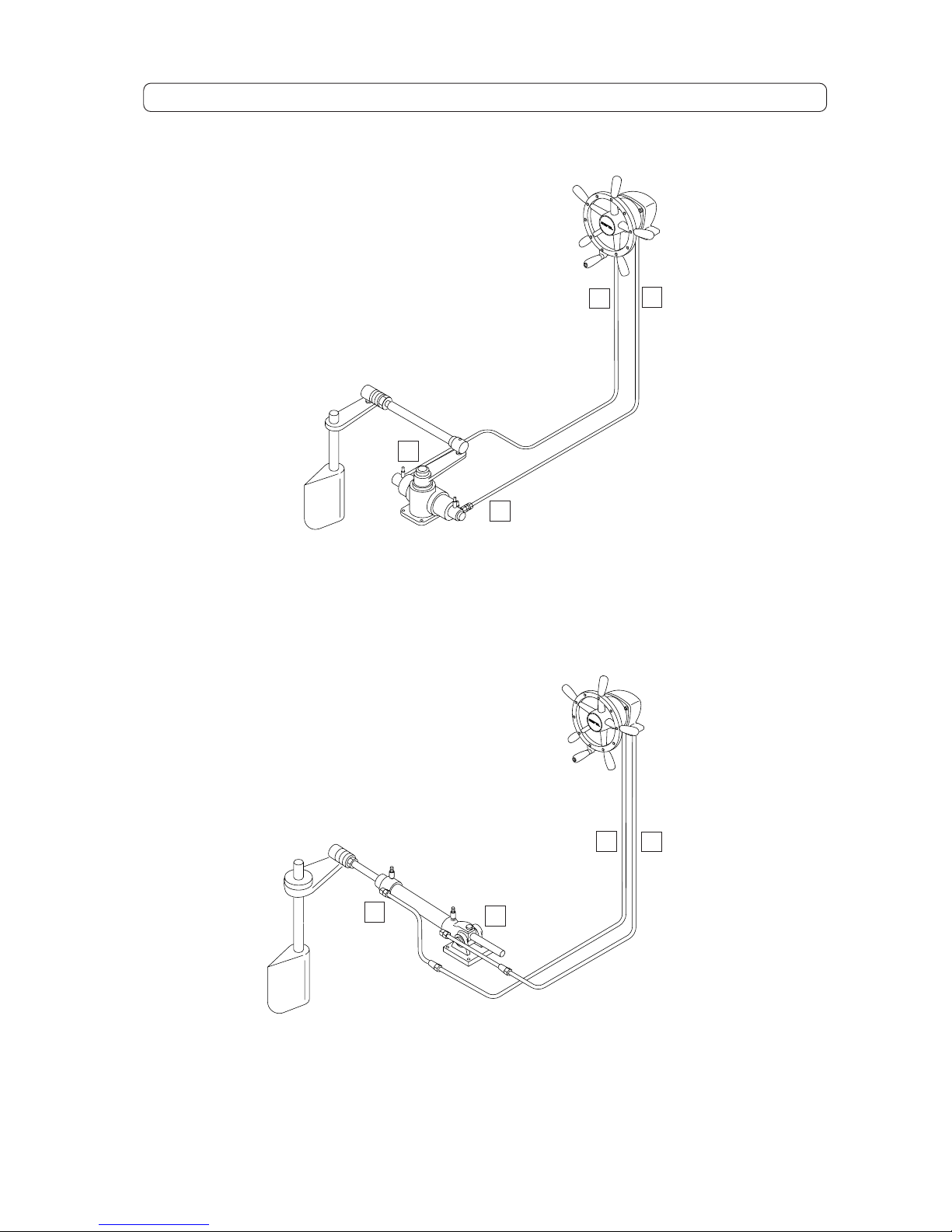

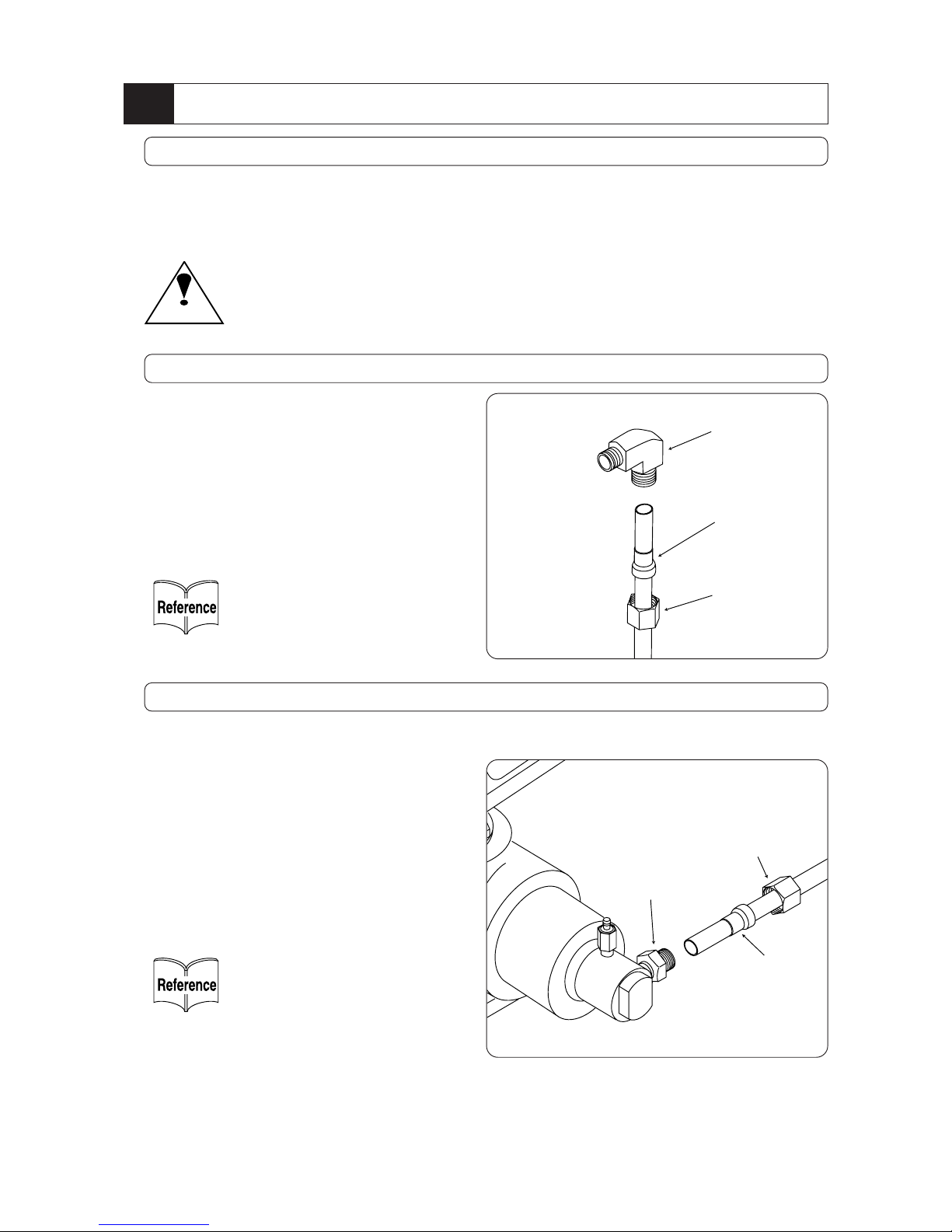

As to Piping

Don't use saw when cutting copper

tubes. Once finished piping works,

clean up all around piping and flush

connectors once removed.

Sawdust and/or fins by saw cutting

may cause poor operation.

Be sure to use pipe cutter and cut the

edges at right angle.

As to Periodical Inspection

Inspect or maintain all the equipment periodically.

Inspection and maintenance should be done periodi-

cally in accordance with Installation Manual.

WARNING shows the assumptive details which may lead

to the possibilities of death or serious injury.

CAUTION shows the assumptive details which may lead

to the possibilities of injury or damage of materials.

