Maruyama QC-E User manual

The POWER in Outdoor Power

Completely read and understand this manual PRIOR to using this product.

Lea y entienda este manual a fondo, ANTES de usar este producto.

Lisez complèment et comprenez ce manuel AVANT d'utiliser ce produit.

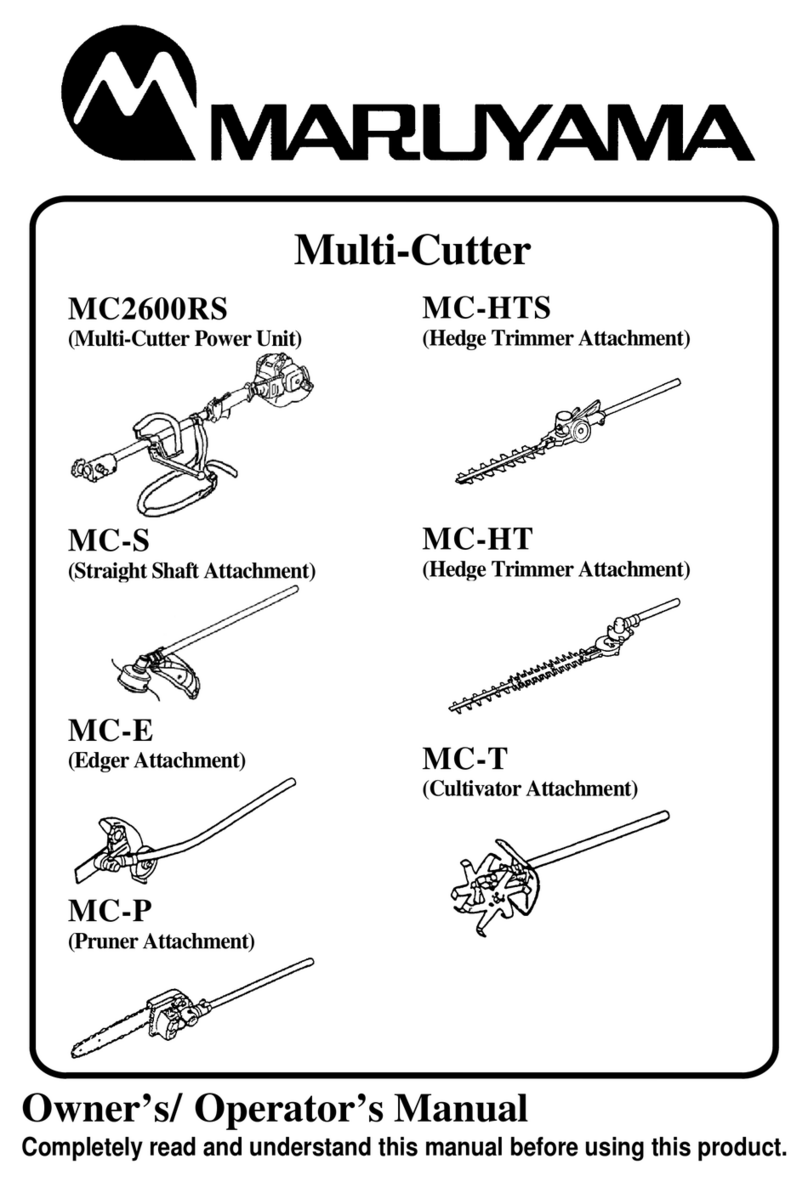

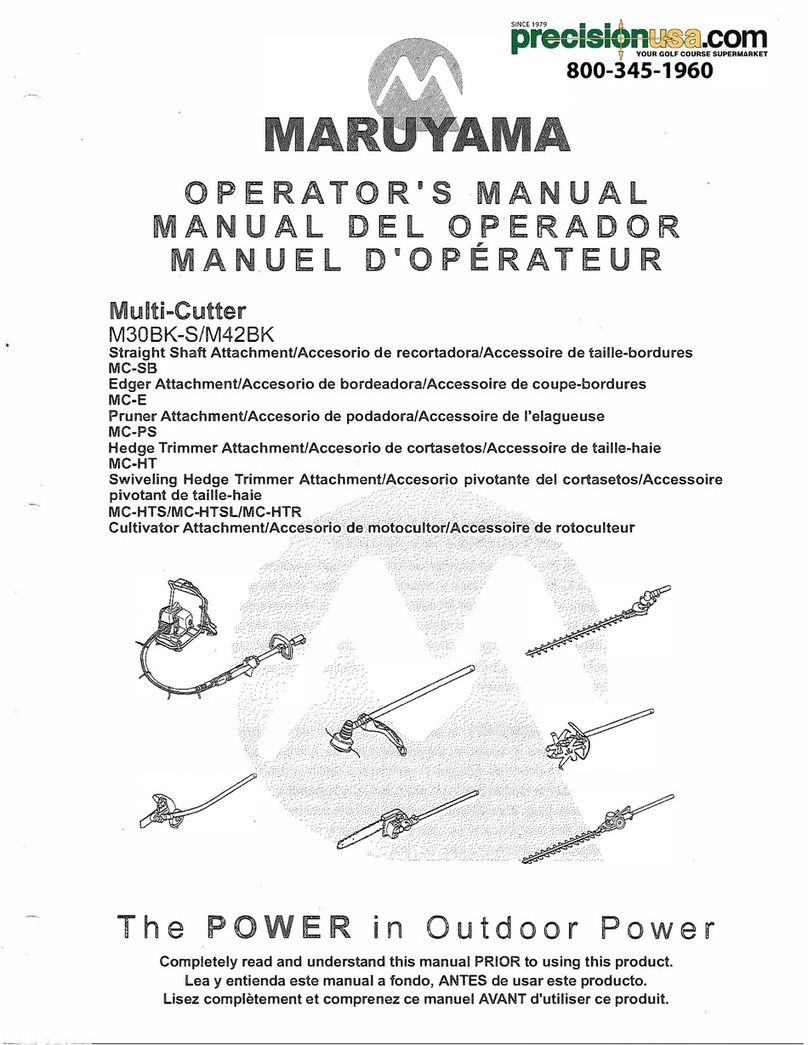

Multi-Cutter

Edger Attachment

Accesorio de bordeadora

Accessoire de coupe-bordures

QC-E/QC-ES

Cultivator Attachment

Accesorio de motocultor

Accessoire de rotoculteur

QC-T

OWNER'S/OPERATOR'S MANUAL

MANUAL DEL PROPIETARIO U OPERADOR

MANUEL DU PROPRIETAIRE/DE L'UTILISATEUR

— US-1 —

Limited Warranty Statement

All Maruyama commercial/ industrial products are warranted to the original purchaser to be free from defects

in material and workmanship from the date of purchase for the time periods listed as follows:

Lifetime for solid steel driveshaft and ignition coils.

5 years for qualified IRON 5-YR™ commercial, institutional, or industrial use.

1 year for residential or 2 years for commercial use with competitor’s oil.

90 days for rental use.

Engine - Refer to engine manufacturer’s warranty statement. Only Maruyama engines are

covered by this limited warranty statement.

Any part of a Maruyama product found to be defective within the applicable warranty period shall, at

Maruyama's option, be repaired or replaced without charge. Warranty consideration is obtained by delivering

any Maruyama product believed to be defective to an Authorized Maruyama Servicing Dealer within the

applicable warranty period.

The purchaser shall not be charged for diagnostic labor that leads to the determination that a warranted

part is defective, if the diagnostic work is performed at a Maruyama Dealer.

Any warranted part which is not scheduled for replacement as required maintenance, or which is scheduled

only for regular inspection to the effect of “repair or replace as necessary” shall be warranted for the warranty

period. Any warranted part, which is scheduled for replacement as, required maintenance shall be warranted

for the period of time up to the first scheduled replacement point for that part. Maruyama Mfg. Co., Inc. is

liable for damages to other engine components caused by the failure of a warranted part still under warranty.

The purchaser is responsible for the performance of the required maintenance, as defined by Maruyama Mfg.

Co., Inc. in the Owner's/Operator's Manual.

EMISSION-RELATED PARTS WARRANTY: In addition to the above warranty coverage, Maruyama Mfg.

