6

PRE-INSTALLATION INSTRUCTIONS

INSPECTION FOR SHIPPING DAMAGE

You are responsible for filing all freight clai s with the delivering truck line. Inspect all cartons and crates for da age

as soon as they arrive. If da age is noted to shipping crates or cartons or if a shortage is found, note this on the bill of

lading (all copies) prior to signing.

If da age is discovered when the cabinet is uncrated, i ediately call the delivering truck line and follow up the call

with a written report indicating concealed da age to your ship ent. Ask for an i ediate inspection of your concealed

da age ite . Crating aterial ust be retained to show the inspector fro the truck line.

INSTALLATION INSTRUCTIONS

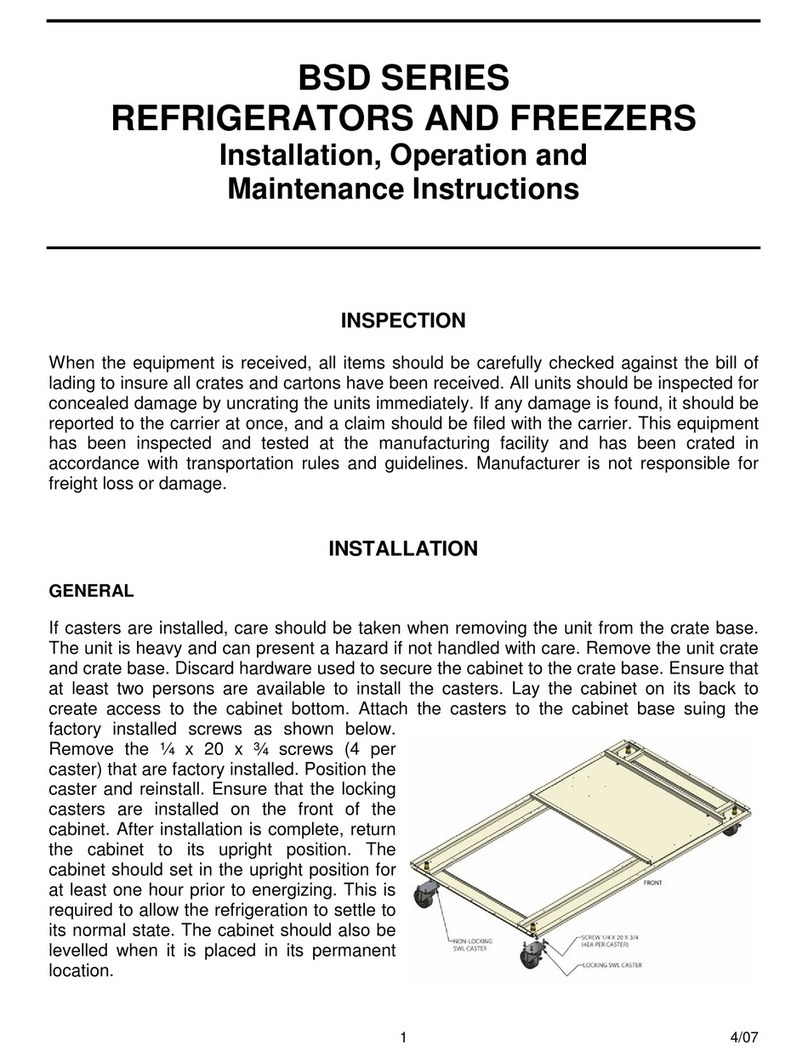

GENERAL INSTRUCTIONS

1. Be sure the equip ent is properly installed by co petent service people.

2. Keep the equip ent clean and sanitary so it will eet your local sanitation codes. Clean the cabinet with a ild

detergent and water, then rinse.

3. Rotate your stock so that older stock does not accu ulate. This is especially i portant for ice

crea . A "First-In, First-Out" rotation practice will keep the products in good salable condition.

4. Do not place product in the case when it is soft or partially thawed. Also, product should not be put in the case for at

least 6 hours after it is started.

5. Stock cases as quickly as possible, exposing only s all quantities to store te peratures for short periods of ti e.

6. When replacing burned out fluorescent tubes, be sure that the electrical power to the lighting circuit is turned off.

NOTICE TO STORE OWNERS / MANAGERS

Moistur or liquid around or und r th cabin t is a pot ntial slip/fall hazard for p rsons walking by or working

in th g n ral ar a of th cabin t. Any cabin t malfunction or hous k ping probl m that cr at s a slip/fall

hazard around or und r th cabin t should b corr ct d imm diat ly.

If oisture or liquid is observed around or under a Master-Bilt cabinet, an i ediate investigation should be ade by

qualified personnel to deter ine the source of the oisture or liquid. The investigation should deter ine if the cabinet

is alfunctioning or if there is a drainpipe leaking.

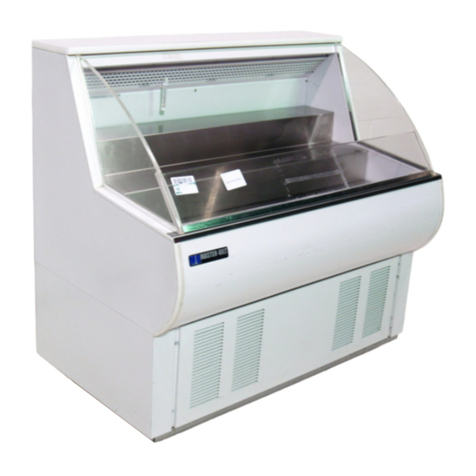

MECHANICAL

Re ove front grille and check refrigeration lines to see that they are free (not touching each other or co pressor).

Spin condenser fan blade to see that it is free.

The co pressor is her etic, it is internally spring ounted and ready to run.

Re ove cabinet fro crate base and slide into location. Cabinet ust be level fro side to side and front to back for

correct draining of coil pan and for self-closing doors to operate correctly. Allow ini u of 4” between back of cabinet

and wall and between top of cabinet and ceiling for proper condensing unit air circulation.

To co ply with Sanitation require ents the cabinet ust be ounted on legs (6” high in.) or casters or the base ust

be sealed to the floor (BMG) with an N.S.F. listed silicone sealant.

Hang provided NSF Listed ther o eter at front of top shelf unless cabinet provided with electronic control.