Maxcess MAGPOWR User manual

Other Maxcess Industrial Equipment manuals

Maxcess

Maxcess FIFE-500 User manual

Maxcess

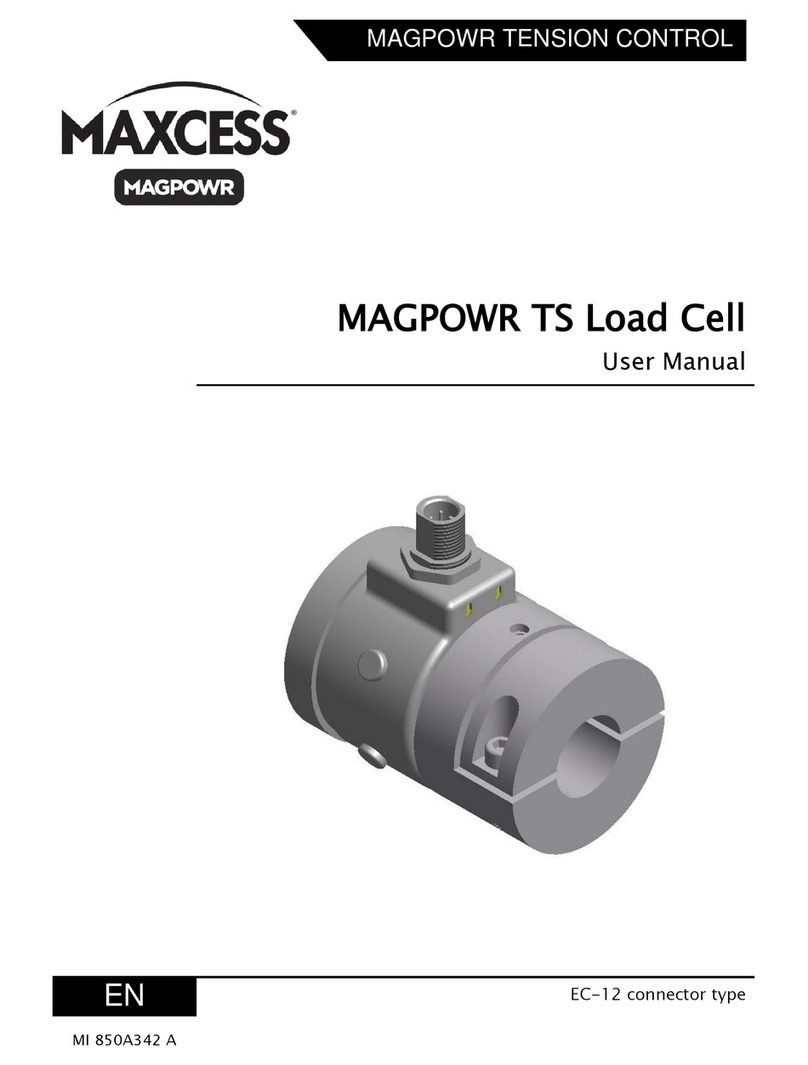

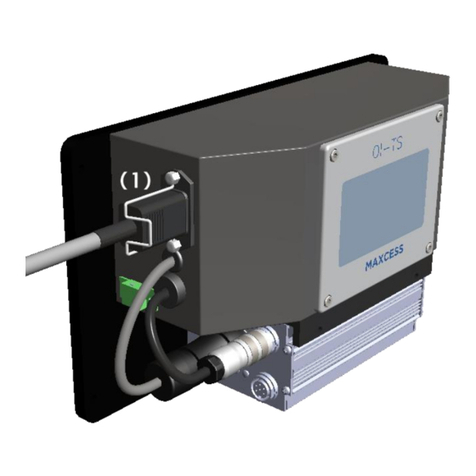

Maxcess MAGPOWR TS Load Cell User manual

Maxcess

