Maple Systems HMI5000 Series Manual

Maple Systems Inc., 808 134th Street SW, Suite 120, Everett, WA 98204-7333 - www.maplesystems.com

1036-0112 Page 1 of 5 Rev. 02, 04/30/2011

C O N T R O L L E R I N F O R M A T I O N S H E E T

Maple Model(s)

PLC or Controller

HMI5000 Series

Yaskawa FSP

Summary

Maple Systems’ HMI5000 Series Human/Machine Interface Terminals (Maple HMIs)

communicate with Yaskawa Controllers using the Yaskawa XW protocol. When configured with

EZware-5000, the Maple HMI is the master in a point-to-point single-master, single-slave format.

Please refer to the Installation and Operations Manual for information on how to connect multiple

Maple HMIs to a single controller.

Compatible Controllers

Communications

Cab

le

The Maple HMI should be connected directly to the CN3 port on the controller. A list of

communications cables offered by Maple Systems as well as cable assembly instructions to assist

you in assembling your own communications cable are available on our website at

www.maplesystems.com.

WARNING If your communications cable is not wired exactly as shown in our cable

assembly instructions, damage to the HMI or loss of communications can

result.

Family

Model

FSP

All

Phone: 425/745-3229 • Fax: 425/745-3429 • Email: support@maplesystems.com • www.maplesystems.com

1036-0112 Page 2 of 5 Rev. 02, 04/30/2011

Accessible

Controller

Mem

ory

Register

M

emory

The following table lists the controller’s register memory ranges that the Maple HMIs are

able to access. Please note that your controller’s memory range may be smaller or larger than

that supported by these HMIs. (Note: d=decimal)

Controller Register Type

Address Range

Format

Register Description

Status

Doesn’t Matter

Reads the Status Word as an integer

Acceleration

Doesn’t Matter

Read/Write the Profile Acceleration

Gain

Doesn’t Matter

Read/Write the Application Gain

Variable

0-65535

ddddd

Read/Write any system variable by

number1

JerkTime

Doesn’t Matter

Read/Write the Jerk smoothing time

Speed

Doesn’t Matter

Read/Write the Speed Reference

ForwardTorqueLimit

Doesn’t Matter

Read/Write the Forward Torque Limit

ReverseTorqueLimit

Doesn’t Matter

Read/Write the Reverse Torque Limit

Outputs

0-65535

ddddd

Read/Write Outputs, display as an

integer value2,3

Inputs

Doesn’t Matter

Read only Inputs, displayed as an

integer value3

UserVariable

1 to 10

dd

Read/Write the User Variables

Run

Doesn’t Matter

Run the program at the specified label4

Notes:

1. Specify the System Variable number in the Device Address field. Some variables are “Read Only”.

2. Specify the Output “state” as 0 or 1 with a “Set Word” or “Numeric Input” object; set the Output

Mask using the Device Address field.

3. For 16 or fewer bits, set the “Number of Words” to 1. For more than 16, but not more than 32 bits, set

the “Number of Words” to 2.

4. Specify the program’s label number with a “Set Word” or “Numeric Input” object.

Maple Systems Inc., 808 134th Street SW, Suite 120, Everett, WA 98204-7333 - www.maplesystems.com

1036-0112 Page 3 of 5 Rev. 02, 04/30/2011

Discrete Memo

ry

The following table lists the controller’s discrete memory ranges that the Maple HMIs are able

to access. Please note that your controller’s memory range may be smaller or larger than that

supported by these HMIs. The following discrete memory is displayable in single-bit format on

the Maple HMI.

(Note: d=decimal)

Controller Bit Type

Address Range

Format

PLCBit Description

StatusBits

0 to 15

dd

Readindividual bits in the Status Word

Control

Doesn’t Matter

Read/write:

0=Disable;

1=Enable

OutputBits

1 to 19

dd

Read/write

individual output bits

InputBits

0 to 22

dd

Readonly, individual input bits

SetZeroPosition

Doesn’t Matter

Read/write:

0=Actual

Position; 1=Demand Position

Important Memory

Con

sideratio

ns

If your PLC’s memory range is smaller than the range supported by the Maple HMIs, it is possible

to configure the HMI to monitor a PLC memory address which does not exist. Since this can

cause unpredictable results, when you configure the HMI please ensure that all selected PLC

memory addresses are valid for your PLC model.

Do not configure the HMI to write to any PLC memory address that should only be written to

by the PLC itself.

Communication Error Messages

Duringcommunications with the controller, the HMI may display one or more of the

following message.

1. “PLC No Response”: the controller did not respond to the HMI’s request. Possible causes:

Cabling between the HMI and the controller (correct pinout, tight connection, not reversed)

Communications settings (baud rate, parity, etc.)

Controller AXISAddress.

Register availability & correct formatting of bit registers

If an error is reported while trying to set an output, make sure the output is not reserved.

If, after double-checking the above items, the problem has not been resolved, try introducing

some Turn Around delay. Set the Turn Around Delay to a small value (start with 15), and

experiment with increasing values. If there is still no resolution, please call Maple Systems

tech support.

Phone: 425/745-3229 • Fax: 425/745-3429 • Email: support@maplesystems.com • www.maplesystems.com

1036-0112 Page 4 of 5 Rev. 02, 04/30/2011

EZwareSettings

The following table lists the communications settings that must be configured in

EZware. These settings can be found in the Edit-Set System Parameters menu under

the Device tab. Please note:

The Recommended Settings column provides the recommended setting based

upon the default settings most commonly used in Yaskawa devices.

