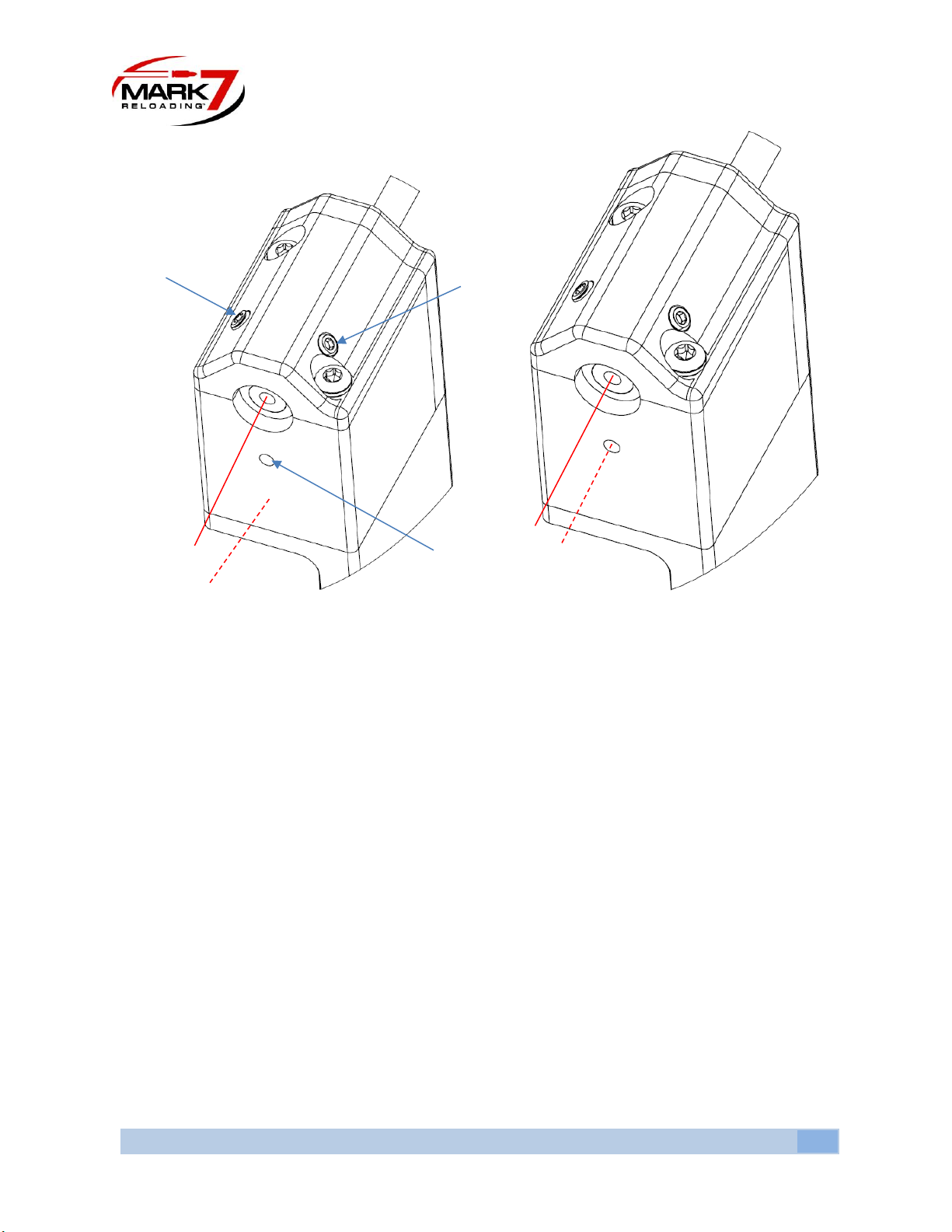

Figure 8: Laser fine adjustment. Before adjustment (left), after adjustment (right)

