Mantech L100 PeCOD User manual

1

L100 PeCOD® COD ANALYZER

Operation Manual

2

Table of Contents

1Introduction ..................................................................................................................................................................................3

1.1 The L100 PeCOD® COD Analyzer...........................................................................................................................................3

1.2 Theory of Operation Mechanism .........................................................................................................................................3

Photocatalytic Oxidation ............................................................................................................................................3

1.3 Technical and General Specifications ...................................................................................................................................4

2General Information......................................................................................................................................................................5

2.1 Safety Information................................................................................................................................................................5

Use of Hazard Information..........................................................................................................................................5

Precautionary Labels ..................................................................................................................................................6

2.2 Overview of Product and Function.......................................................................................................................................6

User Interface (front panel) ........................................................................................................................................7

3Installation ....................................................................................................................................................................................7

3.1 Unpacking the Instrument....................................................................................................................................................7

3.2 Operating Environment ........................................................................................................................................................8

3.3 Power Connections ..............................................................................................................................................................8

3.4 Battery Power.......................................................................................................................................................................8

3.5 Personal Computer (PC) Connection ....................................................................................................................................8

4System Operations ........................................................................................................................................................................8

4.1 Overview ..............................................................................................................................................................................8

4.2 Getting Started – Powering the Analyzer On........................................................................................................................9

4.3 Preparation of Solutions.......................................................................................................................................................9

4.4 Priming of Lines..................................................................................................................................................................10

4.5 New Sensor Routine and Calibration..................................................................................................................................10

4.6PeCOD® Menu Structure ....................................................................................................................................................11

4.7 Running a Sample...............................................................................................................................................................15

4.8 Other Operational Functions..............................................................................................................................................16

Event Log ..................................................................................................................................................................16

Run Standby..............................................................................................................................................................16

4.9 Diagnostic Functions .....................................................................................................................................................16

Factory Settings ........................................................................................................................................................16

System Reset.............................................................................................................................................................17

Set PIN Number ........................................................................................................................................................17

Erase Logs .................................................................................................................................................................17

5Preventitive Maintenance ...........................................................................................................................................................18

5.1 Cleaning Requirements ......................................................................................................................................................18

Tubing and Fluids......................................................................................................................................................18

Analyzer ....................................................................................................................................................................18

Sensor.......................................................................................................................................................................18

5.2 Battery Pack .......................................................................................................................................................................18

5.3 System Storage...................................................................................................................................................................18

Flushing and Storing the Electrode Block .................................................................................................................18

6Troubleshooting ..........................................................................................................................................................................19

6.1 System Diagnostics.............................................................................................................................................................19

6.2 Removing Blockages from the PeCOD® Analyzer ...............................................................................................................23

7Replacement Parts, Accessories and Consumables ....................................................................................................................24

Appendix 1 Warranty..............................................................................................................................................................25

Warranty ..........................................................................................................................................................................................25

Change to specifications...................................................................................................................................................................26

Liability .............................................................................................................................................................................................26

Appendix 2 Glossary of Terms.................................................................................................................................................27

3

1. Introduction

1.1 The L100 PeCOD® Soluble COD Analyzer

Thank you for purchasing the L100 PeCOD® COD analyzer. The L100 PeCOD® COD analyzer has been specifically

designed for quantifying the organic content using a patented photo-electrochemical technique to determine the

Chemical Oxygen Demand (COD). No toxic reagents are required, making this technique an environmentally

friendly method for COD and rapid screening of Biological Oxygen Demand (BOD).

MANTECH products are manufactured, tested and calibrated to meet published standard specifications under

our strict quality assurance guidelines. The main components consist of the sensor, electrode block, light source,

and three ports (one each for sample, blank solutions and waste).

Please read this manual thoroughly before operating your L100 analyzer.

The L100 analyzer is designed to be used only by properly qualified and trained personnel.

1.2 Theory of Operation Mechanism

Photocatalytic Oxidation

The PeCOD® L100 analyzer employs a unique patented technology that can directly measure photocurrent

originating from the oxidation of organic species contained in a sample. The core of the technology is the PeCOD®

sensor, which consists of a UV-activated nano-particulate TiO2 (titanium dioxide) photocatalyst coupled to an

external circuit.