Maxcess MAGPOWR TLC-B Load Cell User manual

Maxcess

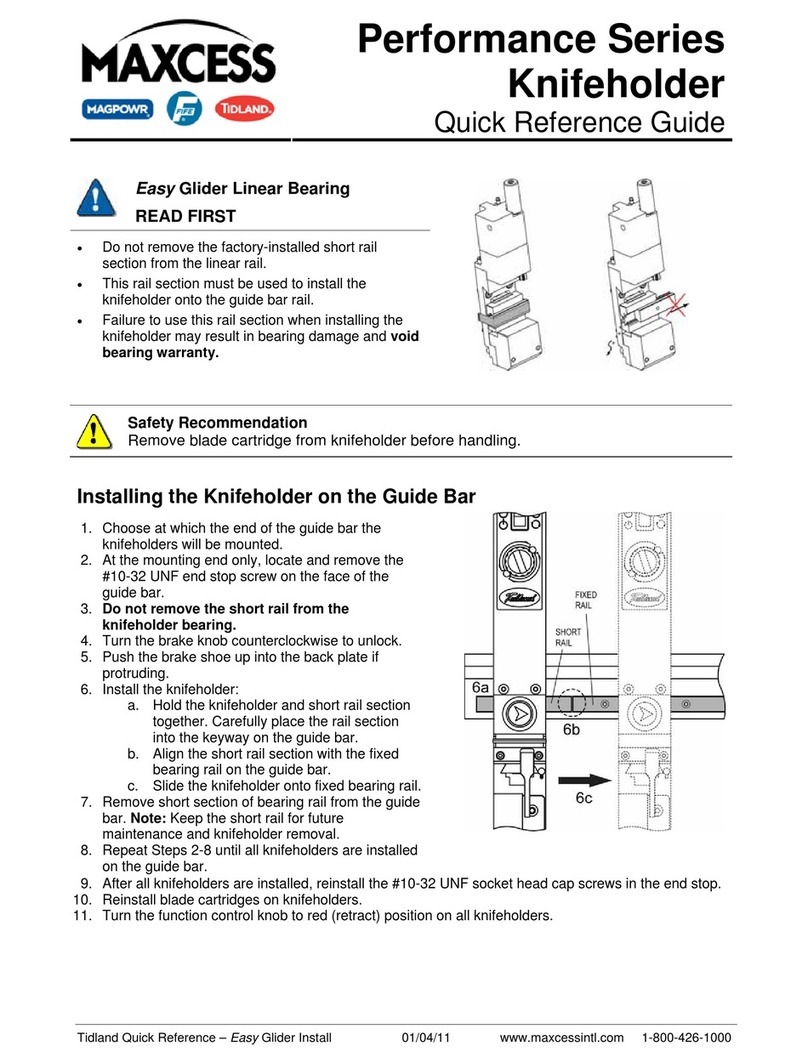

Maxcess Tidland Performance Series Installation and operating instructions

Maxcess

Maxcess MAGPOWR GTS Load Cell User manual

Maxcess

Maxcess VERSATEC S15 Installation and operating instructions

