Page 3

Contents

1. SAFETY INDICATIONS ........................................................................................... 4

1.1. General notes .................................................................................................. 4

1.2. Notes for functioning and use .......................................................................... 4

2. CONSTRUCTION AND REGULATORY REFERENCES ........................................ 5

3. TECHNICAL DATA .................................................................................................. 5

4. ID PLATE AND MARKING DATA ............................................................................ 6

5. RECOMMENDATIONS AND INSTRUCTIONS FOR ASSEMBLY ......................... 6

6. TECHNICAL OPERATING INFORMATION ............................................................ 7

6.1. General instructions ......................................................................................... 7

6.2. Programming .................................................................................................. 8

6.2.1. Programming Display and Programming Menu ......................................... 8

6.2.2. Errors table .............................................................................................. 12

6.3. Settable functions .......................................................................................... 12

6.3.1. General Open-Close (on main board) - In01, In02 ................................. 12

6.3.2. Rain sensor - Parameters P005, P104, P204, P304, P404, P504, P604 13

6.3.3. Wind sensor - Parameters P103, P203, P303, P403, P503, P603 ......... 13

6.3.4. Cron / Timer input (on main board) - Parameters P105, P205, P305,

P405, P505, P605.................................................................................... 13

6.3.5. Sensor priority – Parameter P006............................................................ 14

6.3.6. Motor reset time – Parameters P102, P202, P302, P402, P502, P602 ... 14

6.3.7. Other parameters – Parameters P101, P201, P301, P401, P501, P601,

Add, dEL, Rese........................................................................................ 14

6.4. Saving a PIK radio remote control ................................................................. 14

6.5. Saving a radio remote control without access to the board ........................... 15

7. OVERALL DIMENSIONS ...................................................................................... 16

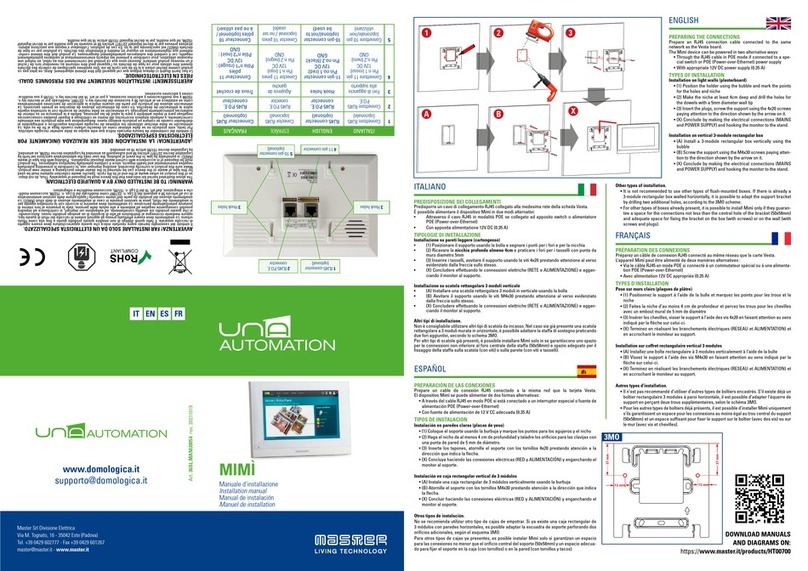

8. CONNECTION DIAGRAM OF THE STATION ..................................................... 17

9. CONNECTION OF THE EXPANSION MODULES TO THE MAIN BOARD .......... 18

10. ENVIRONMENTAL PROTECTION........................................................................ 19

11. CERTIFICATE OF GUARANTEE .......................................................................... 19

12. DECLARATION OF CONFORMITY ...................................................................... 20