Safety technology

7 (12)

Assembly Manual Safety Bumper SB/BK and SB/W (NO/contact)

Rev.1 140805js

5.3 Assembly

Safety bumpers are pre-assembled and ready for use.

The safety bumpers can be mounted by means of mounting screws and the holes, oval

holes, counterbores, T-grooves, etc. in the base plate.

The mounting materials are not included in the delivery.

Safety bumpers must always be mounted level and free of distortion.

The clearance between the vent holes in the base plate and the nearest surface must be

at least 2.0 mm.

When assembling using threaded bushing (rivets), the thread length of the screw must

not exceed the length of the bushing.

For a safety bumper that is fitted with a standard base plate (T-groove mounting), it is

recommended that the distance between the mounting screws does not exceed 500

mm.

When mounting using threaded bushes, threaded bolts, bores etc. use the specified

positions on the base plate.

The slow-down path of the safety bumper must not be shorter than the maximum braking

path of the moving device (machine, gate, platform or other closing devices).

The slow-down path is the displacement path of the signal transmitter after triggering the

interruption contact until reaching the permissible actuation force, depending on the test

specimen. The slow-down path is specified in the technical data.

5.4 Laying cables

All ends of the connecting cable should be fitted with cable-end sleeves. Optionally plugs or

sockets may be used.

