Sonel PAT-810 Installation manual

OPERATING MANUAL

ELECTRICAL APPLIANCE

SAFETY TESTERS

PAT-810, PAT-815 and PAT-820

SONEL S. A.

11 Wokulskiego Str.

58-100 Świdnica, Poland

Version 1.06 24.10.2017

OPERATING MANUAL PAT-810/815/820 version 1.06

2

PAT-810/815/820 testers are modern, high-quality testers, easy and safe in operation. Please ac-

quaint yourself with the present manual in order to avoid measuring errors and prevent possible prob-

lems related to operation of the tester.

OPERATING MANUAL PAT-810/815/820 version 1.06

3

TABLE OF CONTENTS

1SAFETY ................................................................................................................. 5

2GENERAL DESCRIPTION AND FEATURES OF THE INSTRUMENT ............................. 6

3SWITCHING ON AND MAIN MENU........................................................................ 8

3.1 POWER SUPPLY ........................................................................................................... 8

3.2 START TEST AFTER SWITCHING THE TESTER ON .................................................................. 8

3.3 GENERAL SETTINGS –MENU ........................................................................................ 9

3.3.1 Symbols on screen.......................................................................................... 10

3.3.2 Setting date and time .................................................................................... 11

3.3.3 Interface settings ........................................................................................... 13

3.3.4 Measurement settings ................................................................................... 14

3.3.5 Printing........................................................................................................... 15

3.3.6 PAT specifications .......................................................................................... 16

3.3.7 Firmware upgrade.......................................................................................... 17

3.3.8 Information about tester and producer ......................................................... 19

3.3.9 Service ............................................................................................................ 19

3.3.10 Network setting .......................................................................................... 19

3.3.11 List of Users................................................................................................. 22

3.3.12 Memory structure (Clients, Objects, Subobjects and Appliances)............... 24

3.3.12.1 Adding Clients...................................................................................................... 24

3.3.12.2 Adding Objects..................................................................................................... 26

3.3.12.3 Adding Appliances. .............................................................................................. 28

3.3.12.4 Deleting clients, objects and appliances. ............................................................. 29

3.3.13 Communication with PC.............................................................................. 30

4MEASUREMENTS................................................................................................ 31

4.1 PRELIMINARY TEST .................................................................................................... 31

4.2 MEASUREMENT OF PE RESISTANCE............................................................................... 32

4.3 MEASUREMENT OF INSULATION RESISTANCE .................................................................. 35

4.3.1 Measurement of RISO on Class I devices.......................................................... 36

4.3.2 Measurement without using the test socket ................................................. 37

4.3.3 Measurement of RISO on Class II (III) devices .................................................. 37

4.3.4 RISO measurement of IEC power cord ............................................................. 38

4.4 DURABILITY OF INSULATION (FLASH TEST)–ONLY PAT-820.............................................. 38

4.4.1 Measurement on Class I devices .................................................................... 39

4.4.2 Measurement on Class II devices ................................................................... 40

4.5 MEASUREMENT OF SUBSTITUTE LEAKAGE CURRENT.......................................................... 41

4.6 MEASUREMENT OF PE LEAKAGE CURRENT ..................................................................... 43

4.7 MEASUREMENT OF DIFFERENTIAL LEAKAGE CURRENT ....................................................... 45

4.8 MEASUREMENT OF TOUCH LEAKAGE CURRENT ................................................................ 48

OPERATING MANUAL PAT-810/815/820 version 1.06

4

4.9 MEASUREMENT OF PAND SPOWER,PF POWER FACTOR,CURRENT CONSUMPTION AND

VOLTAGE ...........................................................................................................................50

4.10 CURRENT MEASUREMENT WITH CLAMP (ONLY PAT-815 AND PAT-820)..........................52

4.11 IEC CABLE TEST ......................................................................................................54

4.12 MEASUREMENT OF FIXED RCD PARAMETERS ...............................................................56

4.13 AUTO MODE TESTS ................................................................................................58

4.13.1 Configuring AUTO mode tests .....................................................................58

4.13.2 AUTO mode tests.........................................................................................59

4.13.3 Doing measurements (of items like IEC leads, extension leads) with RCD in

AUTO mode .................................................................................................................62

