Marine Air Systems vector compact Installation and operating instructions

vector

compact

INSTALLATION,

OPERATION

&

MAINTENANCE

/HARINE

/IIR

SYSTEMS®

A

Member

of

Taylor

Made

Group.

6/99

Patented

PREFACE

Congratulations

on

the

purchase

of your

Marine

Air

Systems

VECTOR

COMPACT

air

conditioner.

No

matter

which

of

the

following

features

was

the

reason

for

your

purchase

of

this

air

conditioner,

we

are

sure

it

will

meet

your

needs

and

will

give

you

many

years

of

efficient

and

trouble

free use.

The

VECTOR

COMPACT

units

are

self-contained

direct

expansion

air

conditioners

designed

for

marine

applications

incorporating

the

following

features:

•

Patented

compact

design

with

the

condenser

coil

in

the

evaporator

shroud.

•

High

efficiency

rotary

(7-16K)

or

scroll

(24K)

compressors

•

Cupronickel

condenser

coil

•

Raised

lance

fin

designed

evaporator

coil

•

Polyurethane

coated

2"

deep

drain

pan

with

multiple

condensate

drain

locations

•

Anti-vibration

base

pan

•

Pre-charged

and

pre-wired

systems

for

easy

connections

•

Rotatable

insulated

blower

assembly

•

Charge

Guard®

ensures

environmental

protection

and

system

integrity

The

PASSPORT

II

microprocessor

based

digital

controller,

optional

with

this

unit,

offers

the

most

technologically

advanced

design

specifically

made

for

the

unique

requirements

of

marine

air

conditioning.

The

controller

has

been

designed

with

flexibility

and

the

following

"user

friendly"

features

customers

require

for

their

applications:

•

Non-volatile

memory

•

Program

lock

-

prevents

accidental

program

tampering

•

Low

voltage

display

panel

•

Face

plate

air

sensor

for

accurate

temperature

control,

or

optional

remote

sensor

•

LED

cabin

temperature

displayed

in

Fahrenheit

or

Celsius

•

Multiple

fan

speed

selections

with

high

and

low

limits

•

User

selected

programs

for

optimum

control

•

Optional

outside

air

temperature

sensor

•

Compressor

pressure

failsafe

protection

and

run

time

hour

meter

•

Compressor

start

staging

delay

for

multiple

a/c

systems

•

Moisture

mode

cycle

for

humidity

control

•

De-icing

feature

to

prevent

evaporator

icing

•

Blank

display

for

nighttime

operation

This

manual

is

intended

to

provide

the

information

necessary

to

ensure

proper

installation,

operation,

and

maintenance

of

the

unit.

Improper

installation

or

misunderstood

operating

procedures

can

result

in

unsatisfactory

performance

and/or

premature

failure

of

these

units,

so

before

proceeding

please

read

this

manual

completely.

The

VECTOR

COMPACT

a/c

units

are

covered

under

the

existing

Marine

Air

Systems'

warranty

policy

contained

in

this

manual.

In

the

interest

of

product

improvement,

Marine

Air

Systems'

specifications

and

design

are

subject

to

change

without

prior

notice.

REVISION

HISTORY

DOCUMENT

NAME:

Vector

Compact.doc

ORIGINAL

PRINT:

March

1998

REVISED:

5/98,

7/98

&

11/98

CLEAN

AIR

ACT

AMENDMENTS

OF

1990

[TITLE

VI

-

SECTION

608(C-1)]

"Effective

July

1,

1992,

it

shall

be

unlawful

for

any

person,

in

the

course

of

maintaining,

servicing,

repairing,

or

disposing

of an

appliance

or

industrial

process

refrigeration,

to

knowingly

vent

or

otherwise

knowingly

release

or

dispose

of

any

Class

I*

or

Class

II**

substance

used

as

a

refrigerant

in

such

appliance

(or

industrial

process

refrigeration)

in

a

manner

which

permits

such

substance

to

enter

the

environment.

De

minimis

releases

associated

with

good

faith

attempts

to

recapture

and

recycle

or

safely

dispose

of

any

such

substances

shall

not

be

subject

to

the

prohibition

set

forth

in

the

proceeding

sentence."

*Class

I

substances

include

CFC-12

**Class

II

substances

include

HCFC-22

MARINE

AIR

SYSTEMS

Marine

Air

Systems,

Inc.

(MAS)

is

a

manufacturer

of

air

conditioning

and

refrigeration

equipment

for

the

marine

industry.

MAS

is

committed

to

innovative

technology,

competitively

priced

products

and

market

leadership.

The

MAS

team

has

many

years

of

experience

in

the

design,

manufacture,

application

and

support

of

marine

air

conditioning

and

refrigeration.

Our

practical

experience

and

design

capability

allows

our

application

engineers

and

customer

support

team

to

offer

optimum

solutions

for

your

environmental

control

requirements.

Marine

Air

Systems,

Inc.

is

A

Member

of

the

Taylor

Made

GroupT

'TM*

VECTOR

COMPACT

OVERVIEW

ROTATABLE

BLOWER

BLOWER

MOTOR

CONDENSER

COIL

OUTLET

CONDENSER

COIL

INLET

ROTARY

COMPRESSOR

EVAPORATOR

COIL

SHROUD

WITH

CONDENSER

COIL

INSIDE

ELECTRIC

BOX

REVERSING

VALVE

BASE/DRAIN PAN

HANDLE

HOW

IT

WORKS:

Your

self-contained

air

conditioner

consists

of

four

main

components

and

a

refrigerant

gas

circulating

through

the

system.

The

BLOWER

draws

warm

moist

cabin

air

across

the

fins

on

the

EVAPORATOR

where

the

heat

from

the

air

causes

the

refrigerant

in

the

evaporator

coil

to

evaporate

from

a

liquid

into

a

gas.

As

the

refrigerant

evaporates,

it

absorbs

the

heat

from

the

cabin

air.

The

moisture

in

the

air

is

captured

on

the

evaporator

coil

and

fins

by

forming

condensation

as

the

air

is

cooled.

The

COMPRESSOR

then

compresses

the

refrigerant

gas

and

pumps

it

through

the

outer

tube

in

the

CONDENSER

COIL

(located

in

the

evaporator

shroud).

The

seawater

pump

circulates

cool

seawater

through

the

inner

tube

in

the

condenser

coil;

this

cools

the

refrigerant

and

condenses

it

into

a

liquid.

The

heat

from

the

refrigerant

is

exchanged

to

the

seawater

and

discharged

overboard.

The

liquid

refrigerant

is

then

passed

through

the

EVAPORATOR

COIL

and

the

cycle

repeats.

Removing

heat

and

moisture

from

the

cabin

air

lowers

its

temperature

and

humidity

levels.

The

conditioned

air

is

blown

through

the

ducting

and

out

the

supply

air

grille(s).

For

reverse

cycle

heating,

the

refrigerant

flows

in

the

opposite

direction

through

the

reversing

valve.

Heat

is

transferred

from

the

seawater

in

the

condenser

coil

to

the

refrigerant

and

then

to

the

air

blowing

through

the

evaporator

into

the

cabin.

Seawater

temperature

will

directly

affect

the

a/c unit's

efficiency.

This

a/c

unit

can

effectively

cool

your

boat

in

water

temperatures

up

to

90°F

and

heat

it

in

water

temperatures

as

low

as

40°F.

n

TABLE

OF

CONTENTS

INSTALLATION

Unpacking

and

Inspection

1

Safety

Considerations

1

Placement

of

System

(Tools

Required)

2

Spacing

Allowances

and

Dimensions

3

Condensate

Drains

4

Mounting

Brackets

4

Blower

Assembly

4

Supply

&

Return

Air

Grilles

5

Ducting

5

Seawater

Pump

and

Plumbing

6

Electrical

Connections,

Grounding

and

Bonding

7

3

Phase

Notice

7

Vector

Compact

Mechanical

Control

(VCM)

Wiring

Diagrams

8

Vector

Compact

Passport

II

Digital

Control

(VCP)

Wiring

Diagrams

.9

Manual

Control

Panel

(MCP)

Installation

10

Passport

II

Display

Panel

Installation

11

Installation

Checklist

(review

prior

to

installation)

12

OPERATION

Manual

Control

Panel

(MCP)

Operation

10

Quick

Start

Operations

Checklist

12

Passport

II

Control

13

Modes

of

Operation

13-14

Programming

the

Passport

II

14-15

Programmable

Parameters

15-17

Programming

Notes

17

General

Troubleshooting

Guidelines

18-19

Passport

II

Digital

Control

Troubleshooting

Guidelines

19-21

MCP

Mechanical

Control

Panel

Troubleshooting

Guidelines

....21

MAINTENANCE

Seawater

System,

Return

Air

Filters,

Winterization

22

Manufacturers

Limited

Warranty

Agreement

23

Worldwide

Dealer/Service

Network

1998

24-25

in

UNPACKING

AND

INSPECTION

When

the

equipment

is

received,

all

items

should

be

carefully

checked

against

the

packing

list

to

ensure

all

cartons

have been

received.

Move

units in

the

normal

"up"

orientation

as

indicated

by

the

arrows

on

each

carton.

Examine

cartons

for

shipping

damage,

removing

the

units

from

the

cartons

if

necessary.

If

the

unit

is

damaged,

the

carrier

should

make

the

proper

notation

on

the

delivery

receipt

acknowledging

the

damage.

SAFETY

CONSIDERATIONS

VERY

IMPORTANT:

A/ever

install

your

air

conditioner

in

the

bilge

or

engine

room

areas.