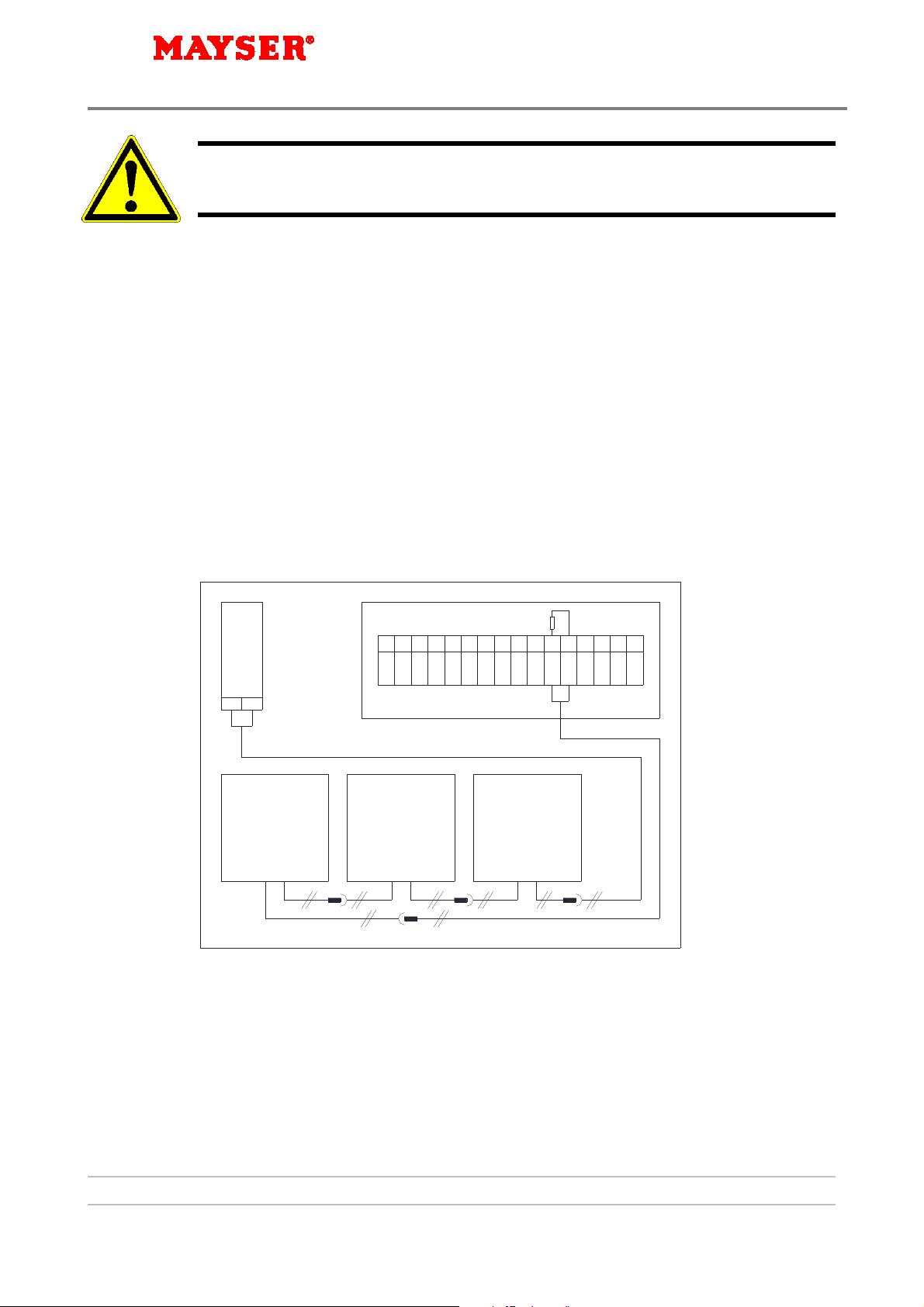

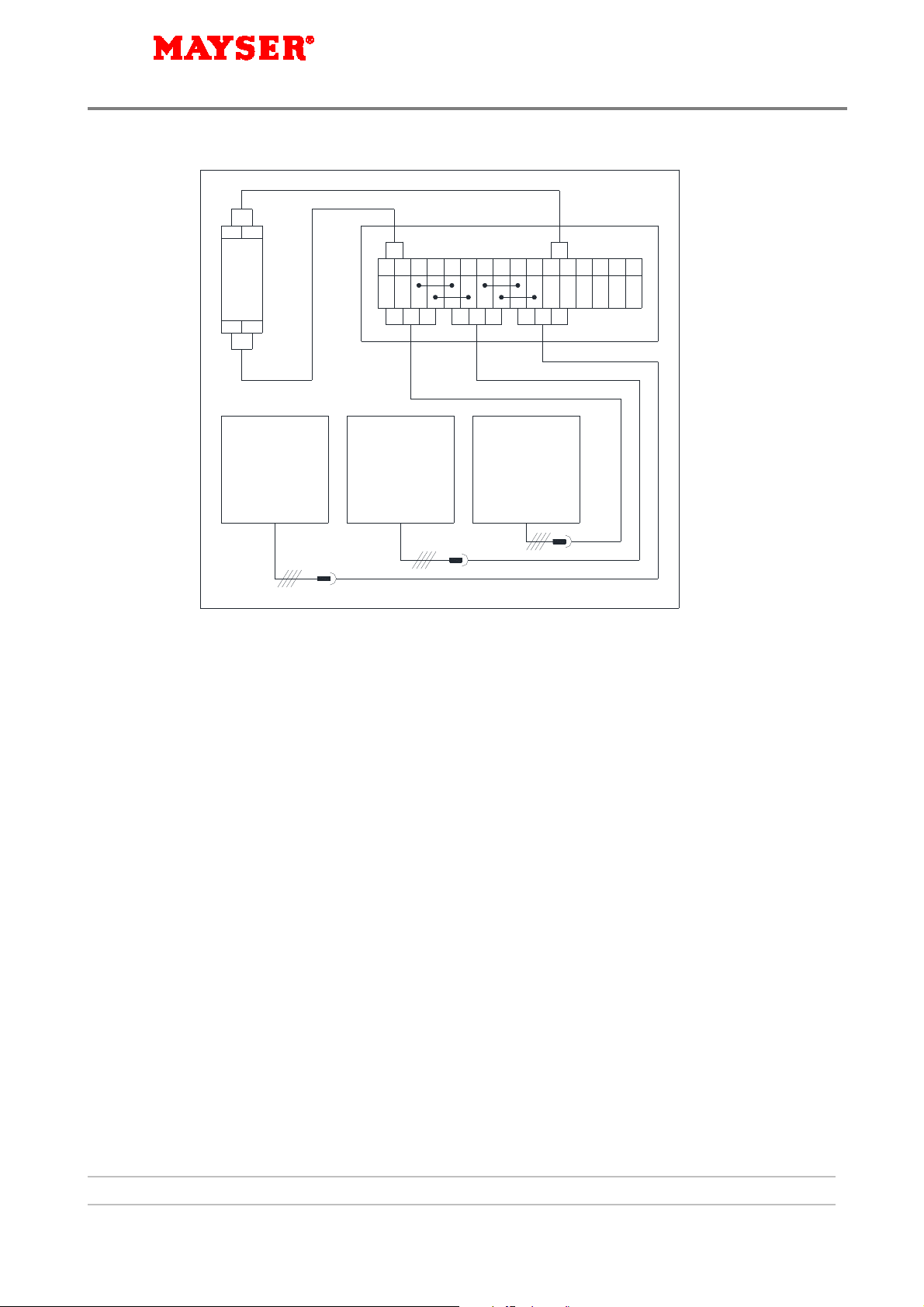

The type of wiring depends on the operating principle of your system.

1. Wire safety bumper cables to each other in accordance with the wiring plan (optional) or

according to the wiring diagrams illustrated under point 5.5. In doing so ensure the

following:

Connect the safety bumper cables to the cable glands.

Connect the safety bumper cables to the cable glands, observing the colour

coding.

Trim the cables if required.

If no plugs or plug sockets (optional) are available, double insulate soldering

points and seal with shrink tubing.

Only extend cables with double-insulated cables with short-circuit protection.