MVLP6

6" LOW PROFILE VISE KIT

AVERTISSEMENT : Cancer et dommages à l'appareil reproducteur. www.P65Warnings.ca.gov

ADVERTENCIA: Cáncer y daño reproductivo. www.P65Warnings.ca.gov

Matco Tools | Stow, Ohio 44224 | www.matcotools.com | 2006093-08

The 6" Low Profile Vise Kit is backed by a Limited Lifetime Warranty. This warranty covers manufacturer defects and workmanship. The warranty

excludes misuse or abuse and normal wear and tear. Exclusion is not allowed in some states and may not apply. This warranty gives you specific legal

rights, and you may have other rights, which vary from state to state.

• Mount only according to these instructions. Improper mounting can create hazards.

• Keep work area clean and well lit.

• Keep bystanders out of the area during use.

• This product is not a toy. Do not allow children to play with or near this item.

• Use for intended purposes only.

• Inspect before use; do not use if parts are loose or damaged.

• Maintain product labels and nameplates. These carry important safety information. If unreadable or missing contact 1-800-255-7011 for a replacement.

• Before drilling vise mounting holes, check for hidden electrical wires or cords in drilling path.

• Medications may impair judgment and reflexes, so please read all safety warning labels on medical prescriptions to determine if you may be affected.

Do not use this product if you are under the influence of drugs or alcohol.

• Use eye and hand protection. Wear ANSI-approved safety impact goggles and heavy-duty work gloves during use.

• DRESS SAFELY. Do not wear loose clothing or jewelry as they can become caught in moving parts. Wear a protective hair covering to prevent long hair

from being caught in moving parts.

• Do not overreach. Keep proper footing and balance at all times.

• Stay alert. Watch what you are doing at all times. Use common sense. Do not operate this product when you are tired or distracted from the job at hand.

• Damage could occur to your vise and/or workpiece if you overtighten the handle.

• Carefully check for damaged parts or any other conditions that may affect operation before using this product. Repair or replace damaged and worn

components immediately.

• When servicing, use only identical, manufacturer-recommended replacement parts.

• Maintain product with care. Keep this product clean and dry, and all moving parts lightly lubricated for better performance. Keep the handle dry, clean,

and free from oil, grease and solvents.

• Use the right tool for the job. Do not attempt to force a small tool or attachment to do the work of a larger industrial tool. This vise was designed for

specific applications. Do not modify this tool or use it for any purpose other than that for which it was intended.

GENERAL GUIDELINES AND WARNINGS:

• Mount only according to these instructions. Improper mounting can create hazards.

• Keep work area clean and well lit.

• Keep bystanders out of the area during use.

• This product is not a toy. Do not allow children to play with or near this item.

• Use for intended purposes only.

• Inspect before use; do not use if parts are loose or damaged.

• Maintain product labels and nameplates. These carry important safety information. If unreadable or missing contact 1-800-255-7011 for a replacement.

• Before drilling vise mounting holes, check for hidden electrical wires or cords in drilling path.

• Medications may impair judgment and reflexes, so please read all safety warning labels on medical prescriptions to determine if you may be affected.

Do not use this product if you are under the influence of drugs or alcohol.

• Use eye and hand protection. Wear ANSI-approved safety impact goggles and heavy-duty work gloves during use.

• DRESS SAFELY. Do not wear loose clothing or jewelry as they can become caught in moving parts. Wear a protective hair covering to prevent long hair

from being caught in moving parts.

• Do not overreach. Keep proper footing and balance at all times.

• Stay alert. Watch what you are doing at all times. Use common sense. Do not operate this product when you are tired or distracted from the job at hand.

• Damage could occur to your vise and/or workpiece if you overtighten the handle.

• Carefully check for damaged parts or any other conditions that may affect operation before using this product. Repair or replace damaged and worn

components immediately.

• When servicing, use only identical, manufacturer-recommended replacement parts.

• Maintain product with care. Keep this product clean and dry, and all moving parts lightly lubricated for better performance. Keep the handle dry, clean,

and free from oil, grease and solvents.

