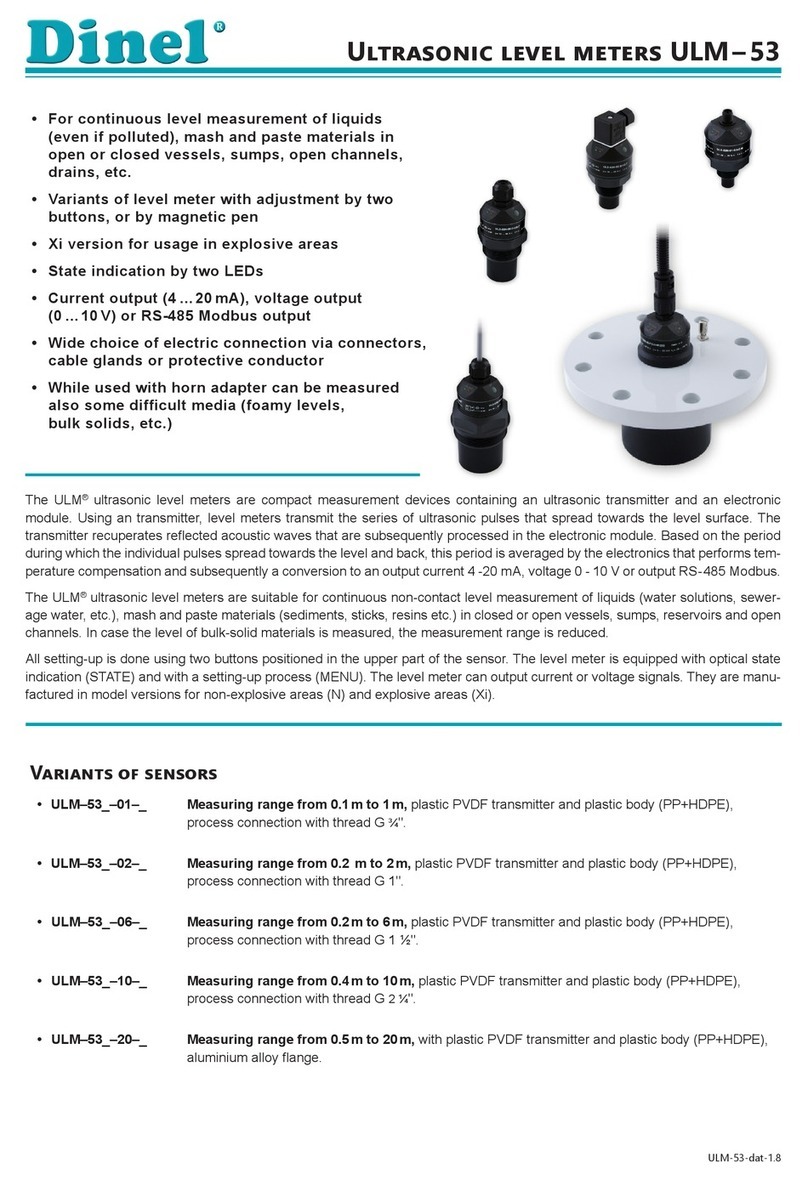

Dinel ULM - 54 User manual

Dinel

Dinel ULM -70 Series User manual

Dinel

Dinel ULM -70 Series User manual

Dinel

Dinel CLM-36 User manual

Dinel

Dinel ULM-53L User manual

Dinel

Dinel GRLM-70 User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel ULM-55N User manual