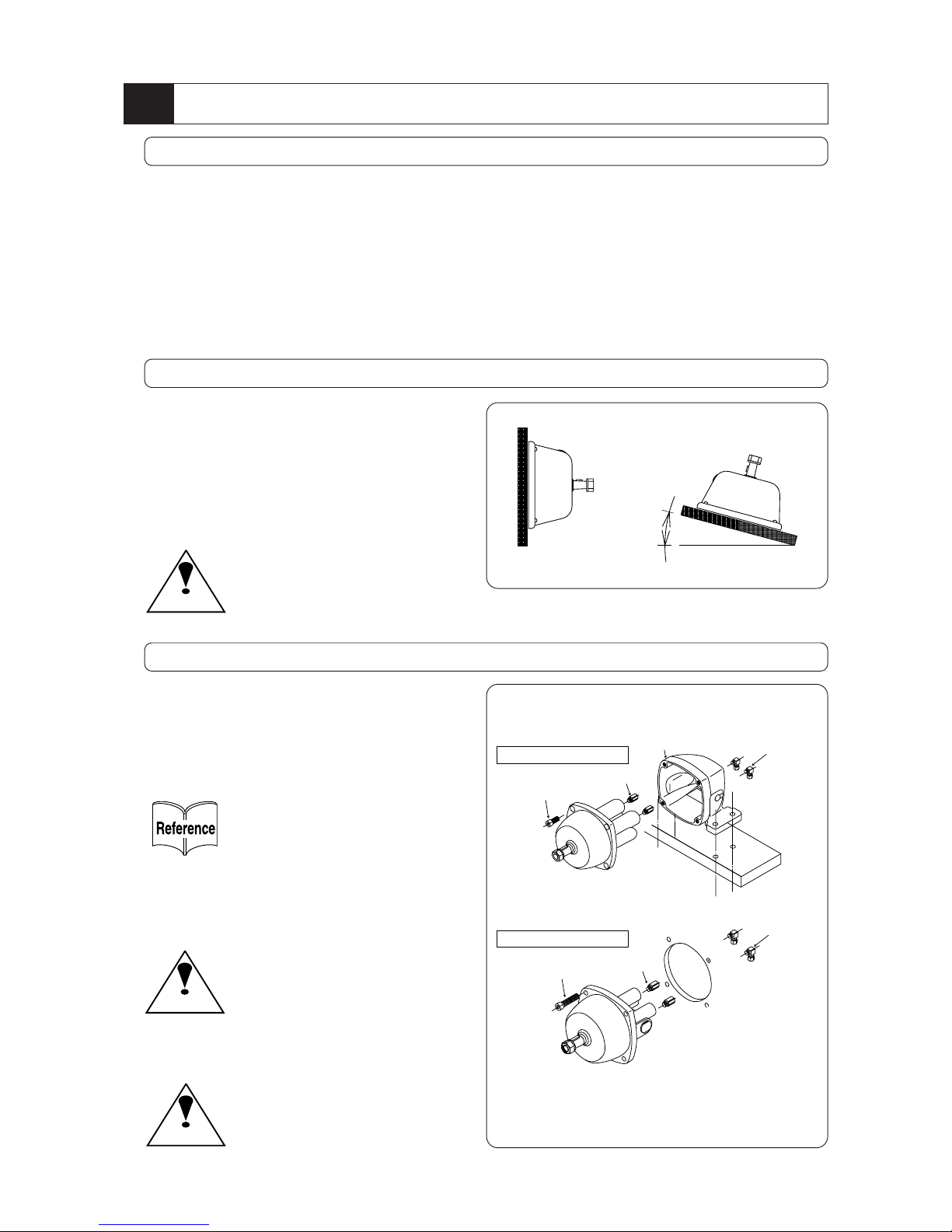

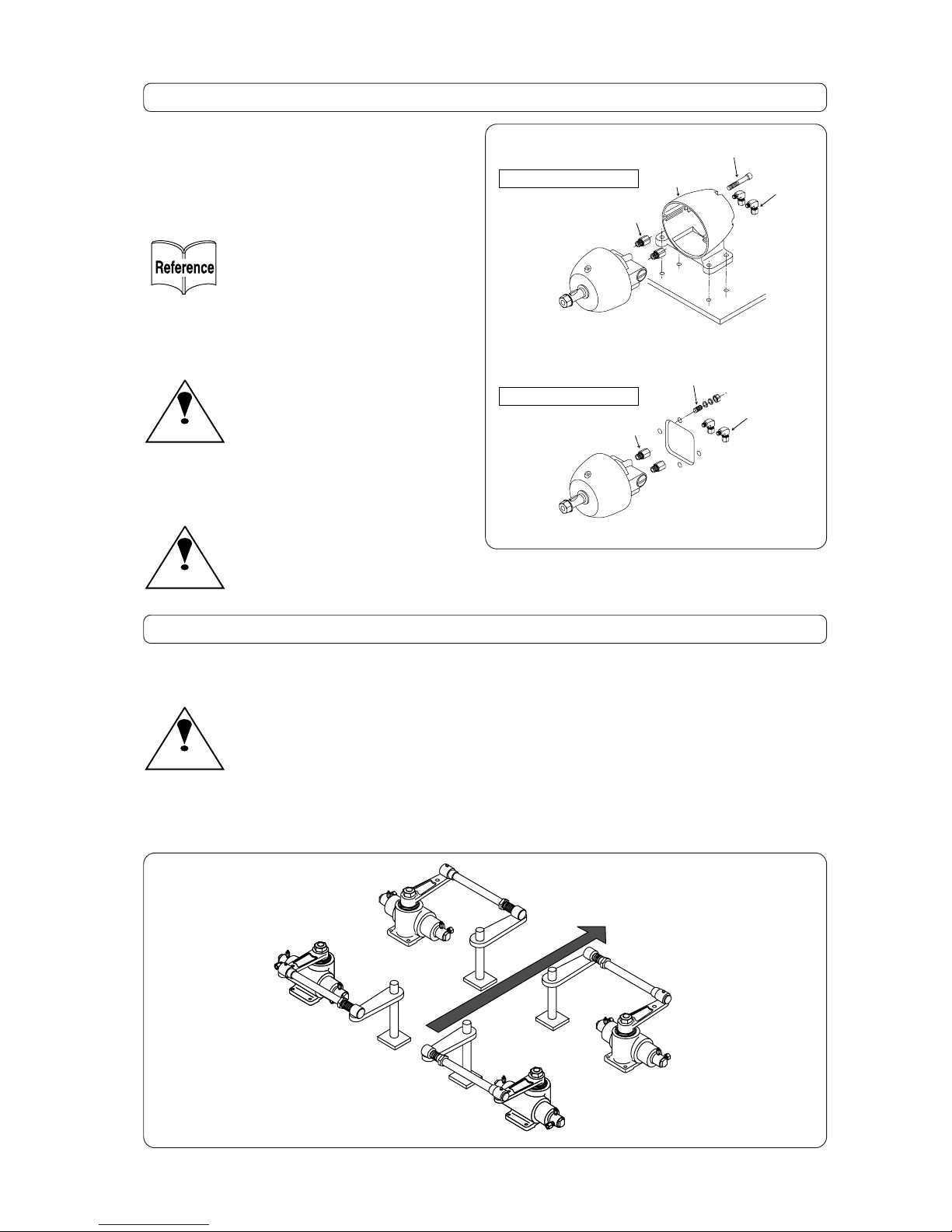

As to Helm Pump

Don't install it at the places where it may disturb

the steering.

Accidents may occur, if it will be installed at the

places where it may impede front visibility and

disturb steering.

On the fitting surface, apply caulking materials, if

necessary.

This is for prevention against penetration of

water into inside of boat.