Co., Inc. will repair or replace, free of charge, for the original purchaser and each subsequent purchaser

any emission-related part or parts found to be defective in material and workmanship for two (2) years from

original retail delivery date. Emission-related parts are the carburetor assembly, the ignition coil

assembly, the ignition rotor, the spark plug, the catalytic converter and the fuel tank. Any replace-

ment part that is equivalent in performance and durability may be used in non-warranty maintenance or

repairs, and shall not reduce the warranty obligations of Maruyama Mfg. Co., Inc.

®

— US-2 —

This warranty does not cover the following:

1. Maintenance items (excluding defects in materials and workmanship) including hoses, spark plugs,

starter rope, air and fuel filters, clutch shoes, vibration isolators, throttle cables and all cutting attach-

ments, etc.

2. Extra expenses including shipping and handling, travel, payment for lost time or pay and for any incon-

venience and storage.

3. Alterations or modifications including aftermarket parts not authorized by Maruyama U.S., Inc.

4. Wear, accident, abuse, neglect, misuse, negligence, improper fuels, lubricants, fuel mixtures (when

applicable), or failure to operate or maintain the product in accordance with instructions approved by

Maruyama.

Repair or replacement as provided under this warranty is the exclusive remedy of the consumer. Maruyama

shall not be liable for any incidental or consequential damages for breach of any express or implied warranty

on these products except to the extent prohibited by applicable law. Any implied warranty of merchantability or

fitness for a particular purpose on these products is limited in duration to the warranty period as defined in the

limited warranty statement. Maruyama reserves the rights to change or improve the design of the product

without notice and does not assume obligation to update previously manufactured products.

This warranty provides you with specific legal rights, which may vary from state to state.

It is the Owner's and Dealer's responsibility to make sure the Warranty Registration Card is properly filled out

and mailed to Maruyama U.S., Inc. Proof of purchase and registration will be required in order to obtain war-

ranty service.

To locate an Authorized Maruyama Servicing Dealer nearest you, contact:.

Maruyama U.S., Inc.

4770 Mercantile Drive, suite100,

Fort Worth, TX

76137

U.S.A.