The sample is introduced into a microcell containing the sensor. The TiO2 is irradiated by UV light, and a potential

bias is applied. The UV light creates a photo hole in the TiO2 sensor with a very high oxidizing power (3.1V) and

organic contents in the cell are oxidized (the chemical potential of the dichromate method is only 1.6V). The

PeCOD® COD analyzer exhaustively oxidizes organics, and counts the electrons that are liberated to provide a

direct measure of equivalent COD.

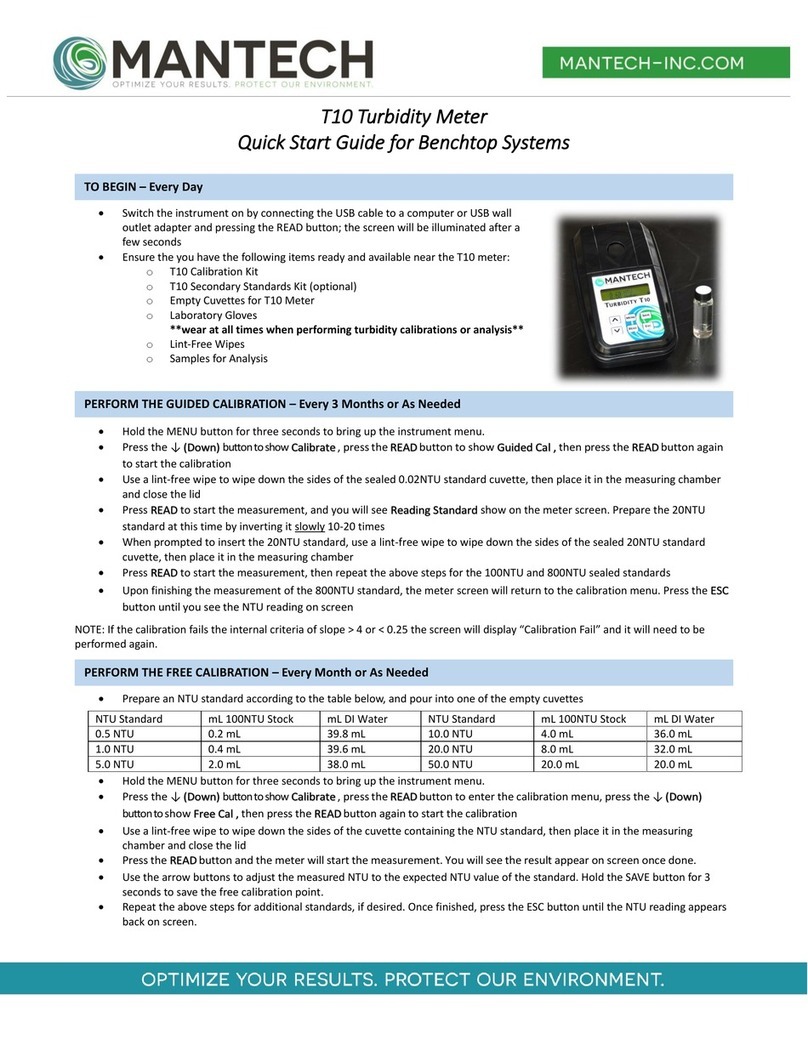

The following figure illustrates the photo-electrocatalytic process involved in the analytical signal generation.

4

The PeCOD® L100 analyzer gives a direct measurement of the oxidation of organic compounds, thus providing a

real measurement of organic pollutants and not an inferred one. The reaction produces mainly carbon dioxide

& water from organic C, H and O.

1.3 Technical and General Specifications

* Specifications are subject to change without notice

ANALYSIS DATA

Oxidation process

Photocatalytic oxidation

Catalyst

Titanium Dioxide (TiO2)

Method Detection Limit

*0.7ppm

Reproducibility

+/- 10%

Light source

UV LED

*MDL determined for Advanced Blue range

GENERAL SPECIFICATIONS

Construction

ABS

Dimensions (approximate L x W x H)

370mm x 230mm x 240mm

Weight

< 5 kg

Security

4 digit pin (optional)

Parameter(s)

COD (unit of measurement: ppm or mg/L)

BOD (ppm or mg/L)