5MEMORY OF MEASUREMENT RESULTS DATA .....................................................67

5.1 STORING THE MEASUREMENT RESULTS IN THE MEMORY ....................................................67

5.2 BROWSING MEMORY DATA..........................................................................................68

5.3 SEARCHOPTION IN THE MEMORY................................................................................69

5.4 MOVING APPLIANCE INTO ANOTHER OBJECT ..................................................................71

5.5 COPYING CLIENTS DATA FROM MEMORY INTO USB FLASH DRIVE (BACK AND FORTH) .............72

5.6 DELETING MEMORY DATA............................................................................................73

6LABEL PRINTING .................................................................................................73

7CLEANING AND MAINTENENCE...........................................................................75

8STORAGE ............................................................................................................75

9DISMANTLING AND DISPOSAL ............................................................................75

10 ANNEXES ............................................................................................................75

10.1 SPECIFICATIONS .....................................................................................................75

10.2 STANDARD ACCESSORIES ..........................................................................................83

10.3 OPTIONAL ACCESSORIES...........................................................................................83

11 MANUFACTURER ................................................................................................84

OPERATING MANUAL PAT-810/815/820 version 1.06

5

1 Safety

PAT-810/815/820 testers are designed for performing check tests on electrical equipment, provid-

ing measurement results which determine the safety status of tested devices. Therefore, in order to

provide conditions for correct operation and the correctness of the obtained results, the following rec-

ommendations must be applied:

Before you commence operating the tester, acquaint yourself thoroughly with the present manual

and observe the safety regulations and specifications determined by the manufacturer.

Any application that differs from those specified in the present manual may result in a damage to

the device and constitute a source of danger for the user.

PAT-810/815/820 testers must be operated only by appropriately qualified personnel. Operating

the tester by unauthorised personnel may result in damage to the device and constitute a source

of danger for the user.

Using this manual does not exclude the need to comply with occupational health and safety regu-

lations and with other relevant fire regulations required during the performance of a particular type

of work. Before starting the work with the device in special environments, e.g. potentially fire-

risk/explosive environment, it is necessary to consult it with the person responsible for health and

safety.

It is forbidden to operate the following:

A damaged tester which is completely or partially out of order,

A tester with damaged test leads insulation,

A tester stored for an excessive period of time in disadvantageous conditions (e.g. excessive

humidity). If the tester has been transferred from a cool to a warm environment with a high-

level of relative humidity, do not start measurements until the tester is warmed up to the am-

bient temperature (approximately 30 minutes).

The tester may be powered only from grounded mains sockets.

Before starting any measurement, make sure the test leads are connected to the proper test

sockets.

Do not touch the tested device during measurements.

Test sockets and the socket for testing IEC cables are protected against improper connection to

the voltage up to 300V AC for 60 seconds.

Repairs may be carried out only by an authorised service point.

NOTE!

Only standard and additional accessories for a given device should be used, as listed

in the "Equipment" section. Use of different accessories can lead to errors in the test

connection and can introduce additional measurement uncertainties.

NOTE:

Due to continuous development of the tester’s software, the actual appearance of the

display, in case of some of the functions, may slightly differ from the display presented

in this operating manual.

OPERATING MANUAL PAT-810/815/820 version 1.06

6

Note:

An attempt to install drivers in 64-bit Windows 8 may result in displaying "Installation

failed" message.

Cause: Windows 8 by default blocks drivers without a digital signature.

Solution: Disable the driver signature enforcement in Windows.

2 General description and features of the instrument

PAT-810/815/820 digital testers are intended to measure the basic parameters of portable elec-

trical devices (power tools, household appliances, etc.) important for their safety: protective conductor

resistance, insulation resistance, continuity of connections, leakage current and RCDs.

The testers may be used to test equipment in accordance with the following standards:

EN 60745-1 Hand-held motor-operated electric tools. Safety. Part 1: General requirements.

EN 61029 Safety of transportable motor operated electric tools. General requirements.

EN 60335-1 Household and similar electrical appliances. Safety. Part 1: General requirements.

EN 60950 Information technology equipment –Safety- Part 1: General requirements.

EN 61557-6 Electrical safety in low voltage distribution systems up to 1 000 V a.c. and 1 500 V

d.c. - Equipment for testing, measuring or monitoring of protective measures - Part 6: Effective-

ness of residual current devices (RCD) in TT, TN and IT systems.

VDE 0404-1 Testing and Measuring Equipment for Checking the Electric Safety of Electric De-

vices - Part 1: General Requirements.