Maxcess

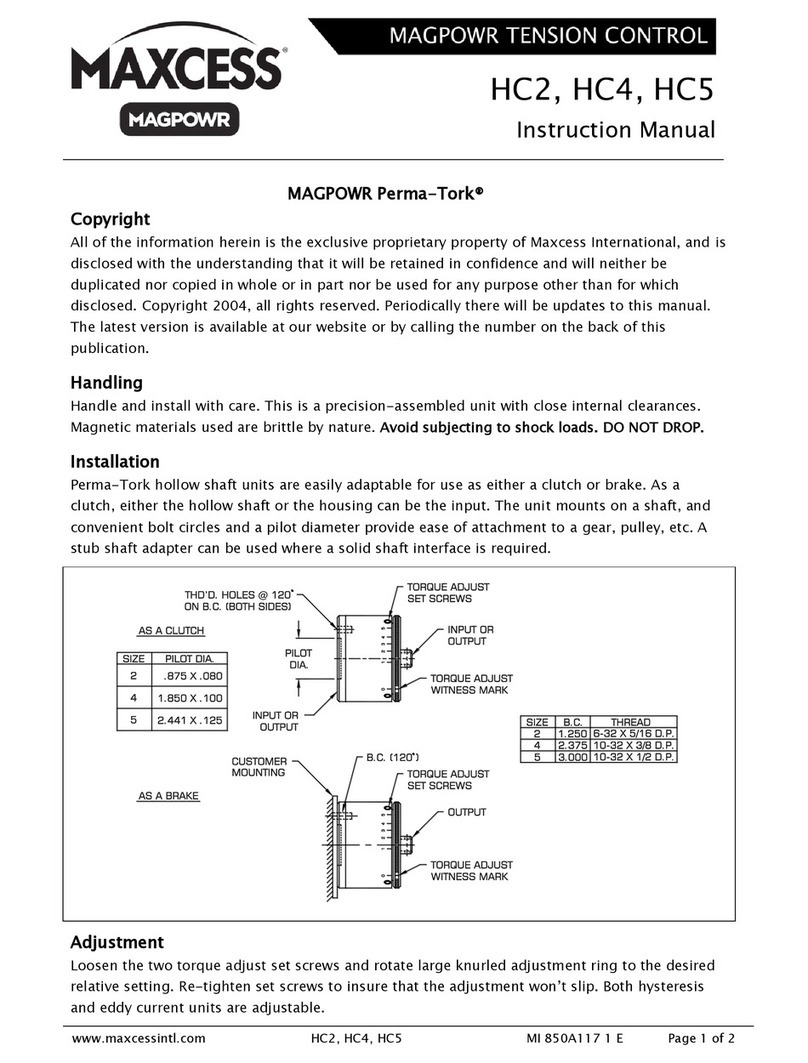

Maxcess MAGPOWR Perma-Tork HC2 User manual

Maxcess

Maxcess FIFE-500 User manual

Maxcess

Maxcess TIDLAND Roll Restorer User manual

Maxcess

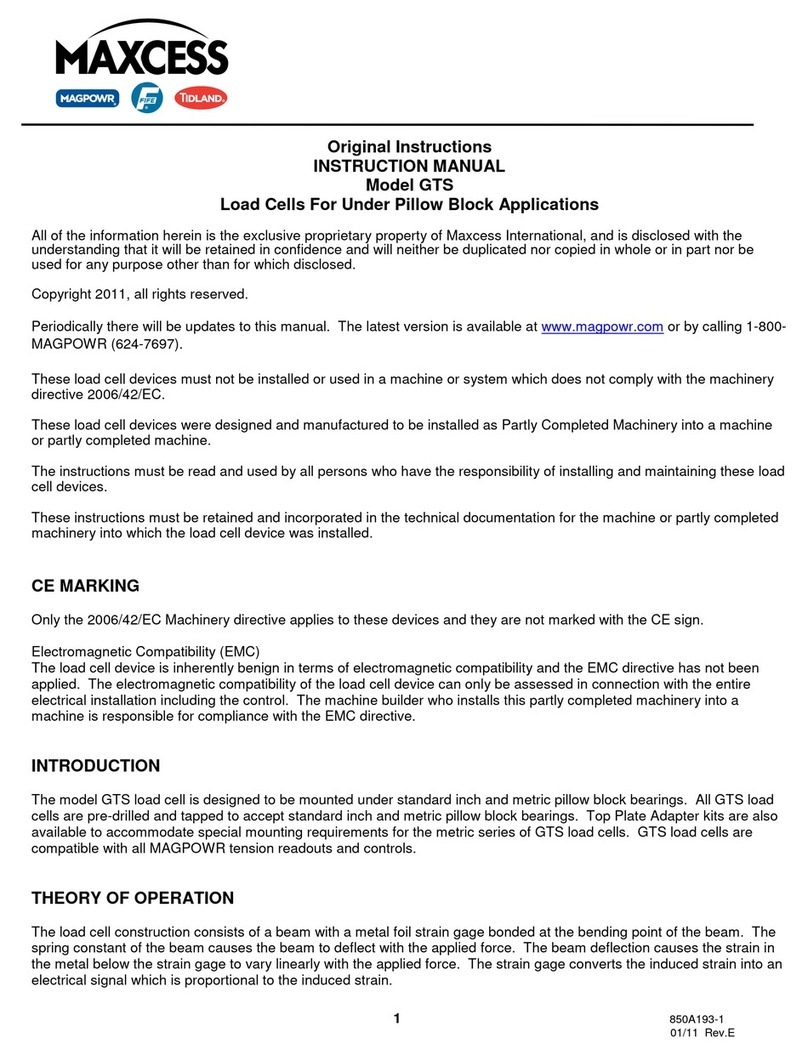

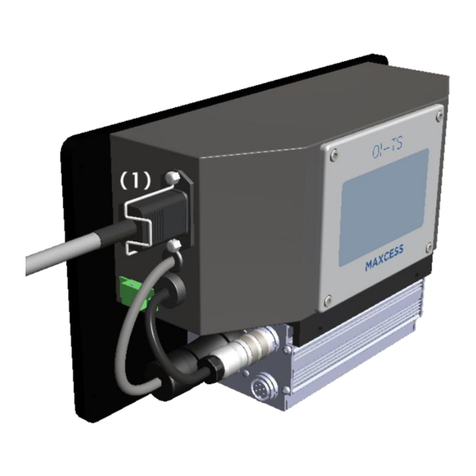