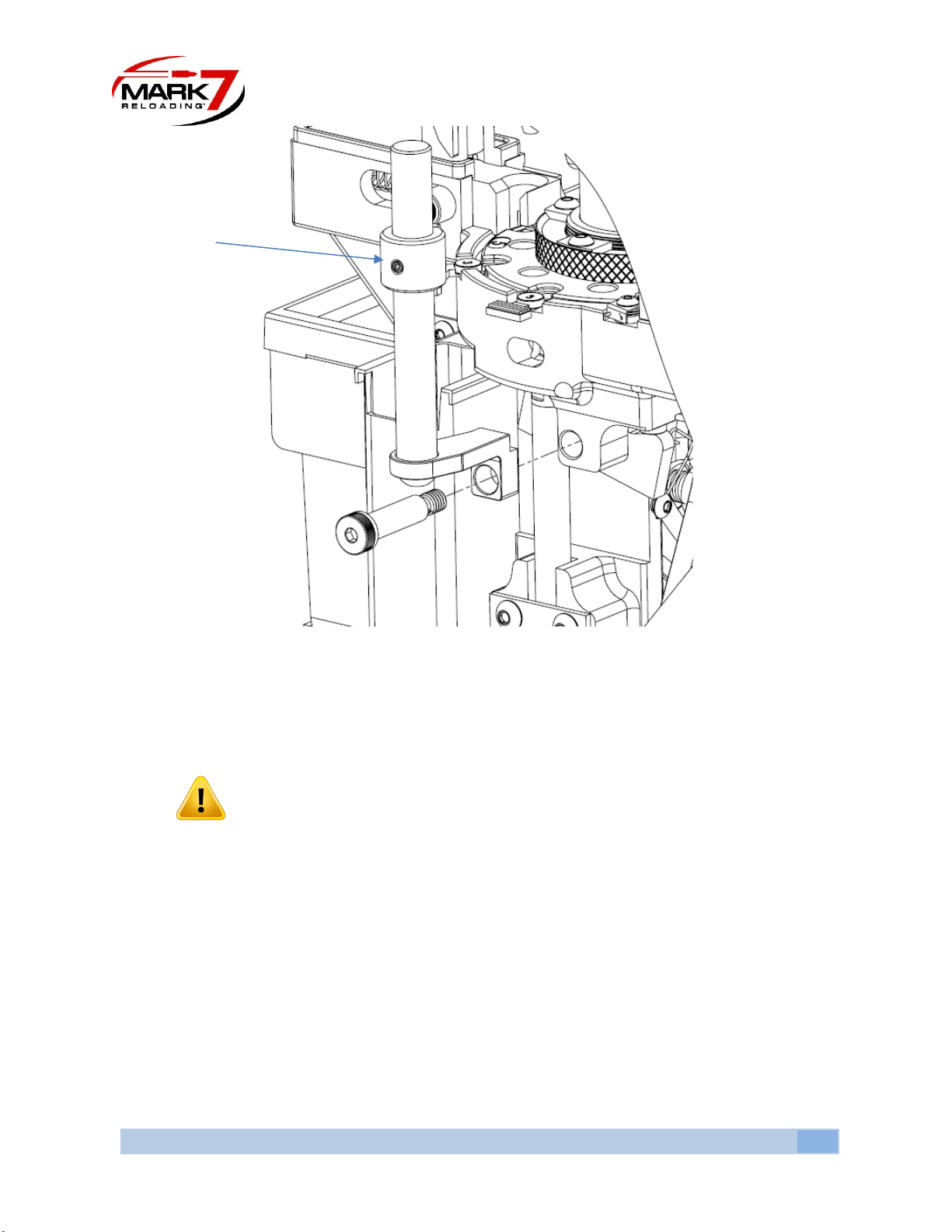

7. Now that the laser beam is aligned, lock the mirror in-place by gently tightening the set screw

on the Mirror Mount. Do not over tighten.

8. Next the Sensor vertical height must be set for the given caliber and projectile being used.

9. To set the height, place a case with the neck flared in Station 7 and place a projectile in the

proper orientation into the case at the level where it would be when dropped from the

Bulletfeeder drop tube.

10. Loosen the 2X brass thumb screws and shaft locking collar and gently position the upper mount,

shown in Figure 9, so the laser beam goes OVER the tip of the bullet and hits the mirror. The

reflected beam should return and hit the tip of the bullet, breaking the beam path, as shown in

Figure 10. When the vertical height is adjusted properly a shadow will be cast on the sensor

preventing the sensor to see the laser beam. When the bullet is not present, upside or sideways

the beam will pass over the bullet and contact the sensor triggering the machine to stop.