Measurement

Dilution ≤ 15,000 ppm

ELECTRICAL AND STANDARDS CONFORMITY

Power Requirements

100V to 240V AC / 45 to 65 Hz INPUT – 24V DC X

Amp OUTPUT, Optional battery pack for field use

Current Consumption

2.0 A (maximum)

Enclosure

IP55 to EN60529

Protection Class

Continuous short circuit protection. CEC Level IV

compliant. UL compliant

EMC Emission and Noise Immunity

EN61326-1:2006

FCC Part 15 Subparts A and B

Certification

CE. FCC

5

Environmental conditions

Ambient Operating Temperature: 10 to 30 °C

Storage Temperature: 5 to 40 °C

Relative Humidity: Max 90% non-condensing

DATA DISPLAY, INPUTS AND OUTPUTS

Display

4 x 20 characters

Keypad

Splash resistant capacitive touch user interface

Data Presentation

Alpha Numeric

Data Logging

Up to 200,000 measurements, events and faults

Fault Monitoring

Error code reporting of faulty conditions

Computer Interface

USB for data and control

2. General Information

2.1 Safety Information

Please read this entire manual before unpacking, setting up and operating this equipment. Pay attention to all

danger and caution statements. Failure to do so could result in damage to the equipment.

To ensure that the protection provided by this equipment is not impaired, do not use or install this equipment in

any manner other than that specified in this manual.

In addition to the instructions in this manual, users must comply with the national general safety and accident

prevention regulations of the country in which the instrument is used.

The UV light is automatically cut off when the analyzer head is open. However, as a safety measure, do not look

directly into the UV light source at any time.

Use of hazard information throughout this manual:

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate injury.

IMPORTANT NOTE

Information that requires special emphasis.

NOTE

Information that supplements points in the main text.

6

Precautionary Labels

Read all labels and tags attached to the instrument. Although highly unlikely, personal injury or damage to the

instrument could occur if not observed.

2.2 Overview of Product and Function

The L100 analyzer is comprised of the following major components:

•Sensor: contains the cell and TiO2 (working electrode) and is the location for photocatalytic activity.

•Electrode block: contains the reference and auxiliary electrodes.

•UV LED as the light source: 400nm wavelength

•Detector (potentiostat)

•Port A and Port B for sample and blank solutions, respectively

•Port W for waste solution

The L100 employs a unique nanotechnology-based photo-electrochemical technique for the determination of

COD in natural and wastewater samples in laboratory and field analyses. It is:

•fast (a typical analysis takes less than 15 minutes),

•sensitive (detection limit at 0.7 ppm level in Advanced Blue range),

•environmentally friendly (does not require any toxic / hazardous chemicals),

•robust, and

•free of the matrix effect due to the highly effective photo-electrochemical system employed that is

capable of fully oxidizing a wide spectrum of organics.

The photocurrent generated is detected with a potentiostat.

The L100 analyzer provides digital readout of COD in ppm or mg/L units. It also provides the equivalent BOD value

(if this function is selected during the parameter set up).

When a user-generated or programmed method is selected, the on-screen menus and prompts direct the user

through the test. The L100 analyser can be connected to a PC with pre-installed software using a USB cable. See

"Note:" in Section 3.5

7

User Interface (front panel)

The L100 analyzer has nine touch keys on its splash proof keypad;

POWER, MENU, RUN, EXIT, ENTER, UP, DOWN, LEFT and RIGHT arrow touch keys.

In addition to this, it also has a status indicator for 'READY' (Green), ‘OFF’ (Red) and 'FAULT / BUSY' (Yellow).

3. Installation

Caution: Only qualified personnel should conduct the tasks described in this section of the manual.

3.1 Unpacking the Instrument

Please refer to the standard packing list included with your L100 for a complete list of L100 accessories and items.

If any of these items are missing or damaged, contact MANTECH or your local authorized MANTECH

representative immediately.

Important Note: Retain the original packaging materials. Instruments returned for service should be shipped in

the original packaging material to protect against damage during transportation.

POWER

RUN

MENU

EXIT

ENTER

STATUS

ARROW KEYS

8

3.2 Operating Environment

The following conditions are necessary to ensure correct instrument operation and accurate results:

•Place the instrument firmly on an even surface. Do not place any objects above or under the instrument.

•Maintain an ambient temperature of 5ºC to 30ºC for proper instrument operation.

•The relative humidity should be less than 90%; moisture should not condense on the instrument.

•Leave at least a 15 cm (6 in.) clearance at the top and on all sides for air circulation to avoid overheating

of electrical parts.