(940)383-7400

www.maruyama-us.com

— US-3 —

Contents

Page US-

Limited Warranty Statement..................................... 1

Contents ................................................................... 3

Introduction............................................................... 4

Safety ....................................................................... 4

Operator Safety ................................................... 4

Multi - Cutter with Tool Attachments Safety ..... 5

Fuel Safety........................................................... 5

Edger Operating Safety ....................................... 6

Cultivator Operating Safety................................. 7

Product Description .................................................. 8

Safety and Instruction Decals ................................... 9

Assembly ................................................................. 10

QC-E(Edger Attachment) .................................... 10

Installing Debris Shield.................................. 10

Installing Edger Blade.................................... 10

QC-ES(Edger Attachment).................................. 11

Installing Debris Shield.................................. 11

Installing Edger Blade.................................... 11

QC-T (Cultivator Attachment)............................. 12

Installing Shaft and Shield ............................. 12

Attaching and Detaching for the Power Unit

and the Shaft Assembly

........................... 12

Operation .................................................................. 13

QC-E/QC-ES (Multi-Cutter with Edger Attachment) ..

13

QC-T (Multi-Cutter with Cultivator Attachment)

... 15

Maintenance.............................................................. 16

Idle Speed Adjustment......................................... 16

QC-E(Edger Attachment) .................................... 16

Flexible Driveshaft......................................... 16

Gearcase ......................................................... 17

QC-ES (Edger Attachment)................................. 17

Gearcase ......................................................... 17

QC-T (Cultivator Attachment)............................. 17

Gearcase ......................................................... 17

Troubleshooting ........................................................ 18

Maintenance Period .................................................. 18

Specifications............................................................ 19

— US-4 —

Thank you for purchasing a MARUYAMA product.

MARUYAMA, it’s distributors, and dealers want you to

be completely satisfied with your new product. Please

feel free to contact your local Authorized Service Dealer

for help with service, genuine MARUYAMA parts, or

other information you may require.

Whenever you contact your Authorized Service Dealer

or the factory, always know the serial number of your

product. This number will help the Service Dealer or

Service Representative provide exact information about

your specific product. You will find the model and seri-

al number located in a unique place on the product

(Product Description on page US-8).

For your convenience, write the product model name

and serial number in the space below.

Read this manual carefully to learn how to operate and

maintain your product correctly. Reading this manual

will help you and others avoid personal injury and dam-

age to the product. Although MARUYAMA designs,

produces and markets safe, state of the art products, you

are responsible for using the product properly and safely.

You are also responsible for training persons who you

allow to use the product about safe operation.

The MARUYAMA warning system in this manual identi-

fies potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

DANGER, WARNlNG and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended precautions

are not followed.

WARNING signals a hazard that may cause serious injury

or death if the recommended precautions are not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed. Two other words are also used to high-

light information. “Important” calls attention to special

mechanical information and “Note” emphasizes general

information worthy of special attention.

Safety

Operator Safety

1. Read and understand this Owner’s/Operator’s

Manual before using this product. Be thoroughly

familiar with the proper use of this product.

2.

Never allow children to operate the Multi-Cutter. It

is not a toy. Never allow adults to operate the unit

without first reading the Owner’s/Operator’s Manual.

3.

Always wear eye protection that complies with ANSI

(American National Standards Institute) Z87-1.

4. Always wear hearing protection.

5. Always wear heavy, long pants, a long sleeved

shirt, boots and gloves. Do not wear loose clothing,

jewelry, short pants, sandals, or go barefoot.

Secure hair so it is above shoulder length.

6.

Never operate this Multi-Cutter when you are tired, ill, or

under the influence of alcohol, drugs or medication.

7.

Never start or run the engine inside a closed room or

building. Breathing exhaust fumes can cause death.

8. Keep handles clean of oil, fuel and dirt.

Introduction

Model Name _______________

Serial No. ________________

— US-5 —

Multi-Cutter with Tool

Attachments Safety

1. Make sure the Unit is assembled correctly and that

the tool attachment is correctly installed and

securely fastened as instructed in the Assembly

section.

2. Inspect the Unit before each use. Replace dam-

aged parts. Check for fuel leaks. Make sure all

fasteners are in place and tightened securely.

Follow the maintenance inst-ructions beginning

on page US-16.

3. Make sure the tool attachment does not rotate at

engine idle speed. Refer to Idle Speed Adjustment,

page US-16.

4. Inspect the tool attachment head and replace any

parts that are cracked, chipped or damaged before

using the Multi-Cutter.

5. Install all required shields and guards prior to

operating the Multi-Cutter or its attachments.

Note: Remove blade cover from Hedgetrimmer

attach-ments prior to operation.

6. Never use a tool attachment head or replacement

parts that are not approved by MARUYAMA.

7. Maintain the Multi-Cutter power unit and tool

attach-ments according to the recommended main-

tenance intervals and procedures in the

Maintenance section.

8. Shut off the engine and wait until the tool attach-

ment head has completely stopped moving before

checking, performing maintenance on or working

on the Multi-Cutter.

9. If running problems or excessive vibration occur,

stop immediately and inspect the unit for the

cause. If the cause cannot be determined or is

beyond your ability to correct, return the Multi-

Cutter with tool attachment to your servicing deal-

er for repair.

