2.1 Safety

The following types of safety instructions and general information appear in this document as

described below:

.5..4.

CAUTION:

“Caution” indicates a hazardous situation which if not avoided, could result

in minor or moderate injury.

WARNING:

“Warning” indicates a hazardous situation which if not avoided, could result

in death or serious injury.

DANGER:

“Danger” indicates a hazardous situation which if not avoided, will result in

death or serious injury.

NOTE:

“Note” provides tips that are valuable for the optimal operation of your

product.

2. Safety & Warning 2. Safety & Warning

2.2 General Safety Instructions

WARNING:

Electrical installations must be done in accordance with the local and national

electrical safety standards.

WARNING:

Please don’t connect PV array positive (+) or negative (-) to ground, it could

cause serious damage to the inverter.

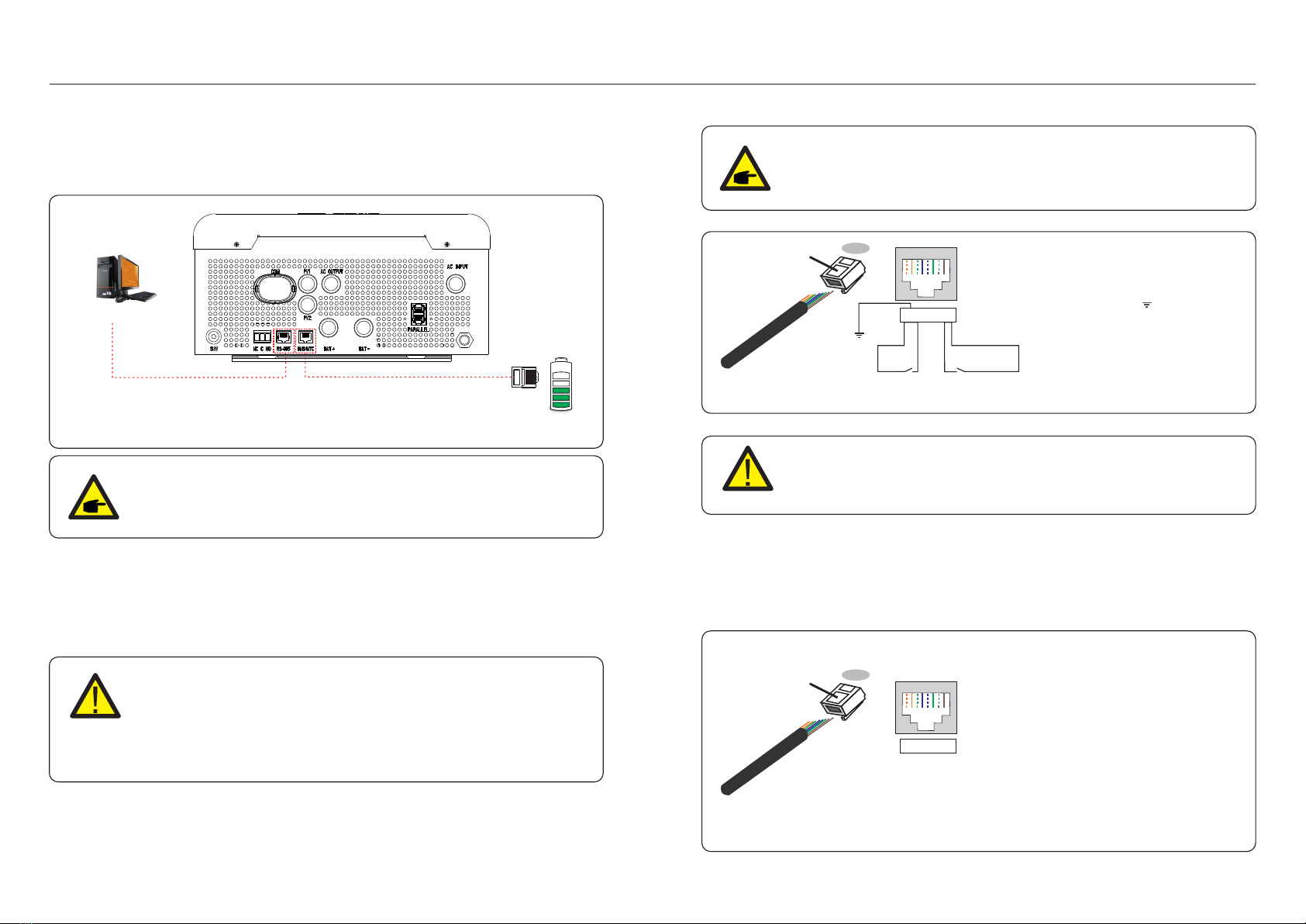

WARNING:

Only devices in compliance with SELV (EN 69050) may be connected to the

RS485 and USB interfaces.

WARNING:

Do not touch any inner live parts until 5 minutes after disconnection

from the utility grid and the PV input.

CAUTION:

The PV array supplies a DC voltage when they are exposed to sunlight.

