Copyright 2004 M-B Companies, Inc.

All Rights Reserved

5

Safety

Read these safety rules and follow them closely. Failure to obey these rules could result

in loss of control of the unit, sever personal injury or death to you, or bystanders, or damage to

property or equipment. The triangle in the text signifies important cautions or warnings which

must be followed.

GENERAL OPERATION

•Read, understand and follow all instructions in the

manual and on the unit before starting.

•Only allow responsible adults who are familiar with

the instructions, to operate the unit (local regulations

can restrict operator age).

•Clear the area of object such as rocks, toys, wore,

etc., which could be picked up and thrown.

•Be sure the area is clear of other people. Stop unit if

anyone enters the area.

•Always look down and behind before and while

traveling in reverse.

•Be aware of broom discharge direction and do not

point it at anyone. Do not point the discharge at glass

enclosures, automobiles, or windows.

•Disengage all clutches and PTO’s before starting

engine.

•Never leave running unattended. Always disengage

the broom and traction controls and stop engine.

•Operate only in daylight or good artificial light.

•Do not operate the unit while under the influence of

drugs or alcohol.

•Watch for traffic when operating near or crossing

roadways.

•Use extra care when loading or unloading the unit

into a trailer or truck.

•Keep in mind the operator is responsible for accidents

occurring to other people or property.

•Data indicates that operators, age 60 years and

above, are involved in a large percentage of power

equipment-related injuries. These operators should

evaluate their ability to operate the unit safely enough

to protect themselves and others from injury.

•All operators should seek and obtain professional and

practical instruction.

•Always wear substantial footwear and appropriate

clothing. Wear footwear that improves traction on

slippery slopes. DO NOT wear long scarves or loose

clothing that could become entangled in moving

parts.

•Before using, always visually check that hardware is

present, in-tact and secure. Replace worn or

damages parts.

•Never operate the machine with defective guards, or

without safety protective devices in place.

•Stop engine before: refueling, removing the broom

assembly, or making adjustments.

•Follow the manufacturer’s recommendations for

wheel weights or counter weights.

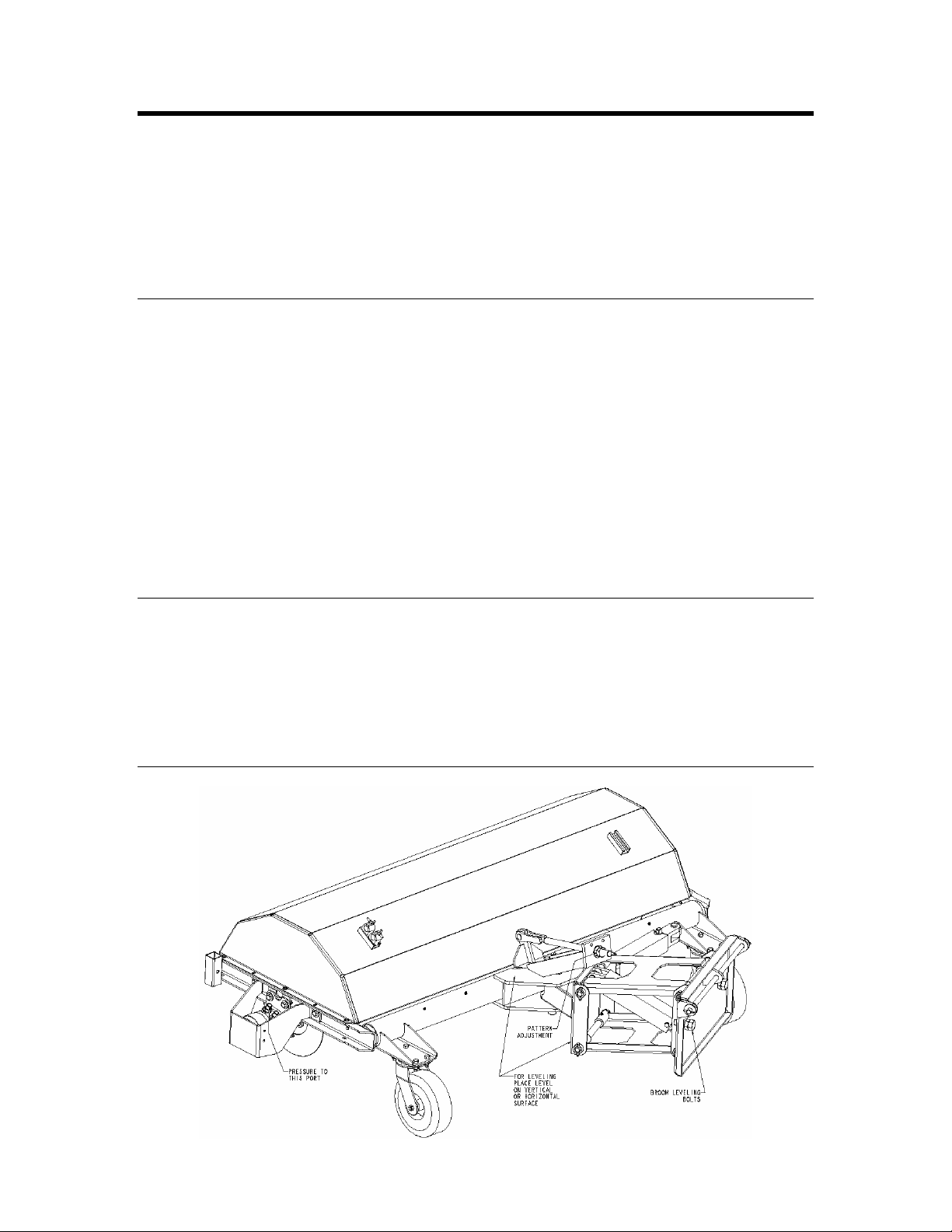

•Adjust leveling and pattern adjustments before

operating.

•Do not touch power broom parts which may be hot

from operation. Allow such parts to cool before

attempting to service the unit.

SERVICE AND MAINTENANCE

•Maintain and replace safety and instruction labels as

necessary.

•Never run a unit in an enclosed area.

•Keep nuts and bolts tight and keep equipment in

good condition

•Never tamper with safety devices. Check their proper

operation regularly and make necessary repairs if

they are not functioning properly.

•Keep unit free of debris and build-up. Clean up any oil

spillage.

•Stop and inspect equipment if you strike an object.

Repair, if necessary, before restarting.

•Never make adjustments or repairs with the engine

running unless specified otherwise in the engine

manufacture’s manual.

•Components are subject to wear, damage, and

deterioration. Frequently check components and

replace with the manufacturer’s recommended parts,

when necessary.

•Check control operation frequently. Adjust and

service as necessary.

•Use only factory authorized parts when making

repairs.

•Always comply with factory specifications on al

settings and adjustments.

•Only authorized service locations should be utilized

for major service and repair requirements.

•Never attempt to make your own repairs on this unit

unless you have been properly trained. Improper

service procedures can result in hazardous operation,

equipment damage and voiding the manufacturer’

warranty.