Fuel Safety

1. Gasoline is highly flammable and must be handled

and stored carefully. Use a container approved for

fuel to store gasoline and/ or fuel/ oil mixture.

2. Mix and pour fuel outdoors, where there are no

sparks or flames.

3. Do not smoke near fuel or Multi-Cutter, or while

using the Multi-Cutter.

4. Do not overfill the fuel tank. Stop filling 1/4-1/2

in. (6 mm-13 mm) from the top of the tank.

5. Wipe up any spilled fuel before starting the

engine.

6.

Move the Multi-Cutter at least 10 ft. (3 m) away

from the fueling location before starting the engine.

7. Do not remove the fuel tank cap while the engine

is running, or right after stopping the engine.

8. Allow the engine to cool before refueling.

9. Drain the tank and run the engine dry before stor-

ing the unit.

10. Store fuel and Multi-Cutter away from open

flame, sparks and excessive heat. Make sure fuel

vapors cannot reach sparks or open flames from

water heaters, furnaces, electric motors, etc.

10 ft. (3 m) minimum

— US-6 —

Edger Operating Safety

1.

THIS EDGER CAN CAUSE SERIOUS INJURIES.

Read the instructions carefully. Be familiar with all

controls and the proper use of the Edger.

2. Make sure the 3 mm hex wrench has been

removed from the gearcase and boss adapter

before you start the engine.

3.

Inspect your work area before you begin. Remove

objects such as broken glass, nails, wire and rocks

which can become dangerous projectiles if thrown

by the Edger. Remove string, rope or similar materi-

als which can become entangled in the Edger head.

4. This Edger will throw objects and cut. Keep chil-

dren, bystanders and animals outside a 50 ft.

(15m) radius from the operator and Trimmer.

Beyond the 50 ft. (15 m) there still may be a risk

of injury to bystanders from thrown objects. It is

recommended that bystanders wear eye protec-

tion. A thrown object can ricochet.

5. If you are approached while operating the Edger,

stop the engine and Edger blade rotation.

6. Never allow children to operate the Edger.

7. Use the Edger only in daylight or good artificial

light.

8. Never operate the Edger without proper guards or

other protective safety devices in place.

9. Do not put hands or feet near or under any rotating

parts. Keep clear at all times. Keep all parts of

your body away from the rotating Edger blade and

hot surfaces such as the muffler.

10. Keep firm footing and balance Do not overreach.

11. Use the right tool for the job. Do not use the

Edger for any job that is not recommended by

MARUYAMA.

50 ft. (15 m) minimum

— US-7 —

Cultivator Operating Safety

1. THIS CULTIVATOR CAN CAUSE SERIOUS

INJURIES. Read the instructions carefully. Be

familiar with all controls and the proper use of the

Cultivator.

2. Avoid using the Cultivator near rocks, graval,

stones and similar material that would cause

harmful missiles.

3. Inspect your work area before you begin. Remove

objects such as broken glass, nails, wire and rocks

which can become dangerous projectiles if thrown

by the Cultivator. Remove string, rope or similar

materials which can become entangled in the

Cultivator head.

4. This Cultivator will throw objects and cut. Keep

children, bystanders and animals outside a 50 ft.

(15m) radius from the operator and Trimmer.

Beyond the 50 ft. (15 m) there still may be a risk

of injury to bystanders from thrown objects. It is

recommended that bystanders wear eye protection.

A thrown object can ricochet.

5. If you are approached while operating the

Cultivator, stop the engine and cultivate tool

rotation.

6. Use the Cultivator only in daylight or good

artificial light.

7. Do not put hands or feet near or under any rotating

parts. Keep clear at all times. Keep all parts of

your body away from the rotating tool and hot

surfaces such as the muffler.

8. If the cultivator tines become jammed, stop the

engine immediately. Make certain all moving

parts have stopped, and disconnect the spark plug

before attempting to remove any obstruction.

9. Use the right tool for the job. Do not use the

Cultivator for any job that is not recommended by

MARUYAMA.

50 ft. (15 m) minimum

— US-8 —

Product Description

1. Gearcase

2. Debris Shield

3. Shaft Assembly

4. Edger Blade

5. Wheel

1. Gearcase

2. Debris Shield

3. Shaft Assembly

4. Edger Blade

5. Wheel

3

3

4

4

2

2

5

5

1

1

QC-E

(Edger Attachment)

QC-ES

(Edger Attachment)

QC-T

(Cultivator Attachment)

1. Gearcase

2. Debris Shield

3. Shaft Assembly

4. Cultivator Tines

3

4

2

1

— US-9 —

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area of potential

danger. Replace any decal that is damaged or lost.

QC - E/QC - ES (Edger Attachment)

ON SHAFT

(Part No.221501)

ON SHAFT

(Part No.221502)

ON DEBRIS SHIELD

(Part No.221528)

ON SHAFT

Only for QC-E

(Part No.223926)

Lubricate drive-

shaft each 30

hours of use.

QC-T (Cultivator Attachment)

ON SHAFT

(Part No.221501)

ON SHAFT

(Part No.221502)

— US-10 —

Assembly

QC-E (Edger Attachment)

Installing Debris Shield

1. Install the collar onto the plate stud.

2.