Dinel

Dinel PDU-40-W Series User manual

Dinel

Dinel MLM-35 User manual

Popular Measuring Instrument manuals by other brands

Levenhuk

Levenhuk Ermenrich Verk DA40 user manual

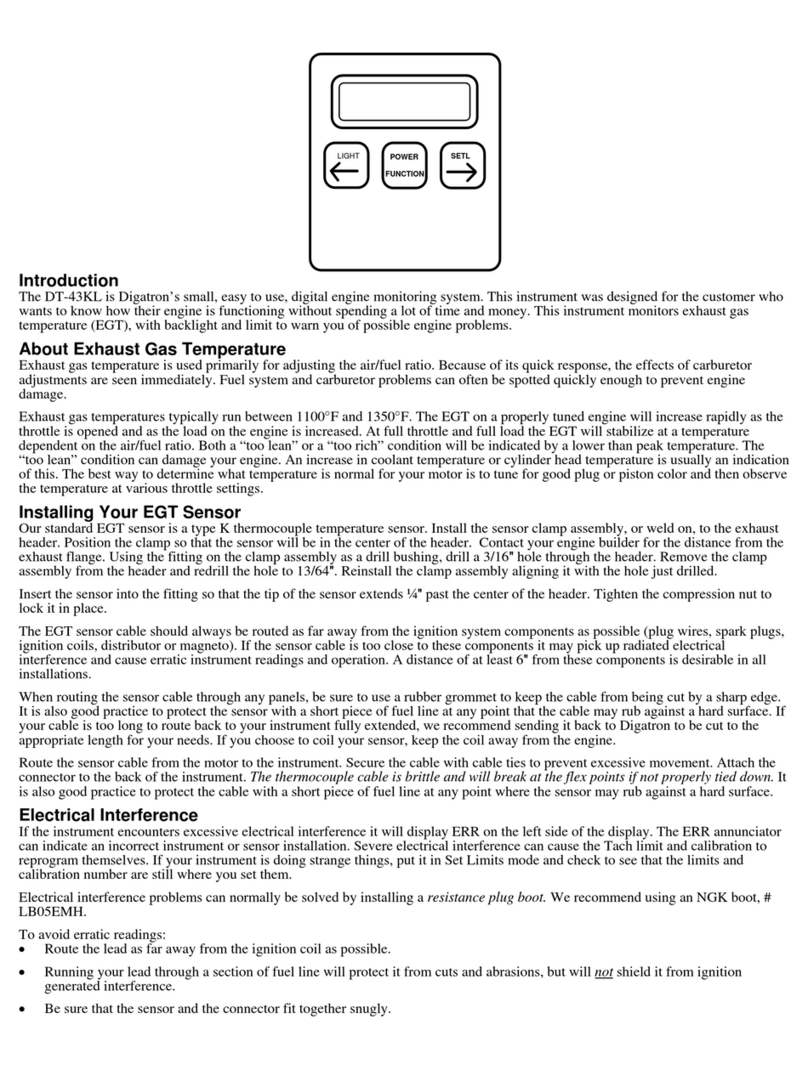

Digatron

Digatron DT-43KL manual

Riken Keiki

Riken Keiki RI-85 operating manual

Endress+Hauser

Endress+Hauser Analytikjena SELECT Head 8/250 ml operating manual

Tektronix

Tektronix TPR1000 Compliance and Safety Instructions

Hilti