• Use the right tool for the job. Do not attempt to force a small tool or attachment to do the work of a larger industrial tool. This vise was designed for

specific applications. Do not modify this tool or use it for any purpose other than that for which it was intended.

GENERAL GUIDELINES AND WARNINGS:

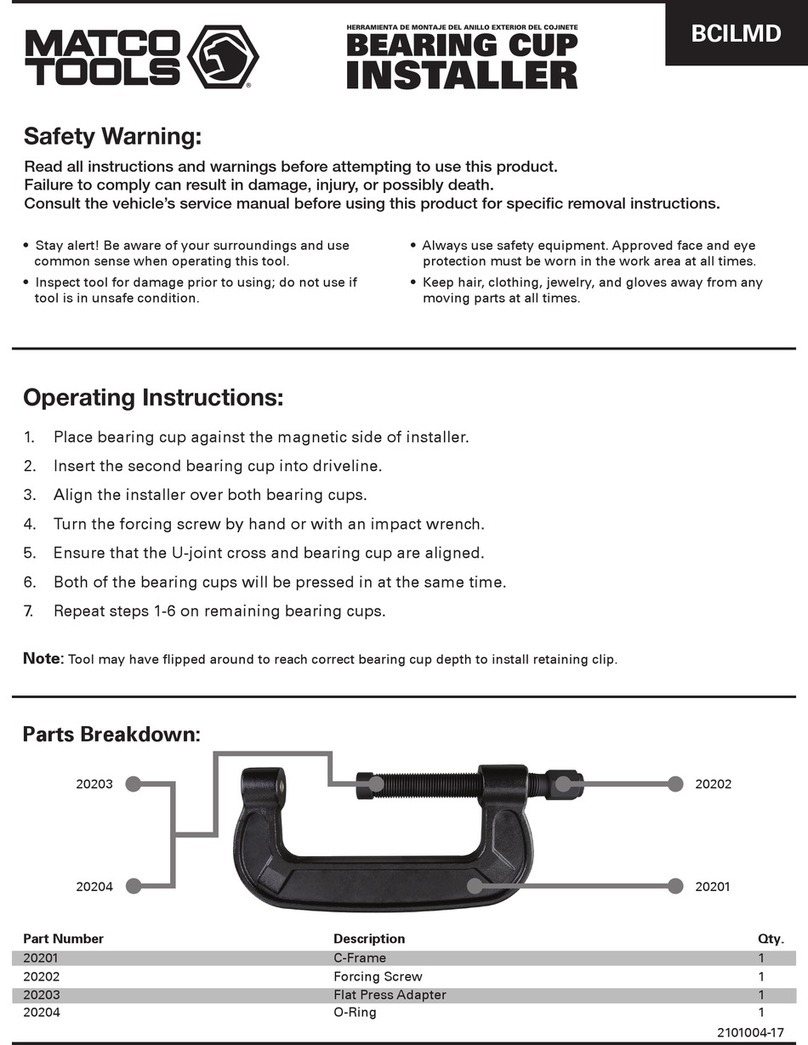

REPLACEMENT COMPONENTS:

MVLP4 MATCO

4" Low Profile Vise

ITEM# VISE PART#REPLACEMENT COMPONENT

Ratcheting Handle

FSMVLP-HAN

4" Jaw Pads - Curved

4" Jaw Pads - Steel

MV2807

MV2808

MV2809 4" Jaw Pads - Non-Marring

Swivel Base Locks

Serrated Jaws

Posi-Clock Disc - Small

FS92746-05

FS92746-07

FS93159

FS92746-12 Large Vise Bolts MVLP6 MATCO

6" Low Profile Vise

Ratcheting Handle

FSMVLP-HAN

6" Jaw Pads - Curved

6" Jaw Pads - Steel

MV2816

MV2817

MV2818 6" Jaw Pads - Non-Marring

Swivel Base Locks

Serrated Jaws

Posi-Clock Disc - Large

FS92748-05

FS92748-07

FS93158

FS92748-12 Large Vise Bolts

ITEM# VISE PART#REPLACEMENT COMPONENT