•Do not operate or store the instrument in extremely dusty, damp or wet locations.

•Keep the surface of the instrument, the cell compartment, and all accessories clean and dry. Splashes or

spills on and in the instrument should be cleaned up immediately.

Important Note: Protect the instrument from temperature extremes, including heaters, direct sunlight, and other

heat sources.

3.3 Power Connections

Plug the power supply into the appropriate connector on the back panel of the analyzer, then plug the power

cord into a power outlet (100 – 240 V~ / 45 – 60 Hz). Touch the red power key on the top right of the analyzer to

turn the instrument on.

3.4 Battery Power

The L100 can also be powered using a battery pack (intended for portable field use). The battery pack is plugged

into the back panel of the analyzer. Please refer to section 5.2 5.2 Battery Pack for more information on battery

charging.

3.5 Personal Computer (PC) Connection

The L100 has one USB interface located on the back of the analyzer. This is used for communication with a PC.

The software is supplied preinstalled on laptop PC and is available for purchase from MANTECH or one of its

authorized distributors.

Note: USB cables must not be longer than 3 meters (10 feet).

4. System Operations

4.1 Overview

The following are the steps involved in setting up the L100 analyzer for sample analysis:

1. Preparation of solutions (calibration/reference, blank and sample).

2. Priming lines and analyzer assembly.

3. Pre-conditioning of sensor/calibration.

4. PeCOD® menu structure

9

The L100 analyzer operates according to four COD ranges as per the following table:

COD range (ppm)

Advanced Blue

< 25

Green

< 150

Yellow

< 1,500

Red

< 15,000

4.2 Getting Started – Powering the Analyzer On

1. Place the L100 analyzer on a stable, level surface.

2. Plug the power supply into the appropriate connector on the back panel of the analyzer, then plug the

power cord into a power outlet (100 –240 V~ / 45 –60 Hz).

3. Touch the red power key on the top right of the analyzer to turn the instrument on. The LCD screen will

be displayed after several seconds and 'READY' above the POWER key will be illuminated in green.

4.3 Preparation of Solutions

For samples with a known COD range, the original sample should be diluted with the appropriate electrolyte as

per the table below. The calibration and blank solutions should also be prepared using the same dilution factor

as was used for the sample.

The following table lists the four COD ranges available and their corresponding dilution factors:

COD Range

(ppm)

Dilution

Dilution Factor

Advanced Blue

0.7 - 20

3 parts X : 1 parts Advanced Blue electrolyte

1.33

Green

10 - 150

1 part X : 1 part Green Electrolyte

2

Yellow

40 - 1,500

1 part X : 9 parts Yellow Electrolyte

10

Red

80 - 15,000

1 part X : 49 parts Red Electrolyte

50

Note: (i) For the sample: X= the original sample

(ii) For the blank solution: X=COD free water

(iii) For the Reference/Calibration solution: X= the original calibrant solution supplied by MANTECH

For example, if you are analysing in the Yellow range;

1. Mix 1 part of your original sample with 9 parts Yellow Electrolyte

2. Mix 1 part of COD-free water with 9 parts Yellow Electrolyte to make your blank solution

3. Mix 1 part of the original Calibrant solution (supplied by MANTECH), with 9 parts Yellow Electrolyte to

make your "reference" or "calibration" solution

10

Ensure you prepare sufficient amounts of each solution, taking into account the volume required for priming

(~2mL per prime), calibration and sample analysis. It is recommended to prepare a total minimum volume of

20mL for each sample, and 250mL and 500mL of pre-mixed calibrant and blank, respectively.

4.4 Priming of Lines

Always prime both Port A and Port B lines 3 times before any analysis to ensure that both lines are filled with

liquid and there are no air bubbles present. This can be confirmed by visually checking all flow lines. For

automated system, 6 primes of Port A are required to accommodate the longer sampling line.

To prime the lines manually from the touchpad:

1. Press MENU.

2. Arrow down to select Operation and press ENTER.

3. In the Operation menu, select Prime Lines and press ENTER.

4. In the Prime Lines menu, select Prime Port A and press ENTER. The solution will flow in through the

tube connected into Port A and flow out through the tube connected to Port W. The analyzer will beep

twice at the end. Repeat two more times.

