222 W. Memorial Road, Oklahoma City, OK 73114-2317

Phone: 1-800-624-7697 ⏐Fax: 405-755-8425

INSTRUCTION MANUAL

CL CANTILEVER LOAD CELLS

Models: CL1-5, CL1-15, CL1-50, CL2-50, CL2-150, CL2-500

(NOTE: DO NOT HAMMER ON CL LOAD CELLS OR TAMPER WITH THE INTERNAL COMPONENTS)

All of the information herein is the exclusive proprietary property of Maxcess International, and is disclosed with the

understanding that it will be retained in confidence and will neither be duplicated nor copied in whole or in part nor

be used for any purpose other than for which disclosed.

Copyright 2007, all rights reserved.

Periodically there will be updates to this manual. The latest version is available at www.magpowr.com or by calling

1-800-MAGPOWR (624-7697).

Remove envelope containing 4 setscrews from bore and install into sensor as shown below.

INTRODUCTION

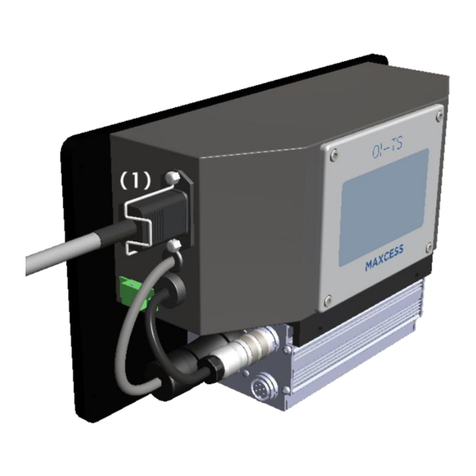

The CL load cells are designed to be mounted on the vertical face of a machine side frame and to incorporate the

customer’s cantilever shaft and roll assembly. The CL load cell can be mounted on either the inside or outside of

the machine side frame as shown in Figure 1.

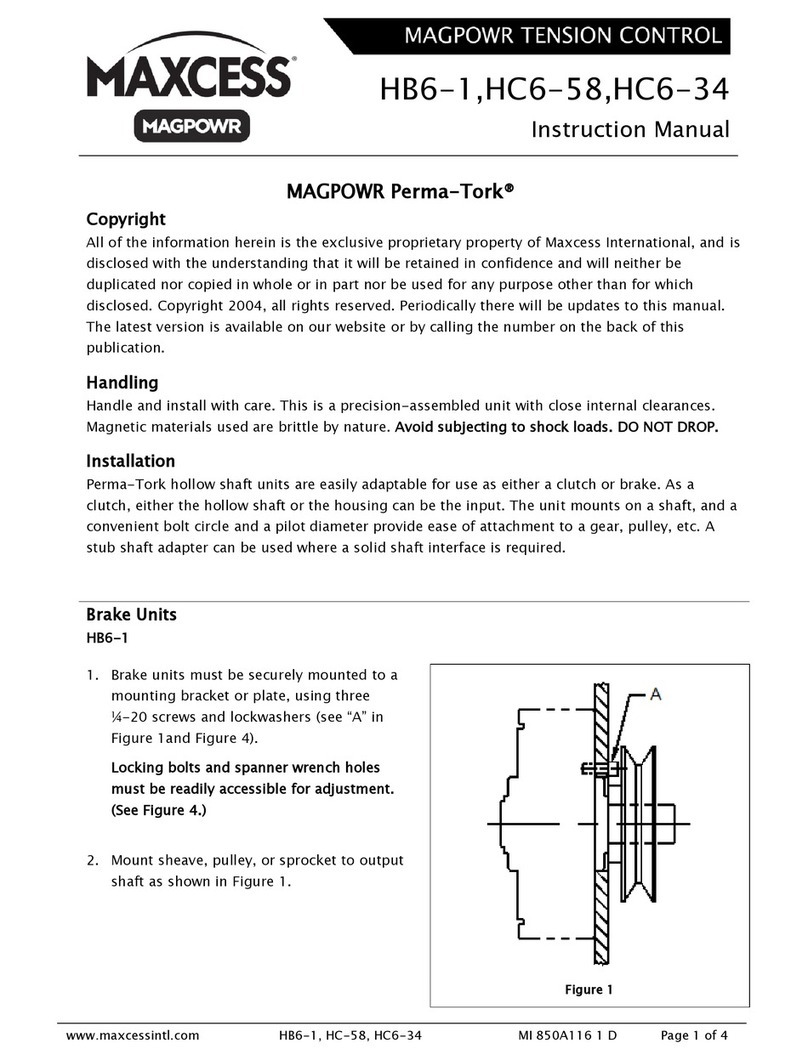

MOUNTING

Select a clean flat surface where the wrap angle of the web does not change. Locate the centerline of the CL load