Insure

that

the

selected

location

is

sealed

from

direct

access

to

bilge

and/or

engine

room

vapors.

Do

not

terminate

condensate

drain

line

within

four

(4)

feet

of

any

outlet

of

engine

or

generator

exhaust

systems,

nor

in

a

compartment

housing

an

engine or

generator,

nor

in

a

bilge,

unless

the

drain

is

connected

properly

to

a

sealed

condensate

or

shower

sump

pump.

Installation

and

servicing

of

this

system

can

be

hazardous

due

to

system

pressure

and

electrical

components.

When

working

on

this

equipment,

always

observe

precautions

described

in

the

literature,

tags

and

labels

attached

to

the

unit.

Follow

all

safety

codes.

Wear

safety

glasses

and

work

gloves

and

place

a

fire

extinguisher

close

to

the

work

area.

The

following

is

a

summary

of

the

labels

on

the

unit:

!

DANGER

ELECTRICAL

SHOCK

HAZARD.

DISCONNECT

VOLTAGE

AT

MAIN

PANEL

OR

POWER

SOURCE

BEFORE

OPENING

ANY

COVER.

FAILURE

TO

COMPLY

MAY

RESULT

IN

INJURY

OR

DEATH.

!

WARNING

THIS

COMPONENT

DOES

NOT

MEET

FEDERAL

REQUIREMENTS FOR

IGNITION

PROTECTION.

DO

NOT

INSTALL

IN

SPACES

CONTAINING

GASOLINE

ENGINES,

TANKS,

LPG/CPG

CYLINDERS,

REGULATORS,

VALVES

OR

FUEL

LINE

FITTINGS.

FAILURE

TO

COMPLY

MAY

RESULT

IN

INJURY

OR

DEATH

NOTICE

THIS

COMPONENT

IS

CHARGED

WITH

HYDROCHLOROFLUOROCARBON

(HCFC)

REFRIGERANT

R22.

EFFECTIVE

JULY

1,

1992

IT

SHALL

BE

UNLAWFUL

FOR

ANY

PERSON

TO

KNOWINGLY

VENT

OR

OTHERWISE

KNOWINGLY

RELEASE

ANY

CLASS

1

(CFC)

OR

CLASS

2

(HCFC)

SUBSTANCE

AS

A

REFRIGERANT

IN

A

MANNER

WHICH

PERMITS

SUCH

SUBSTANCE

TO

ENTER

THE

ATMOSPHERE

PER

THE

CLEAN

AIR

ACT

OF

1990.

PUBLIC

LAW

101-549

TITLE

IV

SECTION

608-C.

FAILURE

TO

COMPLY

MAY

RESULT

IN

SEVERE

PENALTIES,

INCLUDING

FINES

AND

IMPRISONMENT.

!

WARNING

TO

MINIMIZE

THE HAZARD

OF

ELECTRICAL

SHOCK

AND

PERSONAL

INJURY,

THIS

COMPONENT

MUST

BE

EFFECTIVELY

GROUNDED.

REFER

TO

THE

INSTALLATION

GUIDELINES

FOR

FURTHER

INFORMATION.

CAUTION!

HIGH

COMPRESSOR

TEMPERATURE

IS

NORMAL

DO

NOT

TOUCH

PLACEMENT

OF SYSTEM

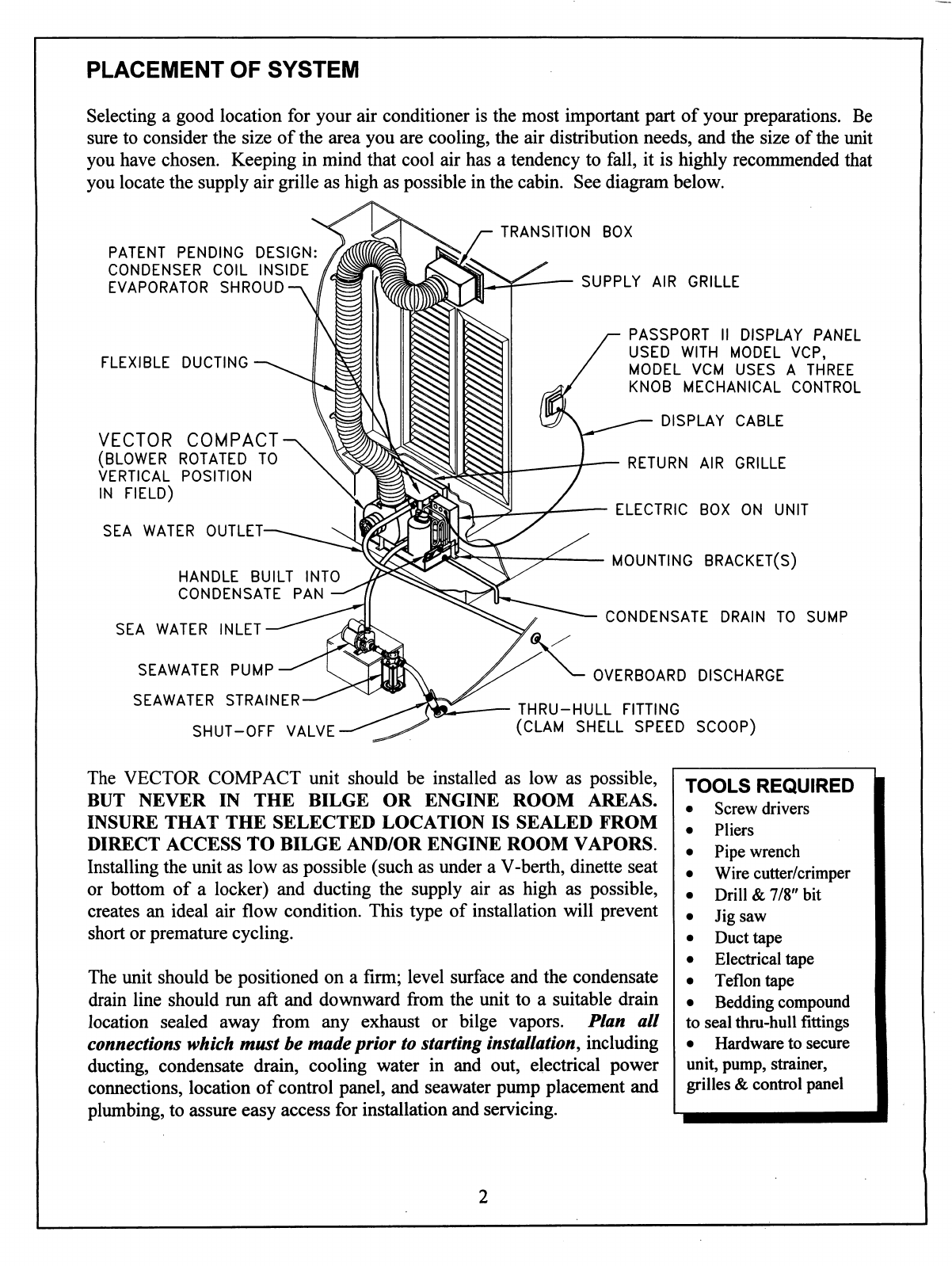

Selecting

a

good

location

for

your

air

conditioner

is

the

most

important

part

of

your

preparations.

Be

sure

to

consider

the

size

of

the

area

you

are

cooling,

the

air

distribution

needs,

and

the

size

of

the

unit

you

have

chosen.

Keeping

in

mind

that

cool

air

has a

tendency

to

fall,

it

is

highly

recommended

that

you

locate

the

supply

air

grille

as

high

as

possible

in

the

cabin.

See

diagram

below.

TRANSITION

BOX

PATENT

PENDING

DESIGN:

CONDENSER

COIL

INSIDE

EVAPORATOR

SHROUD

FLEXIBLE

DUCTING

VECTOR

COMPACT

(BLOWER

ROTATED

TO

VERTICAL

POSITION

IN

FIELD)

SEA

WATER

OUTLET-

HANDLE

BUILT

INTO

CONDENSATE

PAN

SEA

WATER

INLET

SEAWATER

PUMP

SEAWATER

STRAINER

SHUT-OFF

VALVE

SUPPLY

AIR

GRILLE

PASSPORT

II

DISPLAY

PANEL

USED

WITH

MODEL

VCP,

MODEL

VCM

USES

A

THREE

KNOB

MECHANICAL

CONTROL

DISPLAY

CABLE

RETURN

AIR

GRILLE

ELECTRIC

BOX

ON

UNIT

MOUNTING

BRACKET(S)

CONDENSATE

DRAIN

TO

SUMP

OVERBOARD

DISCHARGE

THRU-HULL

FITTING

(CLAM

SHELL

SPEED

SCOOP)

The

VECTOR

COMPACT

unit

should

be

installed

as

low

as

possible,

BUT

NEVER

IN

THE

BILGE

OR

ENGINE

ROOM

AREAS.

INSURE

THAT

THE

SELECTED

LOCATION

IS

SEALED

FROM

DIRECT

ACCESS

TO

BILGE

AND/OR

ENGINE

ROOM

VAPORS.

Installing

the

unit

as

low

as

possible

(such

as

under

a

V-berth,

dinette

seat

or

bottom

of

a

locker)

and

ducting

the

supply

air

as

high

as

possible,

creates

an

ideal

air

flow

condition.

This

type

of

installation

will

prevent

short

or

premature

cycling.

The

unit

should

be

positioned

on

a

firm;

level

surface

and

the

condensate

drain

line

should

run

aft

and

downward

from

the

unit

to

a

suitable

drain

location

sealed

away

from

any

exhaust

or

bilge

vapors.