5. In the Prime Lines menu, arrow down to select Prime Port B and press ENTER.

The solution will flow in through the tube connected into Port B and flow out through the tube

connected to Port W. The analyser will beep twice at the end. Repeat two more times.

4.5 New Sensor Routine and Calibration

Important Note: It is recommended that the system be calibrated a minimum of two times each day it is in use

to ensure that the sensor is fully conditioned before running samples. The “New Sensor Routine” can be used to

speed up the process of “breaking-in” a new sensor.

To run a new sensor routine manually from the touchpad:

1. Press MENU.

2. Arrow down to select Set up and press ENTER.

3. In the Set up menu, arrow down to select Sensor Operation and press ENTER.

4. Select New Sensor and press ENTER.

5. At the prompt “Confirm new sensor?”, press ENTER. The PeCOD® will now begin the new sensor

routine, which comprises of a normalization and burn-in phase of Port B.

6. After 2.5 minutes, the analyzer will beep and ask the user to verify the COD range. Press ENTER to

confirm the range. The PeCOD® will now do a full calibration.

7. Partway through the calibration, the system will beep again. Press ENTER to continue.

11

8. Repeat the new sensor routine once more. If the M and C meet the passing criteria in section as shown

in the box below, the sensor is ready to analyze samples.

To run a calibration manually from the touchpad:

1. Press MENU.

2. Arrow down to select Operation and press ENTER.

3. In the Operation menu, arrow down to select Run Calibration and press ENTER.

4. The analyzer will beep. Check to ensure that the flow line from Port A is placed in the vial containing

your Calibration solution, and that the correct COD range is selected. Press ENTER.

5. Partway through the calibration, the system will beep again. Press ENTER to continue.

6. Repeat these steps to perform the second calibration.

An M value will be displayed on the screen upon calibration completion. Pressing the left arrow button will display

the C value. Verify that the M and C values are within the recommended ranges prior to running samples (see

box below). Note that M and C values vary from sensor to sensor, and will fluctuate with sensor age. The M and

C values should be consistent between daily calibrations (i.e. M +/- 0.03, C +/- 50uC). A third calibration may be

required if M and C values vary beyond these limits.

M and C values are also stored in the calibration log.

To access the Calibration Log manually from the touchpad:

1) Press MENU, select Data and press ENTER.

2) In the Data menu, select Calibration Log and press ENTER.

4.6 PeCOD® Menu Structure

The menu structure is classified into the following four categories:

1. Data

2. Operation

3. Set up

4. Diagnostics

Each of the above categories contains sub level functions / parameters, as listed in the following tables.

0.02 < M < 0.06

Advanced Blue: 50 < C < 300

Green: 150 < C < 700

Yellow: 200 < C < 750

Red: 250 < C < 800

12

DATA

LEVEL 1

DESCRIPTION

Result Log

Data display. Presents result data for previous samples.

Use the Up, Down, Left & Right arrow touch keys to move within each individual log.

Event Log

Data display. Presents event data for previous samples.

Use the Up, Down, Left & Right arrow touch keys to move within each individual log

Calibration Log

Data display. Presents calibration data for previous samples.

Use the Up, Down, Left & Right arrow touch keys to move within each individual log

OPERATION

LEVEL 1

LEVEL 2

DESCRIPTION

Prime Lines

Prime Port A

Primes Port A.

Prime Port B

Primes Port B.

*Check Seals

Checks that the PeCOD® fluidics are sealed.

Run Sample

Commences operation of the analyser.

Run Calibration

Commences the calibration routine.

Run Standby

Commences standby operation which primes Port B using a repeat

cycle time as specified.

*Run Wash

Commences the wash routine.

*Open Analyser

Purges line to allow analyser to be opened and sensor to be

removed.

*Feature which is not implemented in current L100 practises

SET UP

LEVEL 1

LEVEL 2

LEVEL 3

DESCRIPTION

Analysis

Method

COD Range

Choice of:

Advanced Blue (<20 ppm analysis);

*Blue (<20 ppm analysis);

Green (<150 ppm analysis)

Yellow (<1,500 ppm analysis);

Red (<15,000 ppm analysis)

Use the Up & Down arrow touch keys to select

COD range.

*Blue range is not currently implemented in L100

practises

*Set Algorithm

Normal or Pulsed.

Normal method is continuous oxidation. This is

the default method.

