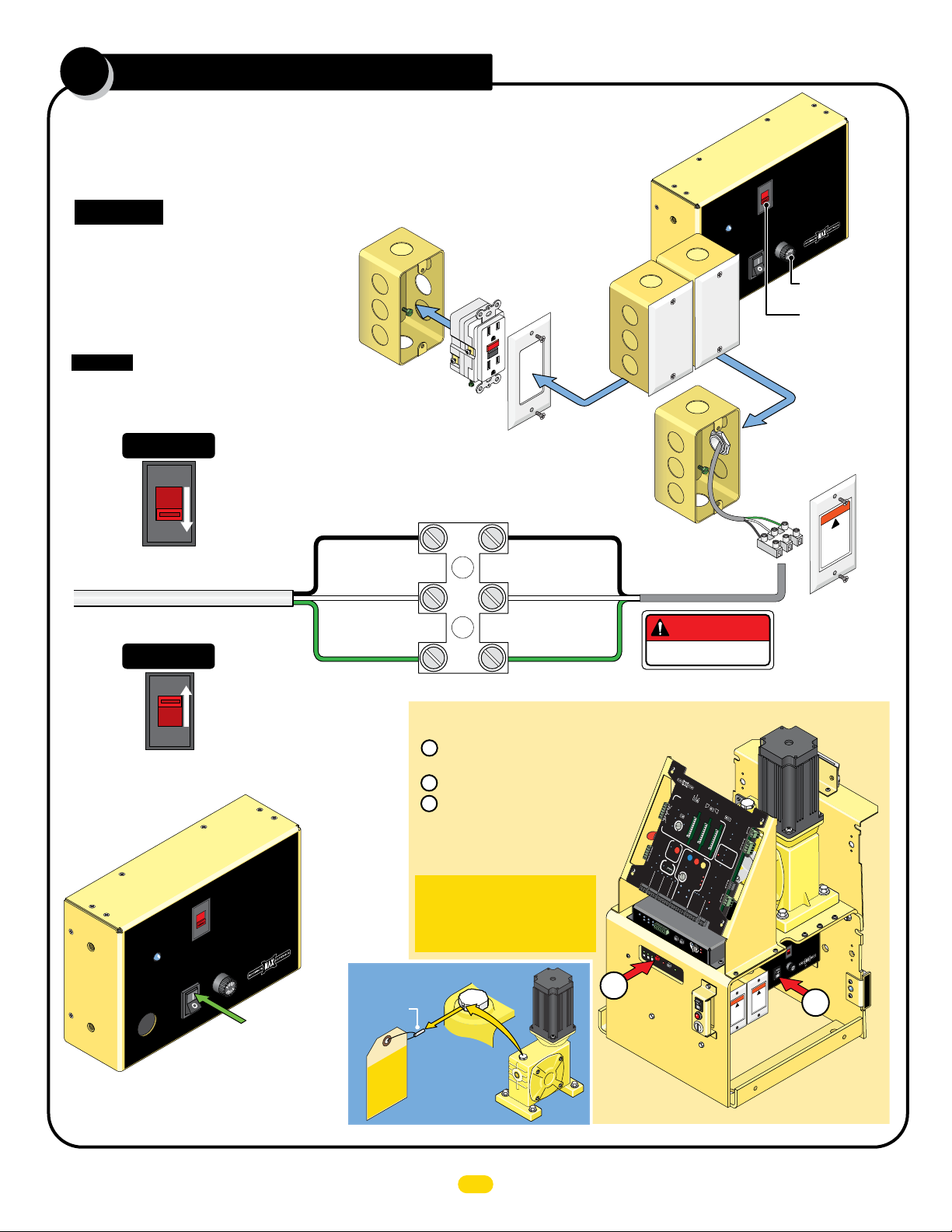

entrapment protection wiring

7

Typical Wiring For:

Normally Closed (N.C.)