CAUTION:

Risk of electric shock from energy stored in capacitors of the Inverter, do not

remove cover for 5 minutes after disconnecting all power sources (service technician

only). Warranty may be voided if the cover is removed without authorization .

CAUTION:

The surface temperature of the inverter can reach up to .60℃ (140 ℉)

To avoid risk of burns, do not touch the surface of the inverter while it’s operating.

Inverter must be installed out of the reach of children.

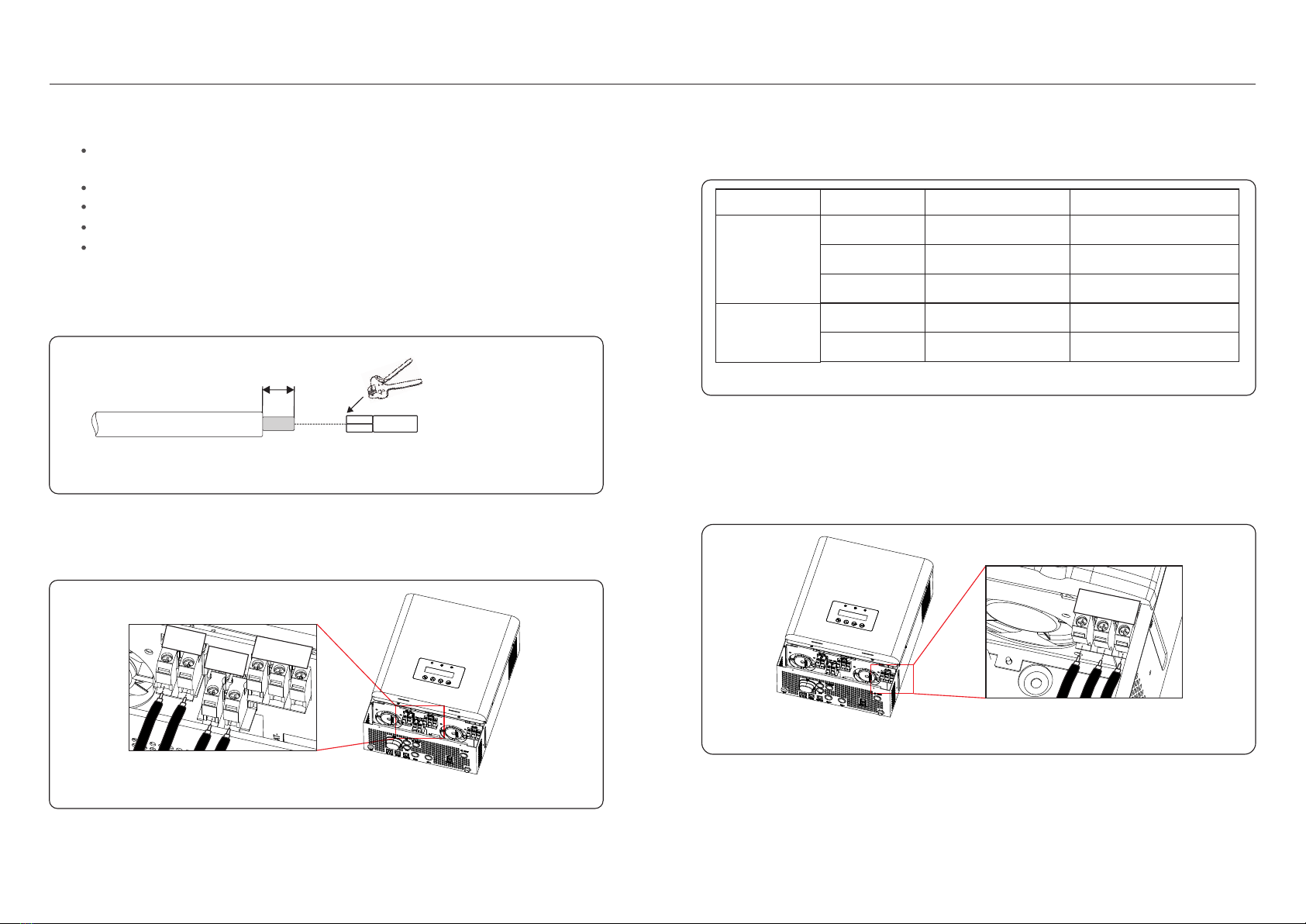

WARNING:

To reduce the risk of fire, over-current protective devices (OCPD) are

required for circuits connected to the inverter.

The DC OCPD shall be installed per local requirements. All photovoltaic source

and output circuit conductors shall have that comply with the NECisolators

Article 690, Part II.

CAUTION:

Risk of electric shock, do not remove cover. There is no user serviceable

parts inside, refer servicing to qualified and accredited service technicians.

NOTE:

PV module used with inverter must have an IEC 61730 Class A rating.

WARNING:

Operations below must be accomplished by licensed technician or MasterPower

authorized person.

WARNING:

Operator must put on the technicians’ gloves during the whole process in case

of any electrical hazards.

WARNING:

For PV system, between the PV string and PV input of the inverter, it is

required to install a DC isolator to meet local installation regulations.