13

LEVEL 1

LEVEL 2

LEVEL 3

DESCRIPTION

Pulsed method is used for specific applications.

Use the Up & Down arrow touch keys to select

method.

Set Precision

Precise or Rapid.

Choice of Rapid or Precise mode.

Rapid mode: uncertainty of >5% (1σ).

Precise mode: uncertainty of ≤ 5% (1σ).

Use the Up & Down arrow touch keys to select

analysis mode.

Sample Replicates

Default value is 1 (1 replicate = 1 measurement

per sample).

Valid values are 1, 2 or 3. Note that an average

COD value is reported.

Use the Up & Down arrow keys to change value.

Cal. Replicates

Default setting is 1. Analyse blank once, then

analyse calibration solution once. Record values

for C and M to be used for future determinations.

Valid values are 1, 2 or 3.

Use the Up & Down arrow touch keys to change

value.

*Pulse Settings

Set Pulse Duration.

Sets the time period for LED ON in seconds.

Minimum value: 0.1 s.

Maximum value: 9.9 s.

Use the Up & Down arrow touch keys to change

value.

Set Pulse Interval.

Sets the time period for LED OFF in seconds.

Minimum value: 0.1 s.

Maximum value: 9.9 s.

Use the Up & Down arrow touch keys to change

value.

Sensor

Operation

New Sensor

YES or NO.

YES begins pre-treatment process. NO exits to

previous menu level.

Press ENTER key for YES or EXIT key for NO.

Set Baseline

Sets the LED intensity to achieve an Iterm value.

Use Up & Down arrow touch keys to change

value.

14

LEVEL 1

LEVEL 2

LEVEL 3

DESCRIPTION

Periodic

Actions

*Cal. Interval

Cal. Cycles.

Not for use for L100

*Wash Interval

Wash Cycles.

Not for use for L100

Standby Interval

Standby (HH:MM)

Default value set to 00:00 (hours: minutes).

Change value to set standby mode interval time.

Use the Up & Down arrow touch keys to change

value.

Reference

Solution

Reference

Input to set calibrant concentration. Valid values

are from 0.0 to 99999.9. Note: this is the

concentration prior to dilution with electrolyte.

Use the Up & Down arrow touch keys to set the

value.

Set Date and

Time

YYYY/MM/DD

HH:MM:SS

Input to set up date and time or to change.

Use the Up & Down arrow keys to set date/time.

Display Units

COD Units

COD units.

Choice of “ppm or mg/L”.

Use the Up & Down arrow touch keys to choose

display units.

Equiv. BOD Units

BOD Factor.

If set to Zero then no BOD data is displayed.

Minimum value: 0.00

Maximum value: 9.99

Use the Up & Down arrow touch keys to enter

COD to BOD multiplication factor.

*Feature which is not implemented in current L100 practises

DIAGNOSTICS

LEVEL 1

LEVEL 2

DESCRIPTION

Factory Settings

Reset to factory

settings.

Resets all parameters to factory settings (default values).

Select YES or NO.

System Reset

Restarts the analyzer.

Set Pin Number

Default PIN = 0000

In this setting, security is switched to OFF.

Use the Up & Down arrow touch keys to change value.

Erase Logs

Erase Result Log

Erases result log.

Erase Event Log

Erases event log.

Erase Cal. Log

Erases calibration log.

15

Analysis of a typical sample manually from the touchpad:

The following parameters should be selected:

1. COD range: Advanced Blue / Green / Yellow / Red, select the appropriate range based on the original

concentration of sample/analyte.

2. Reference Solution: only if the reference solution (Calibrant) provided is not used. Enter the value for

your own solution

3. Display units for COD: ppm or mg/L

4.7 Running a Sample

A complete analysis consists of the following steps:

i. Pre-conditioning of blank (Pre-Burn, Port B) – ensures that the sensor and electrodes are stable.

ii. Pre-burn of sample (Pre-Burn, Port A) – preconditions the sensor to the sample matrix.

iii. Oxidation of sample (Oxidation, Port A) – a small amount of sample is advanced into the cell and is

analyzed to obtain the COD value. The instrument is measuring the charge liberated from the oxidation

reactions.

To run a sample manually from the touchpad:

1. Press RUN.

2. The analyzer will beep. Check that the flow line from Port A is placed in the vial containing your sample

and confirm that the correct COD range is selected.