The Options column lists EZware’s options; your PLC may not support every

option

Name

Recommended

Settings

Options

Important Notes

Name:

Yaskawa FSP

Description label

HMI or PLC:

PLC

Location:

Local

Local, Remote

Select Local if the PLC is

directly connected to the HMI;

Remote if the PLC is connected

thru another HMI.

PLC type:

Yaskawa FSP

PLC I/F:

RS-232

RS-232,

RS-485 2W,

RS-485 4W,

Ethernet

Must match the controller’s port

setting.

PLC default station

no.:

0

0-255

Must match the controller’s Axis

setting, or use 0.

Settings: COM:

COM1

COM1 –COM3

Serial port of the HMI connected to

the controller.

Settings: Baud rate:

19200

9600, 19200, 38400,

57600, 115200

Must match the controller port

setting. Use the fastest baud rate

supported by the controller.

Settings: Data Bits

7

7 or 8

Must match the controller port

setting.

Settings: Stop bits

1

1 or 2

Must match the controller port

setting.

Maple Systems Inc., 808 134th Street SW, Suite 120, Everett, WA 98204-7333 - www.maplesystems.com

1036-0112 Page 5 of 5 Rev. 02, 04/30/2011

Name

Recommended

Settings

Options

Important Notes

Settings: Parity:

Even

Even, Odd, None

Must match the controller port

setting.

Settings: Timeout (sec):

3.0

0.1 –25.5

Adjust if longer timeout required.

Settings: Turn around

delay (ms):

0

0-1000

Timeout period between HMI polls.

Settings: Parameter 1:

0

Not Applicable

Settings: Parameter 2:

0

Not Applicable

Settings: Parameter 3:

0

Not Applicable

Interval of block pack

(words):

5

0-512

See HMI5000 Series

Programming Manual

(Maple p/n 1010-1007)

Max. read-command

size (words):

32

Not Adjustable

Max. write command

size (words):

32

Not Adjustable

Table of contents

Other Maple Systems Controllers manuals

Popular Controllers manuals by other brands

Johnson Controls

Johnson Controls VA-9070 Series Technical bulletin

Danfoss

Danfoss ERC 213 quick start guide

Sensibo

Sensibo Sensibo Air installation manual

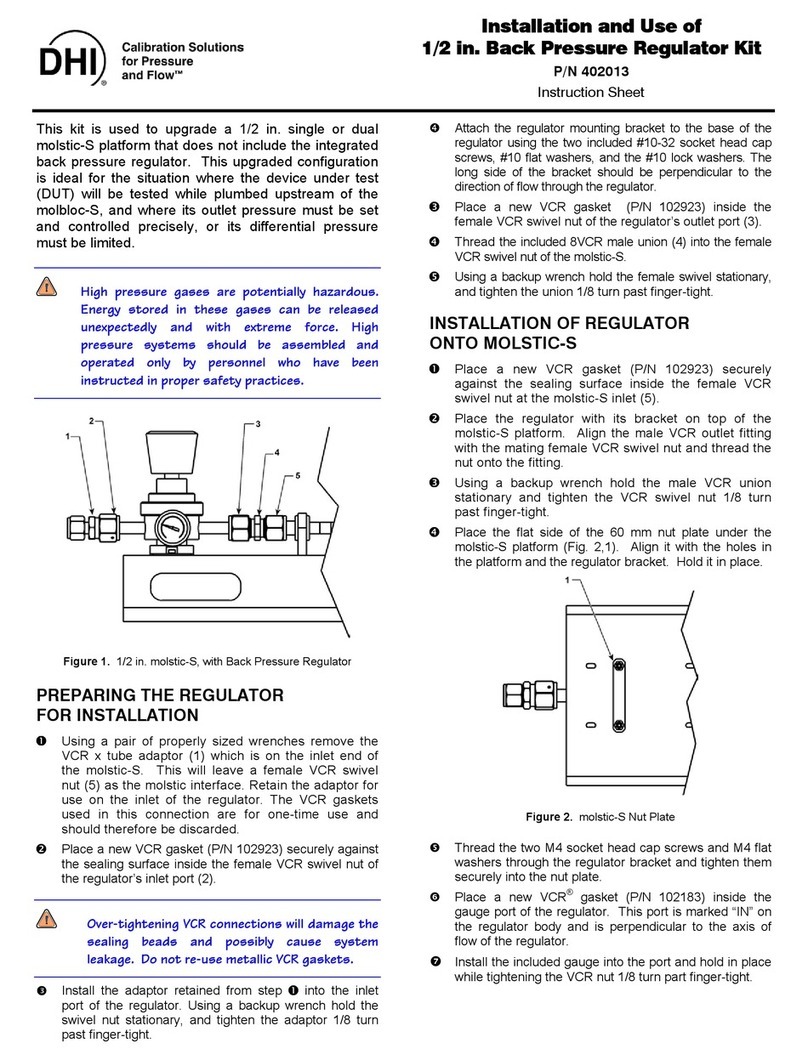

DH Instruments

DH Instruments 1-2 IN. BACK PRESSURE REGULATOR KIT Installation

FUTABA

FUTABA PS-10 BR5.2 instruction manual

Sentera Controls

Sentera Controls RMFPX-2R Mounting and operating instructions