cell mounting holes, so that it bisects the wrap angle of the web. Fasten with two capscrews making sure the

capscrew penetration does not exceed dimension “N” shown on the outline dimension drawing. The force direction

arrow should also bisect the wrap angle of the web and point in the same direction as the resultant tension force as

shown in Figure 2.

NOTE: If the orientation of the load cell requires the force direction arrow to be pointed opposite the resultant

tension force direction, then the black (s-) and white (s+) sensor leads to the MAGPOWR control terminal block

must be reversed. (Figure 3)

SHAFT AND ROLL ASSEMBLY (SUPPLIED BY CUSTOMER)

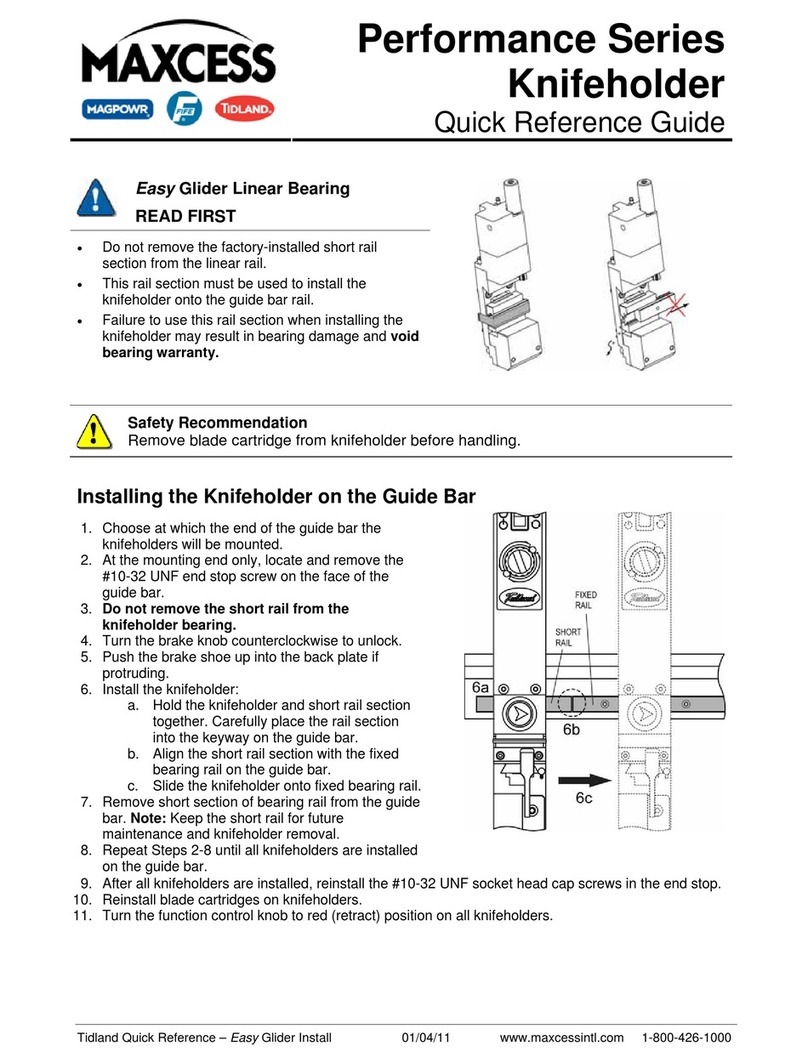

Insert the customer’s shaft and roll assembly into the CL load cell as shown below. Make sure that neither the

shaft nor the roll will interfere with the CL load cell housing or the machine side frame (for outside frame mountings

as shown below, the clearance hole in the machine side frame should be a minimum of .69 inch (17.5 mm)

diameter for CL1 models and a minimum of 1.06 inch (26.9 mm) diameter for CL2 models). Tighten all four

setscrews securely against the shaft. Connect the CL load cell to the control with shielded cable.

Figure 1

850A192-1

06/07 Rev. F