Photo Cell to EDGE 1

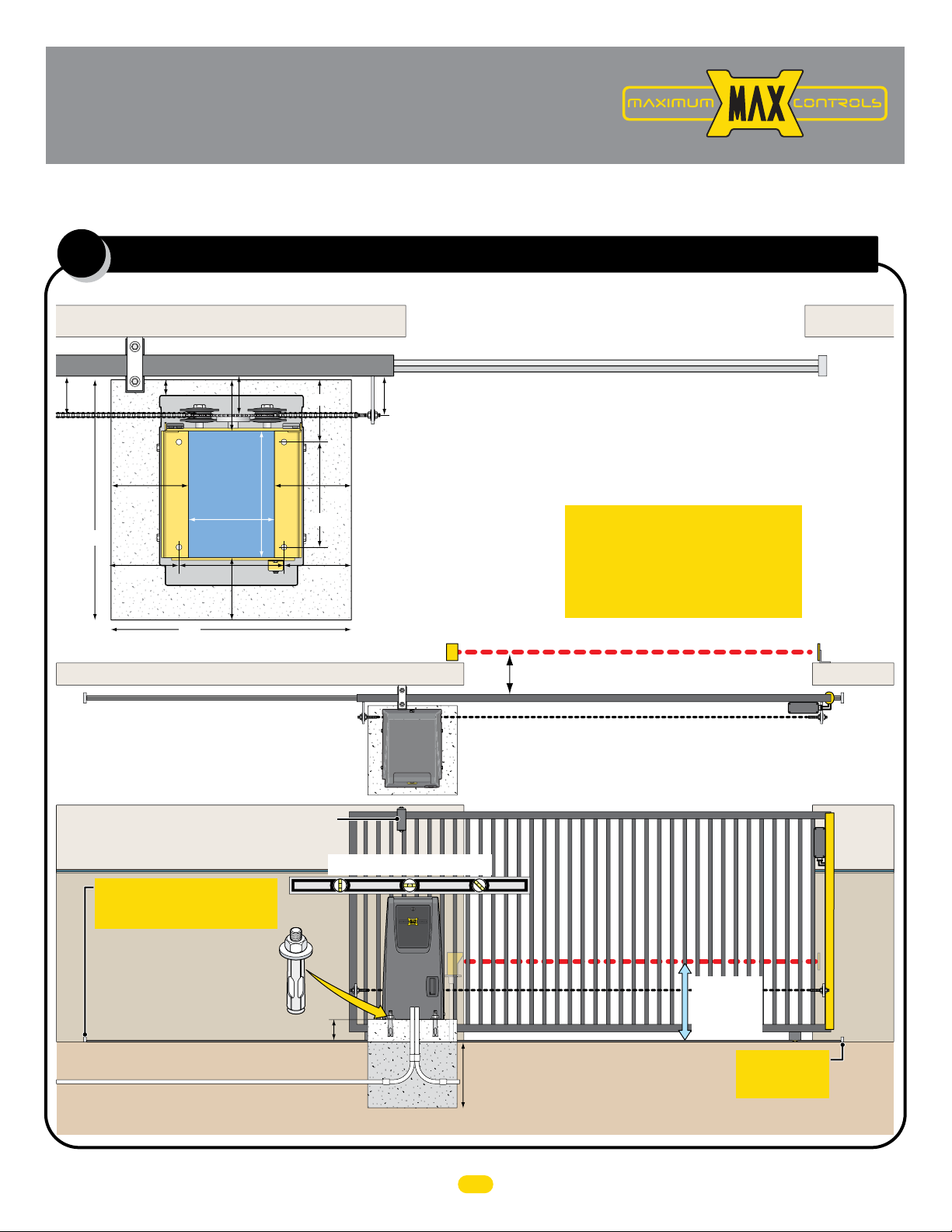

Entrapment Protection Device Locations:

Typical HARDWiring For:

Normally Closed (N.C.)

Sensing Edge to EDGE 1

(CLOSING Direction ONLY)

IMPORTANT Sensing

devices MUST be

powered by MC-200

or they will NOT be

MONITORED.