Install the shield onto the plate stud, making sure the

shield stud fits into the matching slot in the plate.

3. Install the flat washer, lock washer and hex nut

onto the plate stud.

4.

Install the flat washer and knob onto the shield stud.

Installing Edger Blade

1. Install the boss adapter onto the splined shaft out

of the gearcase.

2. Install the edger blade, clamping washer and blade

bolt.

Note: The blade bolt has left-hand threads.

3. Align the hole in the boss adapter with the hole in

the gearcase.

4. Insert the 3 mm hex wrench into the holes in the

boss adapter and gearcase to lock the splined

shaft.

5. Tighten the blade bolt to 100 in.-lbs. (11.3 N·m).

6. Remove the 3 mm hex wrench from the boss

adapter and gearcase.

Debris Shield Guard Stud

Hex Nut

Knob

Plate

Flat Washer

Plate Stud

Collar

Lock Washer

Flat Washer

Edger Blade

Gearcase

Blade Bolt (left

hand thread)

3 mm Hex Wrench Clamping Washer

Attaching Shaft

Boss Adapter

WARNING

POTENTIAL HAZARD

• Foreign objects can be thrown by the

Edger.

WHAT CAN HAPPEN

• Contact with thrown objects can cause

personal injury.

HOW TO AVOID THE HAZARD

• Never operate the

Edger

without the

debris shield in place.

CAUTION

POTENTIAL HAZARD

• If the

Edger blade

is not adequately

tightened, it can come loose from the

Edger

during use.

WHAT CAN HAPPEN

• This may cause damage to property or

personal injury.

HOW TO AVOID THE HAZARD

• Make sure the

Edger blade

is securely

fastened to the attaching shaft in the

gearcase.

— US-11 —

QC-ES (Edger Attachment)

Installing Debris Shield

1. Install the spacer onto the plate stud.

2. Install the shield onto the plate stud, making sure the

shield stud fits into the matching slot in the plate.

3. Install the flat washer, lock washer and hex nut onto

the plate stud.

4. Install the flat washer and knob onto the shield stud.

Installing Edger Blade

1. Install the boss adapter onto the scollar onto the

attaching shaft out of the gearcase.

2. Install the edger blade, clamping washer and blade

bolt.

Note: The blade bolt has left-hand threads.

3. Align the hole in the boss adapter with the hole in

the gearcase.

4. Insert the 3 mm hex wrench into the holes in the

boss adapter and gearcase to lock the splined

shaft.

5. Tighten the blade bolt to 100 in.-lbs. (11.3 N·m).

6. Remove the 3 mm hex wrench from the boss

adapter and gearcase.

WARNING

POTENTIAL HAZARD

• Foreign objects can be thrown by the

Edger.

WHAT CAN HAPPEN

• Contact with thrown objects can cause

personal injury.

HOW TO AVOID THE HAZARD

• Never operate the

Edger

without the

debris shield in place.

Debris Shield Shield Stud

Hex Nut

Knob

Plate

Flat Washer

Plate Stud

Spacer

Lock Washer

Flat Washer

CAUTION

POTENTIAL HAZARD

• If the

Edger blade

is not adequately

tightened, it can come loose from the

Edger

during use.

WHAT CAN HAPPEN

• This may cause damage to property or

personal injury.

HOW TO AVOID THE HAZARD

• Make sure the

Edger blade

is securely

fastened to the attaching shaft in the

gearcase.

Edger Blade

Gearcase

Blade Bolt

(left hand thread)

3 mm Hex Wrench

Clamping Washer

Collar

Boss Adapter

— US-12 —

QC-T (Cultivator Attachment)

Installing Shaft and Shield

1. Attach the shaft assembly to the gearcase

assembly.

NOTE: Carefully inspect both side of the shaft

assembly. The arrow marking side of the

shaft assembly positions to the power unit.

The no marking side of the shaft assembly

connects to the gearcase assembly.

Insert the shaft assembly into the gearcase

assembly whilerotating the driveshaft to engage

the splines. Align the locating hole and install

the locating screw through the side of the gear-

case. Then tighten the clamping screw. If prop-

erly installed, rotating the end of the driveshaft

will cause the cultivator tines to move.

2. Attach the debris shield onto the shaft assembly.

Place the plastic collar onto the shaft assembly

approximately one inch from the cultivator

gearcase, locating the ends as shown in sketch.

Then place the two bracket parts onto the plas-

tic collar and fasten securely with two 6 mm

screws. Attach the shield to the bracket with

four 5 mm screws.

Attaching and Detaching for the Power

Unit and the Shaft Assembly

Attaching

1 First, loosen the clamping knob before attaching

the shaft assembly to the shaft coupler.

Note : Do not over loosen the clamping knob or it

may fall out.