VDE 0404-2 Testing and Measuring Equipment for Checking the Electric Safety of Electric De-

vices - Part 2: Testing Equipment for Tests after Repair, Change or in Case of Repeat Tests.

VDE 0701-0702 Inspection after Repair, Modification of Electrical Appliances.

Repeat Testing of Electrical Equipment. General Requirements for Electrical Safety.

AS/NZS 3760:2010 In-service safety inspection and testing of electrical equipment.

Basic functions of the instrument:

Measurement of network voltage and frequency

Checking the resistance of L-N circuit

Measurement of protective conductor resistance (Protection class - I):

technical measurement method

measurement with sinusoidal current of network frequency and following currents: 200mA,

10A (only PAT-815/820) and 25 A (only PAT-815/820)

adjustable measurement time

adjustable upper limit in the range of: 10mΩ…1.99Ω with 0.01Ωresolution

Measurement of insulation resistance:

three test voltages: 100 V (only PAT-815/820), 250 V (only PAT-815/820) and 500 V

measurement of insulation resistance up to 599 M

automatic discharge of the capacitance of tested object after the insulation resistance meas-

urement is completed

adjustable measurement time

adjustable lower limit within the range of 0.1 ….9.9 MΩ with 0,1MΩresolution

Flash test (only PAT-820)

OPERATING MANUAL PAT-810/815/820 version 1.06

7

Measurement of substitute leakage current::

adjustable measurement time

adjustable upper limit in the range of: 0.01 ... 9.9 mA with 0.01mA/0.1mA resolution

Measurement of PE leakage current:

adjustable measurement time

adjustable upper limit in the range of: 0.01 ... 9.9 mA with 0.01mA/0.1mA resolution

measurement of the current with clamp

Measurement of differential leakage current:

adjustable measurement time

adjustable upper limit in the range of: 0.01 ... 9.9 mA with 0.01mA/0.1mA resolution

measurement of the current with clamp

Measurement of touch leakage current:

adjustable measurement time

adjustable upper limit in the range of: 0.01 ... 1.99 mA with 0.01mA/0,1mA resolution

Measurement of Power

P and S Power measurement

PF Power Factor measurement

Current consumption measurement

Measurement with the PAT's internal measurement circuits or with clamp

Measurement of RCD’s parameters

IΔn= 10 mA, 15 mA, 30 mA

Measurement of IA, tAfor 0,5 IΔn, 1 IΔn, 2 IΔn,5 IΔn

IEC lead test

Other:

automatic selection of measuring range

tree structure of measurement results memory with provision of printing or transfering the re-

sults to PC via USB facilities

configurable with a bar-code scanner and printer

industrial computer equipped with large, readable, touch graphic display

PAT's power supply sustained for 15 minutes after disconecting mains power supply with the

use of built-in battery

ergonomic operation

OPERATING MANUAL PAT-810/815/820 version 1.06

8

3 Switching on and Main Menu

3.1 Power supply

The device is 195 V…265 V, 50 Hz mains powered.

Two 15A fuses protect L and N lines from the supply socket to the test socket, they are tripped

when current consumption from the test socket is too high (>16A).

500mA fuse protects 200mA current controller for RPE measurement.

3.2 Start test after switching the tester on

After switching on, the tester performs a self-test to check its correct operational condition and

when this test is successfully completed, the tester automatically performs the following measure-

ments:

measurement of the voltage in the power supply socket, i.e. the voltage between L and N of

power supply to the tester,

measurement of mains frequency,

checking the continuity PE in the power supply socket,

measuring the voltage between N and PE in the power supply socket,

indicates swapped L and N terminals (icon on the screen).

Upon completing above mentioned measurements main Menu screen is displayed as below,

along with the results of the measurements:

OPERATING MANUAL PAT-810/815/820 version 1.06

9

Note:

- For mains voltages below 195 V and above 256 V all test functions are automatically locked out.

Additional information displayed on the screen

On the right upper corner of the screen mains network monitor is presented. It shows polarity of

the power supply, voltage between N and PE, voltage between L and N, and mains frequency.

Other information:

Dangerous voltage

on PE

Voltage UN-PE > 25 V or lack of PE continuity, measurements

are blocked.

Note: Incorrect volt-

age of the supply.

Switch on tester

again with an audible

signal

Mains voltage > 265 V, measurements are blocked.

