4

Warnings

WARNING:

8. Keep the fuel supply hose away from any heated surface.

9. When cooking with oil or grease, the thermometer provided MUST be used.

Follow instructions in this manual for proper installation and use of the thermometer.

If the thermometer supplied with this fryer has been lost or damaged, a replacement thermometer

must be one specified by the appliance manufacturer.

10. If the temperature exceeds 400°F (200°C) or if oil begins to smoke, immediately turn the

burner or gas supply OFF and wait for the temperature to decrease to less than 350°F (176°C)

before relighting burner according to the manufacturer’s instructions. If there is a lid (cover),

do not remove the lid.

11. When cooking with oil or grease, have a type BC or ABC fire extinguisher readily available.

In the event of an oil or grease fire do not attempt to extinguish with water.

Immediately call the fire department. A Type BC or ABC fire extinguisher may, in some

circumstances, contain the fire.

12. Never overfill the cooking vessel with oil, grease or water. Follow instructions in this manual for

establishing proper oil, grease or water levels.

13. Introduction of water or ice from any source into the oil/grease may cause overflow and severe

burns from hot oil and water splatter. When frying with oil/grease, all food products MUST be

completely thawed and towel dried before being immersed in the fryer.

14. Do not place empty cooking vessel on the appliance while in operation. Use caution when

placing anything in cooking vessel while the appliance is in operation.

15. In the event of rain, snow, hail, sleet or other forms of precipitation while cooking with oil or

grease, cover the cooking vessel immediately and turn o appliance burners and gas supply.

Do not attempt to move the appliance or cooking vessel.

16. Do not move the appliance when in use. Allow the cooking vessel to cool to 115°F (45°C)

before moving or storing.

17. Do not leave the appliance unattended. Keep children and pets away from the appliance at

all times.

WARNING:

Installation Safety Precautions.

•Use appliance only with LP (propane) gas and the regulator/ valve assembly supplied.

•Installation must conform with local codes or, in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, Storage and Handling of Liquefied Petroleum Gases,

ANSI/NFPA 58; or Natural Gas and Propane Installation Code, CSA B1 49.1

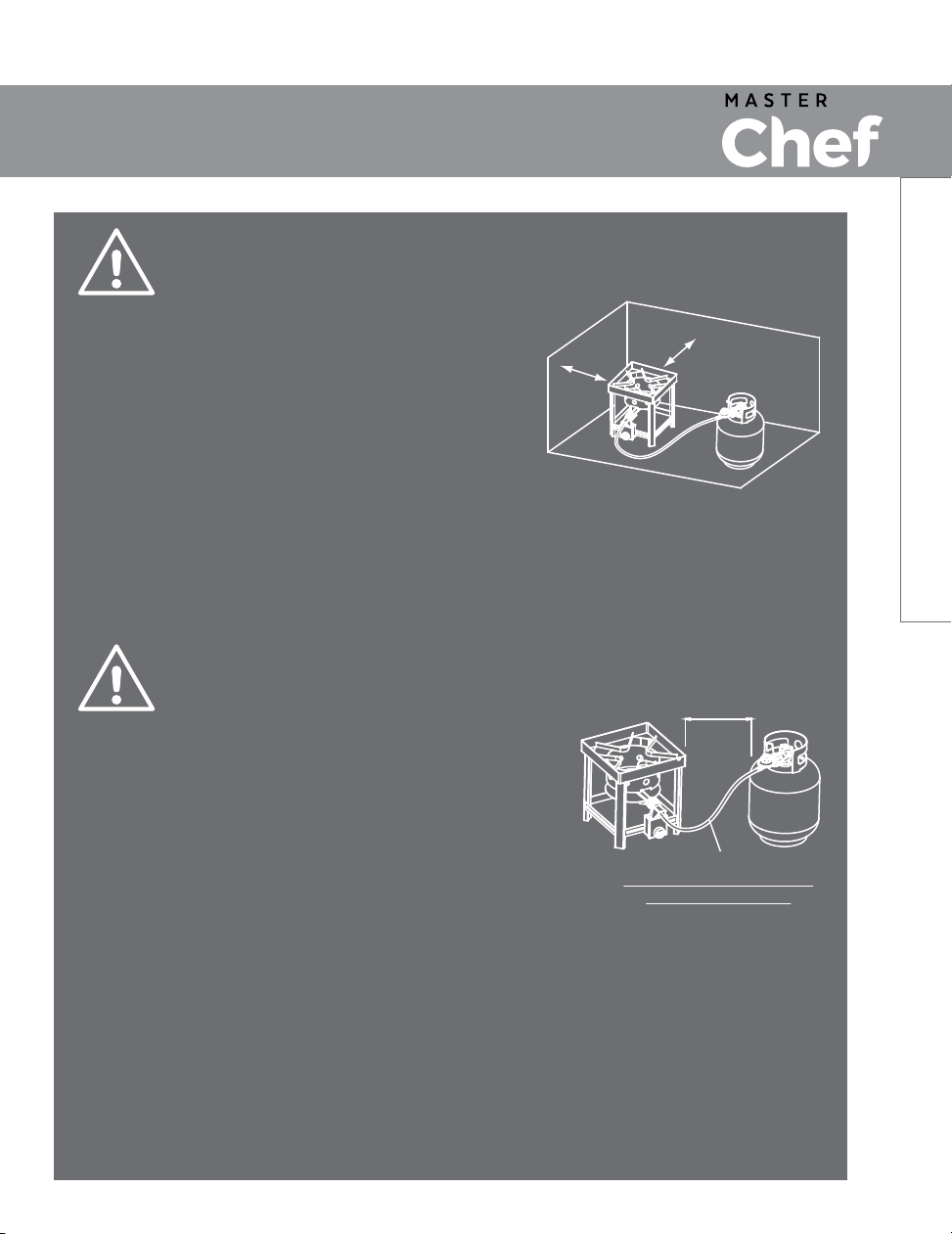

•This appliance shall be used only outdoors, and shall not be used in a building, garage or any

other enclosed area.

•Use appliance at least 10’ (3 m) from any wall or surface. Maintain 10’ (3 m) clearance to objects

that can catch fire or sources of ignition such as pilot lights on water heaters, live electrical

appliances, etc. Never use under balconies made of wood or ANY overhead construction.

Product no. 085-3230-2 (TF2115708-MC-00) |

Contact us: 1-855-803-9313