2 Insert the shaft assembly to the shaft coupler with

the positioning hole faced up as shown. Connect

the both drive shafts completely in the matching

position by moving the shaft assembly to forward

Locating Hole

Shaft Assembly

Arrow Mark

Driveshaft

Gearcase

Splines

Clamping Screw

Locating Screw

Screw 6 mm (2)

Plastic Collar

Bracket

Ends

Bracket

Gearcase

One Inch

DEBRIS SHIELD

Screw 5 mm (4)

Bracket

Clamping Knob

Shaft Coupler

Positioning Lever

Positioning Hole

Shaft Assembly

Insert

TightenLoosen

Positioning

Lever

Positioning lever is

lowered state

Positioning lever is

raised state

Incorrect Assembled

Correct Assembled

— US-13 —

and backward and left turn and right turn. When

the shaft assembly is positioned correctly, spring

tensioned positioning lever will be returned to the

initial position.

3 Tighten the clamping knob firmly.

Detaching

1 First, loosen the clamping Knob before detaching

the shaft assembly to the shaft coupler.

2 Pull out the shaft assembly from the shaft coupler

while holding the positioning lever down.

3 Note : Do not over loosen the clamping knob or it

may fall out.

Operation

QC-E/QC-ES (Multi-Cutter with

Edger Attachment)

Operating Position

Before using the Edger, check the following:

1. Make sure the 3 mm hex wrench has been

removed from the gearcase and boss adapter

before you start the engine.

Edger Blade

Gearcase

Blade Bolt (left

hand thread)

3 mm Hex Wrench Clamping Washer

Attaching Shaft

Boss Adapter

WARNING

POTENTIAL HAZARD

•

Foreign objects can be thrown by

Edger.

WHAT CAN HAPPEN

•

Contact with thrown objects can

cause personal injury.

HOW TO AVOID THE HAZARD

•

Never operate the Edger without the

blade shield in place.

•

Make sure the blade shield is correctly

positioned to shield operator from

thrown debris.

CAUTION

•

Read the Safety instructions on US-6

concerning proper use of the Edger.

[QC-E]

Clamping Knob

Shaft Assembly

Positioning Lever

Removal

Push down

Loosen

— US-14 —

[M27QC, M30QC]

2. The Edger should be on the operator’s right side.

[M42BK-QC]

2. The operator must be set the Knapsack belt, and

the shaft assembly must be on the operator’s right

side.

3. The operator’s right hand should be holding the

shaft grip, with his or her fingers on the throttle

trigger. The right arm should be slightly bent.

4.

The left hand should be holding the loop handle with

the fingers and thumb fully enclosed around the grip.

The left arm should be extended. Reposition the loop

handle up or down the driveshaft if necessary for a

comfortable position.

5. The Edger weight should be evenly distributed

between the arms.

6. Adjust the Edger to the correct cutting depth

before you start the engine. (Refer to the figure in

nextpage.) Make sure the shield is adjusted to

shield the operator from thrown debris.

7. Make sure the blade is rotating (at least half throt-

tle) before inserting the blade into the cut. The

Edger performs best at full throttle.

8. Always release the throttle trigger and allow the

engine to return to idle speed when not cutting.

9. Stop the engine when moving between work sites.

● If the Edger blade becomes jammed, stop the

engine immediately.

● Make certain all moving parts have stopped and

disconnect the spark plug before inspecting the

equipment for damage.

● Never use a Edger that has chipped, cracked or

broken Edger blade or blade shield.

Setting Depth of Cut

IMPORTANT: Set the depth of cut before you

start the engine.

1. Loosen the knob holding the shield to the plate.

2. Rotate the shield as necessary to set the depth of

cut. Note that:

● Rotating the shield to raise the wheel increases

the depth of cut.

● Rotating the shield to lower the wheel decreases

the depth of cut.

3. Make sure the shield is positioned to protect the

operator from thrown debris, then tighten the

knob.

Edger Blade

Gearcase

Blade Bolt (left

hand thread)

3 mm Hex Wrench

Clamping Washer

Collar

Boss Adapter

Hearing

Protection Eye Protection

Right Arm

Slightly Bent Left Arm Fully

Extended, Hand

Holding Loop Handle

Hand Holding

Throttle Grip, Fingers

on Throttle Trigger

Direction of Travel

Guard Adjusted to Clear

Blade, and Guard Operator

from Thrown Debris

CAUTION

•

Always wear gloves and protective

clothing when operating the Edger.

[QC-ES]

— US-15 —

QC-T (Multi-Cutter with Cultivator

Attachment)

Before using the Cultivator, check the following:

[M27QC, M30QC]

1.

The Cultivator should be on the operator’s right side.

[M42BK-QC]

1. The operator must be set the Knapsack belt, and

the shaft assembly must be on the operator’s right

side.

2. The operator’s right hand should be holding the

shaft grip, with his or her fingers on the throttle

trigger. The right arm should be slightly bent.

3. The left hand should be holding the loop handle

with the fingers and thumb fully enclosed around

the grip. The left arm should be extended.

Reposition the loop handle up or down the drive-

shaft if necessary for a comfortable position.

4. Do not operate the Cultivator in hard un-tilled soil

or in rocky areas.

5. Do not operate the Cultivator in areas with vines

or tree roots.

6. Do not operate the Cultivator in water.

7. Always release the throttle trigger and allow the

engine to return to idle speed when not cultivat-

ing.

8. Stop the engine when moving between work sites

●The Cultivator should be operated only while travel-

ing forward. Working the Cultivator with a back-and-

forth motion while traveling produces the best results.