EDGE 1: MONITORED CLOSE ONLY

Photo Cell: LEARNED MONITORED OPEN/CLOSE

Edge 2: LEARNED MONITORED OPEN/CLOSE

IMPORTANT: Photocells

MUST be in alignment

or fault will occur.

NOTE: See manual for more

information about learned

monitored inputs.

NOTE:

Matrix 1 MUST be

removed to wire

MC-200. See pages 18-20

for specific

photocell wiring.

See page 21 to wire a Gate

Link wireless transmitter.

NOTE: See manual for more information about

photcell and sensing edges installation and wiring.

PhotoCell Edge

UL

Entrap

1

2

Limit SW

ON-LINE

MATRIX JOG JOG

LEFT RIGHT

Jog LT

Jog RT

GND

Edge 1

Edge 2

Photo

Cell

ERD

Motor

OverLoad

POWER

MC-200

Motor Controller

1615 14 1312

3

45

MAX

LED ON

Sensitivity

Edge

ERD Sensor Wire

Jumper UNUSED Entrapment Protection

Inputs to GND or a fault will occur.

Example: Inputs 2 & 3

are NOT used and MUST

be jumpered to GND.

1

2

3

GND

1

23

Photo

Edge 2

EDGE 1

PhotoCell Edge

UL

Entrap

1

2

Limit SW

ON-LINE

MATRIX

JOG JOG

LEFT RIGHT

Jog LT

Jog RT

GND

Edge 1

Edge 2

Photo

Cell

ERD

Motor

OverLoad

POWER

MC-200

Motor Controller

1615 14 1312

3

45

MAX

LED ON

Sensitivity

Edge

ERD

MOTOR Power In

ALARM

BATTERY

PACK

LIMIT

SWITCH

MOTOR

INPUTS

PWR12V

-

GND

-

-

-

PWR 24V -

GND -

RS-485 (-) -

RS-485 (+) -

MATRIX 1

Edge 1

Monitored

Reversing

Edge

Monitored

Photo

Cell

OR

GND

Jog RT

Jog LT

Entrapment Protection

Inputs:

MUSTjumper

unused inputs

Entrapment Protection

SensorGuidelines

1

-

-

-

CAUTION:

See installation instructions.

ATTENTION:

Voir la notice d’installation.

Edge 2

Photo Cell

MC-200 PWR 12V MUSTbe used

ONLYpower entrapment protection

sensors withMC-200 PWR 12V

2

3

•

Asensor MUST be wired to EDGE1 or

operator WILL NOTfunction.

•

Wire NORMALLYCLOSED(N.C.)

MONITOREDsensors ONLY, to each

operator’s MC-200 when dual operators

are used.

•

Reversing Edge and/or Photo Cell can

b

e wired to ANY of the 3 Inputs.

•

MC-200 PWR12V MUSTbe used to

p

ower MONITORED sensors.

•

UNUSED inputs MUST remain

JUMPEREDor fault will occur.

GND

1

2

3

Inputs &MUST be “LEARNED”

to MONITORsensors.

To LEARNinputs &:

1.

MONITORED Sensors MUST be

wired to inputsBEFORE they canbe

learned.Any unusedinputsMUSTbe

jumpered.

2.Reversing Edge and/or PhotoCell can

bewiredtoeither input2or 3.

3.P ressand HOLD the OPEN &STOP

buttons atthe same timeon Matrix 1

until beep isheard,learn mode begins.

Learn mode lastsfor 5 min.indicated

bybeeping.

4.

LEDs WILL beON for eachdetected

sensor onMC-200.LEDsWILL beON

f

or BOTHMC-200swhendual

operators are used.

5.

PressSTOP button again within 5min.

tolearn sensors andendlearn mode,

beepingstops.

Inputsare now MONITORED.

23

23

OPEN STOP

CLOSE

MOTORMOTION

MC-200Slide

EDGE 1 (N.C.)

