102D SERIES MAINTENANCE MANUAL

01-FRONT AXLE

1BĆ7 Page

August 2000 Date

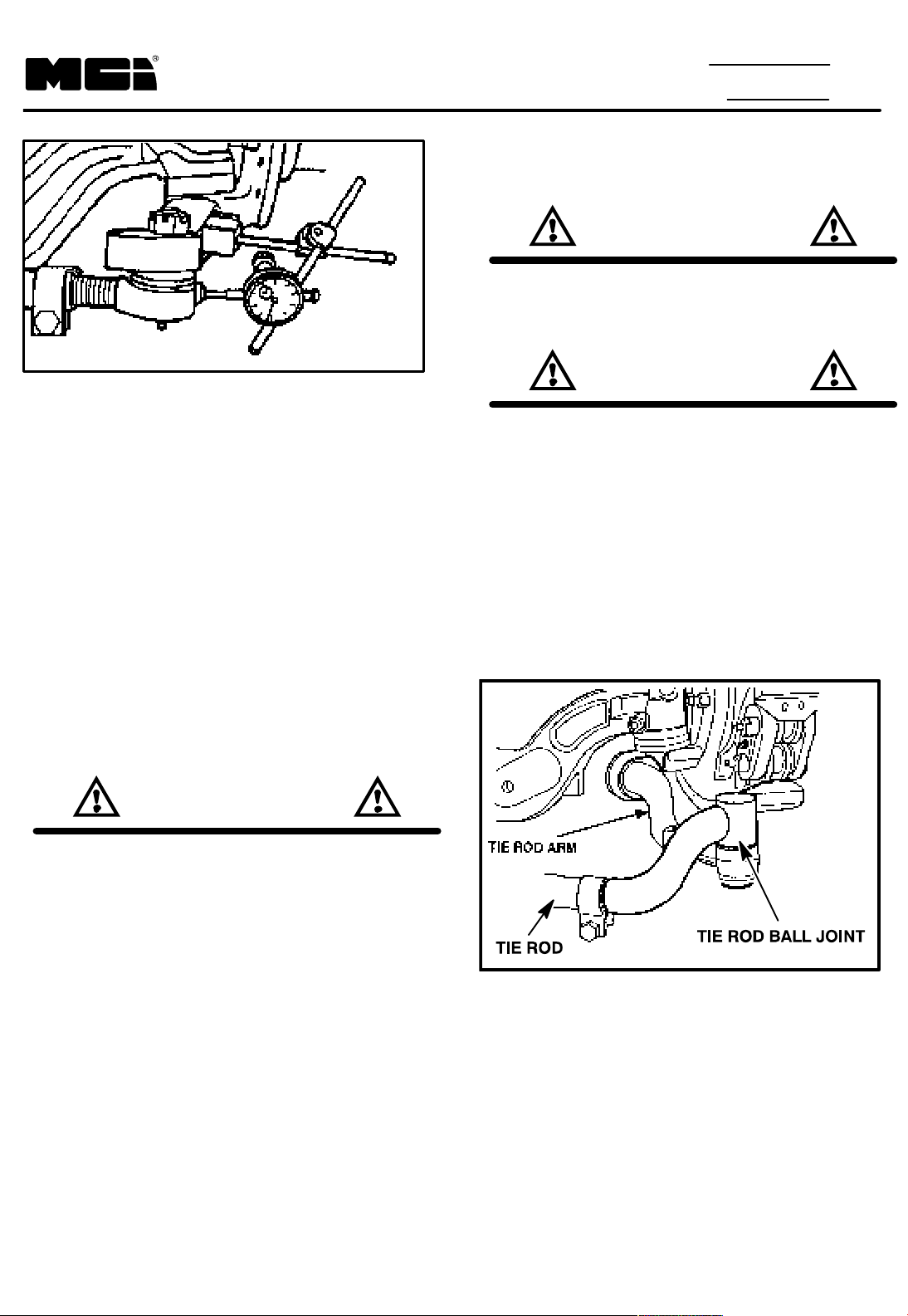

FIGURE 12. Removing king pin seals

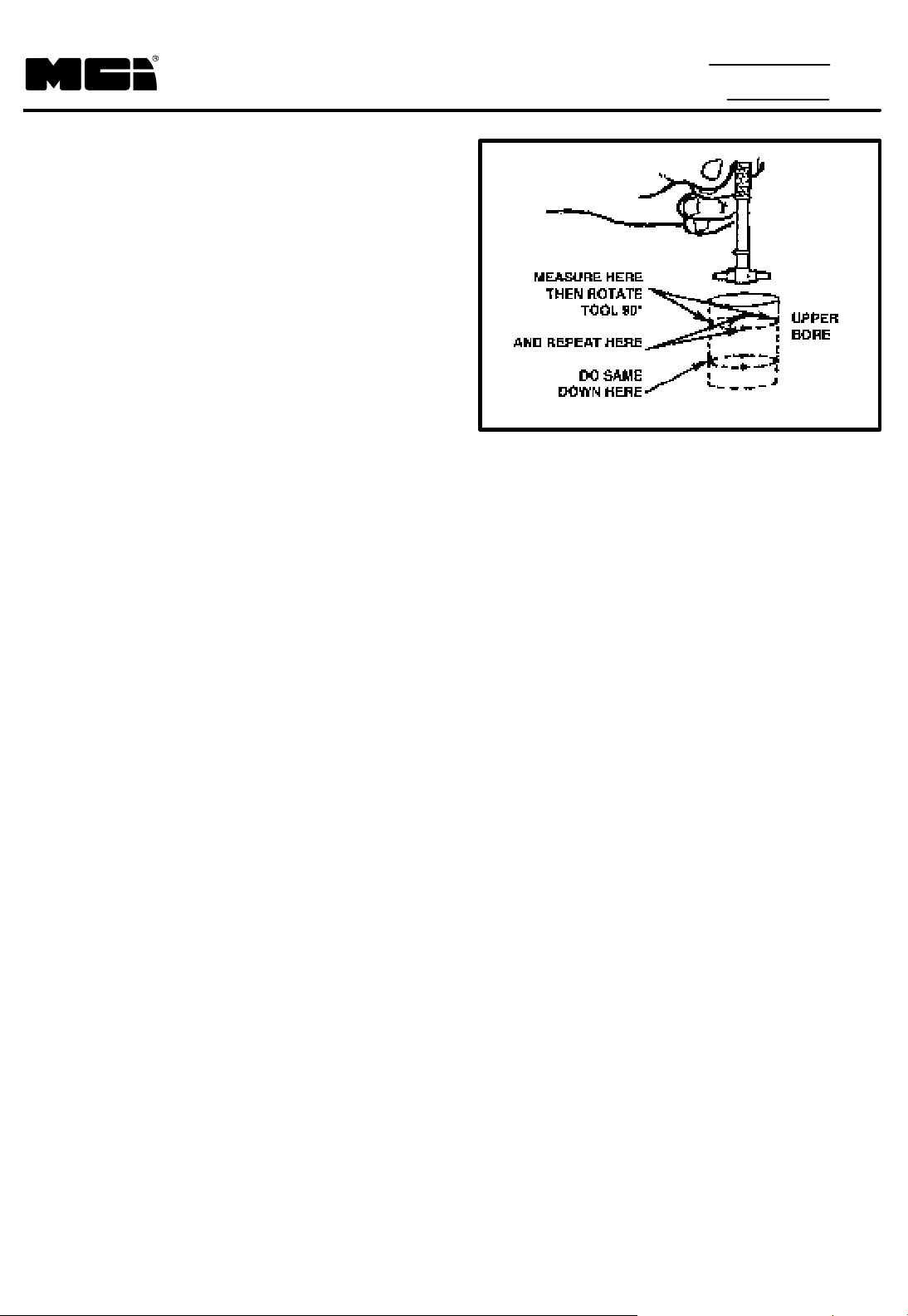

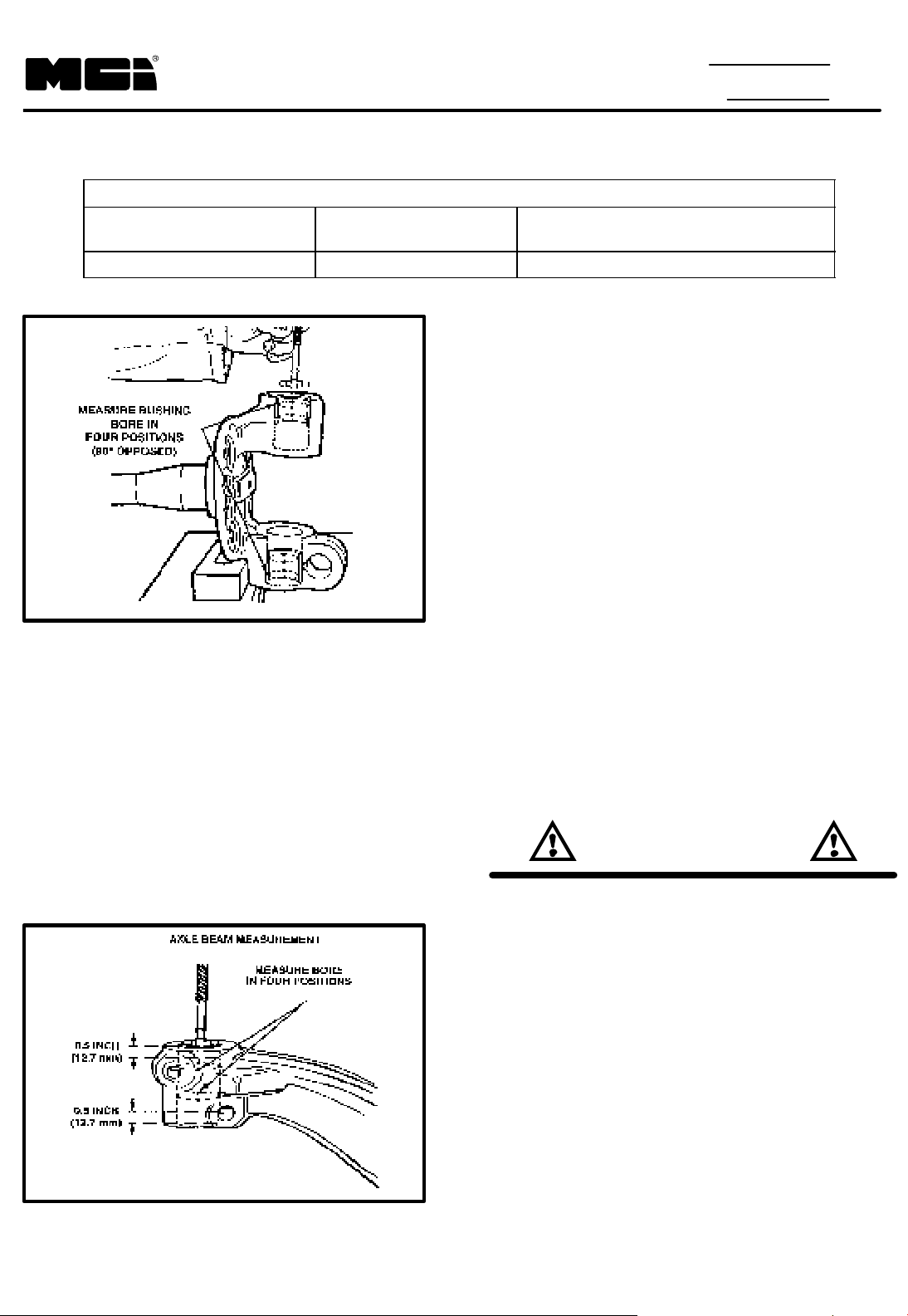

b. Make a tool to remove the bushings. See

Service Tools" later in this section or the tool

dimensions.

c. Put the knuckle on the press.

NOTE: Use a press with a 5 ton (4545 kg) capacity,

and make sure the knuckle does not move when the

bushings are removed.

d. Install the tool in the upper king pin bushing.

e. Press the top bushing rom the knuckle (Figure

13).

FIGURE 13. Bushing removal

. Install the tool in the lower king pin bushing.

g. Press the bottom bushing rom the knuckle

(Figure 13).

REPAIRING PARTS

ARNING

To prevent serious eye injury, always wear safe