Maxcess GTS User manual

Maxcess

Maxcess Magpowr GTSCM User manual

Maxcess

Maxcess FIFE-500-XL Manual

Maxcess

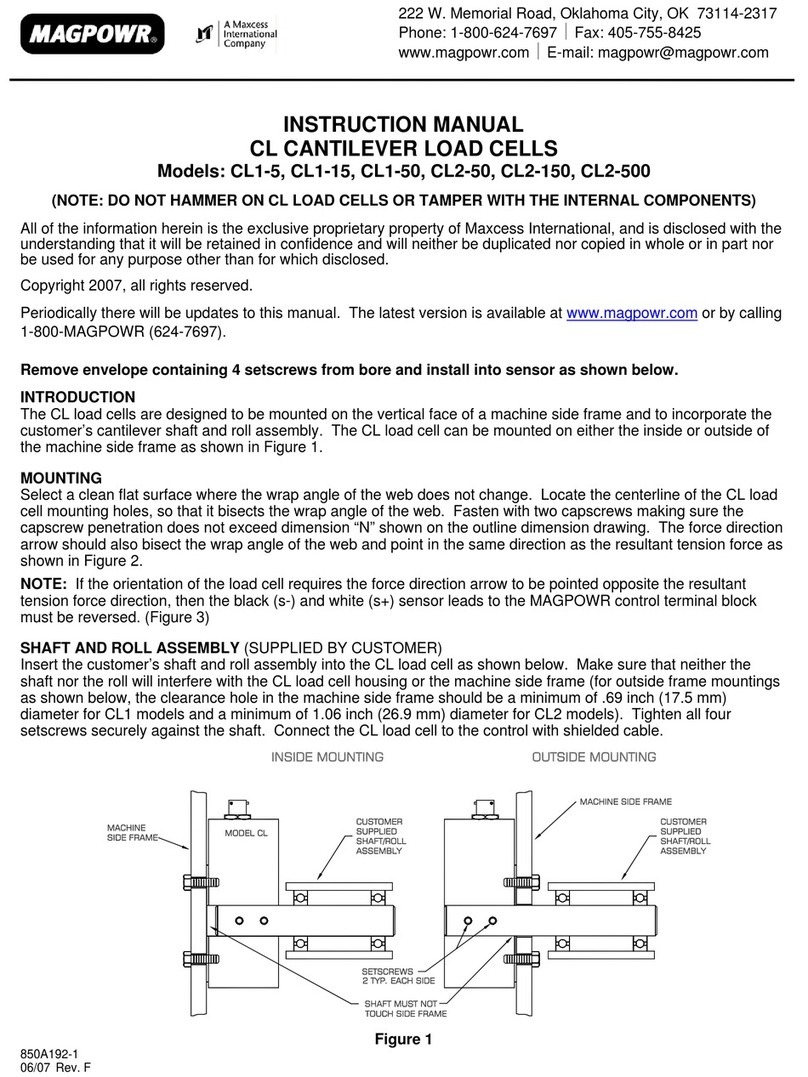

Maxcess Magpowr CL1-5 User manual

Maxcess

Maxcess Fife-200 Manual

Maxcess

Maxcess Tidland Raptor Series User manual