Hilti PR 30-HVS A12 operating instructions

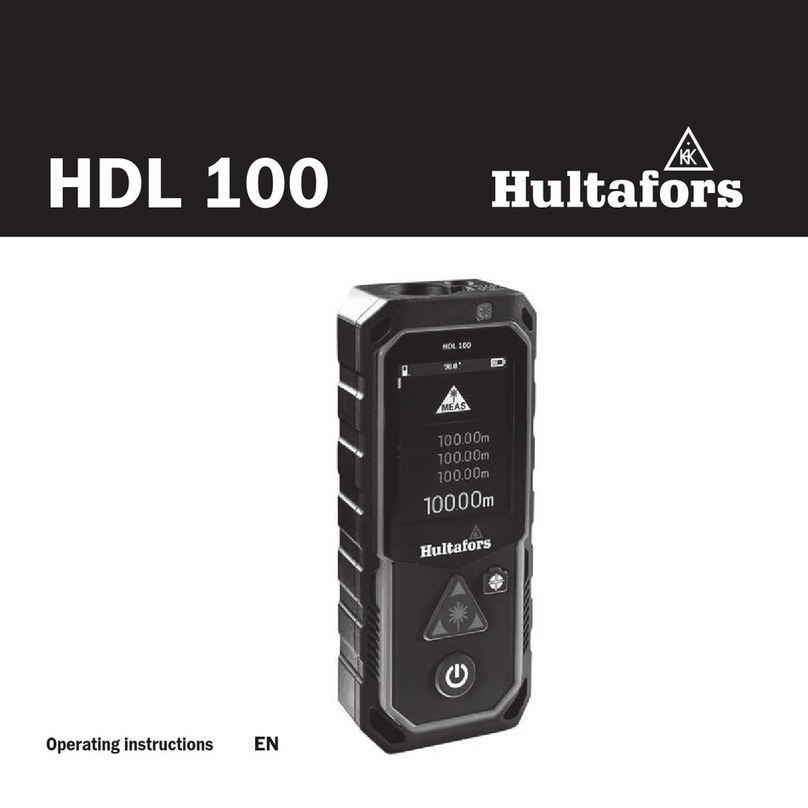

Hultafors

Hultafors HDL 100 operating instructions

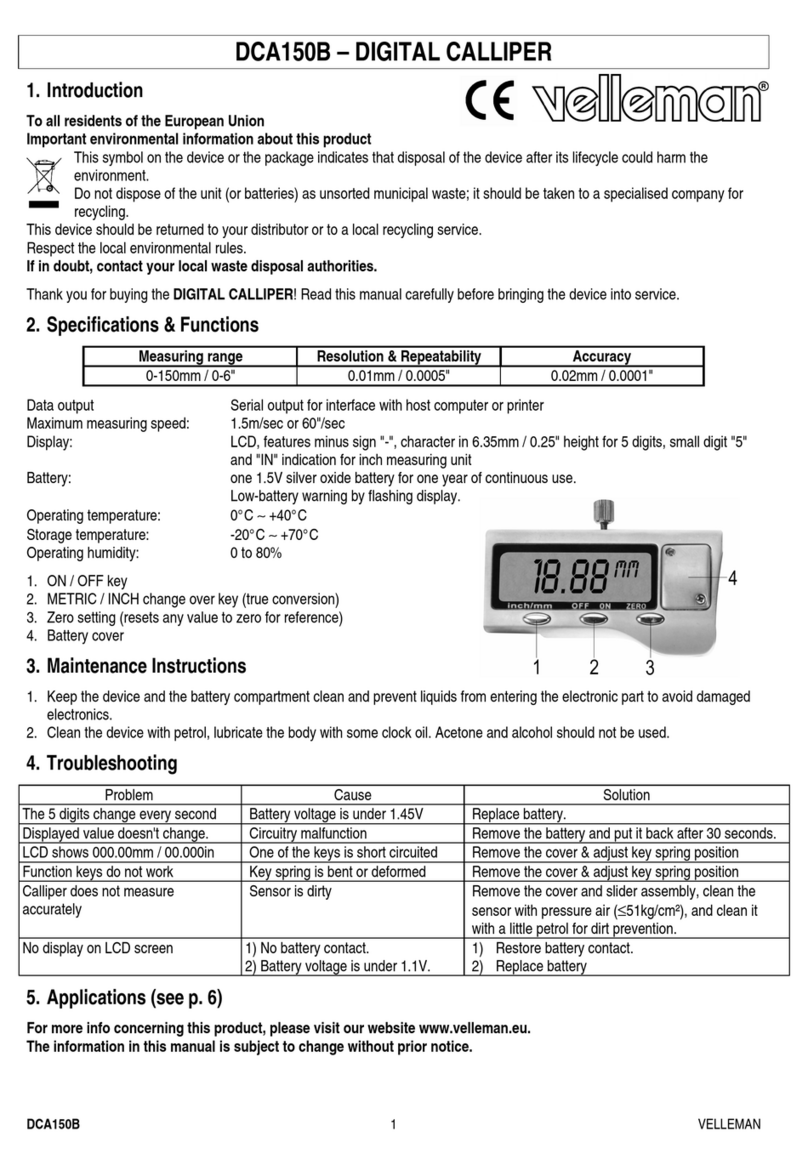

Velleman

Velleman DCA150B manual

DeFelsko

DeFelsko PosiTector PC instruction manual

PCE Instruments

PCE Instruments PCE-DT 50 instruction manual

Levenhuk

Levenhuk Wezzer Air PRO DM30 user manual

PCB Piezotronics

PCB Piezotronics ICP 355A44 Installation and operating manual