Plan

all

connections

which

must

be

made

prior

to

starting

installation,

including

ducting,

condensate

drain,

cooling

water

in

and

out,

electrical

power

connections,

location

of

control

panel,

and

seawater

pump

placement

and

plumbing,

to

assure

easy

access

for

installation

and

servicing.

TOOLS

REQUIRED

•

Screw

drivers

•

Pliers

•

Pipe

wrench

•

Wire

cutter/crimper

•

Drill

&

7/8"

bit

•

Jig

saw

•

Duct

tape

•

Electrical

tape

•

Teflon

tape

•

Bedding

compound

to

seal

thru-hull

fittings

•

Hardware

to

secure

unit,

pump,

strainer,

grilles

&

control

panel

PROPRIETARY

NOTE:

THE

INFORMATION

CONTAINED

WITHIN

THIS

DOCUMENT

IS

THE

PROPERTY

OF

MARINE

AIR

SYSTEMS

INC.

ANY

ATTEMPT

TO

COPY

OR

DISTRIBUTE

WITHOUT

WRITTEN

CONSENT

FROM

MARINE

AIR

SYSTEMS

INC.

SHALL

BE

CONSIDERED

UNLAWFUL

AND

CAN

BE

CONTESTED

IN

A

COURT

OF

LAW.

REV

1

J

K

L

DATE

N/A

4/16/98

1/13/99

5/10/99

REVISION

NO

REVISION

'I'

REVISED

DIMENSIONS

ON

10

&

12

HV

UNITS

CHANGED

24K

M

DIMENSION

ADDED

5K

UNIT

DWG

DKM

DKM

DKM

DKM

APR

R

P

D

D

SPACE

ALLOWANCES

TO

CONSIDER

WHEN

DESIGNING

AREA

FOR

A/C

UNITS

1)

Allow

a

minimum

3.00"

[7.62cm]

of

air

space

in

front

of

evaporator

for

return

air

intake

if it

is

adjacent

to

a

bulkhead.

2)

Allow

a

minimum

1.00"

[2.54cm]

of

air

space

for

electric

blower

motor

ventilation.

Not

applicable

with

HV

units.

3)

For

flexible

ducting

connection:

A)

If

mount

ring

is

used,

allow

2.00"

[5.08cm]

for

the

ring,

1.00"

[2.54cm]

for

duct

bend

radius

and

add

the

diameter

of

the

ducting

to

get

total

distance

as

measured

from

blower

outlet.

B)

When

using

a

transition

box

consider

thot

each

box

is

unique

to

it's

application.

A

general

rule

is

to

add

1.00"

[2.54cm]

to

the

largest

ring

diameter

used

to

get

size

of

box

(5"

min.).

Add

mount

ring

and

ducting

as

figured

above

to

get

approximate

space

needed

to

install

transition

box.

Also

note

that

the

universal

T-box

is

8.00"

[20.32cm]

tall

measured

from

blower

outlet.

4)

Allow

enough

room

for

removal

of

electric

box

cover

for

servicing.

NOTE:

The

above

dimensions

are

minimums.

Enough

space

should

be

allocated

for

installation

and

serviceability.

CONDENSER

COIL

IN

EVAPORATOR

SHROUD

—\

0.63/1.6

MAX.—

DRAIN

PLUG

LOCATIONS

WILL

VARY

—

0.38/1.0

(TYPICAL)

1

>

D

SEE

NOTE

3

/

H

H*

■<

M

\

ROTATED

BLOWER

POSITIONS

MODEL

NUMBER

H

DIMENSIONS

(inches/centimeters)

H*

W

D

M

WEIGHT

(lbs/kg)

VCP/M5K

1

1.75/29.8

N/A

16.5/41.9

9.00/22.9

3.75/9.5

42.0/19.1

VCP/M7K

12.00/30.5

12.25/31.1

12.25/31.1

18.00/45.7

9.63/24.5

3.25/8.3

48.7/22.0

VCP/M10K

13.63/34.6

20.25/51.4

10.63/27.0

4.00/10.2

59.2/26.8

VCP/M12K

13.63/34.6

20.25/51.4"

10.63/27.0

3.75/9.5 62.8/28.5

VCP/M16K

13.63/34.6

20.25/51.4

12.00/30.5

4.00/10.2

64.7/29.3

VCP/M24K

VCP/M7K-HV

18.00/45.7

19.25/48.9

24.75/62.9

18.00/45.7

15.25/38.7

9.63/24.5

3.50/8.9

1.00/2.5**

120.0/54.4

12.00/30.5

12.25/31.1

48.7/22.0

VCP/M10K-HV

12.25/31.1

13.63/34.6

20.25/51.4"

12.00/30.5

1.00/2.5**

59.2/26.8

VCP/M12K-HV

13.63/34.6

N/A

20.25/51.4

12.00/30.5"

1.00/2.5**

62.8/28.5

VCP/M16K-HV

13.63/34.6

N/A

20.25/51.4

12.00/30.5

1.00/2.5**

64.7/29.3

♦HEIGHT

TO

TOP

OF

BLOWER

OUTLET,

BLOWER

MAY

BE

ROTATED

DOWN

BELOW

EVAP

SHROUD

'H'

**MOTOR

IS

INSIDE

FAN

HOUSING

ON

HIGH

VELOCITY

(HV)

UNITS,

HOWEVER,

ALLOW

1

"/2.5cm

FOR

BLOWER

RING

MOUNTING

FLANGE

AND/OR

BLOWER

CAPACITOR

ON

THAT

SIDE

OF

UNIT

ALL

DIMENSIONS

ARE

NOMINAL

-

VERIFY

ALL

CRITICAL

DIMENSIONS

WITH

MAS

ENGINEERING.

9/10/97

1/8

ITATUS:

CURRENT

JRAWN

BY:

DKM

APPROVED

BY:

D

D

ORTHOGRAPHIC

PROJECTION

VCP/M5-24K

(HV)

VECTOR

COMPACT

PASSPORT/MECHANICAL

SPACING

ALLOWANCES

AND

DIMENSIONS

DRAWING

NO:

M1020036L

/MARINE

/IIR

SYSTEMS®

POMPANO

BEACH,

FLORIDA

U.S.A.

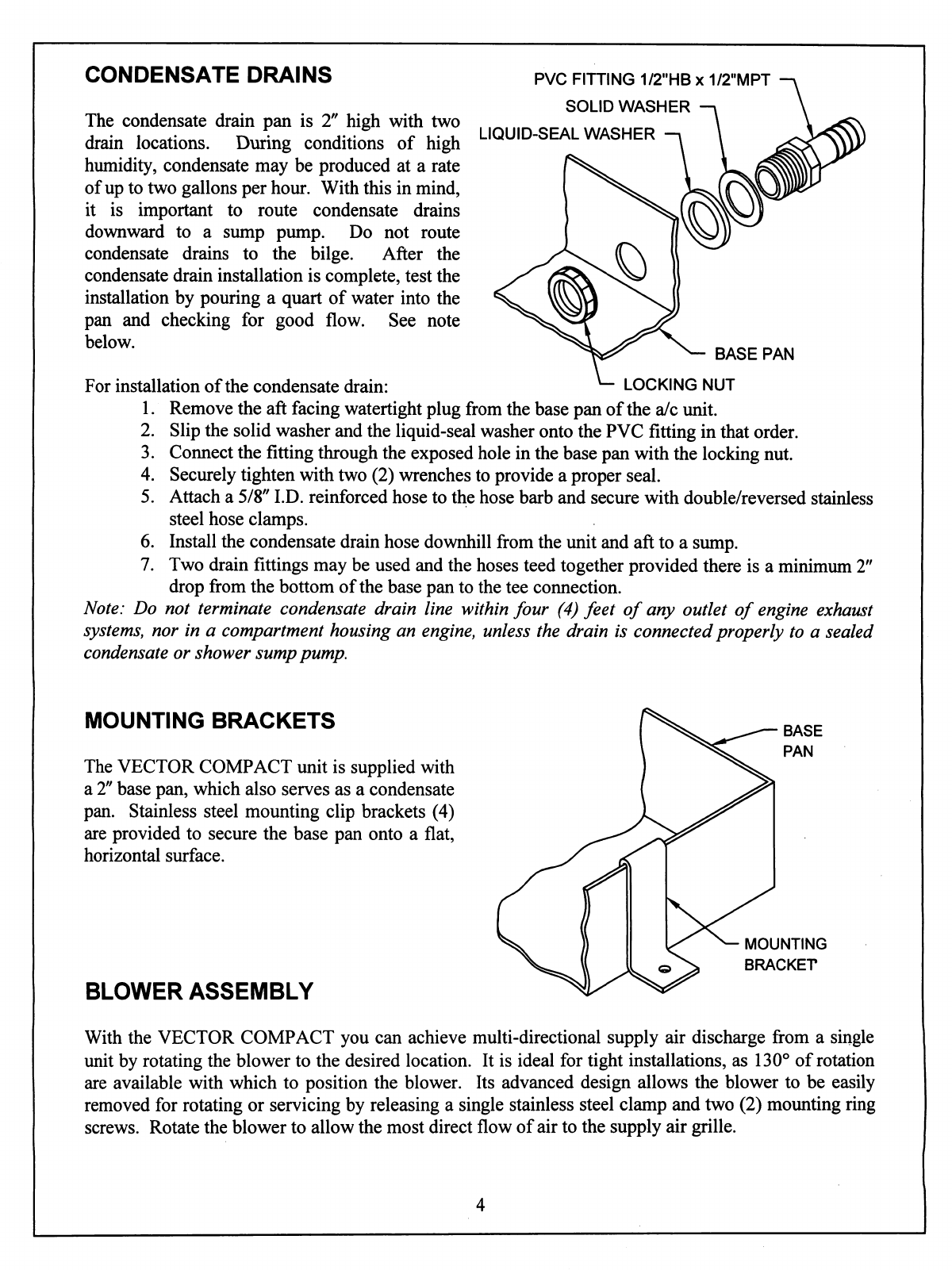

CONDENSATE

DRAINS

The

condensate

drain

pan

is

2"

high

with

two

drain

locations.