Correct polarity of power supply (L i N), measurements pos-

sible.

Uncorrect polarity of power supply, swapped L and N in the

power supply socket of the tester. PAT automatically swaps

L and N in the tester’s test socket, and measurements are

possible.

Note:

- Error message indicating incorrect voltage frequency may be caused by supplying power from an

unstable voltage source (e.g. generator).

3.3 General settings –MENU

In the MENU the following actions are available:

Auto tests,

Manual tests,

Browse memory,

Configuration of tester:

Date and time: setting date and time,

Interface: swithing on/off audible signals and choice of language,

Tests: setting nominal mains voltage and additional options,

Printing: printing settings,

Specifications,

About tester and producer,

Firmware upgrade (update),

Service,

Network setting: Wi-Fi confoguration,

List of users,

PC connection.

OPERATING MANUAL PAT-810/815/820 version 1.06

10

Notes:

- Settings are saved and remembered after switching off the tester.

- Auto tests, Manual tests and Browsing memory are described in other chapters of this manual.

3.3.1 Symbols on screen

- go back to the main menu

- add new element (client, site, appliance), another measurement in multibox function

- save data (select device when saving to memory)

- opening Site or Appliance data

- deleting Site or Appliance

- moving Appliance into other Site

- move one level up

or - previous screen (window)

or - next screen

- close the window without saving changes

- searching (e.g. client, site, appliance)

- help

- editing data of the selected element (e.g. client, site, appliance)

or - checkbox , mark inside the square means that the selected option is on or

given content assigned to this field has been confirmed and is correct.

OPERATING MANUAL PAT-810/815/820 version 1.06

11

- commencing Auto test procedure

- connection with selected network WiFi (see sec.3.3.10)

Others:

- connect measurement probe to the object

- appliance under test must be switched on

- NOTE: mains voltage in the measurement socket of the tester during the mesurement.

Appliance under test will switch on and go

- press START to start the test

- the tester is ready to commence the test

- test procedure is in progres

3.3.2 Setting date and time

Press Configuration of tester.

Press Date and Time.

OPERATING MANUAL PAT-810/815/820 version 1.06

12

Press the field you intend to

change.

In the date edit window type

in proper value and press

to proceed to editing next pa-

rameter or press Enter to

save changes and close the

window.

After entering new values

press Set to confirm the date

and time settings.

OPERATING MANUAL PAT-810/815/820 version 1.06

13

3.3.3 Interface settings

Press Configuration of tester.

Press Interface.

Pressing sqare Auto Incre-

ment Appliance/Device ID

‘ON’ turn on or off automatic

incrementing of the registra-

tion number assigned to the

next added device.

Pressing sqare Sound mes-

sages turn on or off sound

signals.

Pressing Language go to the

choice of language.

OPERATING MANUAL PAT-810/815/820 version 1.06

14

3.3.4 Measurement settings

Press Configuration of tester.

Press Test.

Select chosen options by tick-

ing empty squares.

Press Mains nominal volt-

age [V]: 220/230/240, to

change nominal network volt-

age powering the tester.

Select the proper voltage, and

close the window.

Notes:

- Warnings:

Show warning about dangerous voltage –switch on/off warnings about the possibility of the volt-

age being dangerous to user that may appear during tests.

Show warning about switched off appliance –switch on/off notification that the tested device is

not connected or it's not turned on.

Warn about the possibility of losing unsaved results –switch on/off warning indicating possible

loss of unsaved data, e.g. when the user is closing windows filled with data without saving changes.

Note: It is advised for less experienced users to keep all the above warnings on.

OPERATING MANUAL PAT-810/815/820 version 1.06

15

- Auto-tests:

Perform auto-tests automatically –switch on/off automatic mode of performing autotests, which is

performing the complete set of autotests after single press of START button.

- Polarity IEC L-N:

Allow reverse polarity IEC L-N –allows interchanging of L and N lines in the tested IEC conductor,

the test result is displayed as positive.

- Power cord for the device:

Save lead –after ticking this box, the power cord is saved in the memory and printed on a printout as

a separate device, otherwise it is considered as an integral part of the device.

3.3.5 Printing

Press Configuration of tester.

Press Print.

Select chosen options by tick-

ing empty squares.

Notes:

Enable print document –enable/disable printer.

Auto print: –printing automatically after the test is finished.