eye protection when you perform vehicle

maintenance or service.

Repairing or reconditioning ront and trailing axle parts

is prohibited. The axle manu acturer recommends

replacing damaged or outĆo Ć speci ication components.

All major components are heatĆtreated and tempered.

The components cannot be bent, welded, heated or

repaired in any way without reducing the strength or li e o

the component.

The ollowing operations are prohibited on ront axle

components:

ă1.ăWelding o or to steering arms, tie rod arms,

knuckles, king pins, axle centers, tie rod assemblies,

hubs, drums, or brakes.

ă2.ăHot or cold bending o knuckles, steering arms, tie

rod arms, ball studs, axle centers or tie rod assemblies.

ă3.ăDrilling out o holes in the axle center beam or

knuckle pins.

ă4.ăDrilling out o draw key holes in the axle center

beam.

ă5.ăSpray welding o bearing diameters on knuckles

or in machined bores.

ă6.ăMilling or machining o any component.

ARNING

If you use cleaning solvents, hot solution tanks

or alkaline solutions incorrectly, injury can

occur. To prevent injury, follow the

manufacturer's instructions. DO NOT use

gasoline to clean parts; gasoline can explode.

Cleaning ground or polished parts

Use cleaning solvent to clean ground or polished parts

and sur aces. Kerosene and diesel uel can be used or

this purpose. DO NOT use gasoline.

CAUTION

DO NOT clean ground or polished parts in a hot

solution tank or with water, steam, or alkaline

solutions. These solutions will cause the parts

to corrode.

Cleaning rough parts

Rough parts can be cleaned with the ground or

polished parts. Rough parts can also be cleaned in hot