During

conditions

of

high

humidity,

condensate

may

be

produced

at

a

rate

of

up

to

two

gallons

per

hour.

With

this

in

mind,

it

is

important

to

route

condensate

drains

downward

to

a

sump

pump.

Do

not

route

condensate

drains

to

the

bilge.

After

the

condensate

drain

installation

is

complete,

test

the

installation

by

pouring

a

quart

of

water

into

the

pan

and

checking

for

good

flow.

See

note

below.

PVC

FITTING

1/2"HB

x

1/2"MPT

SOLID

WASHER

LIQUID-SEAL

WASHER

BASE

PAN

For

installation

of

the

condensate

drain:

*-

LOCKING

NUT

1.

Remove

the

aft

facing

watertight

plug

from

the

base

pan

of

the

a/c

unit.

2.

Slip

the

solid

washer

and

the

liquid-seal

washer

onto

the

PVC

fitting

in

that

order.

3.

Connect

the

fitting

through

the

exposed

hole

in

the

base

pan

with

the

locking

nut.

4.

Securely

tighten

with

two

(2)

wrenches

to

provide

a

proper

seal.

5.

Attach

a

5/8"

I.D.

reinforced

hose

to

the

hose

barb

and

secure

with

double/reversed

stainless

steel

hose

clamps.

6.

Install

the

condensate

drain

hose

downhill

from

the

unit

and

aft

to

a

sump.

7.

Two

drain

fittings

may

be

used

and

the

hoses

teed together

provided

there

is

a

minimum

2"

drop

from

the

bottom

of

the

base

pan

to

the

tee

connection.

Note:

Do

not

terminate

condensate

drain

line

within

four

(4)

feet

of

any

outlet

of

engine

exhaust

systems,

nor

in

a

compartment

housing

an

engine,

unless

the

drain

is

connected

properly

to

a

sealed

condensate or

shower

sump

pump.

MOUNTING

BRACKETS

The

VECTOR

COMPACT

unit

is

supplied

with

a

2"

base

pan,

which

also

serves

as

a

condensate

pan.

Stainless

steel

mounting

clip

brackets

(4)

are

provided

to

secure

the

base

pan

onto

a

flat,

horizontal

surface.

BLOWER

ASSEMBLY

MOUNTING

BRACKET

With

the

VECTOR

COMPACT

you

can

achieve

multi-directional

supply

air

discharge

from

a

single

unit

by

rotating

the

blower

to

the

desired

location.

It

is

ideal

for

tight

installations,

as

130°

of

rotation

are

available

with

which

to

position

the

blower.

Its

advanced

design allows

the

blower

to

be

easily

removed

for

rotating

or

servicing

by

releasing

a

single

stainless

steel

clamp

and

two

(2)

mounting

ring

screws.

Rotate

the

blower

to

allow

the

most

direct

flow

of

air

to

the

supply

air

grille.

SUPPLY

&

RETURN

AIR

GRILLES

Install

the

supply

air

grille

as

high

as

possible

in

a

location

that

will

provide

uniform

air

distribution

throughout

the

cabin,

grille

louvers

should

be

directed

upward.

The

return

air

grille

should

be

installed

as

low

and

close

to

the

a/c

unit as

possible

to

insure

direct

uninterrupted

airflow

to

the

evaporator.

The

return

air

grille

should

have

a

minimum

four

inches

(4")

or

clearance

in

front

of

it,

free

from

any

furniture

or

other

obstructions.

In

no

instance

should

a

supply

air

discharge

be

directed

towards

a

return

air

grille,

as

this

will

cause

the

system

to

short

cycle.

Allow

for

adequate

clearance

behind

the

supply

air

grille(s)

for

the

transition

box

and

ducting

connection.

The

following

table

shows

minimum

grille

sizes.

See

the

MAINTENANCE

section

of

this

manual

for

return

air

filter

cleaning

instructions.

DUCTING

Good

air

flow

is

critical

for

the

performance

of

the

entire

system.

It

is

highly

dependent

on

the

quality

of

the

ducting

installation.

The

ducting

should

be

run

as

straight,

smooth

and

taut

as

possible

minimizing

the

number

of

90

degree

bends

(two

tight

90

degree

bends

can

reduce

airflow

by

25%).

The

following

table

shows

minimum

duct

diameters

and

their

corresponding

supply

and

return

air

grille

minimum

areas

in

square

inches.

If

a

transition

box

is

used,

the

total

area

of

supply

air

ducts

going

out

of

the

box

should

equal

the

area

of

the

supply

duct

feeding

the

box.

To

calculate

the

square

inch area

of

a

round

duct,

multiply

the

radius

by

itself

(r2)

and

multiply

that

number

by

3.1416

(tt).

MODEL

DUCT

DIA

DUCT

AREA

R/A

GRILLE

S/A

GRILLE

7K

5"

dia

19.6

sq

in

88

sq

in

40

sq

in

10K

5"

dia

19.6

sq

in

98

sq

in

50

sq

in

12K

6"

dia

28.3

sq

in

140

sq

in

70

sq

in

16K

7"

dia

38.5

sq

in

168

sqin

84

sq

in

24K

8"

dia

50.3

sq

in

280

sq

in

140

sqin

The

following

is

a

summary

of

proper

ducting

connections:

1.

Pull

back

the

fiberglass

insulation

exposing

the

inner

mylar

duct

hose.

2.

Slide

the

mylar

duct

hose

around

the

mount

ring

until

it

bottoms

out.

3.

Screw

3

or

4

stainless

steel

sheet

metal

screws

through

the

duct

hose

into

the

transition

ring.

Make

sure

to

catch

the

wire

in

the

duct

hose

with

the

heads

of

the

screws.

Do

not

use

band

clamps,

as

the

hose

will

slide

off.

4.

Wrap

the

duct

tape

around

the

ducting

and

ring

joint

to

prevent

any

air

leaks.

5.

Pull

the

insulation

back

up

over

the

mylar

to

the

ring

and

tape

this

joint.

6.

Remove

excess

ducting

and

use

the

same

connection

method

at

the

s/a

grille.

All

ducting

should:

•

Be

appropriately

sized

for

each

application.

•

Run

as

smoothly

and

taut

as

possible.

•

Have

as

few

bends

or

loops

as

possible.

•

Be

securely

fastened

to

prevent

sagging

during

boat

operation.

•

Have

all

excess

ducting

lengths

trimmed

off.

•

Not

be

flattened

or kinked.

•

Insulated

when

located

in

high

heat

load

areas

(hull

side,

mechanical compartments,

etc.).

•

Be

properly

protected

against

potential

damage

when

routed

through

open

areas.