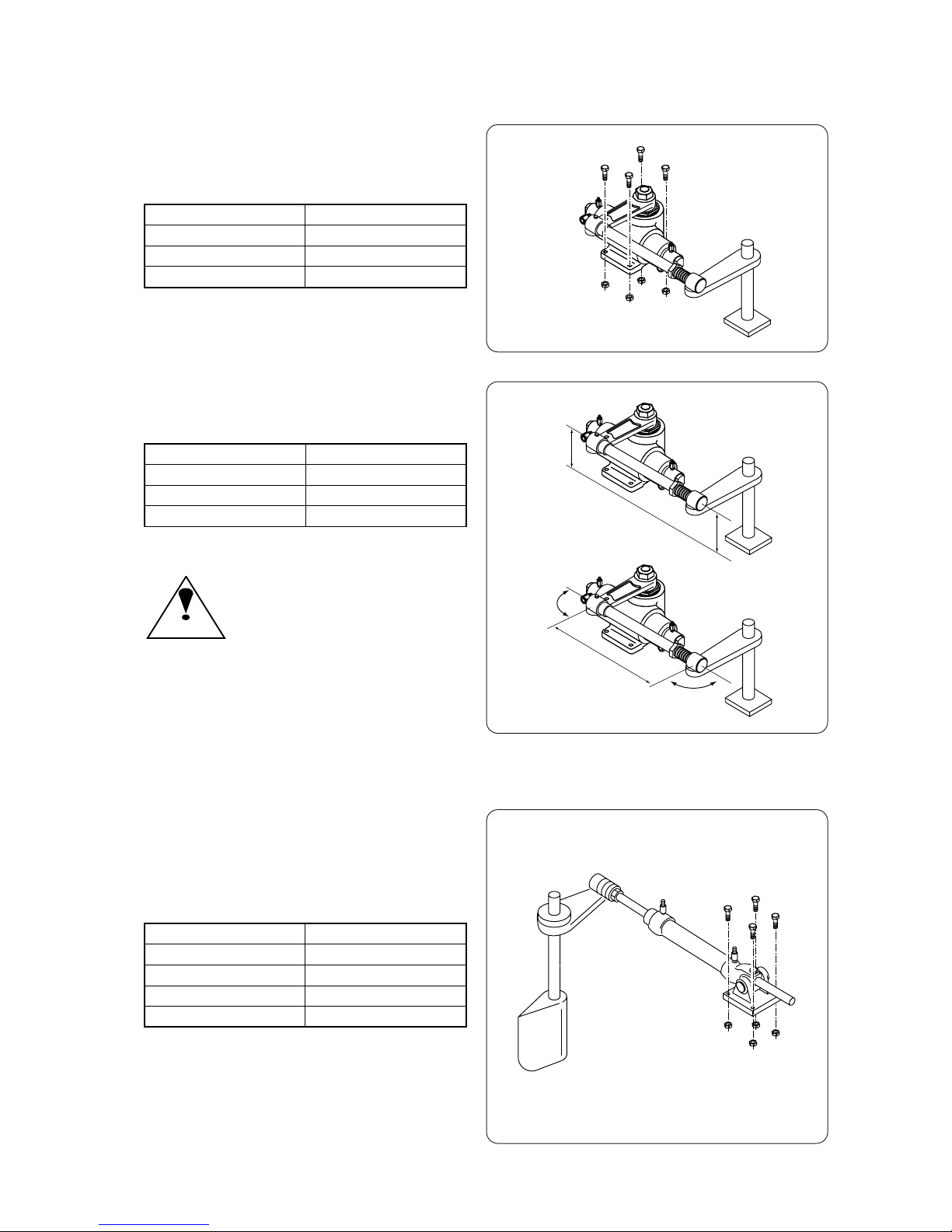

As to Receiving Cylinder Direct-driving type

Install Receiving Cylinder and connect-

ing link of tiller on even level with same

height.

If the connecting link is listed, it may

drop during steering.

Be sure to fasten the locknuts of cylinder

tightly.

After installation or stroke adjustment,

be sure to fasten locknuts tightly.

Otherwise it may cause the falling down

of cylinder.

As to Receiving Cylinder Rotary type

Install Receiving Cylinder and connect-

ing link of tiller on even level with the

same height. If the connecting link is

listed, it may drop during steering.

As to Inspection before Sailing Out

Before sailing out, operate handle and

confirm it to work normally.

Check oil level.