4

INSTALLATION

Installation Information

UNPACKING

Immediately after unpacking, check for possible shipping

damage. If the tilting skillet is found to be damaged, save

the packaging material and contact the carrier within 15

days of delivery.

Before installing, verify that the electrical service agrees

with the specications on the rating plate located on the

right side panel as you face the front of the skillet. If the

supply and equipment requirements do not agree, contact

your dealer.

LOCATION

The installation location must allow adequate clearances

for servicing and proper operation. A minimum front clear-

ance of 36”, and rear clearance of 6” is required.

INSTALLATION CODES AND STANDARDS:

Your Tilting Skillet must be installed in accordance with:

4. Provincial and local codes, or in the absence of local

codes, with: C.S.A. C22.1 Canadian Electrical Code,

Part 1, or in the U.S.A. state and local codes, or in the

absence of local codes, with the National Electrical

Code ANSI/NFPA-70 (latest edition).

5. ANSI NFPA Standard #96, “Vapor Removal from

Cooking Equipment,” (latest edition), available from

the National Fire Protection Association, Battery-

march Park, Quincy, MA, 02269.

LEVELING AND ANCHORING THE SKILLET:

1. Place the skillet in the desired location of installation.

2. Place a carpenter’s level on the top of the skillet pan

and turn the adjustable feet to level the skillet from

side-to-side and front-to-back.

3. Mark hole locations on the oor through the anchor-

ing holes provided in the rear adjustable ange feet.

4. Remove skillet from installation position and drill

holes in locations marked on the oor. Insert proper

anchoring devices (not supplied).

5. Place skillet back in the installation position.

6. Place carpenter’s level on top of skillet and re-level

side-to-side and front-to-back.

7. Bolt and anchor skillet securely to the oor.

8. Seal bolts and anged feet with Silastic or equivalent

compound.

9. If faucet is provided, connect water supply and check

operation.

10. Turn power on and check for proper operation.

ELECTRICAL CONNECTION

WARNING

Electrical and grounding connections must

comply with the appliance portions of The

National Electrical Code and/or other local

codes.

WARNING

Before performing any maintenance discon-

nect the electrical power supply and place a

tag at the disconnect switch to indicate that

you are working on the circuit.

NOTE Donotinstallinsuchamannerthataserviceper-

soncannotremovethecontrolboxcover.

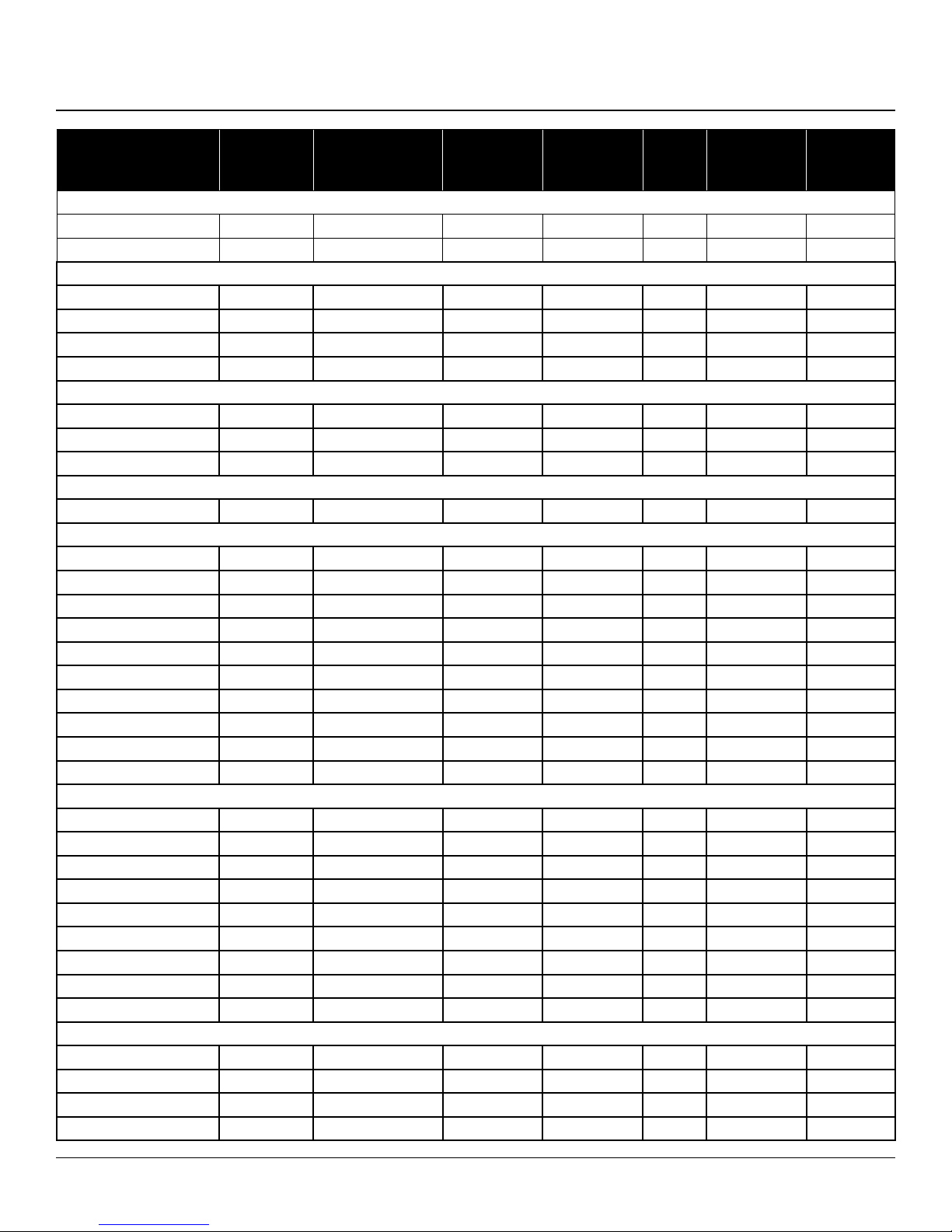

1. Connect unit to a branch circuit having a voltage and

circuit type specied on the name plate and of su-

cient size to carry load. The amps per line wire for the

various voltage rating are shown in the table.

NOTE: Supply wires must be suitable for tempera-

ture of at least 200°F (90°C). Additionally,

allwiringmustconform totherequirements

oflocalandnationalelectriccodes.Conduit

andttingsmustbewatertight.

2. Connect ground wire from electrical service to ground

lug.

3. Ensure that skillet is rmly seated on frame before

checking connection and functioning of controls.

NOTE: Unitisequippedwithaninterlockswitchthat

shuts o current to the heating elements

when skillet pan is more than (10°) above

normalhorizontalcookingposition.

4. Switch on current supply to unit. Check for proper fuc-

tioning of controls and heating elements.

SERVICE CONNECTIONS

1. All internal wiring for the skillet is complete.

2. Make service connections as indicated on pevious

page and electrical connections above.

3. If a faucet is provided, connect the water supplies and

check for proper operation.