3. Press ENTER to begin analysis.

The COD value will be displayed at the end of the analysis.

All COD values are stored in the Result Log, until cleared manually or overwritten by new entries.

To access the Result Log manually from the touchpad:

1. Press MENU, select Data and press ENTER.

2. In the Data menu, select Result Log and press ENTER.

3. The COD value for the most recent analysis will be displayed. Use the left and right arrow touch keys to

access previous COD values.

Each result log entry will contain the sample number, COD value, date and time. If an error had occurred during

the sample run, the event log will store the error code and corresponding date and time.

16

4.8 Other Operational Functions

Event Log

Please refer to section 6, Troubleshooting

Run Standby

This function can be activated when the L100 is not in use and ensures that the instrument is primed and

maintains calibration for the next sample, when left inactive for several hours during the day. When this function

is enabled, the L100 analyzer will prime Port B.

To set “Periodic Standby” manually from the touchpad:

1. Press MENU.

2. Arrow down to select Set Up and press ENTER.

3. In the Set Up menu, arrow down to select Periodic Actions and press ENTER.

4. In the Periodic Actions menu, select Standby Interval and press ENTER.

5. Use the Up, Down, Left and Right arrow touch keys to set the value for standby interval time in hours:

minutes format.

6. Press ENTER.

To run Standby manually from the touchpad:

1. Press MENU.

2. Arrow down to select Operation and press ENTER.

3. In Operation menu, arrow down to select Run Standby and press ENTER.

The analyzer will perform the run standby function periodically according to the interval time set in step (5),

starting from the time the function was activated.

4.9 Diagnostic Functions

Factory Settings

The operational values can be reset back to default (factory) settings at any time.

To reset operational values back to factory settings manually from the touchpad:

1. Press MENU.

2. Arrow down to select Diagnostics and press ENTER.

3. In Diagnostics menu, select Factory Settings and press ENTER.

17

System Reset

The system can be reset at any time.

To reset system manually from the touchpad:

1. Press MENU.

2. Arrow down to select Diagnostics and press ENTER.

3. In Diagnostics menu, arrow down to select System Reset and press ENTER.

Set PIN Number

The user can set a PIN number for added security for the operational settings of the L100 analyser. Once this

function is enabled, other users will not be able to change the parameter settings without the PIN number but

will still be able to run analysis or access data logs.

To set PIN number manually from the touchpad:

1. Press MENU.

2. Arrow down to select Diagnostics and press ENTER.

3. In Diagnostics menu, arrow down to select Set PIN Number and press ENTER.

4. Use the Up and Down arrow touch keys to set the value.

Note: Default value is set to 0000 and security is disabled.

Erase Logs

To erase logs manually from the touchpad:

1. Press MENU.

2. Arrow down to select Diagnostics and press ENTER.

3. In Diagnostics menu, arrow down to select Erase Logs and press ENTER.

4. In the Erase Log menu, select:

a) Erase Result Log (to clear the result log), or

b) Erase Event Log (to clear the event log), or

c) Erase Cal. Log (to clear the calibration log) and press ENTER.

Note that it is recommended that the logs be deleted every time the sensor is changed to prevent data build up

and slow log response. The logs can be downloaded as a .csv file from the PeCOD® prior to deletion for record

keeping. Logs are downloaded to a PC using the PeCOD® software supplied by MANTECH.

18

5. Preventative Maintenance

5.1 Cleaning Requirements

Caution: Always check that the instrument is switched off, the power cord is unplugged, and the analyzer is

allowed to cool before proceeding with preventative maintenance tasks.

Tubing and Fluidics

When the PeCOD® will not be in use for several hours, prime Port A with DI water. The block and sensor can

remain in the PeCOD® for up to three weeks stored in this way. External tubing can be purchased as a PM kit.

Contact your local PeCOD® representative for more details on PM kits suitable for your configuration.

Analyzer

To clean the external surface; wipe with a soft, damp cloth and a mild household grade detergent (if necessary).

Make sure no water penetrates the analyzer.

Sensor

Use a lint free tissue to clean or dry surfaces.

5.2 Battery Pack

An optional battery pack for portable field use is available from MANTECH and your local MANTECH authorized

representative. This battery pack should be plugged into the back of the L100 (for field use) and can be recharged

when plugged into an L100 that is connected to an external power supply. The pack will provide up to 8 hours of

continuous operation.

