94-11 1294Printed in U.S.A. - 1 -

No. 94-11

Powerhead Water Ingestion - 225 Model

Mariner and Mercury

1994 and 1995

225 hp Models

S/N 0D280813 thru 0G178947

Therehavebeensomereportsofwateringestioninto

the lower cylinders on these engines.

Water may enter the lower cylinders from the cooling

slots on the exhaust adapter plate. Water can cause

spark plug misfire, internal rust and possibly power-

head damage. Modifications to the exhaust adapter

plateareto bemadeto avoidwateringestion through

the exhaust ports.

Water may also accumulate in the lower cowl from

leaking hoses or from external spray. Accumulated

water can cause electrical problems and can be

drawn into the lower carburetors to cause spark plug

misfire, internal rust and possibly powerhead dam-

age.Hoseleaksaretoberepaired.Additionalcowlair

inletholes, toreduceunder-cowl vacuum,and longer

water drain check valves are to be added/installed to

help drain the lower cowl.

DEALER OUTBOARD INVENTORY:

Outboards within this serial number range must be

modified before use or retail sale.

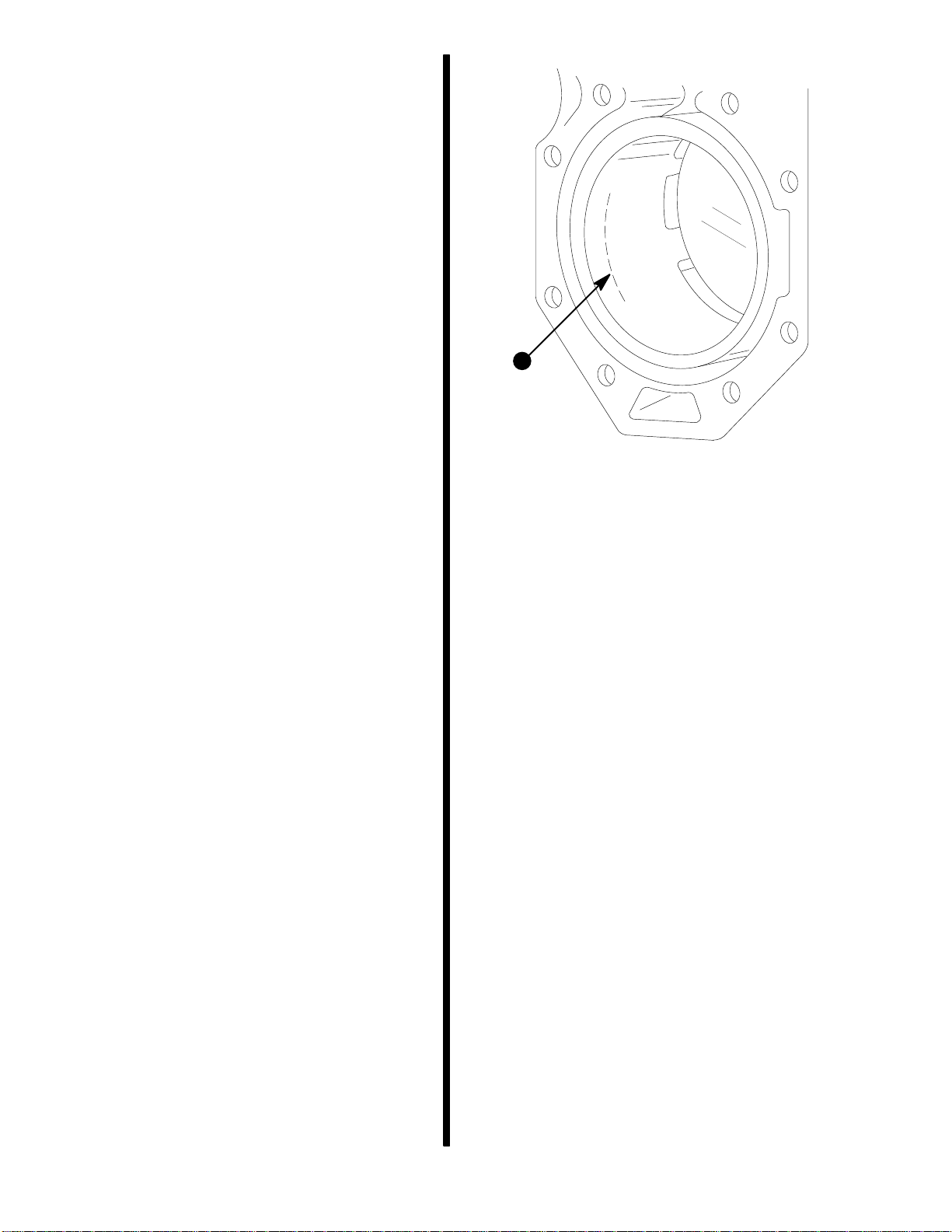

Someoutboardswithinthisserialnumberrangewere

modified at the factory. Factory modifications and

some early field modifications have the new exhaust

adaptor plate p/n 818450A-1 installed. The new

adaptor plate is identified with a raised boss above

the poppet valve opening and p/n 818450C-2 is cast

in the front of the plate as shown in figure 1.

28298

a

b

a - Casting Number 818450C-2

b - Raised Boss

Figure 1. New Exhaust Adaptor Plate.

Outboardsmodifiedat thefactoryalsohave aorange

dot on the outside of the shipping carton next to the

serialnumber. Outboardswiththisnewadaptorplate

haveallmodifications requiredbythisbulletin andre-

quire no further action.

OWNER NOTIFICATION (US AND CANADA):

A combination letter/claim will be sent to registered

owners of outboards within this serial number range.

The letter will advise the owner to return their out-

board to the selling dealer or authorized dealer for

warranty modifications. A copy of the letter is at-

tached to this service bulletin.

provided by http://www.crowleymarine.com