CLOSING Direction ONLY

GND (C)

Reflector

GND

PWR 12V

Polarity does NOT matter

Thru-Beam

Recr Trans

Reflective

Beam

Power

Power Power

PhotoCell Edge

UL

Entrap

1

2

LimitSW

ON-LINE

MATRIX

JOG JOG

LEFT RIGHT

Jog LT

Jog RT

GND

Edge 1

Edge 2

Photo

Cell

ERD

Motor

OverLoad

POWER

MC-200

Motor Controller

1615 14 1312

3

45

MAX

LED ON

Sensitivity

Edge

ERD

MOTOR Power In

ALARM

BATTERY

PACK

LIMIT

SWITCH

MOTOR

INPUTS

PWR12V

-

GND

-

-

-

PWR 24V -

GND -

RS-485 (-) -

RS-485 (+) -

MATRIX 1

Edge 1

Monitored

Reversing

Edge

Monitored

Photo

Cell

OR

GND

Jog RT

Jog LT

Entrapment Protection

Inputs:

MUSTjumper

unused inputs

Entrapment Protection

SensorGuidelines

1

-

-

-

CAUTION:

See installation instructions.

ATTENTION:

Voir la notice d’installation.

Edge 2

Photo Cell

MC-200 PWR 12V MUST be used

ONLYpower entrapment protection

sensors withMC-200 PWR 12V

2

3

•

Asensor MUST be wired to EDGE1 or

operator WILL NOTfunction.

•

Wire NORMALLYCLOSED(N.C.)

MONITOREDsensors ONLY, to each

operator’s MC-200when dual operators

are used.

•

Reversing Edge and/or Photo Cell can

be wired to ANY of the 3Inputs.

•

MC-200 PWR12VMUSTbe used to

power MONITORED sensors.

•

UNUSED inputs MUST remain

JUMPEREDor fault will occur.

GND

1

2

3

Inputs &MUST be “LEARNED”

to MONITORsensors.

To LEARNinputs &:

1.

MONITOREDSensors MUSTbe

wiredtoinputs BEFORE they canbe

learned.Any unusedinputsMUST be

jumpered.

2.

ReversingEdgeand/orPhotoCell can

bewiredtoeither input2or 3.

3.

PressandHOLD theOPEN &STOP

buttonsatthe same timeonMatrix1

until beep is heard,learn modebegins.

Learn modelastsfor 5min.indicated

bybeeping.

4.

LEDs WILL beON for eachdetected

s

ensor onMC-200.LEDsWILL beON

f

or BOTHMC-200swhendual

operators are used.

5.

PressSTOP button again within 5min.

tolearn sensors andendlearn mode,

beepingstops.

Inputs are nowMONITORED.

23

23

OPEN STOP

CLOSE

MOTORMOTION

MC-200Slide

GEM-104 MUST be used.

EDGE 1 (N.C.)

CLOSING Direction ONLY

GND (C)

GND

PWR 12V

Polarity does NOT matter

ON = Obstruction

BLINKING = Fault

PWR

MON.

SAFETY

INPUT

GEM - 104

10K Edge

Normally

Closed

Sensing Edge

ONE Entrapment protection sensor MUST be installed or operator will

NOT function. It MUST be MONITORED and NORMALLY CLOSED (N.C.).

UL 325 2016 Standard

Beam: 5” or LESS

from CLOSED gate.

Run conduit to operator

Entrapment Area

CLOSING Direction

Photocell

Wall

Gate Closed

Outside Property

Inside Property

Continued on next page.

IMPORTANT: Photocells MUST

be in alignment or fault will occur.

NOTE: Photo input on Matrix 1 is NOT

MONITORED (Normally OPEN) and is

NOT UL 325 entrapment protection.

CLOSING direction photocell

to MC-200 EDGE 1 input.

IMPORTANT: Entrapment

Protection Photocells MUST be

Monitored Normally Closed Type.

6

UL 325 2016 Standard-MAX 1700FS Quick Install Rev 3