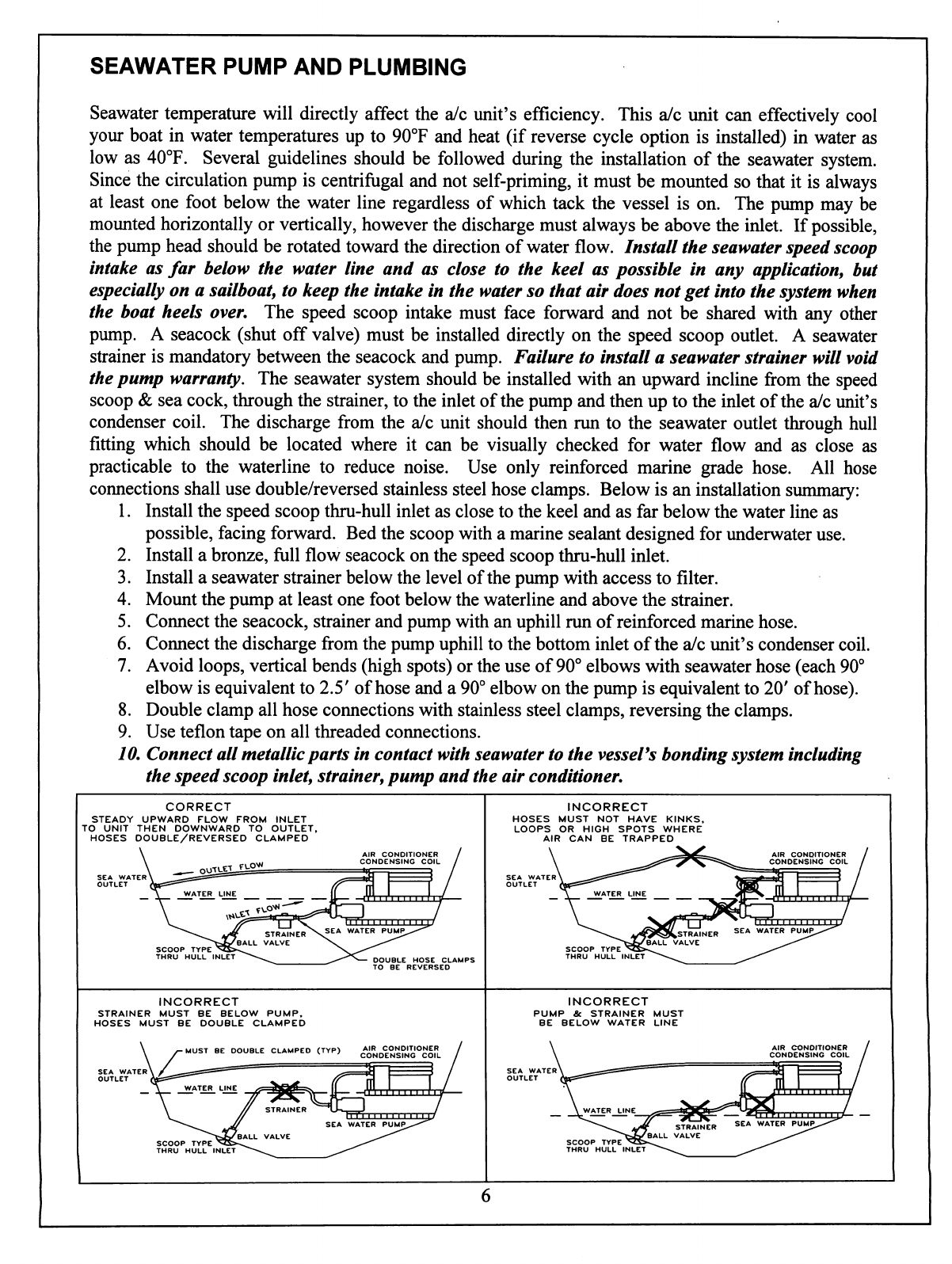

SEAWATER

PUMP

AND

PLUMBING

Seawater

temperature

will

directly

affect

the

a/c unit's

efficiency.

This

a/c

unit

can

effectively

cool

your

boat

in

water

temperatures

up

to

90°F

and

heat

(if

reverse

cycle

option

is

installed)

in

water

as

low

as

40°F.

Several

guidelines

should

be

followed

during

the

installation

of

the

seawater

system.

Since

the

circulation

pump

is

centrifugal

and

not

self-priming,

it

must

be

mounted

so

that

it

is

always

at

least

one

foot

below

the

water

line

regardless

of

which

tack

the

vessel

is

on.

The

pump

may

be

mounted

horizontally

or

vertically,

however

the

discharge

must

always

be

above

the

inlet.

If

possible,

the

pump

head

should

be

rotated

toward

the

direction

of

water

flow.

Install

the

seawater

speed

scoop

intake

as

far

below

the

water

line

and

as

close

to

the

keel

as possible

in

any

application,

but

especially

on

a

sailboat,

to

keep

the

intake

in

the

water

so

that

air

does

not

get

into

the

system

when

the

boat

heels

over.

The

speed

scoop

intake

must

face

forward

and

not

be

shared

with

any

other

pump.

A

seacock

(shut

off

valve)

must

be

installed

directly

on

the

speed

scoop

outlet.

A

seawater

strainer

is

mandatory

between

the

seacock

and

pump.

Failure

to

install

a

seawater

strainer

will

void

the

pump

warranty.

The

seawater

system

should

be

installed

with

an

upward

incline

from

the

speed

scoop

&

sea

cock,

through

the

strainer,

to

the

inlet

of

the

pump

and

then

up

to

the

inlet

of

the

a/c

unit's

condenser

coil.

The

discharge

from

the

a/c

unit

should

then

run

to

the

seawater

outlet

through

hull

fitting

which

should

be

located

where

it

can

be

visually

checked

for

water

flow

and

as

close

as

practicable

to

the

waterline

to

reduce

noise.

Use

only

reinforced

marine

grade

hose.

All

hose

connections

shall

use

double/reversed

stainless

steel

hose

clamps.

Below

is

an

installation

summary:

1.

Install

the

speed

scoop

thru-hull

inlet

as

close

to

the

keel

and

as

far

below

the

water

line

as

possible,

facing

forward.

Bed

the

scoop

with

a

marine

sealant

designed

for

underwater

use.

2.

Install

a

bronze,

full

flow

seacock

on

the

speed

scoop

thru-hull

inlet.

3.

Install

a

seawater

strainer

below

the

level

of

the

pump

with

access

to

filter.

4.

Mount

the

pump

at

least

one

foot

below

the

waterline

and

above

the

strainer.

5.

Connect

the

seacock,

strainer

and

pump

with

an

uphill

run

of

reinforced

marine

hose.

6.

Connect

the

discharge

from

the

pump

uphill

to

the

bottom

inlet

of

the

a/c

unit's

condenser

coil.

7.

Avoid

loops,

vertical

bends

(high

spots)

or

the

use

of

90°

elbows

with

seawater

hose

(each

90°

elbow

is

equivalent

to

2.5'

of

hose

and

a

90°

elbow

on

the

pump

is

equivalent

to

20'

of

hose).

8.

Double

clamp

all

hose

connections

with

stainless

steel

clamps,

reversing

the

clamps.

9.

Use

teflon

tape

on

all

threaded

connections.

10.

Connect

all

metallic

parts

in

contact

with

seawater

to

the

vesseVs

bonding

system

including

the

speed

scoop

inlet,

strainer,

pump

and

the

air

conditioner.

CORRECT

STEADY

UPWARD

FLOW FROM

INLET

TO

UNIT

THEN

DOWNWARD

TO

OUTLET,

HOSES

DOUBLE/REVERSED

CLAMPED

DOUBLE HOSE

CLAMPS

TO

BE

REVERSED

INCORRECT

HOSES

MUST

NOT

HAVE

KINKS,

LOOPS

OR

HIGH

SPOTS

WHERE

AIR

CAN

BE

TRAPPED

INCORRECT

STRAINER

MUST

BE

BELOW

PUMP,

HOSES

MUST

BE

DOUBLE

CLAMPED

INCORRECT

PUMP

&

STRAINER

MUST

BE

BELOW

WATER

LINE

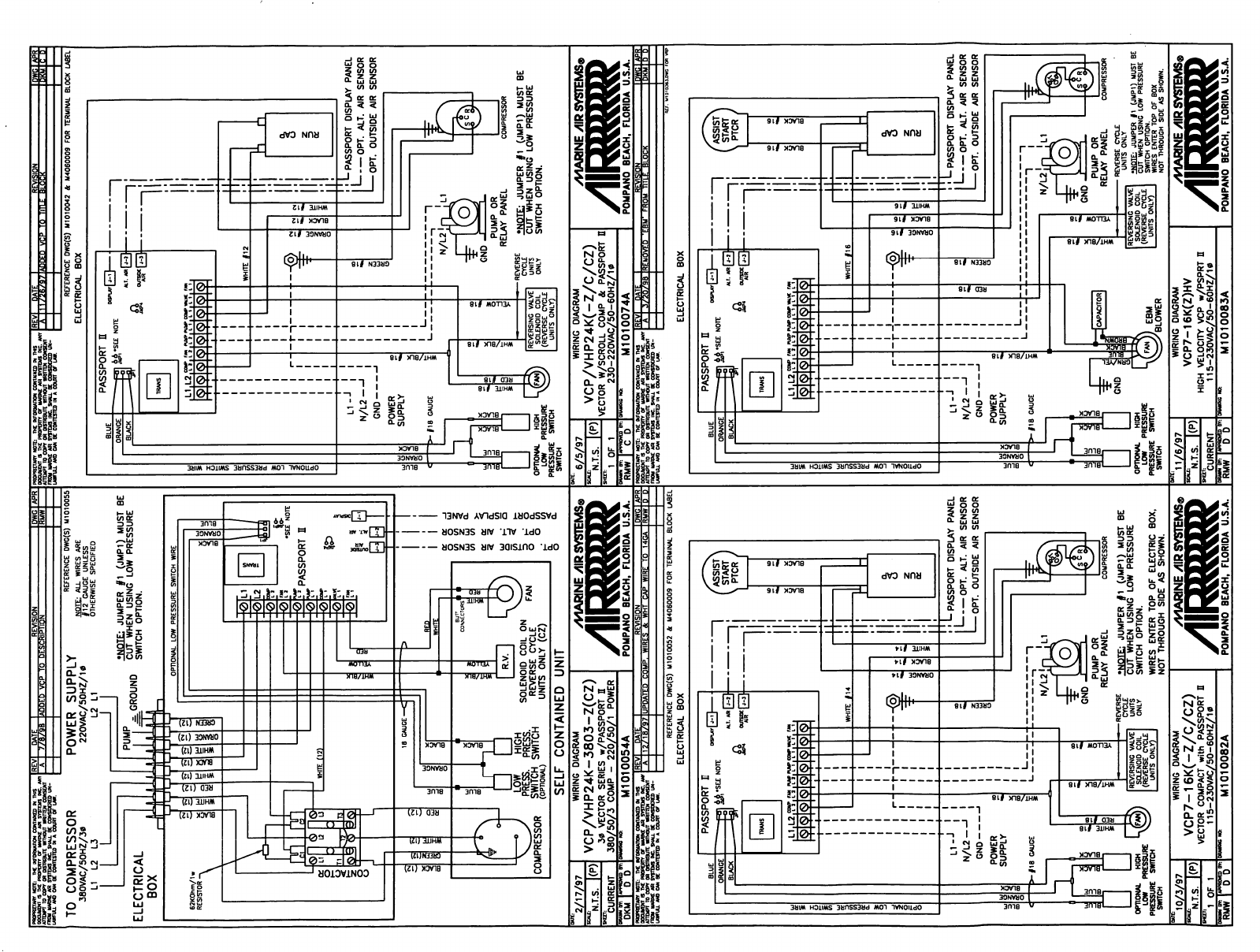

ELECTRICAL

CONNECTIONS,

GROUNDING

AND

BONDING

All

a/c

units

have

a

terminal

strip

mounted

inside

the

electric

box.