A fast or slow engine speed can be used according to

soil conditions.

●If the cultivator tines become jammed, stop the

engine immediately. Make certain all moving parts

have stopped, and disconnect the spark plug before

attempting to remove any obstruction.

●The cultivator gearcase becomes very hot during

operation. Do not touch the gearcase.

●Make certain all moving parts have stopped and dis-

connect the spark plug before inspecting the equip-

ment for damage.

●Never use Cultivator that has cracked or broken tines.

Blade Guard

Knob

Wheel

Increase the

Depth of Cut Decrease the

Depth of Cut

CAUTION

•

Read the Safety instructions on page

US-7 concerning proper use of the

Cultivator.

CAUTION

•

Always wear gloves and protective

clothing when operating the

Cultivator.

Direction of Travel

Cultivator Motion

[QC-ES]

[QC-E]

Knob

Shield

Wheel

Increase the

Depth of Cut

Decrease the

Depth of Cut

— US-16 —

Maintenance

Maintenance, replacement or repair of emission control

devices and systems may be performed by any repair

establishment or individual; however, warranty repairs

must be performed by a dealer or service center autho-

rized by MARUYAMA Manufacturing Company, Inc.

The use of parts that are not equivalent in performance

and durability to authorized parts may impair the effec-

tiveness of the emission control system and may have a

bearing on the outcome of a warranty claim.

Maintenance on today’s low-emission engines is

even more critical for longest life and best perfor-

mance. particularly critical are air and fuel filters,

spark plug heat range, cooling air intake area and

proper gaps of coil and plug.

Idle Speed Adjustment

This Multi-Cutter is equipped with non-adjustable fuel

mixture carburetor. The engine idle speed is the only

adjustment for the operator.

The Attached Tool may be rotating/ moving during idle

speed adjustment. Wear the recommended personal pro-

tective equipment and observe all safety instructions.

Keep hands and body away from the Attached Tool.

When the throttle trigger is released, the engine should

return to an idle speed. The correct speed for models

M27QC, M30QC are 2700 - 3300 RPM, and for

M42BK-QC is 2400 - 2800 RPM, or just below the

clutch engagement speed. The Attached Tool must not

rotate/move and the engine should not stall (stop run-

ning) at engine idle speed.

To adjust the engine idle speed, rotate the idle speed

adjustment screw on the carburetor.

● Turn the idle speed screw in (clockwise) to increase

the engine idle speed.

● Turn the screw out (counterclockwise) to decrease

the engine idle speed.

If idle speed adjustment is necessary, and after adjust-

ment the Attached Tool rotates/moves or the engine

stalls, stop using the Multi-Cutter immediately!

Contact your local authorized MARUYAMA Dealer for

assistance and servicing.

QC-E (Edger Attachment)

Flexible Driveshaft

Maintenance Interval

The Edger uses a flexible driveshaft inside the drive

shaft tube. The flexible driveshaft should be lubricated

after each 30 hours of use.

Flexible Drive Shaft Lubrication

1. Loosen the two Socket head screws holding the

gearcase to the driveshaft tube and carefully

remove the gearcase from the driveshaft tube.

2. Grip the end of the flexible driveshaft and remove

it from the driveshaft tube.

3. Lubricate the flexible driveshaft with a high quali-

ty #2 lithium-base bearing lube.

WARNING

• Idle speed adjustment should be

checked each time the unit is operated.

POTENTIAL HAZARD

•

Engine must be running to make car-

buretor adjustments.

•

When engine is running, attached tool

and other parts is rotating / moving

and other parts are moving.

WHAT CAN HAPPEN

•

Contact with rotating / moving tool or

other moving parts could cause seri-

ous personal injury or death.

HOW TO AVOID THE HAZARD

•

Keep hands, feet and clothing away from

attached tool and other moving parts.

•

Keep all bystanders and pets away from unit

while making carburetor adjustments.

WARNING

Idle Speed Adjustment Screw

— US-17 —

4. Reinstall the flexible driveshaft into the driveshaft

tube. Twist the flexible driveshaft as you insert it

into the to ensure that it seats into the clutch drum.

5. Reinstall the gearcase onto the driveshaft tube,

then tighten the two screws.

Gearcase

Maintenance Interval

The gearcase lubricant should be inspected after every

30 hours of use.

Gearcase Maintenance

Remove the cutting attachment and the boss adapter.

Clean any dirt and debris from the area between the

boss adapter and the gearcase. Remove the grease plug

from the side of the gearcase. While rotating the attach-

ing shaft, inject lithium-base bearing lube (P/N 211337)

through the plug hole until the gearcase is full. Re-

install the grease plug.

QC-ES (Edger Attachment)

Gearcase

Maintenance Interval

The gearcase should be inspect after each 30 hours of

use.

Gearcase Lubrication

The gearcase should be checked for lubrication after

each 30 hours of use. Grease fittings are installed. Use

#2 lithiumbase bearing lubricant.

QC-T (Cultivator Attachment)

Gearcase

Maintenance Interval

The cultivator gearcase should be inspected after each

25 hours of use.

