Manitowoc MLC165 User manual

Other Manitowoc Construction Equipment manuals

Manitowoc

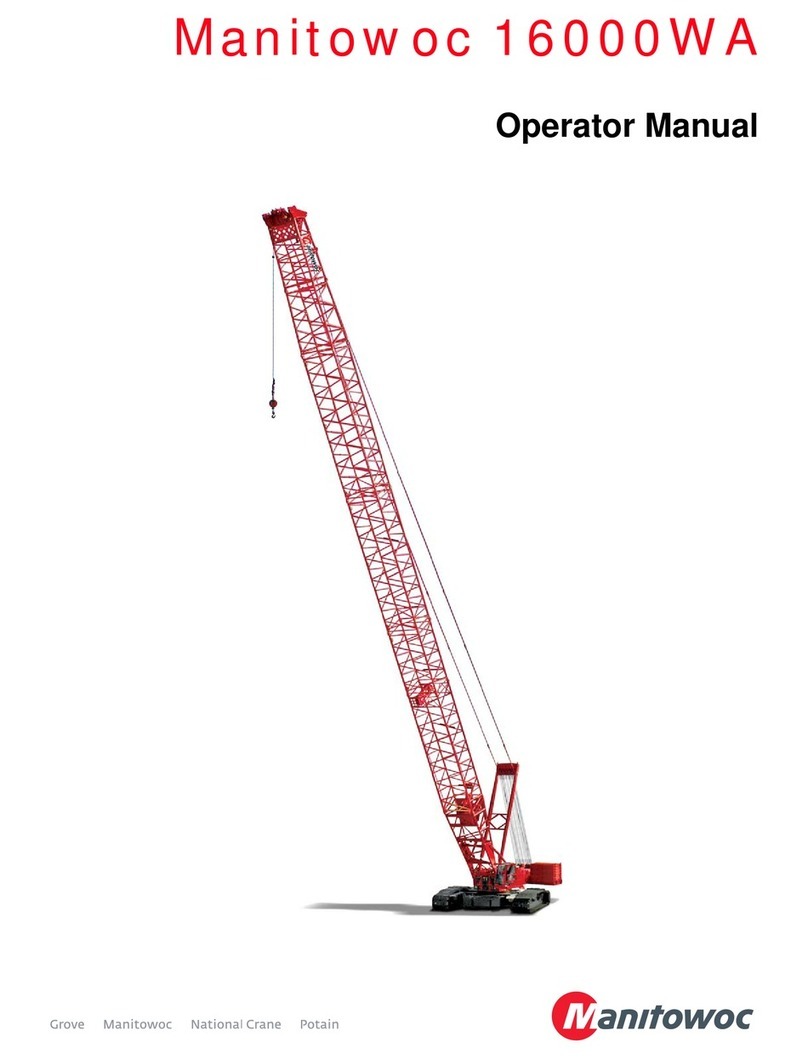

Manitowoc 16000 Series 2 User manual

Manitowoc

Manitowoc MLC80A-1 Installation and user guide

Manitowoc

Manitowoc National Crane NBT50L Series User manual

Manitowoc

Manitowoc 14000 Installation and user guide

Manitowoc

Manitowoc Grove GRT8120 User manual

Manitowoc

Manitowoc MLC80A-1 User manual

Manitowoc

Manitowoc MLC150-1 User manual

Manitowoc

Manitowoc GROVE GMK7450 User manual

Manitowoc

Manitowoc MLC300 User manual

Manitowoc

Manitowoc MLC300 User manual

Manitowoc

Manitowoc GHC 75 Technical specifications

Manitowoc

Manitowoc GROVE GMK 4100 User manual

Manitowoc

Manitowoc 14000 User manual

Manitowoc

Manitowoc Grove RT530E-2 User manual

Manitowoc

Manitowoc Grove TMS800E Installation and user guide

Manitowoc

Manitowoc Grove TMS9000-2 Series User manual

Manitowoc

Manitowoc MLC300 User manual

Manitowoc

Manitowoc MLC300 User manual

Manitowoc

Manitowoc Grove RT770E User manual

Manitowoc

Manitowoc 14000 User manual