¥The measured value of a resistor in a circuit is often

different from the resistor's rated value. This is because

the Meter's test current flows through all possible paths

between the probe tips.

¥In order to ensure the best accuracy in measurement of low

resistance, short the test leads before measurement and

memory the test probe resistance in mind. This necessary

to subtract for the resistance of the test leads.

¥The resistance function can produce enough voltage to

forward-bias silicon diode or transistor junctions, causing

them to conduct. To avoid this, do not use the 40MΩ

range for in-circuit resistance measurements.

¥On 20MΩand 200MΩranges, the meter may take a few

seconds to stabilize reading. This is normal for high

resistance measuring.

¥On 200MΩrange, the display is approx. 10 digits when test

leads are shorted. These 10 digits have to be subtracted

from measuring results. For example, when measuring 100

MΩresistance, the reading will be 101.0 and the correct

measuring result should be 101.0-1.0=100.0 MΩ.

¥When the input is not connected, i.e. at open circuit, the

figure "1" will be displayed for the overrange condition.

3.2.3 Diode Test

To avoid electrical shock and/or damage to the

instrument, disconnect circuit power and

discharge all high-voltage capacitors before

testing diodes.

Use the diode test to check diodes, and other semi-

conductor devices. The diode test sends a current through

the semiconductor junction, and then measures the voltage

drop across the junction; a good silicon junction drops

between 0.5V and 0.8V. 12

To test a diode out of a circuit:

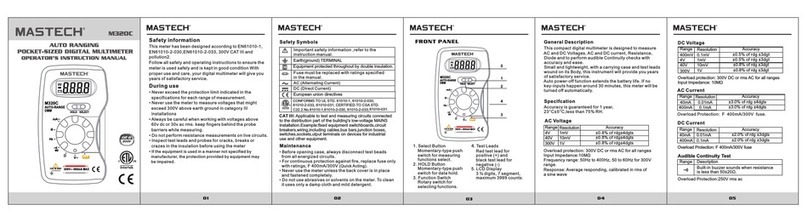

1. Set the rotary switch to range.

2. Connect the black and red test leads to the COM and

terminals respectively.

3. For forward-bias readings on any semiconductor

component, place the red test lead on the

component's anode and place the black test lead on

the component's cathode.

4. The meter will show the approx. forward voltage of the

diode. If the test lead connection is reversed, only

figure "1" displayed.

In a circuit, a good diode should still produce a forward bias

reading of 0.5V to 0.8V; however, the reverse-bias reading

can vary depending on the resistance of other pathways

between the probe tips.

3.2.4 Continuity Check

To avoid electrical shock and/or damage to the

instrument, disconnect circuit power and

discharge all high-voltage capacitors before

testing for Continuity.

Continuity is a complete path for current flow.

The beeper sounds if a circuit is complete. These brief

contacts cause the Meter to emit a short beep.

To test for continuity:

1. Set the rotary switch to range.

2. Press the yellow key twice to activate Continuity Check.

3. Connect the black and red test leads to the COM and

Ωterminals respectively.

4. Connect the test leads to the resistance in the circuit

being measured. 13

5. When the test lead to the circuit is below approx. 30Ω,

a continuous beeping will indicate it.