The

terminal

strip

is

labeled

for

proper

connections

of

the

electrical

supply,

ground

wires

and

pump

circuits.

A

wiring

diagram

is

provided

in

the

electrical

box

and

in

this

manual.

The

correct

size

circuit

breaker

should

be

used

to

protect

the

system

as

specified

on

the

a/c

unit's

data

plate

label.

A

minimum

of

12

AWG

boat

cable

should

be

used

to

supply

power

to

the

a/c

unit

and

the

seawater

pump.

All

connections

shall

be

made

with

ring

or

fork

terminals.

Turn

off

a/c

power

supply

circuit

breaker

before

opening

electric

box.

Each

a/c

unit

installed

requires

its

own

dedicated

circuit

breaker.

If

there

is

only

one

a/c

unit

installed,

the

seawater

pump

does

not

require

a

circuit

breaker;

the

wiring

from

the

seawater

pump

is

connected

to

the

terminal

strip

in

the

electric

box.

If

two

or

more

a/c

units

use

the

same

seawater

pump,

the

pump

wires

will

be

connected

to

a

pump

relay

panel

(PRP)

which

in

turn

has

its

own

dedicated

circuit

breaker

sized

for

the

pump

(20

amp

max).

Please

see

the

wiring

diagram

furnished

with

the

PRP

(NOTE:

PRP

triac

must

have

its

mounting

screw

installed

in

order

to

dissipate

heat).

Electrical

connections

in

the

bilge

and/or

below

the

waterline

should

use

heat

shrink

type

butt

splices.

Field

wiring

must

comply

with

ABYC

electrical

codes.

Power

to

the

unit

must

be

within

the

operating

voltage

range

indicated

on

the

data

plate.

Properly

sized

fuses

or

HACR

circuit

breakers

must

be

installed

for

branch

circuit

protection.

See

data

plate

for

maximum

fuse/circuit

breaker

size

(mfs)

and

minimum

circuit

ampacity

(mca).

All

units

must

be

effectively

grounded

to

minimize

the

hazard

of

electrical

shock

and

personal

injury.

The

following

are

to

be

observed:

1.

AC

(alternating

current)

grounding

(green

wire)

must

be

provided with

the

AC

power

conductors

and

connected

to

the

ground

terminal

(marked

"GRND")

at

the

AC

power

input

terminal

block

of

the

unit(s),

per

ABYC

standard

E-8,

or

equivalent.

2.

Connections

between

the

vessel's

AC

system

grounding

conductor

(green

wire)

and

the

vessel's

DC

(Direct

Current)

negative

or

bonding

system

should

be

made

as

part

of

the

vessel's

wiring,

per

ABYC

standard

E-9,

or

equivalent.

3.

When

servicing

or

replacing

existing

equipment

that

contains

a

chassis-mounted

ground

stud,

the

service

person

or

installer

must

check

the

vessel's

wiring

for

the

existence

of

the

connection

required

in

item

2

above.

ABYC

standards

are

available

from:

American

Boat

and

Yacht

Council

3069

Solomon's

Island

Rd.

Edgewater,

MD

21036

Telephone:

(410)

956-1050

The

a/c

unit

must

be

connected

to

the

ship's

bonding

system

to

prevent

corrosion

due

to

stray

electrical

current

or

voltage.

All

pumps,

metallic

valves

and

fittings

in

the

seawater

circuit

that

are

isolated

from

the

a/c

unit

by

PVC

or

rubber

hoses

must

be

individually

bonded

to

the

vessels

bonding

system

also.

This

will

help

eliminate

any

possibility

of

corrosion

due

to

stray

current

or

voltage.

FAILURE

TO

PROPERLY

GROUND

AND

BOND

THE

SYSTEM

WILL

VOID

WARRANTY!

3

PHASE

NOTICE

It

is

extremely

important

to

insure

that

wiring

and

phase

sequencing

of

a

three

phase

power

source

is

correct.

Marine

wiring

standards

call

for

power

source

phases

LI,

L2,

and

L3

to

be

color-coded

BLACK,

WHITE,

and

RED,

respectively.

These

must

be

connected

to

the

unit

with

the

proper

sequence,

otherwise,

it

will

not

operate

properly.

If

the

wiring

sequence

is

incorrect,

the

unit's

compressor

{Scroll

type

only)

and

pump

(if

applicable)

will

run

in

the

reverse

direction

at

a

significantly

increased

noise

level.

VECTOR

COMPACT

WIRING

DIAGRAMS

1

GREEN

2

BLACK

3

WHT/BLK

4

RED

5

ORANGE

6

YELLOW

7

BLK/RED

8

WHltE

SELF

CONTAINED

UNIT

MALE

FEMALE

POLARIZED

PLUG

DETAIL

3/19/98

N.T.S.

WIRING

DIAGRAM

VCM24K-Z

3PH

VECTOR

COMPACT

3*

24K

WITH

230VAC/50-60HZ/3g

MCP

M1010090A

/III

/MARINE/IR

SYSTEMS®

mi))))

POMPANO

BEACH,

FLORIDA

U.S.A.

oktaino)

m

ths

REV

DATE

AIR

SYSTEMS

NC

ANY

—

*—&

>WFULL

AND

CAN

BE

CCNTESTEO

M

A

COURT

OT

b

POWER

SUPPLY

GND

POWER

SUPPLY

•=BUH

CONNECTORS

FIELD

WIRING

1

CREEN

2

BUCK

3

WHT/BLK

4

REO

5

ORANCE

6

YELLOW

7

BLK/RED

/B

WHITE

SELF

CONTAINED

UNIT

MALE

FEMALE

POLARIZED

PLUG

DETAIL

1

GREEN

2

SLACK

3

WHT/BLK

4

RED

5 ORANGE

6

YELLOW

7

BLK/RED

8

WHITE

SELF

CONTAINED

UNIT

MALE

FEMALE

POLARIZED

PLUG

DETAIL

1/19/98

N.T.S.

WIRING

DIAGRAM

VCM7-16K(-Z/C/CZ)

VECTOR

COMPACT

with

MCP

115-23OVAC/5O-6OHZ/10

M1010086

/HARINE

yiiR

SYSTEMS®

1/30/98

N.T.S.

POMPANO

BEACH,

FLORIDA

U.S.A.

WIRING

DIAGRAM

VCM24K(-Z/C/CZ)

VECTOR

COMPACT

with

MCP

115-230VAC/50-60HZ/1*

M1010087

yVlARINE/IR

SYSTEMS®

POMPANO

BEACH.

FLORIDA

U.S.A.

/B/9B

AUUfcU

VIP

IU

I

PROPRIETARY

NOTE:

THE

INFORMATION

CONTAINED

W

THS

ATTEMPT

TO

COPT

OR

TO

COMPRESSOR

38OVAC/5OHZ/30

L1

L2 L3

LJ

REFERENCE

DWC(S)

M1010055

NOTE:

ALJL

WIRES

ARE

7i2

GAUGE

UNL£SS

OTHERWISE

SPECIFIED

POWER

SUPPLY

220VAC/50HZ/1*

L2

L1

'NOTE:

JUMPER

#1

(JMP1)

MUST

BE

PUM.P

-

rRnuwn

CUT

WHEN

USING

LOW

PRESSURE

^GROUND

SOLENOID

COIL

ON

REVERSE

CYCLE

UNITS

ONLY

(CZ)

SELF

CONTAINED

UNIT

-ML

11/26/9

ADDED

VCP

TO

TITLE

BLOC

REFERENCE

DWC(S)

Ml010042

&

M406C009

FOR

TERMINAL

BLOCK

LABEL

ELECTRICAL

BOX

!

L

PASSPORT

DISPLAY

PANEL

•

OPT.

ALT.

AIR

SENSOR

OPT.

OUTSIDE

AIR

SENSOR

*NOTE:

JUMPER

#1

(JMP1)

MUST

BE

CUT

WHEN

USING

LOW

PRESSURE

SWITCH

OPTION.

2/17/97

*N.T.S.

CURRENT

WIRING

DIAGRAM

VCP/VHP24K-3803-Z(CZ)

3*

VECTOR

SERIES

w/PASSPORT

E

380/50/3

COMP

-

220/50/1

POWER

7V1AR1NE/HR

SYSTEMS®

6/5/97

"N.T.5.

Iff)

1

OF

1

WIRING

DIAGRAM

VCP/VHP24K(-Z/C/CZ)

VECTOR

W/SCROLL

COMP

&

PASSPORT

23O-22OVAC/5O-6OHZ/10

/MARINE

/IR

SYSTEMS®

POMPANO

BEACH,

FLORIDA

U.S.A.

POMPANO

BEACH,

FLORIDA

U.S.A.

REFERENCE

DWC(S)

M1O1OO52

it

M4060009

FOR

TERMINAL

BLOCK

LABEL

ELECTRICAL

BOX

ELECTRICAL

BOX

L-

PASSPORT

DISPLAY

PANEL

'

OPT.

ALT.

AIR

SENSOR

I

OPT.

OUTSIDE

AIR

SENSOR

D

OPTIONAL

HIGH

LOW

PRESSURE

PRESSURE

SWITCH

SWITCH

•NOTE:

JUMPER

#1

(JMP1)

MUST

BE

CUT

WHEN

USING

LOW

PRESSURE

SWITCH

OPTION.

WIRES

ENTER

TOP

OF

ELECTRIC BOX,

NOT

THROUGH

SIDE

AS

SHOWN.