5.3 System Storage

General Guidelines

The sensor and electrode block may be stored in the PeCOD® for up to three weeks, ensure that the PeCOD® has

been primed with DI water to keep the electrode block hydrated. If the unit will not be used for more than three

weeks:

•Prime Port A and Port B with DI water, three times. Repeat with air, priming three times. This ensures

that the fluidics lines are free of liquid.

•Remove the electrode block and sensor, and fill the block with deionized water (see below). Place the

sensor in its original package when not in use as it is light sensitive.

Flushing and Storing the Electrode Block

1. The electrode block should always be kept hydrated. Flushing with DI water is a general preventative

maintenance and troubleshooting procedure to maintain the life of the electrode block and is necessary

for short term storage. Long term storage requires the block to be filled with 3M NaCl.

2. Using the syringe and tips provided in the starter kit, fill the syringe with DI water and find the

appropriate sized tip for the hole indicated below. Push DI water through the hole. This will flush out the

internal channel and come out the other side. Refill the syringe and repeat the process 5-6 times.

19

3. Place electrical tape over one hole to prevent the DI / NaCl from draining out of the internal channel and

fill with the appropriate solution for storage. Once filled, tape over the second hole and write the type

of solution inside and the date it was stored. Tape the O-rings down to prevent them from getting lost.

6. Troubleshooting

6.1 System Diagnostics

System errors are reported and stored in the event log. The following table lists the error codes and description

of possible cause for the error and suggested action to rectify the error.

Error

Group

Sub

Code

Name

Description of Problem

Suggested actions

2

1

Terminated by

User

The exit button on the PeCOD

display was selected

•Error indicating the user has

terminated the current

analysis. No further action

required.

2

2

Sensor

Uncalibrated

Error indicating the sensor is not

calibrated

•Run new sensor routine, or run

calibration.

3

1

COD out of

Range

Sample concentration is too

high.

•Dilute original sample with

COD free water and re-mix

with electrolyte (remember to

multiply this dilution factor to

obtain the final COD value).

•Alternatively, switch to using a

different range electrolyte and

re-prepare your sample. Note:

20

Error

Group

Sub

Code

Name

Description of Problem

Suggested actions

you will need to re-do the

calibration also.

3

2

Reference <

Blank

Reference (calibrant) solution

charge obtained is less than

zero solution.

•Check that calibrant solution is

correctly mixed with

electrolyte and re-calibrate.

3

3

COD Less Than

Blank

COD result is less than the blank

solution.

•Check that sample is mixed

with electrolyte in proper ratio

and that lines are primed.

•Check blank solution for

contamination.

•Sample may be below the

operating range. Switch to a

lower range (e.g. blue), re-

calibrate and then re-run

sample

3

4

Failure Qnet <

Zero

Resultant charge is too low (i.e.

not enough signal detected)

•Ensure that sample is mixed

with electrolyte in proper ratio

and lines are primed.

•Check electrical contacts

between the connection pins

on analyser board with the

electrode block. Very gently

clean if necessary using

isopropanol and a lint free

cloth.

•If the above do not rectify the

problem, the sensor or

electrode block may need to

be replaced.

7

1

Pump failure

Pump error

•Prime lines, and check

sufficient solution is being

expelled from the analyser. If

this does not rectify the

problem, please contact

MANTECH or your local

MANTECH authorised

representative.

7

2

Pump did not

initialize

Pump error

•Prime lines, and check

sufficient solution is being

expelled from the analyser. If

this does not rectify the

Table of contents

Other Mantech Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Calculated Industries

Calculated Industries Scale Master Pro XE user guide

Superior

Superior WATERGUARD WG-702 user manual

NPower

NPower Trio accessible quick start guide

PCB Piezotronics

PCB Piezotronics IMI SENSORS 627A11 Installation and operating manual

jacarta

jacarta SP8 user manual

Nic

Nic MERCURY/MA-3000 Operation manual

Perel

Perel DVM8852 user manual

PCB Piezotronics

PCB Piezotronics Y3713E112G Installation and operating manual

LaserPoint

LaserPoint Cronos Series instruction manual

Baumer

Baumer TA202 operating instructions

Keysight

Keysight E5061B installation guide

Apogee Instruments

Apogee Instruments MQ-620 owner's manual