Maxcess

Maxcess Performance Series User manual

Maxcess

Maxcess FIFE D-MAXE 1 User manual

Maxcess

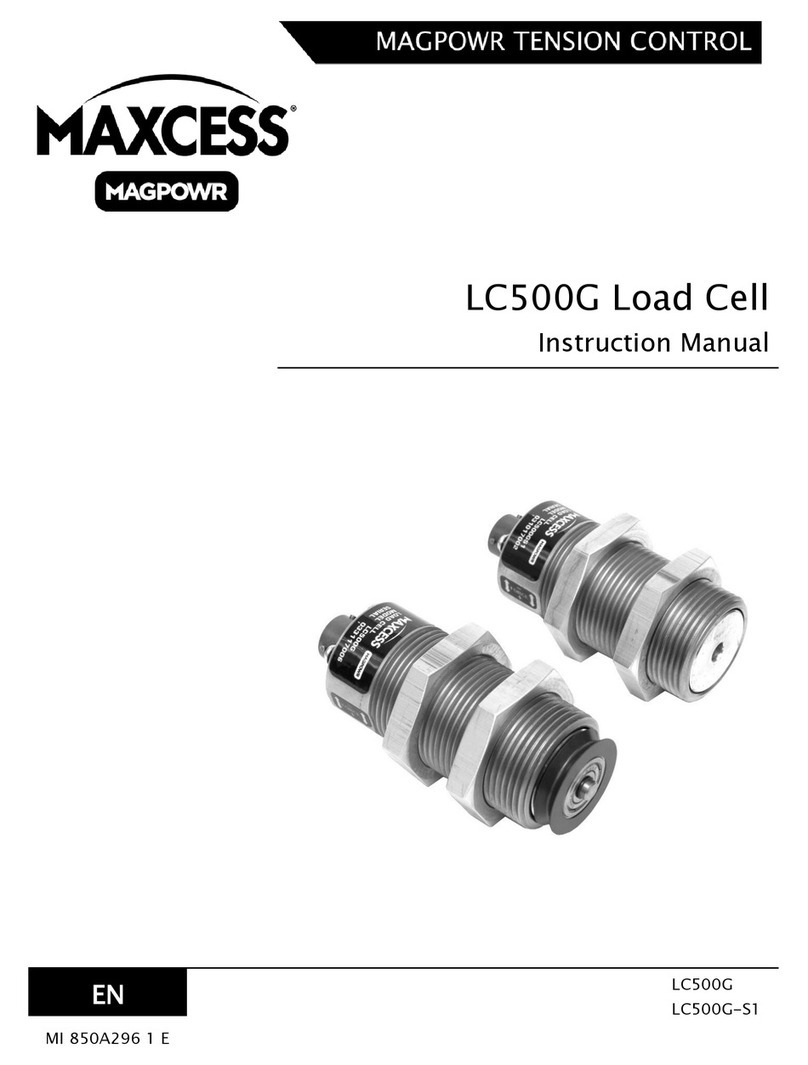

Maxcess MAGPOWR LC500G User manual

Maxcess

Maxcess FIFE D-MAXE 2 User manual

Maxcess

Maxcess FIFE-500 Instruction manual