OPTIONAL

HIGH

LOW

PRESSURE

PRESSURE

SWITCH

SWITCH

EBM

'BLOWER

REVERSING

VALVE

SOLENOID

COIL

(REVERSE

CYCLE

UNITS

ONLY)

COMPRESSOR

REVERSE

CYCLE

UNITS

ONLY

•NOTF:

JUMPER

fi

(JMP1)

MUST

BE

CUT

WHEN

USING

LOW

PRESSURE

SWITCH

OPTION.

WIRES

ENTER

TOP

OF

BOX

NOT

THROUGH

SIDE

AS SHOWN.

10/3/97

"N.T.S.

1

OF

1

RMW

I

D D

WIRING

DIAGRAM

VCP7-16K(-Z/C/CZ)

VECTOR

COMPACT

with

PASSPORT

0

115-230VAC/50-60HZ/1

g

M1010082A

/MARINE

yllRSYSTEMSp

POMPANO

BEACH,

FLORIDA

U.S.A.

11/6/97

"!N.T.S.

CURRENT

RMW

|

D D

WIRING

DIAGRAM

VCP7-16K(Z)HV

HIGH

VELOCITY

VCP

w/PSPRT

H

115-23OVAC/5O-6OHZ/10

M1010083A

/V1AR1NE

y||R

SYSTEMS®

POMPANO

BEACH.

FLORIDA

U.S.A.

MANUAL

CONTROL

PANEL

(MCP)

INSTALLATION

The

MCP

should

be

located

within

cap

tube

length

of

the

a/c

unit.

The

3

knob

MCP

is

configured

either

vertically

(shown)

or

horizontally.

The

cut

out

size

is

2.5"

by

7.0",

see

MCP

for

orientation.

Once

the

cut

out

is

made,

carefully

uncoil

the

copper

cap

tube

with

return

air

sensor

(copper

bulb)

and

route

the

control

wires

and

cap

tube

through

the

hole

and

back

to

the

a/c

unit

using

caution

not

to

kink

the

cap

tube.

Mount

the

return

air

sensor

into

the

clips

provided

on

the

evaporator

coil.

If

the

return

air

sensor

cannot

be

mounted

on

the

evaporator

coil,

mount

it

behind

the

return

air

grille.

The

sensor

must

be

mounted

in

the return

air

stream.

Make

electrical

connections

according

to

the

wiring

diagram

found

in

the

electric

box

and/or

in

the

operations

manual.

MCP

OPERATION

1)

Ensure

seawater

intake

ball

valve

(sea

cock)

is

open.

2)

Turn

SYSTEM

SWITCH

control

knob

to

OFF.

3)

Turn

on

AC

circuit

breaker.

If

the

seawater

pump

has

its

own

circuit

breaker,

turn

that

on

too.

4)

Turn

the

SYSTEM

SWITCH

control

knob

to

START;

this

energizes

the

fan

and

seawater

pump.

Turn

THERMOSTAT

control

knob

to

the

coolest

position

by

rotating

fully

clockwise.

If

system

has

reverse

cycle,

turn

knob

counter-clockwise

for

heat.

5)

Check

for

a

steady

solid

stream

of

seawater

from

the

overboard

discharge.

6)

Turn

FAN

SPEED

control

knob

clockwise

to

highest

setting.

7)

Verify

that

the

fan

is

running

and

that

there

is

steady

airflow

out

of

the

supply

air

grille.

8)

Turn

the

SYSTEM

SWITCH

to

RUN;

this

will

start

the

compressor.

The

indicator

light

on

the

control

will

illuminate.

9)

To

set

the

thermostat,

allow

sufficient

time

for

the

unit

to

cool/heat

the

area

to

the

desired

temperature.

When

the

area

is

sufficiently

cooled/heated,

turn

the

thermostat

knob

slowly

toward

the

center

position

until

it

clicks

once

(the

indicator

light

will

turn

off).

The

thermostat

is

now

set

to

maintain

a

constant

temperature.

While

heating,

if

the

ambient

temperature

is

less

than

50°F,

set

the

FAN

SPEED

control

knob

to

low

for

five

to

ten

minutes

until

the

unit

begins

to

heat

well,

then

increase

the

fan

speed

for

more

heat

output.

START

SYSTEM

SWITCH

FAN

SPEED

THERMOSTAT

O

/MARINE/URSVSIEMS&

2.5"

CUT

OUT

-3.75"

PANEL-

O

5

„

b

t^ °°

The

thermostat

on

the

MCP

control

panel

serves

to

cycle

the

compressor

on

and

off

and

provide

an

automatic

changeover

from

cooling

to

heating

(reverse

cycle

only)

with

a

3.5°

differential.

Rotating

the

thermostat

to

the

left

after

it

has

been

set

for

cooling

will

cause

the

unit

to

heat.

If

you

rotate

the

thermostat

to

the

right,

the

unit

will

cool.

If

the

thermostat

is

left

stationary

after

being

set,

the

unit

will

cycle

from

cooling

to

neutral,

or

heating

to

neutral

depending

on

the

requirement.

Note:

Do

not

turn

the

unit

off

and

immediately

turn

it

back

on.

Wait

at

least

30

seconds.

10

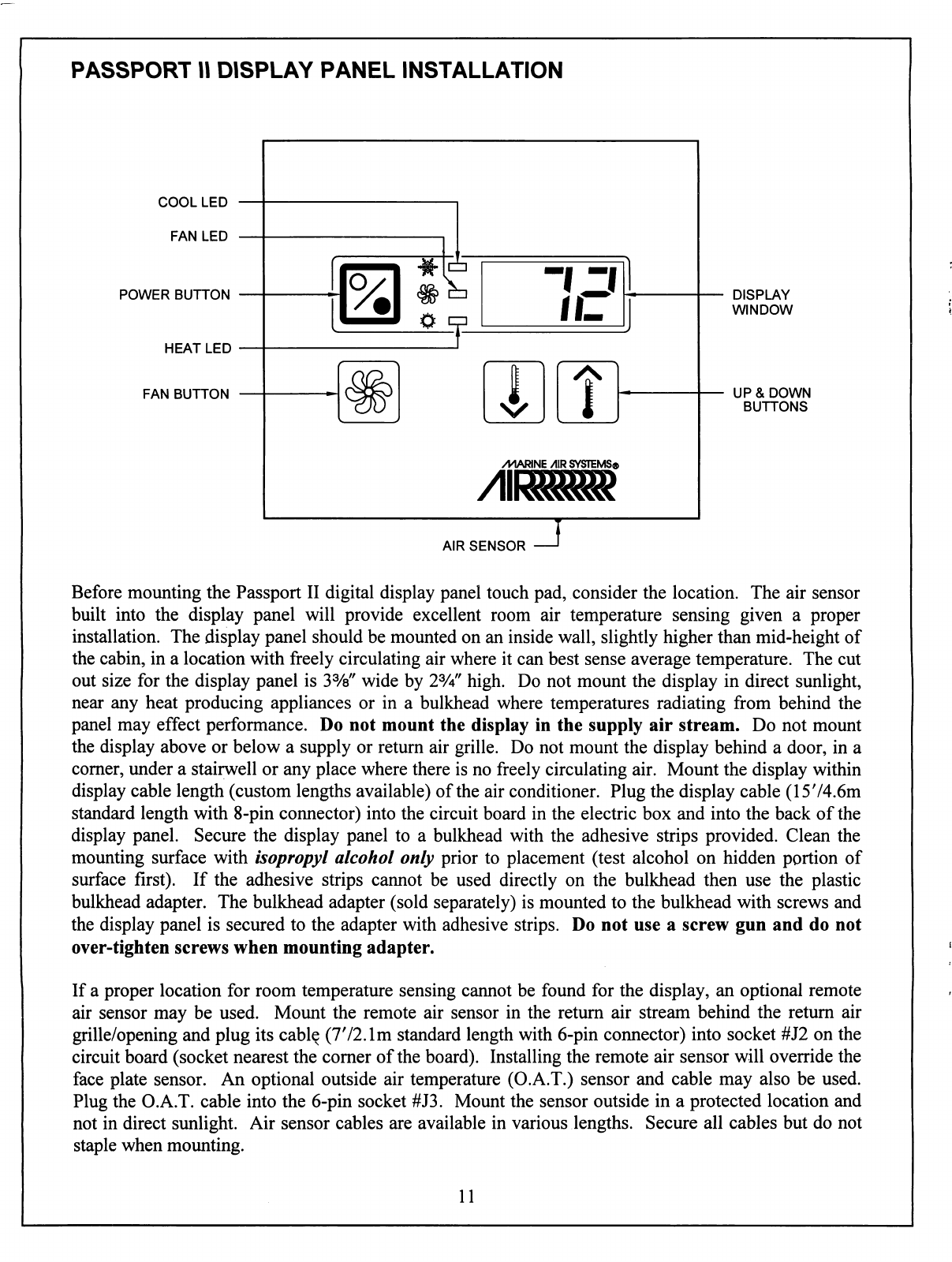

PASSPORT

II

DISPLAY

PANEL

INSTALLATION

COOL

LED

FAN

LED

POWER

BUTTON

HEAT

LED

FAN

BUTTON

DISPLAY

WINDOW

UP

&

DOWN

BUTTONS

AIR

SENSOR

Before

mounting

the

Passport

II

digital

display

panel

touch

pad,

consider

the

location.

The

air

sensor

built

into

the

display

panel

will

provide

excellent

room

air

temperature

sensing

given

a

proper

installation.

The

display

panel

should

be

mounted

on

an

inside

wall,

slightly

higher

than

mid-height

of

the

cabin,

in

a

location

with

freely

circulating

air

where

it

can

best

sense

average

temperature.

