4

Metallic and pearl glimmer coatings of the awning frame

The look of plastic coatings of metal and plastic parts in metallic and/or pearl glimmer

colour vary. These visual dierences concern in particular the intensity and characteristic

of the metallic eect, which may also lead to a change in the perception of the basic

shade.

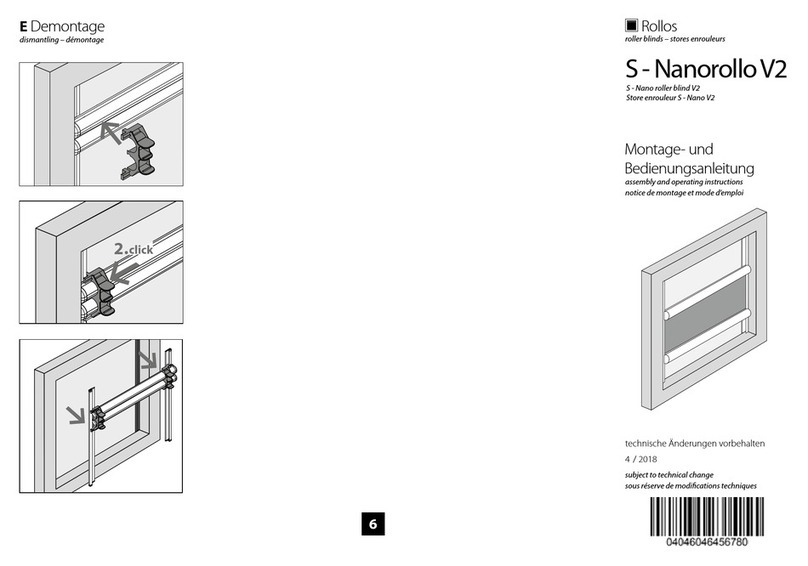

Disassembly and disposal

When disassembling and disposing

of the shading system, the parts under

tension (e.g. folding-arms, counter tension

systems or servo gear unit) have to be

relaxed completely or secured beforehand.

A markilux specialist should be

commissioned for this!

Maintenance and care, characteristics cover and awning frame

Whether a cleansing is necessary or not depends strongly on environmental influences

(traic, air pollution, industrial gases etc.). Depending on the degree of pollution, a

regular cleansing is recommended.

Always use an appropriate ascending aid and never rest against the awning or

hold on to it!

Awning cover in wet condition

If possible, retract the awning only when it is dry! If the awning must be retracted

wet, it has to be extended as soon as possible in order to dry. By the cover permanent

weight, a deflection is possible which increases in wet condition. This occurrence does

not influence the awning function and running qualities.

Depending on the type of awning there are crush and shear zones, e.g. between

front profile and cassette and between moving parts. Items of clothing or limbs can be

grabbed by the unit and pulled in. If the awning is assembled at a height less than 2,5

metres above accessible traic ways, then the awning may only be actuated by a

pushbutton switch which allows viewing the moving parts. Electric controls, radio-

controlled motors with click in-switches are not permitted for such installations.

Crushing and shearing zones

Cleaning the awning cover

The awning cover is equipped with special impregnation which reduces at every

cleansing.. For post-impregnation, commercial tent impregnation can be used. By

re-impregnation, no new condition of the cover can be achieved yet.

Remove dust periodically with a so brush in dry condition. Remove leaves, twigs and

similar debris immediately. Remove small stains on the awning cover with commercial,

preferably liquid mild detergent added to water (water temperature approx. 30°C, soap

solution 5 %). Rinse thoroughly with water until all traces of the detergent have been

removed.

Cleaning the awning frame

For cleaning of the awning frame, use commercial detergent for sensitive surfaces

(pH-value between 5 and 8). Aggressive acids and scraping materials (like grinding fleece,

emery, sand, pumice, etc.) are not allowed because they could alter the surface totally.

Characteristics resulting from the production and manufacture of awning

fabrics

Awning covers are industrially manufactured textile products which serve both a

functional and a decorative purpose. Although only first-class, quality controlled fabric is

used in production, there are limits to the degree of perfection that can be achieved.

Awning owners occasionally complain about certain imperfections in the fabric due to

lack of knowledge. Defects actually to complain are only those which influence the cover

life span. The following specified imperfections influence the awning cover durability and

usage practicality in no way.

• Dogleg and wrinkle creases

At processing, like e.g. trimming, sewing and winding up of the cover onto the awning

frame, dogleg traces can result which can not be avoided. Viewed against the light, the

user of the awning has the impression that he sees dark stripes.

• Chalk and write effect

As with the previously mentioned processes, the cover may show a light change in colour

(pigment shiing) at folded spots caused by kinking the fibre.

• Winding folds / waviness

Winding folds/rippling: This occurs due to the

permanent coiling and uncoiling of the cover on the

roller. This eect can be explained by the fact, that the material is thicker close to the

seams, coils more loosely between the seams of the cover. This eect can occur both

directly next to the seam as well as also in the middle of web.

• Other irregularities

Irregularities caused by the production process which cannot be avoided, such as

• Knots, thread thickening and thinning, which can be seen in the cloth as points of

light or as nubs

• Colour deviations in cloths produced in webs (e.g. in triangular shades)

• Individual thread breakages and expansions at the seams with resulting sagging

• Sagging of the cloth due to its own weight or aer the formation of a "water sack".

can occur, and are unavoidable in production.

Deflexion of the awning frameFlexing of the awning frame

The profile of the wider systems' awning frame can flex as well because of own weight.

This occurrence does not influence the awning function and running qualities.

Tested awning cover

The "Oeko Tex Standard 100" certificate guarantees that no harmful dyes or chemicals

were used in the manufacture of markilux awning covers.

Cloths made of sunvas, sunsilk and sunbow usually achieve the highest possible sun

protection factor for textiles (UPF 50 +). The UPF (Ultraviolet Protection Factor) specifies

how much longer one can be exposed to sunlight when protected from it by the given

UPF without suering sunburn. Fabrics with an ultraviolet protection factor of 50+ (based

purely on the calculated value) would enable you to sit out safely in the sun fiy times

longer than you would otherwise be able to do without suering sunburn, if you were to

rely solely on the protection provided by your skin.

sunvas and sunsilk are innovative awning fabrics with a

self-cleaning eect in rain (a minimum 14° awning pitch is

required to ensure water runs o). The highly dirt-

repellent finish guarantees years of radiant colours.

Legal disclaimer

The graphics and text sections in these instructions have been created with care. No

liability can be assumed for any errors and their eects! We reserve the right to undertake

technical modifications to the product and to these instructions! The instructions contain

copyright-protected information. ll rights reserved! The listed product or trade names are

copyright trademarks.

WEEE DE 11340537

Multiple extension and retraction of the awning in rapid succession results in an

automatic motor switch-o to preserve it from overheating. Aer cooling down the motor

switches itself on again in operating readiness.

The awning must be extended at least 1 m for the windlock meachnism device to be

eective. The declared wind resistance class only applies to a fully extended awning.

windlock mechanism

Protection against overheating

markilux 620 tracfix

markilux.com

Operation manual