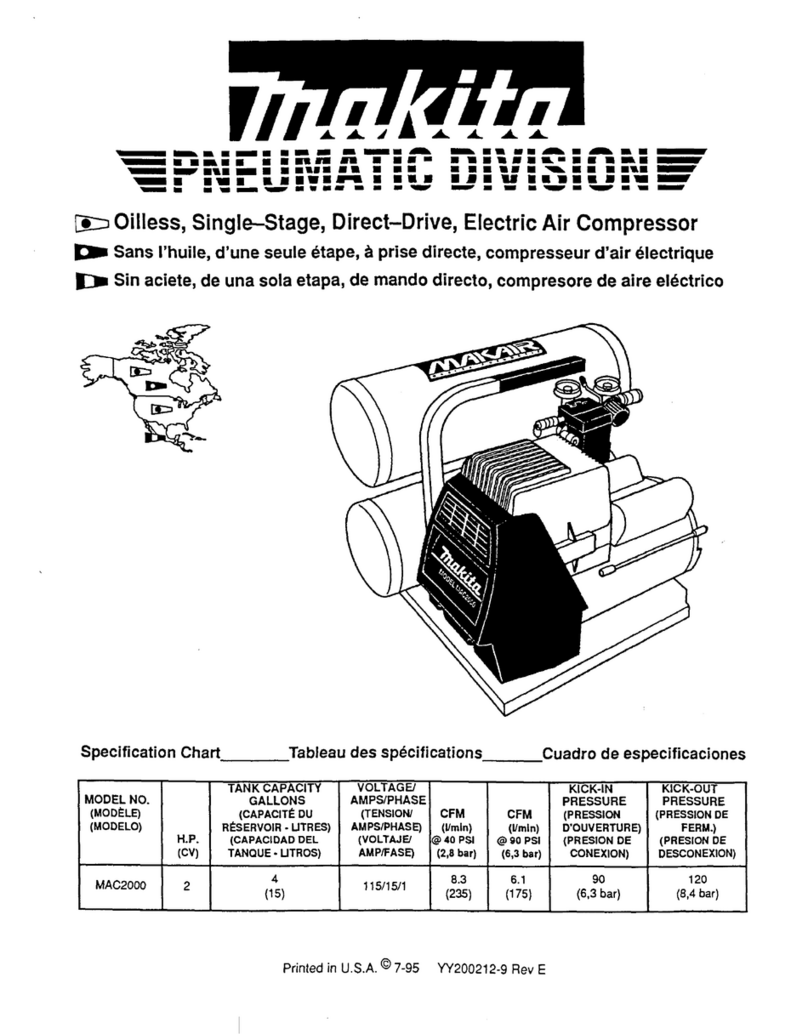

DESCRIPTION

OF

OPERATION

Air Compressor Pump:

To compress air, the piston

movesupanddowninthecylinder.Onthedownstroke,air

isdrawninthroughtheairintakevalves.Theexhaustvalves

remain closed. On the upstroke of the piston, air is

compressed.Theintakevalvescloseandcompressedair

isforcedoutthroughtheexhaustvalves,throughtheoutlet

tubes, through the check valve and into the air tank.

Workingairisnotavailableuntilthecompressorhasraised

theair tank pressureabovethatrequiredattheairoutlet.

CheckValve:

Whentheaircompressor

is

operating,the

checkvalveis’lopen”,allowingcompressedairtoenterthe

air tank. When the air compressor reaches “cut-out”

pressure,thecheckvalve“closes”,allowingairpressureto

remaininsidethe air tank.

Pressure Switch:

The pressure switch automatically

startsthemotorwhentheairtankpressuredropsbelowthe

factoryset “cut-in’’pressure. Itstopsthe motorwhen the

airtankpressurereachesthefactoryset”cut-out”pressure,

Regulator:

The air pressurecomingfrom the air tank is

controlledbytheregulator. Turntheregulatorknobclock-

wiseto increasepressureandcounter-clockwiseto

decreasepressure. Toavoidminorreadjustmentafter

makingachangeinpressuresetting,alwaysapproachthe

desiredpressurefrom a lowerpressure. When reducing

from a higher to a lower setting, first reduce to some

pressurelessthanthatdesired,thenbringuptothedesired

pressure. Depending on the air requirements of each

particularaccessory,theoutletregulatedairpressuremay

haveto beadjustedwhileoperatingtheaccessory.

Outlet Pressure Gauge:

The outlet pressure gauge

indicatestheairpressureavailableattheoutletsideofthe

regulator. Thispressureiscontrolledbytheregulatorand

isalwayslessorequaltothetankpressure. See“Operat-

ingProcedures”.

TankPressureGauge:

Thetankpressuregaugeindicates

thereserveair pressureinthetank.

CoolingSystem:

Thiscompressorcontainsanadvanced

designcoolingsystem. Attheheartofthiscoolingsystem

isanengineeredfan.

It

isperfectlynormalforthisfantoblow

airthroughtheventholesinlargeamounts.You knowthat

thecoolingsystemisworkingwhen air isbeingexpelled.

Air IntakeFilter:

Theunitrequires

no

airfilterdue

to

the

uniquedesign ofthe air intakesystem.

DrainValve:

Thedrainvalve islocatedatthe baseofthe

airtankandisusedtodraincondensationattheendofeach

use.

OnlAuto-Off Switch:

Turn this switch

ON

to provide

automaticpowertothepressureswitchand

OFF

toremove

powerattheendofeachuse.

INSTALLATION AND BREAK4N PROCEDURES

Location

of

the Air Compressor

Your compressor comes to you completely assembled

and ready for use. Operatethe air compressorin a dry,

clean, coolandwellventilatedarea. The aircompressor

pump and casearedesignedto allowfor propercooling.

Clean or blow

off

dust or dirt that collects on the air

compressor. A clean air compressor runs cooler and

provideslongerservice. Theventilationopeningsonyour

aircompressorarenecessarytomaintainproperoperating

temperature.

Do

notplaceragsor othercontainerson or

neartheseopenings.

Voltage and CircuitProtection

Seefrontcover.

Extension Cords

Useextraairhoseinsteadofanextensioncordtoavoid

voltage drop and power

loss

to the motor. An under-

sizedcordwillcauseadropinthelinevoltageresulting

in

loss

ofpowerandoverheating.

Ifan extensioncord must beused, besure it is:

a3-wireextensioncordthathasa3-bladeground-

ingplug,anda3-slotreceptaclethatwillacceptthe

plugonthecompressor

nolongerthan

50

feet

14gauge(AWG)orlarger. (Wiresizeincreasesas

gaugenumberdecreases.)12AWG,10AWGand

8

AWG

mayalso beused.

DO

NOT

USE

16OR

18

AWG.

ingoodcondition

6