The

cut

out

size

for

the

display

panel

is

3%"

wide by

2%"

high.

Do

not

mount

the

display

in

direct

sunlight,

near

any

heat

producing

appliances

or

in

a

bulkhead

where

temperatures

radiating

from

behind

the

panel

may

effect

performance.

Do

not

mount

the

display

in

the

supply

air

stream.

Do

not

mount

the

display

above

or

below

a

supply

or

return

air

grille.

Do

not

mount

the

display

behind

a

door,

in

a

corner,

under

a

stairwell

or

any

place

where

there

is

no

freely

circulating

air.

Mount

the

display

within

display

cable

length

(custom

lengths

available)

of

the

air

conditioner.

Plug

the

display

cable

(1574.6m

standard

length

with

8-pin

connector)

into

the

circuit

board

in

the

electric

box

and

into

the

back

of

the

display

panel.

Secure

the

display

panel

to

a

bulkhead

with

the

adhesive

strips

provided.

Clean

the

mounting

surface

with

isopropyl

alcohol

only

prior

to

placement

(test

alcohol

on

hidden

portion

of

surface

first).

If

the

adhesive

strips

cannot be

used

directly

on

the

bulkhead

then

use

the

plastic

bulkhead

adapter.

The

bulkhead

adapter

(sold

separately)

is

mounted

to

the

bulkhead

with

screws

and

the

display

panel

is

secured

to

the

adapter

with

adhesive

strips.

Do

not use

a

screw

gun

and

do

not

over-tighten

screws

when

mounting

adapter.

If

a

proper

location

for

room

temperature

sensing

cannot

be

found

for

the

display,

an

optional

remote

air

sensor

may

be

used.

Mount

the

remote

air

sensor

in

the

return

air

stream

behind

the

return

air

grille/opening

and

plug

its

cable

(772.1m

standard

length

with

6-pin

connector)

into

socket

#J2

on

the

circuit

board

(socket nearest

the

corner

of

the

board).

Installing

the

remote

air

sensor

will

override

the

face

plate

sensor.

An

optional outside

air

temperature

(O.A.T.) sensor

and

cable

may

also

be

used.

Plug

the

O.A.T.

cable

into

the

6-pin

socket

#J3.

Mount

the

sensor

outside

in

a

protected

location

and

not

in

direct

sunlight.

Air

sensor

cables

are

available

in

various

lengths.

Secure

all

cables

but

do

not

staple

when

mounting.

11

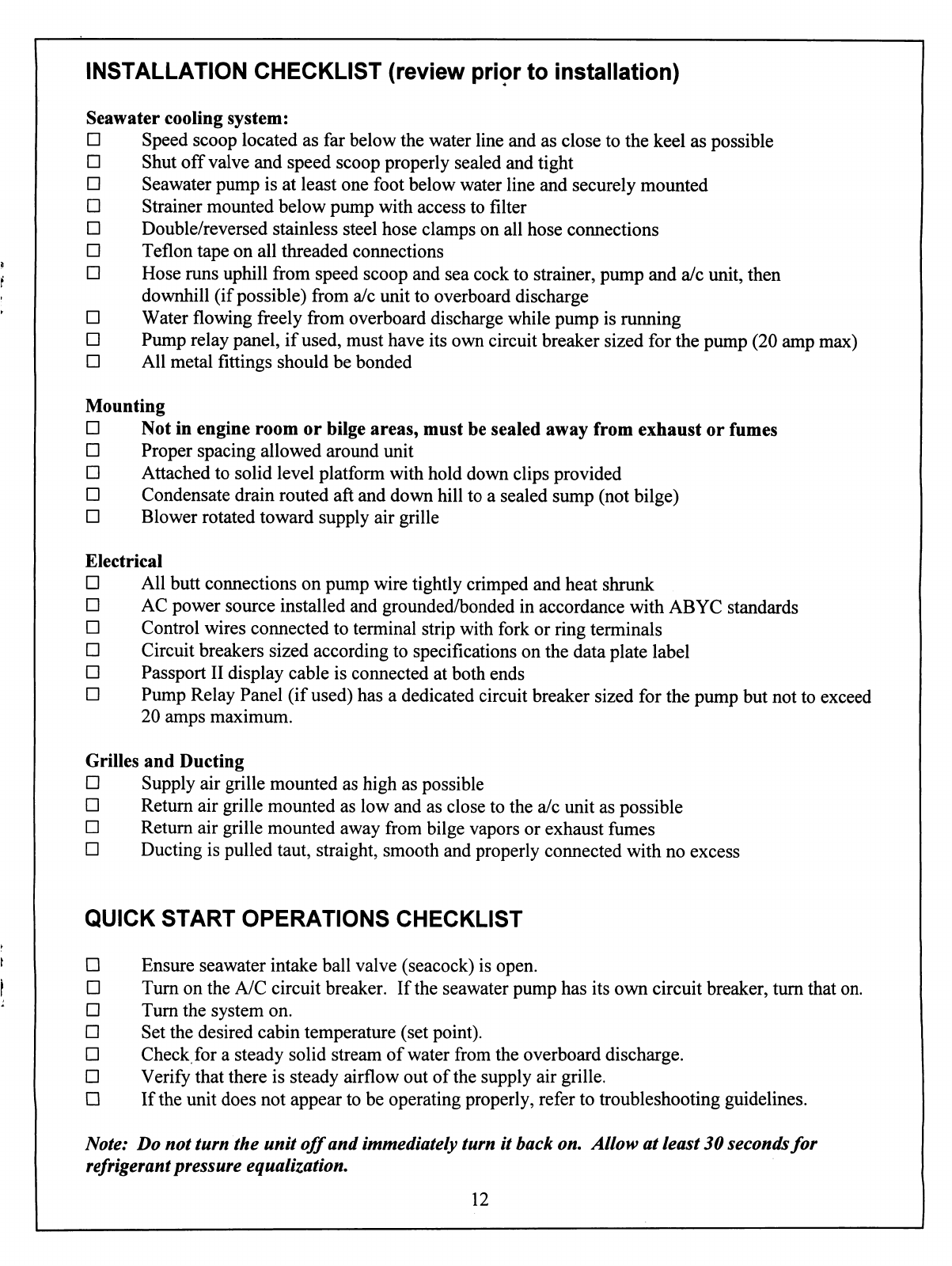

INSTALLATION

CHECKLIST

(review

prior

to

installation)

Seawater

cooling

system:

□

Speed

scoop

located

as

far

below

the

water

line

and

as

close

to

the

keel

as

possible

□

Shut

off

valve

and

speed scoop

properly

sealed

and

tight

□

Seawater

pump

is

at

least

one

foot

below

water

line

and

securely

mounted

□

Strainer

mounted

below

pump

with

access

to

filter

□

Double/reversed

stainless

steel

hose

clamps

on

all

hose

connections

□

Teflon

tape

on

all

threaded

connections

□

Hose

runs

uphill

from

speed

scoop

and

sea

cock

to

strainer,

pump

and

a/c

unit,

then

downhill

(if

possible)

from

a/c

unit

to

overboard

discharge

□

Water

flowing

freely

from

overboard

discharge

while

pump

is

running

□

Pump

relay

panel,

if

used,

must

have

its

own

circuit

breaker

sized

for

the

pump

(20

amp

max)

□

All

metal

fittings

should

be

bonded

Mounting

D

Not

in

engine

room

or

bilge

areas,

must

be

sealed

away

from

exhaust

or

fumes

□

Proper

spacing

allowed

around

unit

□

Attached

to

solid

level

platform

with

hold

down

clips

provided

□

Condensate

drain

routed

aft

and

down

hill

to

a

sealed

sump

(not

bilge)

□

Blower

rotated

toward

supply

air

grille

Electrical

□

All

butt

connections

on

pump

wire

tightly

crimped

and

heat

shrunk

□

AC

power

source

installed

and

grounded/bonded

in

accordance

with

ABYC

standards

□

Control

wires

connected

to

terminal

strip

with

fork

or

ring

terminals

□

Circuit

breakers

sized

according

to

specifications

on

the

data

plate

label

□

Passport

II

display

cable

is

connected

at

both

ends

□

Pump

Relay

Panel

(if

used)

has

a

dedicated

circuit

breaker

sized

for

the

pump

but

not

to

exceed

20

amps

maximum.

Grilles

and

Ducting

□

Supply

air

grille

mounted

as

high

as

possible

□

Return

air

grille

mounted

as

low

and

as

close

to

the

a/c

unit as

possible

□

Return

air

grille

mounted

away

from

bilge

vapors

or

exhaust

fumes

□

Ducting

is

pulled

taut,

straight,

smooth

and

properly

connected

with

no

excess

QUICK

START OPERATIONS

CHECKLIST

□

Ensure

seawater

intake

ball

valve

(seacock)

is

open.

□

Turn

on

the

A/C

circuit

breaker.

If

the

seawater

pump

has

its

own

circuit

breaker,

turn

that

on.

□

Turn

the

system

on.

□

Set

the

desired

cabin

temperature

(set

point).

□

Check

for

a

steady

solid

stream

of

water

from

the

overboard

discharge.

□

Verify

that

there

is

steady

airflow

out

of

the

supply

air

grille.

□

If

the

unit

does

not

appear

to

be

operating

properly,

refer

to

troubleshooting

guidelines.

Note:

Do

not

turn

the

unit

off

and

immediately

turn

it

back

on.

Allow

at

least

30

seconds

for

refrigerant

pressure

equalization.

12

PASSPORT

II

CONTROL

POWER

BUTTON:

Press

and