Lubrication

The cultivator gearcase holds 1.4 ounces of lubricant. A

grease tting is located in the top of the gearcase.

Lubricant should be checked at least every 25 hours of

operation. Use a #2 lithium-based EP lubricant with

Molybdenum additive.

Gearcase Fitting

Bearing Lube

(P/N 211337) Grease Plug

Plug Hole

Gearcase

Attaching Shaft Boss Adapter

DriveShaft Tube

Flexible Driveshaft

Gearcase

#2 Lithium-base

Bearing Lube

Screw (2)

Gearcase

Attaching Shaft

Grease Fitling

Boss Adapter

— US-18 —

Troubleshooting

If further assistance is required, contact your local authorized MARUYAMA service dealer.

Maintenance Period

●: Service to be performed by an authorized MARUYAMA engine dealer.

■: Service more frequently under dusty conditions.

NOTE:

The service intervals indicated are to be used as a guide.

Service to be performed more frequently as necessary depending on operating condition.

Use MARUYAMA standard 50:1 two-stroke engine oil.

Maintenance Daily Every

25 hours

Every

50 hours

Every

100 hours

Check and replenish fuel ●

Check for fuel leakage ●

Check bolts, nuts and screws for tightness or missing ●

Check engine idle speed adjustment ●

■Clean air lter element ●

Clean spark plug and adjust eleatrode gap ●

■Remove dust and dirt from cylinder ns ●

●Clean spark arrester ●

Tighten bolts and nuts ●

●Remove carbon deposits in exhaust port ●

Replace fuel lter ●

●

Remove carbon deposits on piston head and combustion chamber

●

●Remove carbon deposits in transfer port ●

Replece fuel tube, fuel tank cap gasket It is recommended to replace every 3 years

Problem Cause Action

Engine Will Not Start • STOP switch set to off position

• Empty fuel tank

• Primer bulb wasn’t pushed enough

• Engine ooded

• Move switch to on position

• Fill fuel tank

• Press primer bulb until fuel flows

through fuel return line

•

Use warm engine starting procedure

Engine Will Not Idle Idle speed set incorrectly Set idle speed

Engine Lacks Power or Stall When

Cutting

Throttle wire has come loose

Dirty air lter

Clogged spark arrester or exhaust port.

Tighten throttle wire

Clean or replace air filter

Clean spark arrester or exhaust port.

— US-19 —

Emission durability of 300 hours.

※1. Dry weight without fuel and edger blade.

※2. Dry weight without fuel.

Specifications

M27QC with

QC-E QC-ES QC-T

Weight (lbs.) ※1 14.0 (6.3kg) ※1 14.3 (6.5kg) ※2 15.5 (7.0kg)

Engine Displacement (cm3)

25.4

Anti Vibration Dual Isolatin-grip and engine mount

Shaft Bent Flexible shaft Straight Solid Shaft

Carburetor Walbro Diaphragm Type

Ignition Syatem Solid State

Fuel Tank Capacity (qts.) 0.63 (0.6L)

Gas to Oil Ratio 50:1

Spark Plug NGK BPM8Y

Spark plug Gap (in.) .024-.028 (0.6-0.7mm)

EPA and CARB Approved

Phase 3, Tier 3

M30QC with

QC-E QC-ES QC-T

Weight (lbs.) ※1 13.8 (6.3kg) ※1 14.1 (6.4kg) ※2 15.3 (7.0kg)

Engine Displacement (cm3)

30.1

Anti Vibration Dual Isolatin-grip and engine mount

Shaft Bent Flexible shaft Straight Solid Shaft

Carburetor Walbro Diaphragm Type

Ignition Syatem Solid State

Fuel Tank Capacity (qts.) 0.63 (0.6L)

Gas to Oil Ratio 50:1

Spark Plug NGK BPM8Y

Spark plug Gap (in.) .024-.028 (0.6-0.7mm)

EPA and CARB Approved

Phase 3, Tier 3

M42BK-QC with

QC-E QC-ES QC-T

Weight (lbs.) ※1 27.7 (12.6kg) ※1 28.0 (12.7kg) ※2 29.3 (13.3kg)

Engine Displacement (cm3)

41.5

Anti Vibration Dual Isolatin-grip and engine mount

Shaft Bent Flexible shaft Straight Solid Shaft

Carburetor Walbro Diaphragm Type

Ignition Syatem Solid State

Fuel Tank Capacity (qts.) 1.06 (1.0L)

Gas to Oil Ratio 50:1

Spark Plug NGK BPM8Y

Spark plug Gap (in.) .024-.028 (0.6-0.7mm)

EPA and CARB Approved

Phase 3, Tier 3

This manual suits for next models

15

Table of contents

Languages:

Other Maruyama Cutter manuals

Maruyama

Maruyama MC2600RS Owner's manual

Maruyama

Maruyama BM240 Owner's manual

Maruyama

Maruyama QC-HT User manual

Maruyama

Maruyama M27QC Owner's manual

Maruyama

Maruyama M270QC Owner's manual

Maruyama

Maruyama QC-PS User manual

Maruyama

Maruyama M42BK-QC Owner's manual

Maruyama

Maruyama M30BK-S User manual

Maruyama

Maruyama QC-S User manual