Logo –placing SONEL logo on the print-out.

Prefered format:

Detailed –contains a list of questions of the visual examination together with the assessment and

the results of individual measurements with the assessment.

Standard –includes overall result of the test, logos and additional data (name of the device, measur-

ing person).

Shorted –similar to standard format but without the logo and additional information.

Templates for automatic printout:

OPERATING MANUAL PAT-810/815/820 version 1.06

16

Appliance label –label with a test result of an appliance.

Appliance + IEC label –label with a test result of an appliance and IEC power cord.

RCD label –label with an RCD test result.

Print line with retest [months]: –Printing stripe on the left, right, or both sides of the label, depend-

ing on the number of the months, after which retest of the appliance must be done. The number of

months is selected by clicking on proper field, similarily to setting date and time.

3.3.6 PAT specifications

Press Configuration of tester.

Press Specifications.

A window with general meas-

urement parameters of the

tester will be displayed. Detai-

led parameters are listed in

the PAT Operating Manual.

OPERATING MANUAL PAT-810/815/820 version 1.06

17

3.3.7 Firmware upgrade

In order to upgrade the PAT's firmware, new firmware has to be downloaded from

www.sonel.pl/en website. The new firmware file has to be uploaded into USB flash drive. It is advised

to copy all the data from the tester's memory before starting upgrading procedure, to avoid accidental

memory erase.

Press Configuration of tester.

Press Update.

Read the warning message.

To perform an update insert

the USB drive with the update

files and click Update or en-

sure Internet connection of

the meter via WiFi, and click

Download and update.

Press YES only if the up-

grade asks for it, as all data

stored in the memory will

be erased, along with all

user settings. In most ca-

ses user should press NO.

OPERATING MANUAL PAT-810/815/820 version 1.06

18

This screen shows up only

when USB flash drive is not

inserted or it's not detect-

ed/proper. Insert USB flash

disk with upgrade files on it

and press Update to upgrade

the firmware or press Cancel

to cancel upgrading proce-

dure.

Note:

- Firmware upgrade is preformed automatically and can be completed in several stages. During the

upgrade procedure it is not allowed both to switch off the tester's power supply and to remove USB

flash drive. Once the upgrade is completed it will be confirmed by the below message.

Remove USB flash disk and

press OK to complete the up-

grade procedure.

Note:

- Upon completing this operation the tester will reset. It is not allowed to swith off the tester's power

supply at this stage. The upgrading/configuring changes process is continued and will last until main

MENU screen comes up.

Only at this stage it is allowed

to switch off the power supply

or to start using the tester.

This manual suits for next models

2

Table of contents

Other Sonel Measuring Instrument manuals

Sonel

Sonel MRU-200-GPS User manual

Sonel

Sonel MZC-304 User manual

Sonel

Sonel LXP-2 User manual

Sonel

Sonel MRU-10 User manual

Sonel

Sonel MRU-11 User manual

Sonel

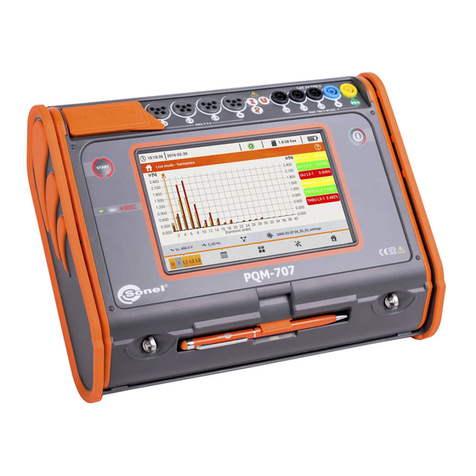

Sonel PQM-702 User manual

Sonel

Sonel CMP-402 User manual

Sonel

Sonel MIC-5010 User manual

Sonel

Sonel LKZ-2500 User manual

Sonel

Sonel CMP-200 User manual

Sonel

Sonel LXP-1 User manual

Sonel

Sonel LMW-100 User manual

Sonel

Sonel WMGBMRU120 User manual

Sonel

Sonel MIC-10k1 User manual

Sonel

Sonel MPI-525 User manual

Sonel

Sonel MIC-2501 User manual

Sonel

Sonel LXP-2 User manual

Sonel

Sonel MRU-200 User manual

Sonel

Sonel KT-128 User manual

Sonel

Sonel CMP-200 User manual